During the operation of a car, problems with the starter quite often arise. Moreover, even if the battery is charged and power comes to the starter after turning the key in the ignition, the device still does not work and the engine does not start.

In such a situation, there are only two ways to start the engine:

- starting the engine “from the pusher”;

- attempt to close the starter directly;

Although the second method is less common, in some cases this method is more “convenient”. The main thing is to know how to bridge the starter correctly to start the power unit. Read more in our article.

Why doesn't the starter work?

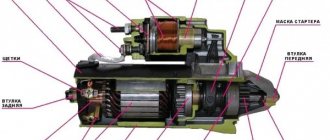

The car starter is actually an electric motor that is “attached” by its gear (Bendix starter gear) to the flywheel (flywheel crown), rotates the crankshaft and is then disconnected after the engine starts.

In this case, there are a number of reasons why the starter does not work:

- problems with wiring and contacts;

- the starter relay does not work;

- The starter solenoid relay is faulty.

- the starter winding burned out;

- the overrunning clutch has worn out, etc.;

As a rule, the main and most common problem is the failure of the starter solenoid relay. If the retractor is faulty, the starter will not turn the engine. A problem with the retractor is indicated by a click that can be heard when turning the ignition key.

If the starter clicks, the relay is turned on, but the overrunning clutch is unable to turn the crankshaft. In the case when the starter does not work precisely for the specified reason, you can try to supply power to it directly (close the starter).

Starting the engine while towing a vehicle

This is another common method for starting a car engine with a faulty starter.

Important! This method is not suitable for vehicles equipped with an automatic transmission, since due to certain features of its design, towing the vehicle is strictly contraindicated.

To implement this method, you will need a tow rope and another car. It is extremely important to strictly follow the following sequence of actions during towing:

- the leading machine should start moving smoothly and start moving at low speed to tension the cable;

- the driver of a towed car should not brake sharply;

- after the vehicle starts, it will begin to accelerate sharply;

- you should stop only after the leading car stops;

- Do not turn off the engine while unhooking the cable, otherwise it may not start, and towing will be required again.

How to close the starter

To close the starter, you need to connect the starter power contacts with a metal part of a suitable tool. This will allow voltage to be applied to the winding directly. To do this, you need an assistant who must turn the key in the lock to the “start” position.

In general, the process looks like this:

- the car is put on the “handbrake”, the manual transmission is switched to neutral or the P mode is switched on “automatic”;

- The contact plate is removed from the starter, after which the contacts need to be short-circuited with the tip.

In this case, it is important that a current conductor of suitable length and cross-section be used as a jumper. Typically, a screwdriver with a thick shaft or a wrench with an insulated handle is used for these purposes.

To understand how to close the starter with a screwdriver, you need to pay attention to the following:

- you need to close the contacts of the power line precisely on the solenoid relay.

- All actions should be performed carefully and carefully, without touching other elements under the hood;

- Do not touch the starter housing with a screwdriver, etc.

- after starting the engine, the screwdriver must be removed;

In this case, closing two power contacts on the solenoid relay with a screwdriver is similar to closing them from the inside with the relay armature. In fact, the operation of a retractor starter motor for connecting the electric motor is simulated. If the ignition is turned on, the starter will start working with such a short circuit and the engine will start.

Please note that when the contacts are closed there will be sparks, since the starter connection is direct. Another disadvantage of the method is that not all cars have direct access to the starter (it is impossible to close the contacts on the solenoid relay). After the engine starts, the screwdriver will need to be removed from the contacts, after which the starter will turn off.

If we take a closer look at the question of how to connect the starter directly, pay attention to the following points:

You need to find the control (pin that looks like a petal). Other contacts (one with potential +12 has a thick wire). Another contact is an electric motor contact. You need to close the control terminal (usually closed with a rubber cap) and the contact tab (usually closed with a plastic plug).

Closing with a screwdriver

Closing the starter with a screwdriver can only be done if the cause of the breakdown is the solenoid relay.

