From the article, the reader will learn why a sensor and an absorber purge valve are installed on a vehicle. What malfunctions occur with these devices and how to fix them yourself, without resorting to the help of experienced mechanics at a service station.

And here is a little about electrical circuits on Toyota cars.

Problems that lead to breakdown of the fuel pump or even the engine sometimes appear due to malfunctions of secondary devices. New car owners do not pay attention to minor breakdowns, confuse them with other problems and do not go to a service center to have the vehicle undergo a routine inspection.

Such secondary devices include the absorber valve and the gravity valve, located in the same system as the first. A gravity device is needed to block the flow of fuel from the gas tank to the outside when the car overturns.

What is an adsorber for?

Environmental standards provide for restrictions on exhaust gases emitted into the atmosphere by vehicles. Every year the standards become stricter. Car manufacturers have come up with special devices that protect the natural environment from exhaust gases from internal combustion engines.

Such devices are called adsorber. Although it correctly sounds like “Absorber” from the Latin word “Absorbeo” - “to absorb”. These devices are installed on gasoline engines of all vehicles.

This is what adsorbers look like for various car brands:

Adsorber VAZ

Audi adsorber

Toyota adsorber

New car owners are often interested in where the EVAP . This is the name of the equipment that is installed in cars and acts as a trap for harmful vapors. It includes an absorber valve.

Canister valves of various models:

Toyota canister valve

Audi canister valve

VAZ adsorber valve

EVAP stands for Evaporation Emission. In Russian it means the gas tank ventilation system. Comes from the Latin word - Evaporation or evaporation.

Attention! The adsorber is a secondary component in car engines. But its breakdown negatively affects the engine and its components.

Experts advise that if signs of malfunction of this device appear, contact a machine repair service center.

What is an adsorber and what is it for?

What does the adsorber look like?

The adsorption process is the absorption of gaseous media by bodies of solid or liquid consistency. Accordingly, the main task of the adsorber is to absorb gases, preventing them from entering the environment. However, these are not exhaust gases, but gasoline vapors emanating from the cavity of the fuel tank. When the car engine is running, the trapped vapors are transferred to the intake manifold; while parked, gasoline vapors are neutralized inside the adsorber.

Thus, the adsorber does not allow gasoline vapors to penetrate into the environment, which is required by modern environmental standards, and also does not allow them to enter the cabin. In addition, delaying, condensing vapors and returning gasoline back to the fuel system provides additional savings.

We recommend: The starter turns, but the engine does not start - how to find and eliminate the causes of the malfunction?

It should also be noted that the function performed by the adsorber is complex ventilation of the fuel tank. When fuel is consumed, the freed space is filled with air, which is supplied through the adsorber. Here the air is filtered and dried, which has a positive effect on the operation of the engine as a whole.

The key basis for dividing adsorbers into separate classes is its filling. Currently the following options are used:

- granular adsorbent in a stationary state;

- granular adsorbent capable of moving in the cavity of the device;

- fine-grained filling with a boiling bottom layer.

Adsorbers with static coarse-grain filling show maximum efficiency. Its main advantage is protection from partial or complete loss of the active substance along with fuel vapors.

Where is

On most cars it is located under the ignition coil, on the left side of the engine. To remove it, you need to remove the battery terminals, loosen and remove the mount, and remove all the hoses that are connected to it.

Locations of the adsorber in various brands of cars:

The nuances of removing the adsorber

There are situations when the adsorber is simply removed from the system. However, during such events you need to remember the following points:

- Replace the fuel tank cap with a leaking one.

- Insulate the supply/discharge pipes.

- Reflash the ECU.

We mentioned earlier that the adsorber is an important part in the car, and if you decide to remove it, all manipulations must be done correctly.

The tank needs ventilation

There is an important advantage when converting an engine from a carburetor to an injector. If you do not touch the tank pipes, the ventilation of the carburetor type tank is not impaired in any way

In this case, an adsorber is not required.

However, in the case of the VAZ-2114 the situation is somewhat more complicated. There is no point in removing the adsorber, because this device in the car works to reduce harmful emissions into the environment.

