January 23, 2017 Lada.Online 99 358 11

The adsorber is designed to capture fuel vapors and prevent them from entering the atmosphere. One of the elements of this system is the adsorber purge valve. Let's consider the main malfunctions of this part, as well as ways to eliminate them.

Replacing the canister purge valve

- Move the latch stopper upward.

- Disconnect the block with wires from the valve by pressing the latch.

- Disconnect the connection tube with the intake manifold by pressing the spring clips.

- Similarly, we disconnect the connection tube with the adsorber from the valve branch pipe.

- Remove the adsorber valve from the bracket.

Installation of the canister purge valve is carried out in the reverse order.

“We treat” the adsorber

If a breakdown occurs, the problem needs to be solved as soon as possible, there are four options to solve it, depending on the features, you can: replace the valve, replace the adsorber, try to repair the valve, remove the adsorber, we will consider each option in more detail.

Replacing the adsorber

On a VAZ 2114, replacement is very simple, you can go to a service station, but if you do the procedure yourself it will take about 20 minutes. We dismantle the spare part:

- disconnect the hoses from the throttle;

- disconnect the wires and block;

- remove the purge valve and purge and separator hoses;

- unscrew the three bracket bolts;

- the part has been removed.

- We attach a long pipe to the point where vapor is supplied to the blow-off valve;

- We connect a short hose to the fence from the separator;

- put the spare part in place;

- connect the supply hose to the valve;

- install a purge channel (on the engine cover);

- connect the wiring and block;

- place a tube between the valve and the adsorber;

- the work is finished, connect the power and go.

We repair the valve

The valve is clogged due to bad gasoline, before buying a new one, let's try to fix the old one. If a characteristic smell of gasoline appears in the cabin, then the problem is in the valve pipes, they are replaced by simple replacement, and the problem is revealed by a visual inspection, we look at which pipe has burst, buy a new one and install it.

It happens that there is no breakdown, after visually inspecting the pipes, you may find that everything is intact and working, just one pipe has flown out of its place, in this case, you need to put it in place and tighten the clamp.

- We unscrew the adjusting screw, counting the revolutions (it is filled with epoxy resin, it will be easy to find).

- We drip carburetor flushing into the fittings.

- Holding the valve in the open position, we blow it with a compressor.

- We repeat points 2 and 3.

- We put it in place, screw in the adjusting screw to the previously calculated number of revolutions.

Valve replacement

If the valve breaks due to overheating of the radiator, it cannot be repaired; a new part is needed.

The procedure is simple, let's consider it in order:

- We turn off the power to the car and disconnect the KPA plug.

- We loosen the air control inlet pipe, remove it, and move it to the side.

- We bend the fastening, dismantle the valve (remove the fastening no more than 1 cm).

- Lift the valve along the grooves (you need to pull it up).

- We disconnect the fitting, there are two inlets, the first one can be easily removed, the second one will have problems - on the raised fitting, the fixing tendrils are prying up, on the recessed clamp (it’s easy to do with two people, you’ll have to “sweat” alone).

- We install the new adsorber valve in the reverse order.

Removing the adsorber

This is not recommended, but if there is no money (for a new one) and no desire to understand the problem (fix something), it is removed. In addition to the above-described dismantling of the part, three more procedures need to be performed:

- dig into the ECU (reflash);

- seal the pipes leading to it;

- replace the tank cap (it needs a leaky one).

- The VAZ 2114 adsorber is an important part; it should not be removed.

- You now know how to replace a part, determine if it is broken and try to repair it, so it’s better to do just that.

- If you decide to remove it, remember, now the car is environmentally friendly “Euro 1”, later problems may arise with this.

Checking the canister purge valve

1. Disconnect the block with wires and visually check the condition of the contacts. If oxides are detected on them, we treat the terminals with a means for cleaning and protecting electrical contacts.

2. Remove the adsorber valve. We measure the resistance of the valve winding with a multimeter, which should be within 20-30 Ohms. The canister valve should be replaced if a short circuit or break is detected in the valve winding.

3. To avoid short circuit, one terminal of the valve should be insulated with PVC pipe. We supply 12 V from the battery to the valve terminals. At this moment, the valve terminals should open with a characteristic click. We repeat the test, creating a vacuum in the valve with a rubber bulb.