You can recognize such a breakdown

by the clicking sound coming from under the hood when you turn the key.

This means that the retractor relay is turned on, but the drive gear does not turn the crankshaft. In such a situation, nothing can be done other than jumping the starter with a screwdriver and thus applying voltage to the windings. This is interesting: Painting a car with liquid rubber

To close the starter using a screwdriver, you need to set the gearshift lever in the neutral position and tighten the brake. Under these conditions, the screwdriver will act as a pull-in relay. We insert a screwdriver between the power terminals, closing them.

In order to start the car directly through the starter, it is best to resort to the help of an assistant. So this will make things easier. One will insert the screwdriver, the other will close the contacts. With an assistant, everything will go much faster and easier.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

Connecting the starter directly from the battery

It happens that problems arise with the wiring or contact group of the ignition switch. In this case, the engine can be started by supplying power from the battery to the starter. To do this, you need a copper wire, a connector and an alligator clip.

The wire is soldered to the connector. Next, the power wire to the starter is disconnected, and a copper wire with a connector is inserted instead. Then the “crocodile” must be connected to the “plus” of the battery. If the starter is working properly and there are no other problems, the engine will start. After starting, you need to remove the crocodile from the battery terminal.

The main thing is to perform all actions carefully, connecting the starter directly to the battery. Do not short the wire with any elements under the hood. After starting the engine and removing the copper wire from the connector, the starter plug can be returned to its place. It is also important to remember that you should not connect the wires to the battery and the connector for a long time, so as not to drain the battery.

What to do if there is no key

The method we just looked at is not the only way to start the starter.

There are several more options. The first involves starting the starter from inside the car. To do this, you will need to remove the plastic panel that is located under the steering wheel of the car. The next step is to separate the wiring harness going to the ignition switch.

Find the wire that goes to ground (could be black, green, or yellow with a black stripe). It is possible to determine the required conductor using a tester. Connect one tip to the wire being tested, and the other to the car body. If the display shows zero, then that's what we need.

We recommend: Restoring the panel after airbag deployment

Strip the neutral wire, insulate it and move it to the side. Power to the starter on the VAZ-2114 is supplied through a red or yellow wire. To avoid confusion, check with a tester.

Next you need to determine the conductor that is responsible for the starter. To do this, connect the supply wire with the remaining ones in turn. From which the mechanism will work, we will continue to work.

Connect the remaining bundle to the positive wire, and then close it with the starter terminal. If you have determined everything correctly, the engine should start. Keep in mind that you cannot connect the wires for a long time, so as not to discharge the battery.

As with the first method, the gearbox must be in neutral.

Recommendations

- It is important to ensure that contacts other than the control terminal and spade contact are not short-circuited or accidentally connected.

- Taking into account the fact that access to the starter is usually from below, you need to be prepared for the need to remove standard or additional protection

- On many cars, the control terminal has the form of a threaded outlet (a nut is screwed onto a bolt), while the terminal is of the “petal” type.

We also recommend reading the article about what to do if the alarm blocks the engine from starting. From this article you will learn how to remove the engine blocking alarm if a failure or error occurs.If there is such a possibility, it is better to close the contacts not with a screwdriver, but with a wrench that has a handle (the handle should be well wrapped with insulation).

- After completing the process of starting the engine, you should check the fuses separately, as they can burn out if mistakes are made;

- Considering that the traction voltage uses 30-50A and higher, the connection points may stick.

- Owners of old cars, where the switch does not control the voltage supply to the coil, need to remember that when the starter closes, the coil may fail;

We close the starter “in French” (special cases)

Access to the starter is always open from under the bottom - you just need to remove the crankcase protection. An example is in the photo below.

Under the bottom of Renault Megane 2

It is difficult to reach the starter from the engine compartment. In the best case, it is closed by a filter (VAZ), in the worst case, by a battery. You can remove the filter, but what about the battery?

Starter installation location (circle)

Everything is done so that the starter can be changed, repaired, but not short-circuited.

What does terminal S look like?

