The starter is one of the main links in the ignition system. The correct operation of this unit is responsible for starting the internal combustion engine. Reasons why the mechanism may fail: problems with the solenoid relay, discharged battery, opening of the ground contacts, ignition malfunction, violation of the integrity of the electrical wiring, etc. We will discuss the development mechanism, fault diagnosis and methods for eliminating them in more detail in the article.

Troubleshooting

You can often hear the phrase from car enthusiasts: “I get into the car, turn the key in the ignition, and nothing happens.” This occurs due to a breakdown of the starter unit or its electronics if:

- under the hood there are extraneous sounds (clicks, ringing, buzzing), but nothing happens;

- The engine will not start;

- The starter spins when starting, but the engine does not start;

- the crankshaft rotates slowly and the engine is silent;

- You can hear knocking noises under the hood, crackling gears and grinding noises.

How to start the engine if there is a problem with the starter and solenoid relay?

If the starter mechanism is not working, the car owner has the opportunity to start the power unit. There are several ways to start the engine.

Close the starter directly

An example of a launch is considered on a VAZ 2110 car:

- The transmission lever in the cabin is set to the neutral speed position. The parking brake lever is raised.

- The ignition system is activated by turning the key in the switch. The engine compartment of the car is opened, the following steps are performed under the hood.

- The air filter device is being dismantled. It is retracted to the side so that the driver can gain access to the contact elements of the starter assembly.

- The chip that goes to the contact component is turned off.

- Using any metal product, for example, a screwdriver, the contact components of the starter assembly terminals are short-circuited. You can use a piece of cable.

- After closing the contacts, the starter mechanism should begin to rotate, which will lead to the engine starting. It is important that the battery is charged when performing this task.

After completing the action, the chip is put back in place, and the filter device is mounted back. Such steps will allow you to start the power unit in the future. But since the problem remains, it will still have to be solved.

Sergey Tsapyuk spoke in detail about the procedure for starting the power unit by directly closing the starter unit.

Wheel spin

The implementation of this method is only possible on front-wheel drive vehicles equipped with a manual transmission:

- The car is placed on a jack, one of the front wheels must be suspended.

- The suspended wheel is turned outward until it stops. If it is the left wheel, then it turns to the left, the right wheel, respectively, to the right.

- A cable is wound around the surface of the tire, which is used for towing. If it is not available, a strong rope may be used. It is necessary to wind 3-4 layers, while at least one meter of rope or cable must remain free.

- The gearshift lever is moved to the third speed position.

- The key turns in the ignition switch.

- Then you need to strongly pull the end of the rope or cable, this is done to unwind the wheel. It is not recommended to perform this task while standing in one place; you should take a short run-up.

- If the vehicle's power unit starts, the neutral speed is activated. To do this, it is not necessary to depress the clutch pedal. You have to wait until the car wheel stops.

- Then the jack is loosened and the wheel is lowered to the surface of the ground.

From the pusher

The implementation of the “old-fashioned” method from the “pusher” is performed as follows:

- An assistant will be needed to complete the task. You can act on your own if the car is on a descent.

- The parking brake handle is lowered.

- The key is turned to the ignition mode, the transmission selector is set to the third gear position.

- Then the car must be pushed. If there is an assistant, the driver sits in the cabin and waits until the speed is at least 10-30 km/h. The clutch pedal on the car must be depressed.

- After increasing the speed, the pedal is carefully lowered, while the driver presses on the gas. When the engine starts, you can put the gear in neutral and stop to wait for it to warm up.

The most common causes of breakdowns

These are faults in the electrical circuit. These include:

- battery charge less than 12 V;

- oxidation of contacts;

- lack of current on the solenoid relay;

- breakage of the solenoid relay;

- wear of the brush assembly;

- armature commutator wear.

In the case when the retractor does not work and the starter is silent when the key is turned, the breakdown may be the result of a short circuit or open circuit to ground of the traction relay, or short circuit of the turn.

The culprit is electronics even if, when the ignition is activated and the engine starts, the flywheel disk rotates too slowly.

