There are always vapors in the gas tank of any car due to a decrease in atmospheric pressure or heating of the fuel. To prevent fuel vapors from escaping into the atmosphere, Kalina is equipped with a special gasoline vapor recovery system (EVAP). Thanks to this, the vapors retained by the adsorber (actually activated carbon) enter the intake manifold and burn in the engine cylinders. To regulate the amount of gasoline vapor coming from the adsorber into the manifold, a special solenoid valve is used.

Principle of operation

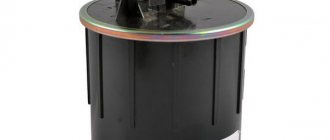

The adsorber itself allows fuel vapors to accumulate in a special place - the separator. As a result, gasoline condenses and returns to the tank. Untreated vapors pass through double valves of the system, one of which prevents fuel leakage in the event of an emergency (for example, a rollover), and the second “participates” in regulating the pressure in the tank. The adsorber purge valve is located under the hood, and the adsorber itself is located on the tank. KPA guarantees the normal operation of the entire system: it ventilates and removes condensation.

Design and operation of the adsorber purge valve

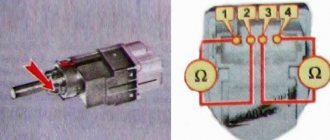

KPA is an electromagnetic blocking device that operates from the vehicle’s on-board network. The valve consists of:

- Plastic container;

- valve with spring;

- windings;

- metal core;

- connector

When the car engine is turned off, the valve is de-energized and is in the closed position. That is, on the engine side, the vapor recovery system is blocked. At the same time, the adsorber begins to “collect” steam. When the transmission starts, voltage is applied to the valve, which opens it and allows fuel vapor to enter the intake manifold. As soon as the ignition is turned off, the control unit is de-energized and the pipeline is closed: no vapors enter the receiver.

High-end cars have a more complex vapor recovery system. These machines are equipped with special sensors that “calculate” the amount of air and steam as a percentage. This allows you to more accurately control the supply of gasoline to the injector.

What repairs can fix the P0441 code?

- Replacing the fuel tank cap

- Repairing a leak in the fuel vapor recovery system

- Repair or replace damaged evaporative emission system components

- Replacing the purge valve

- Vacuum switch replacement

- Repair or replacement of wires

Additional comments for troubleshooting P0441

To properly diagnose the P0441 trouble code, a mechanic will need an advanced OBD-II scanner. It is necessary to check the operation of the vacuum switch and purge valve, as well as to carry out certain tests.

In some cases, a smoke leak test may be necessary to detect a leak in the evaporative emission system. This test can help detect even the smallest fuel vapor leak. The fuel tank shall not be completely empty or completely full during this test.

Need help with error code P0441?

The company - CarChek, offers a service - on-site computer diagnostics; specialists from our company will come to your home or office to diagnose and identify problems with your car. Find out the cost and sign up for on-site computer diagnostics or contact a consultant by phone +7(499)394-47-89

Signs of a malfunction of the control unit

First, start the engine: at idle or in cold weather, you will hear a characteristic, barely audible chirping sound. Indicates that the valve is operating correctly. To avoid confusing this sound with running noise, press the gas sharply. The nature of the tweet should not change. The following symptoms indicate a malfunction of the control unit:

- turning on the CHECK signal on the instrument panel;

- detection of error PO441 during testing;

- increased gasoline consumption;

- unstable operation of the power unit when driving;

- unstable minimum;

- increased CO2 content;

- a hissing sound when unscrewing the tank cap (a vacuum has appeared);

- the appearance of a fuel smell in the cabin.

Valve check on site

You will need a tester (voltmeter, multimeter) and a screwdriver. The KPA itself is installed on the radiator frame. The device can be recognized by the approaching two pipes through which the vapors move. Further:

- disconnect the electrical connector from the control unit by pressing the latch;

- using a multimeter, check for the presence of voltage by touching the negative (black) probe of the device to ground, and the red probe to “A” (the letter on the connector connector);

- insert the panel: the multimeter should show the vehicle's on-board voltage. If not, check the wiring.

How to check the adsorber valve removed from the car

you need to take a medical syringe of sufficient volume, just pull out the piston 2-3 cm and connect it to the drainage fitting. If you push down on the piston, it will become hard, indicating pressure in the valve. Now connect the battery to the electrical part of the control unit and press the piston again: the resistance should disappear. If this does not happen, you will need to purchase a new valve.