On Renault cars, the terminal looks like a threaded outlet. The nut screwed onto it is “white”, although it itself is made of copper (see photo).

Starter Renault Logan, phase 1

We have already talked about the VAZ - they use a plug. If you remove it, you can see the “petal”.

The starting method using a screwdriver is not the best. The problem is limited access.

50 Amps

The pull-in relay on the “Ten” consumes 50 Amps. For budget Lada models the current is 30 A, for many foreign cars it is higher. This means that a current of 40-50 Amps will flow from terminal B to terminal S. Think about the dangers of this.

We are going to short-circuit the starter with a screwdriver, but at the connection points where the current will flow, it may “stick”. In this case, without unnecessary panic, remove the negative terminal from the battery.

To remove the minus terminal, you need a 10mm open-end wrench. Keep it with you.

What's the result?

As you can see, if the engine does not start, the starter may be the main cause of this problem. In this case, the culprit is often the starter solenoid relay or problems with contacts, wiring, etc.

We also recommend reading the article about why the starter clicks but does not turn the engine. From this article you will learn about the main reasons why the starter makes clicking noises but the crankshaft does not turn.

In any case, you need to know how to start the starter directly from the battery or by closing the contacts if the engine starting system has failed. However, it should be understood that connecting the starter directly is a last resort and is used only in emergency cases.

If there is such a possibility, it is better to refuse to try to start the engine from a pushrod in a car with any type of automatic transmission, and also not to try to directly connect or close the starter. In some cases, a short circuit of the starter or errors when trying to close the device lead to a short circuit, blown fuses, breakdowns of the vehicle’s electrical equipment, etc.

Finally, we note that knowing how to close the starter with a screwdriver to start the engine still does not solve the problem. First of all, this method may not be effective in many cases. For this reason, it is important to accurately determine the nature of the malfunction, and only then decide on which method to start the power unit.

Method two - towing

No less efficient and even more reliable, but you need another machine more powerful than your car. It will be enough to tow the vehicle for a short distance, and then start the engine in the same manner as described above. In this case, I would like to give a couple of practical tips:

- Do not turn off the car after it has started and then go straight to the service center;

- Do not forget that after starting the car, it will pick up speed if it is in second gear and you press the accelerator pedal;

- Don’t forget that after starting, the car towing you will stop. Therefore, you will need to have time to slow down.

Each of the listed options can be used to get to your home or service station. It is highly not recommended to use them every day.

Repair of VAZ 2109 starter - work flow diagram

Now we will tell you how to check the described “nine” mechanism and eliminate the faults found. First, we unscrew the fasteners that hold the shield, then remove the hose from the air intake device and remove the shield. To dismantle the starter, perform the following steps:

- unplug the wire from the battery terminal;

- disconnect the starter connector from the relay;

- remove the wire (by unscrewing the nut) from the relay bolt;

- unscrew the mounting bolts to remove the crankcase protection;

- at the bottom we unscrew the existing nuts, after which we unscrew another fastening element, which is located in the upper part of the engine compartment.

And it’s done like this: we apply a negative voltage to the housing, a 12-volt voltage to the relay output, and connect an ohmmeter to the contact bolts. When the relay is working properly, voltage fluctuations are recorded on the device (the bolts close and open). In the case where there are no indicated “jumps”, we take a new relay and install it instead of the one that has failed.

Next, you should check the functionality of the brushes. To get to them, you need to remove the cover from the starter, and then unscrew the screw that secures the wires in the device. The brush will come out of its place without any problems after you compress the spring located above it. The height of the brush must be 12 millimeters or more. If the height is lower, take a repair kit and install a new part.

Also, the repair kit for the “nine” starting system contains replaceable clutch gears. If you see chips and nicks on the old gear, it is advisable to replace it. Sometimes there are no visible defects on a given component. In this case, it is recommended to turn the gear in one direction (it should rotate without difficulty), and then try to turn it in the opposite direction. A working part will stop when scrolling in the opposite direction.