The mechanical causes of malfunctions can be judged by the lack of rotation of the crankshaft when the starter is working. When turning the key, the engine may not operate in the following cases:

- the slip clutch is broken;

- the release lever is faulty or disconnected from the axle;

- the buffer spring is worn out;

- Drive ring is broken or worn.

How to start a car - the starter does not turn

If the starter is faulty due to the solenoid relay, then the car engine can be started if the contacts are closed forcibly. This is an emergency measure, but it is sometimes used when there is an emergency.

Let's look at an example of how to start the engine of a VAZ-2110 car.

- Place the gearshift lever in neutral position.

- Pull out the handbrake handle.

- Turn the ignition key and open the hood.

- Remove the air cleaner from its seat and move it to the side to provide access to the starter.

- Disconnect the plug from the contacts.

- Connect the two contacts of the pull-in relay together with a metal object or thick wire.

- If the other components are working properly, the engine should start.

Install the air filter and connect the wires. In many cases, the engine then starts without problems using the ignition key. But the problem has not disappeared, so you need to contact a workshop soon.

There is another method that is suitable for an urgent emergency start. It can only be used for cars with front-wheel drive and manual transmission.

Procedure:

- Raise the car with a jack so that one of the front wheels is suspended.

- Turn the raised wheel all the way.

- Wrap a rope or cable around the tire 3 turns, leaving an end 2 meters long.

- Turn on third speed.

- Turn on the ignition by turning the key.

- Pull the cable sharply, spinning the wheel and running away.

- After starting the engine, place the gearbox lever in the neutral position. You don't have to press the clutch pedal to do this. Wait for the wheel to stop.

- Use a jack to lower the car to the ground.

Attention!

The described method requires caution and safety measures. Otherwise, you may damage the vehicle and injure yourself.

This method is similar to starting with a handle on old cars, for example, Moskvich-412, or VAZ-2101. The raised wheel powers the gearbox and then the engine.

Lack of contact in the starter circuit

Occurs as a result of metal corrosion or loosening of bolted wires. In addition, you need to check the grounding of the retractor and main relay of the starter assembly. You can check your car's electronics using a multimeter. Before doing this, inspect the wiring, tighten the bolts and check the terminals. If there is contact loss, restore their integrity.

GAZ Gazelle 1999, 100 l. With. - breakdown

Cars for sale

GAZ 2217, 1997

GAZ 21 Volga, 1968

GAZ 3110 Volga, 1999

GAZ 2217, 2010

Comments 26

what to do the ignition does not work the snout clicks but the starter does not crank

I bought a power fuse block a long time ago, but it turned out to be a new model with 6 mm studs. And I have smaller terminals!

I need to work hard on the wiring, but it’s still cold!))

Today! I use the indicator to touch the chip of the “+” wire leading from the fuse block to the PC, it doesn’t light up, I touched the insulated terminal “it’s on”, I jumped into the cabin, I turn the key, the starter doesn’t work.

I threw a parallel wire “+” from the block and secured it to the PC, everything works!

Thank you all so much for your advice!

Does the relay click from the key? if yes, the control circuit is working.

Assuming that the starter itself is working, since it directly comes to life when shorted, a power circuit remains: a wire from the main fuse box to the relay and from the relay to the starter. Well, and, to the heap, the largest and thickest wire with + battery.

check for snot and oxidation of compounds. and that's all.

does it spin straight, but the retractor does not work, or does it click straight?

I have a small wire (which I temporarily ran in parallel) leading from the PC (in parallel) to the lilac wire, I put it on the “+” terminal on the starter and the starter turns!

Well, the retractor itself works or clicks. The nickels may just burn out, or the holding winding may burn out.

Yes, the retractor works!

And does the engine turn normally in a straight line? then the lock, the starter relay, and if there is a relay in the gap from the signaling system, then look at that too

In short, when I bought the car, I started to wash everything and discovered that a wire was laid from the starter relay (it was just dangling), I threw it away, four months later a friend came up and said there is a SHABASHKA), give the car, I say, take it of course. I left for work, he calls 2 hours later, he says the starter isn’t working, he came, he says let’s change it, and there’s a snowstorm outside, we call another friend and say melt the potbelly stove in the garage, we’re on our way, we got stuck, we transferred snow with a volume of GAZ -53)), they changed it the starter but it doesn’t work, I bought a new starter relay, again “0”, that’s where I remembered about this wire. In the end they set the starter to “RETAKES ITSELF”, the battery is new and it barely turns!