According to the requirements of new environmental regulations limiting the content of harmful substances in exhaust gases, cars must be equipped with an EVAP system. This equipment prevents harmful fuel vapors from entering the atmosphere. The main function in the fuel vapor recovery system is performed by the adsorber. Some people underestimate the importance of this element in a car's performance. However, a malfunction of this seemingly minor unit can damage the fuel pump and affect the operation of the entire engine. Therefore, experts recommend checking the canister valve when signs of engine malfunction appear.

Addresses of companies providing installation/replacement services (Moscow, St. Petersburg, Kyiv region)

| № | Name | Address |

| 1. | "Diesel Master" | Russia, St. Petersburg, Moskovskoe highway, 13A, Zvezdnaya metro station |

| 2. | "Author+" | Russia, St. Petersburg, Mineralnaya str., 13O, Vyborgskaya metro station |

| 3. | "Service Team" | Car service, automatic transmission repair, tire side cut repair, car air conditioner repair, Strogino metro station, Marshala Proshlyakova street, 12k1s1 |

| 4. |

Car services, repair of electronic vehicle control systems, repair of electrical equipment, repair of fuel equipment for diesel engines, metro station Gagarina Square, Vavilova, 13a, 1st floor

5. “Kulibins” Kyiv, st. Borova 2/38

6. “Renault-Life” Kyiv, st. Novokonstantinovskaya, 1 G

Purpose and principle of operation of the adsorber purge valve

Absorber valve diagram

The EVAP system is installed on gasoline internal combustion engines to prevent fuel vapors from entering the atmosphere. The canister purge solenoid valve is part of this system. Therefore, to know what the canister valve is used for and how it works, it is important to understand the operating principle of the entire system. The design of the adsorber is a container filled with an adsorbent, most often activated carbon. The device is connected to the fuel tank and control valve of the vehicle using special hoses.

The canister valve is installed between the intake manifold and the canister and performs the function of ventilation.

Gasoline vapors generated in the fuel tank enter the separator, where they are condensed and discharged back into the tank. Some of the vapors do not have time to condense in the separator and enter the adsorber through the steam line. In the filtration system, they are absorbed by activated carbon, accumulated and then, when the engine starts, enter the intake manifold. The process of absorption of fuel vapors occurs only when the engine is turned off. When the car is in motion, the electronic control unit opens the canister purge solenoid valve, through which air enters, and then ventilation occurs. In this case, the accumulated condensate along with the air is sucked in by the adsorber and again enters the engine, where it is replenished with fuel. The cylinder valve provides ventilation to the entire mechanism and redirects fuel condensate to the engine.

How does a mechanic diagnose a P0441 code?

- First, the mechanic will connect the OBD-II scanner to the vehicle's diagnostic port and read all the stored data and error codes.

- He will then clear the error code from the ECM and test drive the vehicle.

- If P0441 appears again, have a mechanic visually inspect the evaporative emission system.

- The mechanic will then check the fuel pressure sensor in the fuel tank for damage.

- He will also check the fuel cap.

- He will then check the operation of the vacuum switch and purge valve.

- If no problem is found, the mechanic will perform a thorough check of the evaporative emission system to check for leaks.

Common errors when diagnosing code P0441

The most common mistake when diagnosing a P0441 code is not following the diagnostic protocol, as well as not performing a smoke leak test.

Also, mechanics often assume that the problem is a damaged fuel cap, but do not perform thorough diagnostics to verify this. It is imperative to check the fuel tank cap for leaks, for example using a vacuum tester.

Malfunctions of the adsorber valve and their elimination

Almost continuous operation of the fuel vapor absorption system tank can lead to damage to the drain valve. A malfunction of the canister valve often leads to breakdown of the fuel pump. Due to poor ventilation of the adsorber, gasoline accumulates in the intake manifold, the engine loses power, and fuel consumption gradually increases. This may cause the engine to stop completely. The operation of the entire vehicle depends on how the adsorber valve works.

How to check the functionality of the canister purge valve?