In very rare cases, a new bushing may need to be installed. This procedure is carried out in a couple of minutes. Before assembling the unit, professionals advise treating all starter elements that come into contact with each other with motor lubricant, and also lubricating elements made of plastic with lithol. It is advisable to perform this procedure even if the trigger mechanism components are in very good condition. The renovation is complete! Reassemble the starter in reverse order and safely.

Many car owners in their practice are faced with a problem when when starting the car (only clicks are heard). And needless to say that not all of them, especially inexperienced drivers, understand such automotive nuances and know what to do in such a situation?!

Yes, the easiest way out here is to contact a car service center, where auto mechanics will figure out exactly what’s what. However, if you are an inquisitive person and want to figure out all the problems yourself, and not just figure it out, but solve them, then this article is for you: in it I will tell you what could be the reasons why the VAZ 2109 starter does not turn and how these reasons can be eliminated.

Rotation is not transmitted

Sometimes the car does not start, although the electric motor receives voltage and rotates the rotor. However, the force is not sent to the flywheel. We recommend looking for root causes based on the following factors:

- The bendix has broken down. The basis of its design is an overrunning clutch, which limits the rotation of the drive gear in only one direction. Damage to the mechanism will result in the inability to transmit torque to the flywheel.

- Flywheel teeth are damaged. From intensive use or after exceeding the permissible force on the ring gear, breakdown occurs. Its repair is quite labor-intensive, since it will be necessary to dismantle the gearbox.

- Broken timing belt or chain. The driver will be able to diagnose such a breakdown from inside the car by the extremely rapid rotation of the crankshaft and electric motor rotor. High speeds are a consequence of the lack of load created under normal conditions by the valve mechanism.

To restore functionality, you will have to restore the rotation transmission chain. New parts and repairs may be required.

Some information about the ignition switch device

Lada Priora cars use anti-theft locks that block the next start of the starter and connect the key to the standard anti-theft system. The device is located directly under the steering wheel in a special way (four screws with tear-off caps that prevent unscrewing) and is fixed to the steering column.

The engine is started using a key that is inserted into the lock cylinder.

The device is powered by a battery, and a special relay marked “K4” is responsible for ensuring proper protection of the electrical circuit. The starter locking is achieved by a locking rod that is retracted and prevents the key from being removed in all its positions except the zero stage (position “0”). With one key position, only electrical circuits are activated. In a different condition they are different. For example, at the first mark, some on-board equipment is activated (windshield wipers, power windows, dashboard indicators, etc.), and the next time you turn the key in the ignition switch, an additional power circuit is activated, and the engine starts.

Ignition

If the previous steps did not help, proceed to checking the ignition. The most common problem occurs due to moisture accumulation in the distribution cap. Do the following:

- Remove the cover and inspect for condensation.

- If there is one, wipe with a dry cloth. Before wiping, check the lid for cracks - if there are any, just throw it away and buy a new one.

If everything is fine with the cover, check the wires for electrical conductivity. Bring the tester to the insulation and wait for a successful outcome. It will be so if you do not detect current: with normal wires, the insulation will not allow it to pass through.

Checking and disassembling the starter

If, when trying to start the engine, clicks were heard, and then silence, but after several attempts the starter still started working, the problem lies in the solenoid relay

You need to remove it, to do this, unscrew the three nuts from the studs and carefully remove the device. If you have experience with a soldering iron, then disassemble the device, inside of which you will see 3 “heels”: copper (usually rectangular) pads that “must” contact each other

Simply sand them down with sandpaper and reassemble the device. If there is no experience, replace the solenoid relay in accordance with its marking.

Rotor and stator testing

To do this, first remove the back cover by removing a couple of screws with a Phillips screwdriver. Next, use the same flat tool to pry the lock washer on the shaft and remove it. After:

- unscrew a couple of tightening bolts and disconnect the starter;

- pull out the rotor, for which you need to remove the stopper with the cotter pin;

- look inside the stator: you will see 4 brushes - if they protrude less than 5 mm, they need to be replaced.