Motorists are eager to remove this equipment due to the high cost of maintaining it and simply because it interferes with the installation of more important parts.

Experienced motorists dismantle the adsorber due to breakdowns and so as not to spend money on a new one. Removing it is very simple:

- The separator hose is equipped with a fine filter, and gasoline vapors are released into the atmosphere.

- The hose on the valve is blocked.

- The engine firmware is adjusted so that the CheckEngine error does not occur.

- It is advisable to make a 2 mm hole in the tank lid to ensure ventilation. Otherwise, the tank may not withstand the pressure that is created inside. There are vacuum situations that can crush the container like an empty tin can.

Removing the adsorber for replacement:

Disconnect the equipment from its mountings. Remove the block along with the wires

Together with them, disconnect the gas supply hose to the throttle. Remove the purge valve. Disconnect the fuel vapor outlet pipe from the separator. The adsorber bracket is secured to three bolts - they need to be unscrewed and this element must be carefully removed. The new part is placed in the same place, and the gasoline vapor supply hose is connected to the purge valve. What is the VAZ 2114 adsorber and for what purpose is it installed on the car? And it’s worth remembering such a thing as European standards for car toxicity

Every year they become stricter; only those cars that emit a permissible amount of harmful substances into the atmosphere are put on the road. Someone will say that Europe is small, and it really needs this so as not to suffocate in the smog (and in England there has always been smog without cars). But for the Russian Federation this is irrelevant - a large territory and a huge number of forests that require carbon dioxide to live

What is a VAZ 2114 adsorber and for what purpose is it installed on a car? And it’s worth remembering such a thing as European standards for car toxicity. Every year they become stricter; only those cars that emit a permissible amount of harmful substances into the atmosphere are put on the road. Someone will say that Europe is small, and it really needs this so as not to suffocate in the smog (and in England there has always been smog without cars). But for the Russian Federation this is irrelevant - a large territory and a huge number of forests that require carbon dioxide to live.

But in order to supply cars to other countries, they have to be improved and adjusted to standards, including environmental ones. And immediately you need to highlight two main points:

- An absorber is a substance that absorbs vapors. In this case we are dealing with activated carbon. It is also used in gas masks.

- An adsorber is a device in which the vapor absorption process takes place.

This, in general terms, applies specifically to cars. In fact, absorbers can be of several types, just like adsorbers. But if you need it, consult your chemistry textbooks.

Operating principle of the adsorber

To understand where it is located and how to repair the blower, you need to know the operating principle of the device and the entire system. The absorber device itself is filled with activated carbon, which absorbs harmful substances.

EVAP catches gases from burned fuel as follows:

- Fuel vapor enters the separator. Condensation occurs. The resulting drops flow into the tank.

- Those vapors that have not turned into condensate flow into the absorber. Here the harmful substances they contain are absorbed by activated carbon.

- Gas accumulation occurs. And when the engine starts, they are supplied to the intake manifold.

- Absorption occurs when the engine is not running.

- When the engine starts, this very valve comes into action. It provides air flow from outside.

- Together with the air stream, the accumulated gases in the adsorber return to the engine.

- Here they undergo another burning.

- Now these vapors enter the exhaust system.

Thus, the absorber purge apparatus creates ventilation of the mechanism. Proper operation of the device is silent. During the cold season, the driver may hear a chattering sound on some cars. This is how the device works.

In case of any malfunction, the car owner will hear knocking, grinding, clattering sounds and blame the faulty engine for everything. In fact, the problem may be in the blower. Sometimes the purge sensor fails.

Attention! In order not to personally disrupt the operation of the ventilation system, experts do not recommend filling the car up to the neck of the gas tank. It is also recommended to promptly remove the pistole from the gas tank at gas stations.

Automotive absorber design

In simple words, the absorber design is a plastic jar with a filled filter catching element. The best substance for trapping and neutralizing fuel vapors is activated carbon.

The absorber consists of:

- Separator. The separator captures gasoline vapors and sends them back to the fuel tank.

- Gravity valve. It protects against fuel overflow if the car overturns. The valve blocks the movement of fuel.