Checking the absorber valve

Regular inspection of the canister valve is required to detect and correct problems in a timely manner. In this case, the breakdown can be identified by some indirect signs. When the engine is idling or in cold weather, the vapor absorption system makes a characteristic sound when the canister valve clicks. Some people confuse this sound with a faulty timing belt, pulleys, or other parts. You can check this by sharply pressing the accelerator pedal. If the sound has not changed, the canister valve clicks. Experts can explain what to do if the tank valve is knocking too loudly. To do this, you need to tighten the adjusting screw, having first cleared it of epoxy resin.

The absorption valve can be adjusted.

The screw turns approximately half a turn. If you tighten too much, the controller will generate an error. This adjustment of the adsorber valve will make its operation softer and the beating quieter. However, how can you check if the cylinder valve is broken? Valve failure can be determined using an error diagnostic system or mechanical monitoring. Electronic fault codes are stored in the controller's memory and indicate electrical damage. To control the valve, it is recommended to pay attention to controller errors such as “open circuit for controlling the canister purge valve.” Signs by which a malfunction of the adsorber valve can be mechanically determined:

- Engine idling occurs.

- Very low engine thrust.

- When the engine is running, there is no noise from the valve operation.

- A hissing sound when opening the gas tank cap indicates a vacuum in the system. This is a sure sign of a malfunction in the adsorber ventilation.

- The smell of fuel inside the car. However, there may be other reasons for its occurrence.

Malfunctions in the fuel vapor recovery system Lada Kalina

Why do you need a check valve on a fuel pump and how to replace it yourself?

Since the solenoid valve itself is not a complex device, it has few malfunctions as such - it may not open or close when necessary, or it may get stuck in some certain position. But the culprit of the breakdown may not only be Evap-Solenoid; the gasoline vapor recovery system does not work correctly for other reasons:

- connecting pipes are pinched or clogged;

- normal vacuum is not created in the system;

- due to an open circuit, there is no voltage on the valve;

- the carbon filter is completely clogged (which is rare);

- The control unit malfunctions.

If the CPA is stuck in the open position and does not block the channel, the following defects may occur:

- the fuel mixture becomes richer, causing “blackness” to appear on the electrodes of the spark plugs;

- the engine begins to operate unstably, this is especially noticeable at idle;

- gasoline consumption increases;

- The throttle response of the internal combustion engine decreases.

When the EVAP channel is constantly blocked by the purge valve, excess vapor pressure is created in the gas tank, due to this:

- there is a risk of fuel pump failure;

- The fuel level sensor may fail.

It should be noted that purge occurs in a certain mode after starting the engine, the program is executed depending on the crankshaft speed, and the system does not work at idle. An impulse arrives at the CPA if:

- the coolant has heated to a temperature of at least 75 degrees Celsius;

- the throttle valve is open at least 4%;

- the car is moving at a speed of more than 10 km/h (but this is not a necessary condition).

Problems in the electrical part of the EVAP are detected by the control unit, and the Check Engine warning lamp lights up on the instrument panel. The fault code can be determined using a special diagnostic scanner or a computer with a program installed; the most common errors in the vapor recovery system detected by the diagnostic device are P0441 and P0455.

Do-it-yourself absorber valve replacement

If signs of malfunction are detected, the valve must be repaired or replaced. The cylinder valve is inexpensive and easy to replace. To disassemble, you need to have a pair of Phillips screwdrivers and know where the canister purge valve is located. Operating procedure:

The markings on the old and new valves must match.

- Open the hood and you will find a cylindrical device - an adsorber.

- Remove the negative terminal from the battery.

- Disconnect the terminal block by pressing the latch and pulling it towards you.

- Loosen the valve.

- Remove the fittings under the holder and disconnect the hoses.

- Remove the valve together with the bracket from the adsorber.

- The new valve is installed in the reverse order.

Therefore, even such a small element as the absorber valve performs important functions, and its failure can seriously affect the operation of the entire engine. Therefore, it is important to monitor the condition of your car and carry out diagnostics on time.

There are many different parts in the structure of a modern car, the existence of which the average car enthusiast does not even suspect. The adsorber, an adsorption valve, the malfunction of which can significantly impair the operation of the machine, is one example.

“We treat” the adsorber

If a breakdown occurs, the problem needs to be solved as soon as possible, there are four options to solve it, depending on the features, you can: replace the valve, replace the adsorber, try to repair the valve, remove the adsorber, we will consider each option in more detail.