Disconnect the stator contacts and check the resistance to ground: it should be greater than 10 kOhm. Next, measure the resistance between the coil terminals: if it approaches infinity, there is a break; “0” indicates a short circuit.

Bushings

There are two of them (one larger, the other smaller): in the front and rear of the starter shaft. Wear of these parts over long periods of use is common. As a result, the rotor begins to approach the stator due to play and the starter does not develop full power

Be careful when pressing in new bushings - they are fragile.

Disadvantages of the method

The main disadvantage of this method of starting the starter is that you can easily burn the ignition coil. That is why experts recommend carrying out this action only once. But sometimes the engine does not start using this method, so the reason lies much deeper.

It is also worth considering that in those places where the screwdriver comes into contact with the terminal, a current of up to 50 A is issued. It can easily become stuck, and it will also kick back into your hand; it can be quickly removed using an open-end wrench.

Functional features of the starter

Unfortunately, the service life of the device does not differ in duration compared to the period of operation of the power unit. On average it lasts about 5 years. It is extremely important to pay attention to the diagnostics of the device both on a newly purchased vehicle and on a car with a significant mileage, since this measure will help in the future to significantly extend its life.

In the design of the engine starting system, the starter spins its crankshaft, which creates the necessary degree of compression for the correct formation of the mixture and its combustion. Since the device works in conjunction with various mechanisms and electronic systems, it can therefore experience both mechanical and electrical failures. When the starter turns the crankshaft slowly or does not turn it at all, most likely the power source needs to be recharged, there is no contact in the vehicle's on-board network or in the ignition switch. Sometimes the cause of the malfunction is so trivial that the breakdown can be eliminated by simply cleaning the contacts from dirt and oxide deposits.

If the device does not function completely, it is quite possible that the traction relay has failed, or the winding on the coil has burned out. When the clutch slips, the starter does not start the power unit, while its armature rotates. Mechanical damage to the shaft, wear of bearings and problems with the ignition switch lead to the fact that even after starting the engine, the starter still continues to work.

The engine starting device is constantly subjected to high loads, due to the fact that it has to be aggregated with a large and heavy flywheel and rotate it to start the piston part, for this reason you should not neglect to diagnose the device and follow the proper rules for its operation.

It is necessary to accurately determine the reason for the incorrect operation of the starter, since it is not always possible to start the power unit in this way.

A little theory

In principle, everything is clear with the main question. The entire procedure for closing the starter is accessible and does not require special knowledge and practice. But most people may be wondering why the starter does not want to start the internal combustion engine?

The fact is that the solenoid relay has a solenoid, an electromagnetic coil and a contact group in its design. The latter, in turn, has a washer and two bolts (copper).

If the engine

affectionately called the “heart of the car,”

the starter

can safely be dubbed the “right atrium.”

When the starter fails, problems immediately arise with starting the engine

. Sitting in the cockpit, you simply won't be able to do this. But there are several reliable ways to get out of this situation.

First, let's look at the reasons for the failure of the starter

. You may be able to fix some damage on site.

- The starter relay

has failed ; - The solenoid relay

has failed ; - The pendix is worn out, that is, the gear rotates and the starter does not connect to the engine flywheel

; - And finally, the worst thing is that the starter winding

.

Let's move on directly to starting the engine with a non-working starter. There are actually few methods, but they work flawlessly.

The most common and easiest way

— start the car “from the pusher”. To do this, you will need volunteers in the form of sympathetic car enthusiasts (preferably strong guys with toned legs). The method is ingenious in its simplicity: turn on the ignition, engage first gear, a couple or three volunteers rest their hands on the trunk and begin to accelerate. At the thirtieth meter the engine will start, it all depends on the take-off speed of the pushers (the faster you push, the faster you will start the car). You can do without assistants if your health and strength allow. The algorithm is the same: ignition, first gear, get out of the car, rest your left hand on the front pillar, and hold the steering wheel with your right hand. Of course, this task is not an easy one, but in the absence of people there is nowhere to go;