I came home tired, my father said, “You don’t have mass,” and this wire is “MASS,” and in the end I didn’t understand what the wire was. I installed the old starter and everything works!

This happened about two months ago! And today it refused again!

The ground on the retractor relay is short, it is screwed to the cabin, + goes from the fuse block through the relay to the retractor plug, control comes from the lock.

The engine should turn straight if you connect the plug on the retractor with a wire from the battery positive

if the engine does not turn, or poorly, then it is a thick mass on the body. if it is normal, then + nuts. If it clicks, it's the retaining winding. if it clicks and doesn’t turn, then nickels

To be honest! I didn’t understand! + on PC comes from the lock? The ground is short on the body! (on a PC) How to check the ignition switch?

control + ground from the lock to the body and to the engine somewhere, it looks either like a healthy pigtail or like a thick black wire, check from the lock, there is either a pink or red thin one, you can easily find it by holding the key in the starter position

mass RS there is a small thin wire

The weight on the engine is normal! I picked it today!)

does it spin straight, but the retractor does not work, or does it click straight?

Damn, I have such a problem: the starter doesn’t turn directly, just like with the key, it can’t turn it over, what’s the matter?

Why does the engine rotate inefficiently?

There are times when the starter works, but does not turn the engine with the required force. Let's list the situations when this happens:

- When using oil that does not correspond to the temperature conditions. The lubricant thickens and prevents the crankshaft from rotating. It is necessary to replace the lubricant with one regulated for the given weather conditions.

- Low battery charge. Does not provide energy for effective rotation. The battery needs to be recharged or replaced.

- In case of a malfunction of the brush assembly. It is necessary to check the contacts of the brushes and the tightening force of the tips going to the part.

Bendix failure

The starter clicks, the electric motor rotates, but the crankshaft does not turn

These are signs of a Bendix malfunction. Remember, its gear should rotate freely in one direction, and jam when you try to turn it in the opposite direction?

So, the cylinders that are in the overrunning clutch are not pressed against the outer race and the gear rotates freely in both directions. This means that when it engages with the flywheel, the Bendix cannot turn the crankshaft as it spins.

This is accompanied by the sounds of a running electric motor. It will work at high speeds, since nothing prevents it from spinning up to maximum values. If the bendix has not yet completely “died”, then this sign of malfunction will appear periodically . That is, today the starter started the engine, but an hour later it may not turn the crankshaft, but simply squeak at maximum engine speed.

Starting a car engine is accompanied by a terrible grinding noise.

This could be for two reasons:

- The Bendix did not engage the flywheel completely.

- The teeth on the gear or flywheel are worn.

In the first case, the bendix jams on the starter shaft. It is enough to disassemble it, clean the splines along which it moves, and lubricate them.

In the second case, only replacing the gear or flywheel. By the way, this malfunction does not appear immediately, but due to long-term use of the starter with poor engagement of the bendix and flywheel. That is, because of the first reason.

The mechanism does not function on a hot engine

The answer to the question of why the starter does not turn when hot lies on the surface. The bushings expand during engine operation, the unit begins to “wedge”, or it fails. As a rule, this problem occurs in cars with high mileage. Let's look at why this happens in the table.

| Cause of malfunction | Solution |

| Wear of standard bushings | Replacement |

| Bad contacts | Clean, tighten, treat contacts |

| Reducing the insulation resistance of the stator winding | Replace winding |

| Oxidized contact plates in the relay | Clean or replace |

| Foreign particles in the starter housing | Clean up |

| Brush assembly wear | Cleaning the brushes or replacing the unit |

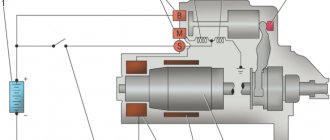

Working principle of VR

A constant plus is supplied from the battery to the upper power bolt of the “traction” bolt. In the free state, the contact plate does not touch the “nickels” of the power bolts in the cover. Both windings – the pull winding (VO) and the holding winding (CU), are connected with one terminal to a small “control” terminal, which receives the starting pulse from the ignition key (plus). The second output - a more powerful VO - goes to the jumper with the lower power bolt (plus of the starter electric motor), and the OU - to the “ground” (housing).