Replacing the adsorber

On a VAZ 2114, replacement is very simple, you can go to a service station, but if you do the procedure yourself it will take about 20 minutes. We dismantle the spare part:

- disconnect the hoses from the throttle;

- disconnect the wires and block;

- remove the purge valve and purge and separator hoses;

- unscrew the three bracket bolts;

- the part has been removed.

We install a new one:

- We attach a long pipe to the point where vapor is supplied to the blow-off valve;

- We connect a short hose to the fence from the separator;

- put the spare part in place;

- connect the supply hose to the valve;

- install a purge channel (on the engine cover);

- connect the wiring and block;

- place a tube between the valve and the adsorber;

- the work is finished, connect the power and go.

We repair the valve

The valve is clogged due to bad gasoline, before buying a new one, let's try to fix the old one. If a characteristic smell of gasoline appears in the cabin, then the problem is in the valve pipes, they are replaced by simple replacement, and the problem is revealed by a visual inspection, we look at which pipe has burst, buy a new one and install it.

Direct repair:

- We unscrew the adjusting screw, counting the revolutions (it is filled with epoxy resin, it will be easy to find).

- We drip carburetor flushing into the fittings.

- Holding the valve in the open position, we blow it with a compressor.

- We repeat points 2 and 3.

- We put it in place, screw in the adjusting screw to the previously calculated number of revolutions.

Valve replacement

If the valve breaks due to overheating of the radiator, it cannot be repaired; a new part is needed.

The procedure is simple, let's consider it in order:

- We turn off the power to the car and disconnect the KPA plug.

- We loosen the air control inlet pipe, remove it, and move it to the side.

- We bend the fastening, dismantle the valve (remove the fastening no more than 1 cm).

- Lift the valve along the grooves (you need to pull it up).

- We disconnect the fitting, there are two inlets, the first one can be easily removed, the second one will have problems - on the raised fitting, the fixing tendrils are prying up, on the recessed clamp (it’s easy to do with two people, you’ll have to “sweat” alone).

- We install the new adsorber valve in the reverse order.

Removing the adsorber

This is not recommended, but if there is no money (for a new one) and no desire to understand the problem (fix something), it is removed. In addition to the above-described dismantling of the part, three more procedures need to be performed:

- dig into the ECU (reflash);

- seal the pipes leading to it;

- replace the tank cap (it needs a leaky one).

Summarize:

- The VAZ 2114 adsorber is an important part; it should not be removed.

- You now know how to replace a part, determine if it is broken and try to repair it, so it’s better to do just that.

- If you decide to remove it, remember, now the car is environmentally friendly “Euro 1”, later problems may arise with this.

Purpose

This part was not always an integral part of the car. We owe our appearance to modern requirements for environmental friendliness of cars, or rather to the Lada Granta adsorber, acquired thanks to Euro-3.

(Euro-3 is an environmental standard introduced in 1999, but Russian manufacturers were able to meet its requirements only in 2008)

The adsorber, for which Granta became one of the first “shelters” on the domestic automotive market, is a spare part directly connected to the catalyst. Allows you to store gasoline vapors, preventing them from entering the exhaust manifold.

These actions help preserve the catalyst and prevent its premature wear, since the combination of a cold catalyst with gasoline vapor is unacceptable. As soon as the engine warms up to the required temperature, the adsorber purge sensor is activated. The cylinder valve returns vapor to the gas tank.

Additional features

Of course, the Lada Granta adsorber, originally created to create environmentally friendly engine operation, the price of which is low, was underestimated. Manufacturers tried all sorts of tricks to get around this new trend, but the law forced all car manufacturers who did not comply with this innovation to pay huge fines.

Although AvtoVAZ has never stood out for its large exports, it was nevertheless forced to take measures to install an adsorber, since it has a small, but still small, sales market. Today, an adsorber is required to be installed on Lada Granta, as world research has revealed the following capabilities of this component:

— reduction in gasoline consumption

A similar result is achieved because the adsorption valve allows gases to be discharged into the gas tank, from where they enter the engine, which, when heated, can process them. If this device is not available or the canister valve itself fails, Granta loses fuel, which significantly increases fuel consumption.

— normalization of the exhaust system

Thanks to filtration, the likelihood of premature wear of the system and its components disappears.

What is an adsorber?

An adsorber is a device whose main purpose is adsorption.

