In every car, the gas pump is considered one of the important devices that pumps fuel from the tank to the engine. The main thing is that it functions smoothly for good engine performance.

When checking the pump, it is necessary to determine the pressure. As a rule, the pressure of a submersible electric fuel pump is 2-4.5 bar (depending on the brand of the machine). Some engines reach 6 bar. Checking the pressure is not difficult, you just need to connect the pressure gauge to the car. The pump is also checked for productivity and the amount of current consumed.

How does a fuel pump work?

The main function of the gas pump is to transfer fuel from the tank to the engine. In injection engines, the fuel pump is connected to the fuel rail, and in carburetor engines - to the carburetor. Moreover, it is necessary not only to pump fuel, but also to provide a specific pressure.

Very high pressure usually leads to excessive enrichment of the mixture, as well as huge fuel consumption. And too low pressure leads to a decrease in the mixture, as well as a decrease in power. Both the 1st and 2nd cases negatively affect the life of the motor. That is, the fact that the pump pumps gasoline does not confirm its full serviceability.

Let's sum it up

High-quality car parts allow you to operate your car for a long time without any problems. It is worth paying attention to components of original origin or close in quality to the originals. If the fuel pump in your car has failed, you will most likely have to replace it. In some cases, repairs are possible when the problems do not directly affect the pump itself and its working part. With a faulty pump, it is impossible to even get to a service station, so you should pay attention to signs of breakdown in time and take action in advance to eliminate such a problem.

If your car has trouble starting the engine, the sound of the pump from the tank, floating idle speed and other signs of problems with fuel pressure in the rail, you should immediately run diagnostics and find out what the problems are related to. It is quite possible that the troubles are related to other devices, but the gas pump is working properly and performs its tasks without problems. A good diagnosis will help you definitively answer this question.

Difficulties with fuel supply - common symptoms

Failures of the fuel supply system are conventionally divided into 2 groups:

- The combustible composition does not enter the cylinders at all.

- Fuel flows intermittently or under low pressure.

In the first case, the engine cannot start and does not engage the starter during rotation, i.e. it does not work. In such a situation, it is much easier to determine the cause of the malfunction.

If little gasoline enters the cylinders, the following symptoms occur:

- turning on the power device “when cold” is too difficult, the engine seizes, “sneezes”, and starts after 3–10 attempts;

- The idle speed is unstable, the engine “troubles”;

- active acceleration becomes unrealistic - sudden opening of the throttle causes a prolonged dip, as well as deceleration;

- if the driver releases the accelerator pedal, the engine usually quiets down;

- The car has difficulty climbing hills and also accelerates slowly when fully loaded.

The cause of the above phenomena may be a breakdown of the fuel pump or other system components. In addition, the main features are almost the same. To perform a clear diagnosis, you need to know how the power supply structure of the machine works.

The main signs of a malfunction - how to understand that fuel is not supplied?

First you need to figure out whether the fuel pump is to blame for the problem. Very often, car owners come to a service station and declare the need to replace fuel equipment, but in fact, only a fuse or a certain filter needs to be changed. You should take a closer look at how the car behaves, what errors are shown on the on-board computer screen, and how the engine reacts to an attempt to start. All these features will tell you whether the fuel pump is to blame for the problem, or whether you need to look for other problems.

The main signs of fuel pump failure:

- when you turn on the ignition, you can’t hear the operation of the fuel pump, which should turn on at this moment and pump up pressure (in some cars the fuel pump turns on when the driver’s door is opened or when the security system is disarmed);

- when trying to start, the engine does not start at all, the starter turns the power unit monotonously, there is no hint of an attempt to start - this happens when the pump is completely faulty;

- at the moment of starting, the engine starts, but then it starts to work very unstably, the speed fluctuates, errors appear on the BC screen, the engine stalls, knocks, “chokes” - this happens when the functions of the pump are disrupted;

- Also, at the initial stage of failure of the fuel pump, problems are possible while driving, when the engine starts to run unevenly, stalls or reduces speed while accelerating, and dips appear;

- if the pump suddenly fails, the engine gradually reduces speed and stalls, despite the driver’s attempts to press the gas pedal, and then the engine simply does not start.