- Pressure meter. The pressure sensor performs an important function - it monitors the vapor pressure in the fuel tank. When the maximum permissible pressure in the tank is reached, the sensor opens and releases the pressure.

- Filter element (activated carbon). The filter element in a car absorber is carbon in large granules. Large granules allow vapor to pass through the layer of carbon powder and condense.

- Connecting tubes. Connecting tubes serve to connect all structural elements.

- Solenoid valve. The solenoid valve changes the fuel vapor recovery modes.

Reviews have been published about the performance of the Full Free fuel saver.

Symptoms of a problem

The driver will feel a malfunction in the device immediately. The following happens to the car:

- engine power decreases;

- dips appear during engine idling;

- when opening the gas tank cap, the car owner hears it making a hissing sound. This indicates that the EVAP system is not ventilated;

- the smell of burning fuel in the vehicle appears in the cabin;

- Gasoline consumption per 100 kilometers increases.

The fuel pump breaks down due to the vacuum occurring in the system. This happens because without ventilation, fuel accumulates in the intake manifold. The engine will idle or may stop completely.

You can check whether the device is faulty or not by sharply pressing the gas pedal while driving. If the knocking and grinding noises remain, then the problem is in the adsorber.

Attention! The device can be adjusted using a special screw. If you tighten it half a turn, you can reduce the natural knocking of the device. When twisted one full turn, the controller will generate an error.

The adjustment itself will make the operation of the unit adequate and soft. It will stop knocking while driving and getting on the nerves of drivers. But in order to unscrew it, the car owner will have to clean the screw from the epoxy resin.

What is an adsorber and EVAP system

Many motorists call the device for absorbing fuel vapors an “absorber,” but this is incorrect, since the name “adsorber” comes from the Latin words “ad” (translated as “on”) and “sorbeo” (translated as “absorb”) , which together means “surface absorption” (accumulation on the surface). In turn, the absorber absorbs the entire volume and cannot be used in this case.

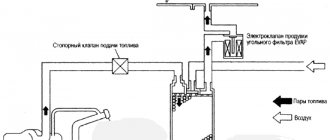

Diagram of the fuel vapor recovery system

Since the largest amount of vapor accumulates in the fuel tank, the adsorber is located not far from it. In fact, it is part of an entire gasoline vapor recovery system (EVAP). The latter consists of the following elements:

- Gasoline vapor separator.

- An adsorbent element is a container with an adsorbent substance.

- Ventilation valve.

- Canister purge solenoid valve (located between the canister and the intake manifold).

- Pipes and hoses for connection to the fuel tank, intake manifold and atmosphere.

In addition to the main elements, the EVAP system is part of the OBD-II on-board diagnostic system and includes a number of sensors (fuel evaporation, pressure) and an electronic control unit (ECU) that actuates the solenoid valve.

Determining the health of an element

To determine whether the system purge sensor and the device itself are working properly, you can use the error codes on the electronic engine control unit. Or do it mechanically yourself.

The car owner will need the following tools:

- multimeter;

- wire sections.

Absorber testing steps:

- Open the hood and disconnect the block with wires from the valve.

- The dipstick with a negative value is placed on the body. And with a positive one - to the terminal of the wire block under the name “A”. Each pin has its own designation, which can be found in the vehicle’s operating manual. At this point, the valve sensor output is needed.

- Turn on the ignition and look at the multimeter display.

- If it shows 12 Volts, then this means that everything is normal. If no electric current is supplied to it, then the multimeter will show 0. This means you need to check the battery.

Errors of a faulty unit that can be generated by the electronic engine control unit when a scanner is connected:

- break in the control circuit of the absorber purge valve;

- "Check Engine" signal;

- errors 0443, 0449;

- 0451 – is responsible for the readings of sensors in the gas tank. If it lights up, there is a malfunction in the sensors;

- 0442 – there is a leak in the engine ventilation system;

- 0455 - indicates that the leak in the ventilation system is large;

- error P0441.

To check the valve itself for malfunction, you need to remove it. Removal procedure:

- Remove the plunger from the injection syringe.

- Insert it into the outlet fitting on the device.

- Put pressure on him. The piston must move under pressure.

- After this, connect the battery to the electrical part of the valve. Press the piston again.