They are actively used in oil refining and some industrial sectors. In addition, these days adsorbers have found very wide application in vehicles equipped with internal combustion engines - they prevent gasoline vapors from entering the atmospheric air. These devices are equipped with injection systems; tubes connect them to the gas tank and throttle pipe. Switching operating modes is carried out by means of a valve; it closes when the engine is turned off, stopping contact between the device and atmospheric air. It is then that gasoline vapors enter the adsorber from the fuel tank, after which they are immediately absorbed.

When the engine starts, a special device that controls the injection system begins sending control pulses that initiate communication between the device and atmospheric air. The sorbent begins to be purged, and gasoline vapors enter the combustion chamber, where they are burned. The duration of control pulses and the intensity of sorbent blowing are directly dependent on the amount of air consumed by the motor.

The most important element of the described apparatus is the purge valve. The valves installed on the Lada Granta were inherited from the Lada Kalina, which makes possible malfunctions similar. Below we will look at problems that arise during the operation of the adsorber, as well as their symptoms and methods of elimination.

Valve - as the most important component of the device

When talking about how an adsorption valve works, it is necessary to imagine the device itself. This is roughly a coal can that is equipped with a valve to condense and direct the vapors. The canister purge valve is controlled by the ECU, which sends a signal to open/close it.

Important. The canister solenoid valve can cause inconvenience to the driver. In cold weather, a certain clicking noise may be heard when starting a cold engine. This sound is normal as a cold tube may not function properly.

In order not to confuse this sound with possible failures, it is necessary to apply progassage. If there are no changes, you can safely cancel pressing the absorber.

What's the result?

Considering the above information, it is clear that the canister and the canister valve perform important functions. Moreover, system malfunctions can have a serious impact on engine performance. As a rule, the signs and symptoms of valve problems discussed above often indicate the need for in-depth diagnostics. In this case, the fuel vapor ventilation system is often the culprit.

We also recommend reading the article about what an adsorber is. From this article you will learn about why this device is needed, what functions it will perform, as well as what signs and symptoms indicate that the adsorber is faulty and needs to be checked, serviced or replaced.

For this reason, experienced specialists recommend regularly performing both computer diagnostics of the car and periodically performing mechanical checks (assessing valve performance, engine performance in different modes, etc.). This approach allows you to avoid unexpected breakdowns, as well as significantly increase the overall life of the internal combustion engine, gearbox, and other components, assemblies and systems of the vehicle.

Features of valve operation

The canister purge valve itself was inherited by Grant from Kalina. Therefore, the Kalina adsorber purge valve and the Lada Granta adsorber purge valve are completely identical. This allows us to state that the symptoms of a malfunctioning adsorber in both cars are identical.

If we take into account the Kalina adsorber purge solenoid valve, then the malfunctions and their symptoms may well be transferred to a malfunction of the younger brother’s adsorber.

How to understand a malfunction of the absorber

As for the adsorber valve, the symptoms of the malfunction will be fairly standardized, which makes it possible to obtain a fairly detailed description. So, signs of a malfunctioning adsorber valve:

— Constant smell of gasoline in the cabin.

This fact is caused by improper circulation of gases, which may have some leakage. Due to the proximity of the system to the air filter, odors can easily penetrate into the cabin.

Signs of a malfunction of the subsidy canister purge valve is this sound, familiar to all subsidy owners.

(to fix this, you can tighten the nut, or you can buy a new one, since the Lada Granta adsorber valve is available for purchase, the price of which is low)

— Increased fuel consumption.

A malfunctioning canister vent valve cannot control the correct path of gases, which prevents them from being processed in the form of combustion.

— The amount of harmful substances released through the system increases.

When talking about how the canister purge valve works and why, do not forget that improving the environmental performance of the car is an important task that can be solved if the canister purge solenoid valve is faulty.

- It looks like hissing.

A loud hissing sound in the canister tube caused by gas accumulation is not uncommon. Since modern vehicle regulations do not allow gases to be emitted when parked, some accumulation is acceptable.

— Typical sounds from a gas tank.

Speaking about the Lada Granta adsorber, the malfunction of which is always characterized by extraneous noise emanating from the gas tank, it must be said that they are the most typical sign of a malfunction. In this case, the adsorber sensor may not show any signs of malfunction, so it must be replaced.

Therefore, signs of a malfunction of the Lada Grant canister purge valve are quite easy to identify. In addition, they are detected during simple refueling of the car, during which it is necessary to open the gas tank cap.