Useful video

You can get additional information about the design of the adsorber and options for replacing it from the video below:

According to the requirements of new environmental standards that limit the content of harmful substances in exhaust gases, vehicles must be equipped with an EVAP system. This equipment prevents harmful fuel fumes from entering the atmosphere. The main function in the fuel vapor recovery system is performed by the adsorber. Some people underestimate the importance of this element in the operation of a car. However, a malfunction of this seemingly minor component can lead to damage to the fuel pump and affect the operation of the entire engine. Therefore, experts recommend checking the adsorber valve when signs of engine malfunction appear.

The canister valve is knocking, clicking or clicking

We make sure that the noise comes specifically from the adsorber valve, and not from the timing belt, rollers and other elements. To do this, simply press the gas pedal sharply. If the chattering noise does not change, then the source of the noise is the adsorber valve. It is not uncommon for the clatter of the adsorber valve to appear only in cold weather at sub-zero temperatures.

What can you do about it?:

1. Contact an authorized dealer with the problem. If the adsorber valve is truly faulty, it will be replaced under warranty. If they consider that such valve operation is the norm, then there is no point in writing in support of AvtoVAZ.

2. Advice from car enthusiasts (you lose your warranty!). There is an adjusting screw on the side of the valve, which is filled with glue. Remove the glue and turn the screw clockwise 90 degrees. After this, the adsorber valve no longer clicks in the cold.

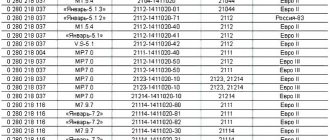

If you decide to buy a canister purge valve, then look for it by article number:

- 82 00 248 821 (for Lada Vesta or XRAY).

- 11180-1164200-00, 11180-1164200-01 (for Lada Granta/Kalina)

- 21103-1164200-01, 21103-1164200-02 or 21103-1164200-03 (for Lada Priora and Niva 4x4)

- 8200692605 (for Lada Largus)

Have you encountered problems with the adsorber valve?

It clicks for me too, I don’t think I noticed it before or didn’t pay attention

I discovered it only with a mileage of 5700 km, I hadn’t noticed it before, but it seems like it should be)) gasoline 95 Well, as soon as I paid attention, many people began to notice, for some reason I assume that it’s a matter of low temperatures, in the summer I definitely have Everything was quiet, I listened carefully in the car, maybe the gasoline vapor pressure in the tank is lower in the cold, or the condensation has frozen. IMHO

Well, as soon as I paid attention, as many began to notice, for some reason I assume that the problem is in low temperatures, in the summer everything was definitely quiet for me, I listen carefully in the car, maybe the gasoline vapor pressure in the tank is lower in the cold, or condensation where frozen. IMHO

You will laugh, but I just noticed a few days before your post, I listened to the engine, it seemed that the gene began to howl and noticed clicks, although earlier at the beginning of the start of sales I read about it, but did not pay attention

Forum members, I have a stupid question. on the cap I saw an adsorber, such a huge thing next to the battery, but on the grant I don’t see anything, where is it?

ps additional supply vapor from the tank changes the ratio of the gas-air mixture, but the brains don’t take this into account, especially when evaporation is most active in the heat.

DK will immediately catch this.

and damn, I’m definitely dumb about the exhaust.

Possible malfunctions in the operation of the device

The VAZ 2114 absorber, due to its intended purpose, is susceptible to clogging and at some point may become faulty. Problems are not easily determined and often only by secondary symptoms, for example, increased pressure in the fuel tank. It’s just that gasoline vapors, due to wear of the separator, remain locked in the space of the tank and begin to put pressure on its walls. An increase in pressure can be detected when unscrewing the tank cap - a characteristic hissing sound is heard.

Sometimes the gas tank cap simply shoots out of the neck, which means that the pressure has reached a critical level and the adsorber must be urgently changed. If there is a problem with the adsorber, the engine speed begins to jump up and down. Many car owners write on forums that you can remove the VAZ absorber and not suffer. But everything is not so simple, and there are never unnecessary parts in cars.

Removing the absorber alone is not enough; you need to think about what to do with gasoline vapors that have nowhere to be discharged, and that the ECU may also have to be reconfigured. After all, some types of on-board engine processors find a malfunction in the purging of the fuel system and put the engine into emergency mode, in which it will not be possible to drive normally.

As for malfunctions, the problem area of this adsorbent system is the purge valve. You can repair it yourself. All you need is a flathead screwdriver, but be careful when removing it. The problem is the valve fastening; often it is not metal, but plastic; it is not difficult to break. The mount is located on the engine cover. There are also clamps on the valve itself, which also require a careful approach. We remove them and take out the problematic part.