- If it moves under pressure, it is not working properly. If the piston goes down without resistance, then everything is in order.

Here you can find out where the Toyota starter is located.

Checking the functionality of the adsorber

To make sure that the malfunction is related specifically to the valve of this element, you can send the car for a full diagnosis. But this is expensive, so let’s first try to identify possible problems ourselves.

First of all, you need to see if the controller is generating errors, for example, “open circuit control.” If everything is fine, then it will use a manual check. To do this, just prepare a multimeter, a screwdriver and several wires. After this you need to follow a few simple steps:

- Raise the hood of the car and find the valve you need.

- Disconnect the wiring harness from this element. To do this, you must first release the special lock that secures the pad.

- Check if there is voltage going to the valve. To do this, you need to turn on the multimeter and switch it to voltmeter mode. After this, the black probe of the device is connected to the ground of the car, and the red probe is connected to the connector marked “A”, which is located on the wiring harness. The next step is to start the engine and see what readings the device gives. The voltage should be the same as the battery. If it is not there at all or is too small, then you will probably have to look for a more serious problem. If everything is fine with the voltage, then you can move on to the next step.

- Remove the purge valve. To remove it you need to use a screwdriver to slightly loosen the clamps. After this, you can easily move the valve slightly up and smoothly pull it out along a small bracket. After this, the device must be connected directly to the battery terminals. One wire goes to the purge valve (to “+”), and the second is connected to “minus”. After this, both conductors are connected to the corresponding battery terminals. If there is no click, then the valve is completely out of order and it is best to replace it.

We recommend: Turbocharging - what is its operating principle?

The procedure for removing the adsorber

When purchasing a new vehicle engine ventilation unit, pay attention to the markings. Both should be identical. Otherwise, there will be no compatibility and the valve will not be able to work and provide ventilation to the gas tank.

The replacement procedure is as follows:

- Remove the negative terminal from the battery.

- Open the hood and find the absorber.

- Press the latch that holds the wire block. And disconnect it.

- Unscrew the screws that hold the device in place.

- Disconnect the hoses.

- Remove the bracket and the old piston from the absorber.

- Install a new device.

- Repeat all steps in reverse order.

Attention! To assemble in the same order, you need to mark each device with a marker in what order it was removed.

In this simple way, a new device for venting the EVAP system is installed.

Like all devices, this type of absorber has its positive and negative sides. Due to the disadvantages, experienced car owners most often remove the valve. Although this threatens to destroy the coordinated work of the mechanisms.

Do-it-yourself absorber valve replacement

If signs of malfunction are detected, the valve will need to be repaired or replaced. The adsorber valve is inexpensive and easy to replace. To dismantle you need to have a pair of Phillips screwdrivers and know where the canister purge valve is located. Operating procedure:

The markings on the old and new valves must match.

- Open the hood and find a cylindrical device - an adsorber.

- Remove the negative terminal from the battery.

- Disconnect the wire block by pressing the latch and pulling it towards you.

- Loosen the valve.

- Remove the fittings under the latch and disconnect the hoses.

- Remove the valve together with the bracket from the adsorber.

- The new valve is installed in the reverse order.

Thus, even such a small element as the adsorber valve performs important functions and its malfunction can seriously disrupt the operation of the entire engine. Therefore, it is important to monitor the condition of your car and carry out diagnostics on time.

Adsorber, purpose

The adsorber is the brainchild of the EURO-2 standard. It is this that ensures the absence of emissions of hydrocarbons into the environment, both in solid, liquid and gaseous form. The most difficult thing to prevent is “gaseous release”. When the vehicle moves, as well as when parked, gasoline evaporates. Gasoline vapors accumulate in the tank cavity, creating excess pressure.

First of all, it's dangerous. Theoretically, such a process could lead to an explosion, especially if there is a small amount of fuel left in the tank. True, gasoline vapors in their pure form do not explode - they also need air supply. Secondly, through microcracks and crevices, gasoline vapors penetrate into the interior and surrounding space, creating unpleasant odors and polluting the environment.