Second way

- tug. Every novice and experienced motorist should have a tow rope in their trunk. We take it out, stop any car, hook the cable, get behind the wheel, turn on the ignition, first gear and wait. Be careful, when the car starts, it will certainly begin to accelerate. You need to immediately inform the tug driver that your iron horse has started working and there is no need to go further, and when it stops, do not forget to stop your car. Do not turn off the engine when you get out to unhook the cable unless you want to repeat the towing procedure again;

Third way

Suitable for front wheel drive vehicles only. You will need a jack. Raise the front wheel, turn on the ignition, engage third or fourth gear and begin to turn the raised wheel with your hands. Of course, the method is not the most convenient, but when pushing alone is not possible, it can help you out;

Well, the last way

, which is suitable only for owners of old models of passenger cars (mainly UAZ, Moskvich and Zhiguli). In those days, cars were equipped with special handles. With the ignition on and neutral, turn the handle. There is a danger that the handle will suddenly move in the opposite direction when the engine starts. Therefore, you should be careful.

Knowing how to close the starter with a screwdriver can be useful in some specific cases. I would like to note right away that to carry out such a procedure you will need an assistant, and the algorithm of actions is not at all complicated and even a novice car enthusiast can cope with all this. But first it is necessary to carry out a general diagnosis.

Before closing the starter, a very important step is testing in order to determine the sources of possible malfunctions and try to correct at least some of the problems. The most serious damage is considered to be complete or partial wear of the bendix, deformed or completely burned out due to high temperatures, starter winding, lack of functionality of its relay and solenoid relay. If you notice at least one such problem, then you can try methods for starting an engine whose starter has actually failed. There are few options, but they are effective.

For example, the first method requires the help of several strong men, since you will have to accelerate the car by pushing from the trunk. At this moment, the driver must turn on the ignition key and shift into first gear. In general, the more actively the assistants push the car from behind, the faster it will be able to start. This method is the most popular due to its simplicity.

Another method is towing. The essence of the action is that the “leading” car tows the car with a non-working starter over a certain distance, using a strong cable. However, when resorting to this method, you need to be extremely careful, since after successfully turning on the engine, the car will begin to accelerate and should be controlled. When the “leading” car slows down, you need to brake to avoid a collision.

I advise you not to turn off the engine when you stop the car in order to get out and unhook the cable.

There are other methods that involve direct intervention in the insides of the machine. This refers to a way to close the starter using a screwdriver.

Push launch

This is a classic way to start the engine on almost any car. It should be used when other methods are powerless. To do this you will need to do the following:

- Place the gear lever in neutral.

- The driver gets behind the wheel.

- Two assistants are pushing the car.

- Once the car has accelerated a little, engage first or second gear.

- Turn the key to engine start mode.

This method can be used while towing a car. But remember that when you start the engine, the car will accelerate significantly and may drive into the bumper of the towing car.

We will open Priora in Moscow and Moscow Region

Promptly, carefully and professionally, experienced technicians from the LOCKSERVICE emergency service will provide assistance with the problem of how to open a Priora without a key. We have been working in the emergency car opening market for more than 12 years and know how to open a Lada Priora or open a car of any other brand without any damage. In what other situations may you need to call LOCKSERVICE specialists?

- The doors locked spontaneously, the keys remained in the cabin;

- The battery is dead;

- The lock cylinders are faulty or dirty;

- Locks froze in the cold due to moisture that accumulated on the seals;

- The key is lost or broken;

- The alarm went off from the inside and the driver was locked inside the car;

- The car stalled in a traffic jam, the central locking was blocked;

- The key fob is discharged, the car does not open;

- The lock in the glove compartment is broken;

- The trunk does not open;

- The key broke in half in the door keyhole;

- The gas tank cap does not come off;

- The lock of the tank filler cap is broken.

There are many ways to open any car without a key. We offer you those that can be used in any conditions, while remembering that the best way to open a car is to entrust it to professionals.