If you blow into the valve and air comes out of it, this means a 100% malfunction. A normal part will not allow air to pass through. If there is a problem with the valve, the car experiences problems when starting the engine hot, and gasoline consumption increases. If the problem is not corrected, there will be a Check Engine and loss of normal driving dynamics. Failure of the adsorber seal and failure of the purge valve can cause unstable engine operation at idle until it stops.

So, let's move on to valve repair. In its upper part there is an adjusting screw fixed with epoxy resin. Screw the screw in until it stops, counting the turns so that if something happens, you can return the canister valve to its original position. You can drop a little carburetor flushing fluid into the valve fittings. Then we blow it in the open position with compressed air. The repairs are done.

The valve can also wear out due to heat near the radiator, and there is nothing you can do to help it. The quality of the material from which the adsorber valve is made is not the best. The only solution can be to replace or change the location to a cooler one, for example, closer to the adsorber itself.

What is an adsorber?

An adsorber is a device whose main purpose is adsorption. They are actively used in oil refining and some industrial sectors. In addition, these days adsorbers have found very wide application in vehicles equipped with internal combustion engines - they prevent gasoline vapors from entering the atmospheric air. Until recently, adsorbers were not part of automobile spare parts; their appearance was associated with stricter requirements for the environmental performance of vehicles.

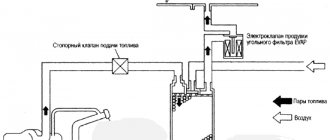

These devices are equipped with injection systems; tubes connect them to the gas tank and throttle pipe. Switching operating modes is carried out by means of a valve; it closes when the engine is turned off, stopping contact between the device and atmospheric air. It is then that gasoline vapors enter the adsorber from the fuel tank, after which they are immediately absorbed.

When the engine starts, a special device that controls the injection system begins sending control pulses that initiate communication between the device and atmospheric air. The sorbent begins to be purged, and gasoline vapors enter the combustion chamber, where they are burned. The duration of control pulses and the intensity of sorbent blowing are directly dependent on the amount of air consumed by the motor.

The most important element of the described apparatus is the purge valve. The valves installed on the Lada Granta were inherited from the Lada Kalina, which makes possible malfunctions similar. Below we will look at problems that arise during the operation of the adsorber, as well as their symptoms and methods of elimination.

Operating principle of the adsorber

Adsorption is the process of absorption of gaseous substances by solids or liquids. For example, the first gas masks used filters in which the adsorber was activated carbon. The same thing is done in a car, but a little more complicated. The cylindrical plastic body of the adsorber contains a special filler that traps gasoline vapors. The VAZ 2114 absorber does not end with just a can of filler; pipes and valves are connected to it.

The VAZ absorber does not affect fuel consumption in any way; it is installed only to improve the environmental friendliness of the engine. As the gas tank empties, fuel vapors rise to the neck and enter the separator. There they again turn into a liquid state and return to the tank. And the part that did not have time to condense ends up in an adsorber filled with activated carbon, which absorbs harmful gases. This happens when the engine is turned off.

When the engine is running, the VAZ absorber is purged using a special valve, and all gases are burned in the vehicle’s exhaust system. As for fuel consumption, it varies within insignificant limits. The main purpose of the adsorber is only to neutralize gasoline vapors. This is a container with activated carbon, equipped with inlet and outlet hoses for gasoline vapors.

Replacing the canister purge valve

To carry it out, you will need to sequentially perform the following steps:

- first, the latch's stupor moves upward;

- by pressing the latch, disconnect the block with wires from the valve;

- to disconnect the tube connecting the valve to the inlet pipeline, press the spring clips;

- the tube connecting the adsorber to the valve pipe is disconnected in the same way;

- The process will be completed by removing the valve itself from the bracket.

Removal Features

The VAZ absorber is sometimes removed completely. To do this, you need:

- replace the gas tank cap with a leaky one;

- plug the supply and discharge pipes;

- often change the ECU firmware.

As mentioned above, you should not approach the adsorber as an unnecessary thing, and if you decide to remove it, remove it correctly so that the gas tank remains ventilated and not tightly sealed, as if there is an adsorber. Those who convert a carburetor engine to an injection engine have an advantage. If they do not touch the tank pipes, they do not disturb the carburetor ventilation system of the tank, so they do not need an adsorber.

How is the valve checked?

To carry out this procedure you need:

- Disconnect the block with wires, and then visually check the condition of the contacts. If you find oxides, immediately treat the contact terminals with special cleaning agents.