There may be other symptoms, it all depends on the nature of the breakdown. You should pay attention to the overall operation of the engine. Sometimes the fuel pump begins to fail due to minor problems. At some moments, the fuel pressure is not enough for stable operation of the unit, and it may stall. After restarting everything starts working normally again. But very often the failure is spontaneous and occurs unexpectedly while driving or after the car has been parked for a long time. If the spark plugs are dry, there is fuel in the tank, the starter turns the engine without problems, the battery is charged, you need to carefully examine the fuel pump.

The gasoline pump does not pump: reasons

If the gasoline pressure becomes lower than possible and the pump stops functioning, then it is necessary to understand why the pump does not pump fuel. If there is no hum in the fuel pump, i.e. it does not turn on when the ignition is turned on:

- You need to check the 12 Volt power supply, as well as the ground on the pump chip. If the relay does not work, then you need to install an electronic control unit “brains”. If there is no voltage, then the cause should be found and eliminated in the electrical circuit of the machine.

- Then, if there is voltage and ground, you need to check whether the wires in the fuel pump are damaged. To do this you need to remove it from the tank. On VAZ modules, the chip in the pump housing often burns out. Then you will need to replace the chip and the upper connector on the module body.

- If everything is fine here, but the motor does not work, then connect 12 volts from the battery to the module and also check the hum of the pump. If the pump does not function, this means that it is broken and the pump motor needs to be replaced.

And if the fuel pump is functioning, but does not pump fuel, then you need to check:

- Fuel pressure in the rail.

- Clogging of pipelines, fine and coarse filters.

- Fuel pressure stabilizer for functionality. It is located on the ramp or in the fuel pump module (in the tank).

- A frequent cause of breakdown is water in the tank, which turns into ice in winter, so the pump functions, but does not provide the necessary pressure.

Mechanical fuel pump failed: what are the reasons?

There may be several reasons why the VAZ-2110 fuel pump does not work:

- The most common breakdown is damage to the diaphragm, since it is the one that pumps gasoline, which means it does the bulk of the work, and is therefore most susceptible to wear.

- Failure of fuel pump valves.

- The internal strainer of the fuel pump is dirty.

- Pump drive failure.

Checking the serviceability of the pump on the injector

If you hear a slight noise when turning the ignition key, then this is how the fuel pump functions. By pushing up the fuel, it creates pressure in the structure. If, when trying to start, there are no similar symptoms of the fuel pump, then we can assume a breakdown of the electrics, the fuel pump or its separate elements.

How to change filters

The filter mesh often becomes clogged with dirt - this leads to unstable operation of the fuel system. To remove it, the pump does not need to be disassembled, but it must be removed. Next, the mesh will need to be changed or simply cleaned.

First reduce the pressure in the system, otherwise gasoline will spread throughout the cabin. To do this, pull out the fuse, start the engine and let it stall.

Replacing the mesh is done as follows:

- turn off the ignition;

- raise the rear seat;

- remove the hatch (fixed with two screws);

- open the connector with the wires;

- Use a wrench (17 mm) to unscrew the fuel hoses;

- unscrew the nuts securing the pump (8 pcs.);

- remove the plate;

- pull out the assembly (along with the gasket);

- change the mesh;

- Reassemble in reverse order.

How to check a fuel pump: techniques, methods, breakdowns

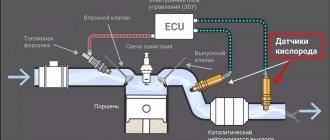

Modern cars are equipped with an electronic engine control system. Gasoline is injected into the combustion chamber using nozzles. An electric pump is provided to supply fuel. Fuel from the tank at a specific pressure of approximately 3-4 atm enters the nozzles and is distributed over the valve plate or directly onto the piston.

Most often, a submersible centrifugal pump is used. As a module, it is placed directly into the tank. There are also mounted fuel pumps, but they are not very popular.