Error p0441 Lada Granta

Question

: A friend has a Lada Kalina 1.6 8 valve, M-74 computer, error P0441 constantly appears - incorrect air flow through the absorber valve. Two valves were replaced. We changed the software of the ECU on the E-2 in the hope that at least this would help - it was useless. How many of these viburnums drive around the city - not one has stopped by with such a malfunction. And the client constantly fills the tank completely. This may be the cause of this malfunction.

Answer

: 1) This is an interesting topic not only on Kalina and Grant with M74-CAN (mass air flow sensor). Where the owner is an idiot - if the tank runs dry until it dies, or even if you knock on your head, but still fills it until it pours out of the neck, then this error comes out, well, even if the gun at the gas station is not entirely working, the same nonsense.

2) Today the classic also arrived with the same error (block m73). When communicating with the owner, it was clear that he works in Moscow and is also a fan of refueling his car.

3) Advise to turn off the car before opening the gas tank cap.

How to repair a problem

When talking about repairing the adsorber, the fault should be clearly identified. For example, if we are talking about a purge valve for a subsidized adsorber, the malfunction of which can be indicated by the lack of high-quality gas removal, then a new VAZ adsorber purge valve can be a solution to the problem.

Repairing the canister valve itself involves using a Phillips screwdriver and applying it. The procedure for influencing the Lada Granta adsorber sensor:

1) Remove the terminals so that there are no dire consequences.

2) Use physical force and carefully remove the valve.

3) Let's compare the new valve and the old one, because in life everything happens. Buying an adsorption valve is, of course, not difficult, but there are seller/retailer mistakes that can cause you to mistakenly sell an unnecessary spare part.

4) We insert a new valve, assemble this system, put the terminals in place and enjoy life. The Grant adsorber purge valve, the price of which is almost equally low throughout the Grant sales area, also causes a small, but nevertheless joy.

Throughout the history of the adsorber, one cannot fail to mention the fact that a huge number of Lada Grant owners prefer to get rid of this device. There are two reasons for this action:

- lack of desire to repair

— uncertainty about the possible environmental benefits of installing this device in a car

Lada 2110 PhiX Logbook Removing the adsorber on a VAZ 2110

Crankcase ventilation valve

Hi all! Today, I will tell you how to properly remove the adsorber on a VAZ 2110-12. First, a little background. It all started when one day I removed the locker from the rear left fender and saw frayed hoses clogged with dirt and some kind of container, which, as it turned out later, turned out to be a separator. Judging by the condition of the hoses, it was clear that the adsorber was not performing its function, but was just cracking the valve in vain. Even then, the first thoughts crept in about getting rid of this device. Recently, in connection with the transition to DBP, I had to switch to a sports engine management program, in which the adsorber is not involved. I still don’t understand whether the customizer considered it unnecessary to turn it on, or whether the firmware did not allow this, but one way or another, I decided to completely remove the adsorber from under the hood. The procedure for removing the adsorber is not complicated, but there are some aspects that you need to know.

First of all, we remove the adsorber itself, along with the two-way valve.

We turn off the hose that comes from the gas tank and move it to the side. We carefully wrap the connector that went to the adsorber valve to the wiring harness and hide it under the decorative cover of the internal combustion engine. There is no point in removing connectors and hoses, they do not interfere, and if necessary, you can return the adsorber back.

We remove the hose coming from the throttle completely and plug the hole in the throttle assembly. I did it a little differently, to the fitting to which the adsorber hose was connected, I connected the small crankcase ventilation circuit, and plugged the upper ventilation fitting, i.e. I did it essentially like I had before on the mass air flow sensor

An important point, since the hose coming from the tank is now plugged, a hole with a diameter of 1-2mm should be drilled in the gas tank cap. I removed the lid cylinder plug and drilled a hole under it. This does not interfere with the air flow, but will protect against excess dirt.

Price policy

Speaking about the Grant adsorber purge valve, which today can be bought in all large and not very large places where spare parts for the Russian automobile industry are sold, it is impossible not to notice its pleasant price. The Grant adsorber valve, the price of which is equivalent to the probability of its failure, allows for independent replacement and is the simplest mechanism.

Therefore, compliance with Lada Grant environmental standards is the work of man. The adsorber has become a part that, in addition to caring for the environment, can significantly reduce fuel consumption and improve the removal of exhaust gases.