- Then remove the valve and measure the resistance of its winding with a multimeter; it should be between 20 and 30 ohms. If a short circuit or winding break occurs, replace the part.

- Insulating one of the valve outlets with a PVC tube will help to avoid a short circuit. Apply 12 V from the battery to the contact terminals; their opening should be accompanied by a click. Then the test will need to be repeated by creating a vacuum in the valve using a rubber bulb.

Chip tuning and EVAP

To increase engine power, changes are made to the operation of the gasoline vapor recovery system. They can be performed in two ways: by correcting the operation of the electronic control unit (ECU) programmatically and mechanically. In the first case, manual changes are made to the operation of EVAP, blocking signals from the canister valves, which regulate the performance of the fuel supply pump and air meter.

With the mechanical version everything is simple; the high-pressure safety valve is dismantled. Both methods allow you to increase the power of the car, but have a detrimental effect on the catalyst, which should also be gotten rid of. These “upgrades” lead to a deterioration in the vehicle’s environmental performance.

What is an adsorber, what task does it perform, what problems can arise, we’ll talk about this and much more in today’s article.

Many car owners have no idea, let alone the structure of the system, and sometimes even its existence. Therefore, the goal of this article is to “put everything into perspective,” including finding out how the device works, as well as where it is located.

Why do you need an adsorber?

It was originally created as a tribute to environmental standards, more precisely under EURO2. By and large, the motor can be configured so that it can do without it. But, taking into account modern standards, vapor leaks are unacceptable. Plus, the adsorber does not allow fuel vapors to enter the cabin, which, as you understand, is also unpleasant. If on old cars, still of the carburetor type, such a system did not exist, in principle, on all modern injectors, it is mandatory.

Possible valve malfunctions and ways to eliminate them

Signs indicating a malfunction in the purge valve include an increase in the usual fuel consumption standards and a constant smell of gasoline in the cabin. However, the main sign of a breakdown is extraneous sounds: the valve begins to knock, and noises resembling hissing and clicking may appear.

First, make sure that these sounds do not come from the timing belt or other elements of the car by sharply pressing the gas pedal. If the noise situation does not change, then the cause of its occurrence is a faulty valve. Note that quite often noises are observed only in the cold.

There are two ways to solve this problem:

- The first solution is for the car owner to contact official dealers - if the part is found to be faulty, it will be replaced under warranty.

- If the dealer does not find any deviations from the norm and the valve is not replaced, you can use the second option to solve the problem, which, however, will lead to loss of warranty. There is an adjustment screw on the side of the valve. Remove the glue from it and turn the screw 90 degrees clockwise. The clicking of the valve at low temperatures will stop immediately after this manipulation.

Work principles

Fuel typically evaporates, and in sealed containers like a tank, the evaporation builds up pressure. From the tank, vapors go to the separator, condense and return back to the tank, excess vapors are sent to the adsorber, where the active element absorbs them.

If you have ever stored gasoline in a canister, you have seen how it swells during long-term storage; if you are not so lucky, you could see how it “explodes,” usually on the lid, but on plastic canisters the weakest point is not determined by the lid.

This is what this process looks like when the engine is turned off, when the engine is running, the system opens the adsorber valve (purge valve), when the valve is open, the vapors do not reach the absorber, but are directly blown into the intake pipe, where the engine successfully burns them.

This algorithm is designed to obtain two advantages of the system:

- Increasing the environmental friendliness of the car due to the absorption of fumes.

- Fuel economy when driving (savings are 1%, but present).

As we figured out, gasoline vapors are absorbed by the adsorber or blown into the intake valve, which is responsible for changing operating modes and controlling the system. It switches during system startup, thanks to the engine start controller; during ignition, it turns on the receiver, the sorbent is purged and unabsorbed vapors are immediately sent to the engine, saving every milligram of evaporated fuel.

In addition to the above advantages, the system also does not allow the smell of gasoline into the lard of the car, but such a system also has disadvantages (albeit controversial), motorists complain that it:

- takes up space under the hood;

- is the culprit of unstable operation when broken;

- Expensive.

The absorber sensor of the VAZ 2114 clicks

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Here from the chiptuner: Question:

The sound of the adsorber valve operating is very audible.

How to fix it? Answer:

The adsorber valve, thanks to the outstanding VAZ acoustics, is best heard from the driver’s seat. . There is also a way to “pacify” the valve, suggested by Tom: you need to carefully pick out the epoxy covering the valve screw and turn it 1/2 - 3/4 clockwise. The valve will stop rattling and will still function normally.