Starter connection diagram

The part does not work either cold or hot

The reasons why the starter does not turn, does not start the vehicle and does not click may be:

- detachment of magnets;

- violation of the integrity of the contact group fuses;

- break in the control wire supplied to the starter. Carry out an emergency engine start. If it helps, the reason is in the ignition, if not, it’s in the wire;

- return spring failure.

A little theory: what is an electric starter

A car starter is a compact DC electric motor, a commutator type, on the shaft of which there is a gear that matches the profile of the teeth on the flywheel. A traction relay (solenoid) is screwed onto the body of this electric motor, the core of which, at the moment the key is turned, pushes the gear into engagement with the flywheel and at the same time - closes the contact plate - makes a “bridge” for powering the windings.

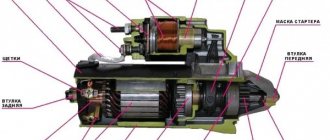

Starter device

The rotor just has to apply force, turn the flywheel and start the engine. The force is usually applied through a reduction gearbox, since the standard rotation speed of the motor is high. While the trigger mechanism is spinning, the Bendix gear will be pressed against the flywheel. To prevent the engine from starting to rotate the starter itself after starting, this gear was placed on an overrunning clutch, which opens the engagement when the speed of the flywheel becomes greater than the speed of the gear. The Bendix is engaged by a “fork-lever”, which is pumped by the “traction” core. As soon as the internal combustion engine starts and the key returns to its previous position - the current in the relay winding disappears, the gear returns under the housing, remaining fixed there.

The mechanism makes clicks but does not rotate

When the starter clicks once, but does not start the engine, this means that the unit requires repair. You need to try to start the car again. If it doesn't work, then it's probably the following:

- Bendix is broken;

- the starter winding is broken;

- a short circuit has occurred;

- the solenoid relay is faulty;

- brushes are worn out.

In this case, you need to replace the parts.

Replacing starter brushes: step-by-step instructions with photos

Let's see how you can replace the starter brushes with new ones yourself, if the need arises. Regardless of the car model, the process will always be approximately the same. For you - step-by-step instructions with photographs.

Step 1. First you need to unscrew the nut securing the brush assembly from the relay bolt.

Unscrewing the nut securing the brush assembly

Starter relay bolt

Step 2. Next, remove the brush assembly output contact from the relay bolt. This is a kind of cap plate with a hole in the middle.

Removing the brush assembly output contact

Step 3. The next step requires unscrewing the starter tie bolts, two in number.

Unscrewing the starter bolts

Step 4. Next you need to remove the motor from the housing.

Removing the motor from the housing

Step 5. Then you need to remove the so-called anchor along with the brush assembly.

Removing the armature with brush assembly

Step 6. Next, you need to unscrew the screws that secure the rear cap, and then remove the cap itself.

Unscrewing the screws securing the rear cap

Removing the rear cap

Step 7. After this, you need to remove the retaining ring from the back of the “anchor”.

Removing the retaining ring

Step 8. Next, the back cover from the armature also needs to be removed - after removing the retaining ring, this is not difficult to do.

Removing the starter rear cover

Step 9. All that remains is to remove the old brush assembly.

Removing the old brush assembly

Step 10. Now you can put the starter back together, but using a new brush assembly. You need to take it out of the package and put it in place of the old one.

Installing a new brush assembly

Step 11. All that remains is to assemble the starter by repeating steps 9 to 1 in reverse order.

Reassembling the starter in reverse order

Video - Replacing starter brushes

Summarizing

It is advisable that the starter spins the engine crankshaft during an attempt to start it for no more than 10 seconds, then the device must be given a minute pause. Failure to comply with this rule will, at best, lead to a discharge of the power source, and at worst, it will completely disable the starter. Only replacing it can save the situation, since not every auto electrician will undertake the task of rewinding burnt windings, since it is not always possible to perform this procedure efficiently. In addition, the cost of this service is comparable to the cost of a new element.