An adsorber is a special device (system) designed to absorb fuel vapors that form in the tank. It not only absorbs vapors, but also returns them in liquid form to the tank or intake manifold to participate in the ignition process. That is, the adsorber simultaneously increases environmental friendliness and reduces fuel consumption. The adsorber system operates constantly. When the engine is not running, gasoline vapors accumulate in the separator, condense, and flow into the tank. During engine operation, evaporation flows into the adsorber, condenses there (settles), and is then “sucked out” into the intake manifold due to vacuum.

The name adsorber comes from the Latin sorbeo, “to absorb.” There is a console in front of him. Many car enthusiasts are confused about whether it is an adsorber or an absorber. The main element of the adsorber is the filter element. It is made of large granules of activated carbon.

Why large granules? The fact is that the task of this filter is not to absorb gasoline vapors, but to deposit them on the surface of the granules so that liquid gasoline flows down and accumulates at the bottom, and then enters the intake manifold. This absorption is called superficial and is designated by the prefix “Hell”. Internal absorption is indicated by the prefix “Ab”. For greater clarity, I recall the picture.

So the adsorber is correct.

Positive and negative aspects of adsorber

The advantages of the device include the following protection functions that it performs:

- the car does not emit harmful gases into the atmosphere;

- saving fuel, as unexhausted vapors burn out;

- There is no unpleasant smell from fuel in the cabin. This item is not performed at the proper level on some modifications of vehicles.

The negative aspects of the adsorber include the following parameters:

- instability of engine operation when the valve is dirty;

- takes up a lot of free space under the hood;

- the cost of installing an absorber is high. Accordingly, the vehicle itself becomes more expensive;

- the tank cap may fly off if the valve is not working properly and gases accumulate inside the gas tank;

- if the device fails, this results in the loss of the fuel pump;

- large accumulations of an explosive mixture if the absorber is faulty, but the engine continues to operate. This happens with older car models produced before 2000.

Many car owners remove this device. Since some drivers are sure that the device leads to increased fuel consumption. Others say that it causes the fuel pump to break and the engine itself will not last long.

When removing the absorber, the car owner should know that the tube from the valve must be closed. And adjust the program in the electronic control unit. Therefore, it is better to perform this procedure in the presence of experienced mechanics or at a service center. Although many mechanics do not want to remove the device and will try their best to dissuade the car owner.

Absorber valve: what is it for and what does it affect?

The valves in the absorber are a technically simple device that operate differently depending on whether the engine is running or not. Like all valves, it must open and close.

When the absorber cavity is clogged or some other malfunction occurs, the valve malfunctions. With a faulty adsorber valve, serious vehicle damage can occur because pressure is not released from the fuel tank and the cavity is not purged.

Symptoms of Absorber Valve Problems

There are several signs and symptoms that can help identify the technical condition of the valve:

- The fuel gauge shows either a full tank or an empty one.

- After starting the engine, after 5-10 minutes the revolutions begin to fluctuate.

- At idle speed, when you press the pedal, the car begins to stall.

- The engine does not gain speed when driving. It takes a long time to accelerate.

- When opening the gas tank cap, a vacuum is felt and a whistle is heard.

- Increased fuel consumption.

- When it’s cold (when the engine is running but not yet warmed up), knocking noises from the absorber are heard, as if valves are knocking.

The cause of absorber failure is not always the valve. This may be severe contamination of the absorbent element, in this case coal. Gases should easily pass through the coal granules and condense there.

The valve is very cheap. Therefore, it is possible to change if signs of improper engine operation are detected. You can also replace the adsorber filter element with your own hands: disassemble it, pour out the old coal, pour in new coal in large granules.

Absorber malfunction

Over time, the absorber becomes clogged and may become unusable. Signs of malfunction of this element of the fuel system can be determined by indirect signs. One of them is the formation of excess pressure in the fuel tank. This happens due to the formation of vapors that have nowhere to escape from the gas tank. In this case, when you unscrew the lid, you will hear a hissing sound.

On my VAZ 2112, as soon as I started unscrewing the tank cap, it was knocked out with such force that it’s scary to imagine. I wish I knew then that this is a problem with the absorber. And so I had to just let off steam several times a day. Also due to poor performance of the absorber, the car's idle speed may begin to “float”.