I did it myself. Now I enjoy the silence.

Has anyone done this to themselves?

And where, actually, to pick?

Take a close look at the valve body itself, from the headlight side.

By the way, I didn’t have epoxy there, but white sealant, I didn’t even pick it out, but tightened the screw through it.

Another question: What is this screw for?

Please tell me what the character of this sound is. It’s quiet inside my cabin, but outside there’s something clicking in the adsorber—is that the sound?

The knocking sound of the adsorber does not sound like a clicking sound. It sounds more like a belt knocking on a plastic casing at engine speeds of approximately 1500-2000 rpm. You can hear it very well (for me it’s like this): the hood is closed, I’m driving slowly in 2nd gear, revs

2000, the door windows are closed, the heater is turned off, the music is too. Moreover, for some reason it can only be heard well from the driver’s seat.

Is this knocking noise constant or does it go away? I can’t determine what’s knocking - some say valve, others hydraulic - when you come to the service there’s never a knock.

No, the sound is not constant, I hear this sound only when the engine is warm, and when

But if you pick out the plug, problems with the IPG

, God knows what will happen to the brakes, the adsorber will be violating.

What is IPG

. And what does the brakes have to do with it?

What is IPG

. And what does the brakes have to do with it?

But if you pick out the plug, problems with the IPG are possible, God knows what will happen to the brakes, the adsorber will be damaged.

I missed something in this post.

problems with IPG, . the adsorber will be violative.

. strongly.

leon112 wrote: What is IPG. And what does the brakes have to do with it?

I'm tormented by the same 2 questions

I understand that IPG is a warranty engineer. And the adsorber will be to blame for the fact that the car will be removed from the warranty and the brakes will have to be repaired at its own expense. under a fortunate combination of circumstances. Sorry for the dark humor.

By the way, the topic was recently discussed with warranty providers - a colleague was tormented by the question “should I remove a self-installed radio or not?”

But I’m interested in another question: If the adjusting screw is filled with sealant, then it is necessary for some reason: WHY? Could there be a “keg of gunpowder” under the hood? Still, it “catches” gasoline vapors.

But I’m interested in another question: If the adjusting screw is filled with sealant, then it is necessary for some reason: WHY? Could there be a “keg of gunpowder” under the hood? Still, it “catches” gasoline vapors.

Exactly. The descriptions of the adsorber do not say anything about this bolt. I’ve been driving for the 4th day now, and everything seems to be working fine.

Then it’s not clear why the factory doesn’t immediately install the screw in such a position so that the adsorber doesn’t rattle.

Additional features

Of course, initially, created to create environmentally friendly engine operation, the Lada Granta adsorber, the price of which is insignificant, was underestimated. Manufacturers tried with all sorts of tricks to circumvent this newfangled trend, but the law obliged all car manufacturers who did not comply with this innovation to pay heavy fines.

Although AvtoVAZ has never been known for its large exports, it was forced to take measures to install an adsorber, since it has a small, but still a sales market. Today, the adsorber is installed on the Lada Granta without fail, since world research has revealed the following capabilities of this component:

– reduction in gasoline consumption

A similar result is achieved because the adsorber valve allows gases to be driven back into the gas tank, from where they enter the engine, which, when warm, is capable of processing them. If this device is missing, or the canister valve itself does not work, Granta loses fuel, which significantly increases consumption.

– normalization of exhaust system operation

Thanks to filtration, the likelihood of premature wear of the system and its components disappears.

What is the problem?

The purge valve operates based on the temperature sensor readings, that is, it opens and closes at the right time.

When opened, vapor from gasoline enters the cylinders, as well as air that was not taken into account by the air flow sensor.

Next, the controller and oxygen sensor react to all this, subsequently changing and adjusting the injection time at the injectors.

If any malfunction is detected in this system, then most often the CHECK lights up on the dashboard.

There are a few signs that indicate a faulty valve: floating speed, idling is unstable, the car may jerk when accelerating, and fuel consumption increases.

Well, checking this sensor for serviceability is not difficult.

We identify the causes of malfunctions on the Priora adsorber

On the Lada Priora we are considering, a valve failure is indicated by low engine thrust, and dips appear at idle. Also, while the engine is running, you will not hear the characteristic sound of the valve operating. There are other signs of device malfunction. A hissing sound may occur when opening the fuel tank cap. If the car owner notices a hissing sound, it means that the tank is under vacuum, which indicates that there is a malfunction in the ventilation system. The sensor will need to be replaced.