In our country, the problem of faulty parts is solved very simply, especially those without which the car can drive. Take off and move on, as the craftsmen unanimously advise. Here, of course, it’s up to you to decide, but something tells me that you and I can breathe this same air. And if everyone takes and removes all the “extra” eco-details, since they are not really needed in the car, then one “fine” day there will be nothing to breathe.

What is a filter element and how does it work?

In simple terms, the absorber is a large can filled with activated carbon. In addition, the system contains:

- Separator with gravity valve. It is responsible for trapping fuel particles. The gravity valve, in turn, is used very rarely, but in an emergency (for example, if the car overturned during an accident), it will prevent fuel from overflowing from the gas tank.

- Pressure meter. It is necessary to control the level of gasoline vapor in the tank. As soon as their level is exceeded, harmful components are released.

- Filter part. In fact, this is the same can of granular activated carbon.

- Solenoid valve. Used to switch between modes for capturing emitted gasoline vapors.

If we talk about the principle of operation of the system, it is very simple:

- First, gasoline vapors rise in the gas tank and are sent to a separator, where partial condensation of the fuel occurs, which is sent back to the gas tank in liquid form.

- That part of the vapor that could not settle in the form of liquid passes through a gravity sensor and is sent to the adsorber.

- When the car engine is turned off, gasoline vapors begin to accumulate in the filter element.

- As soon as the engine starts, the canister valve comes into play, which opens and connects the canister to the intake manifold.

- Gasoline vapors are combined with oxygen (which enters the system through the throttle assembly) and pass into the intake manifold and engine cylinders, where harmful fumes burn out along with air and fuel.

As a rule, it is the adsorber valve that fails. If it begins to open and close in the wrong mode or fails completely, this can negatively affect the operation of the entire vehicle and cause breakdowns.

How to properly remove the adsorber

In a car, the adsorber absorbs fuel vapor from the gas tank ventilation system and supplies it to the intake, because according to environmental standards, the gas tank must be isolated from the atmosphere.

From Wikipedia;

Adsorber (from Latin ad - on, with and sorbeo - absorb) is a device for absorbing (thickening) a surface layer of a solid, called an adsorbent (absorber), of dissolved or gaseous substances, not accompanied by a chemical reaction. The adsorber is used in chemical, oil refining and other industries. The process occurring inside this apparatus is called adsorption.

Now the first question is - why filter gasoline vapors if they still go into the intake? The answer is simple - adjusting the internal combustion engine control program by adding the nth number of clean air at the inlet is much easier than making adjustments based on the fuel-air mixture (gasoline vapor from the tank) of an unknown proportion.

In general, over time, the adsorber becomes clogged and stops passing air. As a result, we get excess pressure in the tank, which interferes with the normal operation of the fuel pump. In the cabin (sometimes under the hood) we get a periodic smell of gasoline, the vapors of which are squeezed out of the ventilation tube. And the engine starts running on a rich mixture due to lack of air.

A fuel filter from a carburetor classic is usually placed on the tube from the gas tank, and the solenoid valve, through which clean air should flow into the engine, is simply shut off with a bolt.

And now it already shows how it SHOULD be done. The same filter from the classics is put on the hose from the valve to the adsorber, which now serves as an air filter and prevents dirt from getting into the receiver. This is how the fuel-air mixture is brought to normal parameters.

Everything is clear here, one tube goes to the gas tank, the second through the valve to the engine.

Enter your email and receive emails with new crafts.

Bottom part of the adsorber. There is a fitting for supplying air from the atmosphere so that a vacuum is not created in the adsorber.

Installing a new adsorber valve

To replace an element, it is not necessary to contact a car service. You can do the work yourself using several Phillips screwdrivers. You also need to purchase a new valve (its markings must completely match the data on the old device).

- We find the adsorber.

- Remove the negative terminal from the battery.

- Disconnect the wire block by pressing the latch and pulling the device towards you.

- We loosen the fastenings of the solenoid valve and disconnect the hoses.

- We take out the old device (the bracket will come out along with it) from the absorber.

- We install the new device and put everything back together in reverse order.