Car owners may encounter a situation where the car does not start, pulls weakly, or drives irregularly. The reason for this, for example, could be a pump failure. It stops providing the necessary pressure to the fuel structure, and the nozzle sprays gasoline poorly, and the composition in the combustion chamber will not ignite.

The fuel pump needs to measure the pressure in the rail or near the pump. Usually the ramp has a separate fitting for a pressure gauge. In addition, it is possible to measure the pressure with your own hands using a pressure gauge at home, if one is available.

Difficulties in this procedure do not appear if there is a pipe in the ramp. And if it is missing, then you need to find the connection area in the fuel pipeline, and also install the device in the gap in the fuel supply hose, for which you will need a tee.

It is pointless to check the pressure by pressing the nipple in the ramp, because due to fuel vapors, as well as heating, you may mistakenly think that there is pressure. If there are no sounds from the pump, then you need to check the power using a multimeter or test lamp. Measuring rail pressure is included in the cost of checking the engine. It would be wiser to check the entire fuel structure and also eliminate the violations on site.

Power check

You can establish the presence of voltage at the TN connector using a simple test to check electrical circuits. To check the fuel pump, in the electrical diagrams for your car model, find the pinout of the electrical connector of the fuel module. For the pump motor to operate, “–” and “+” are required. If, after turning on the ignition and connecting the control contacts to the corresponding pins of the block, the light comes on, then everything is in order with the supply voltage. Using this method, you can check for the presence of +12V and ground in the fuel pump relay connector, and establish the presence of supply voltage from the ECM to the relay. If the fuel pump does not turn on, but there are no problems with the components of the electrical circuit, the reason is in the fuel pump itself.

The most convenient way to determine why there is no power to the fuel pump is to use a multimeter. Let's say that + 12V to the pump comes from the relay, but does not reach the fuel module connector. In this case, it is necessary to ring the wires from the relay to the fuel section. In ohmmeter mode, you will not only find an open, but you will also be able to see the parasitic resistance in the circuit. When considering possible reasons why the fuel pump does not pump, do not forget about the immobilizer failure. Often in such cases the engine starts, but stalls after a few seconds.

Preventing fuel pump malfunctions

The best prevention for long service life of the fuel pump is its careful and correct use and, in addition, following the following rules:

- Absolutely all scheduled vehicle repairs must be accompanied by the replacement of all fuel filters.

- You should check the fuel tank, that is, make sure the tank and filters are clean; and check the quality of the gasoline being filled (the absence of water, sand and other impurities in it).

- Eliminate the possibility of water entering the fuel tank.

- Protect the pump housing from mechanical stress, which may cause dents and cracks to appear on the machine, which contribute to the formation of corrosion processes.

The fuel pump, like every other device, gradually wears out and stops functioning. If you suspect that the pump is faulty, you must immediately diagnose it.

Fuel pump relay and fuse

As soon as the ignition is turned on, the pump motor starts working - this is indicated by a characteristic sound. Complete silence indicates a breakdown.

Thus, the relay protects the circuit from high inrush currents, sometimes reaching 80 or even 300 amperes. The operating principle of this element is as follows: voltage is supplied to an electromagnetic coil, which attracts the armature and closes the contacts.

The relay in question can withstand 30 amperes. Exceeding the specified indicator disables the element (its winding may burn out).

To detect a relay in an injection machine, no pinout is needed - the unit is located in the cabin, under the instrument panel. Remove the housing (unscrew the 2 screws) and you will see three elements. The one you are looking for is exactly in the center.

The location of the fuel pump fuse is to the left of the relay. By the way, it is also capable of burning out, and therefore the test begins with it. Do this:

- pull out the fuse and inspect;

- make sure the block is not broken;

- replace if necessary.

Sometimes the fuse blows right away. This means that the wiring is shorted (the insulation can be corroded by oil, or it can fray due to vibration). If there is no pinout, the required cores are found with a tester.

Also, the fuse-link burns out when the pump motor itself short-circuits.

If everything is in order with the fuse, then the question arises: how to verify that the relay is working. The easiest way is to try to start the car with the block open. A working unit will make a click. When the coil burns out, you will not hear any sounds.

Sometimes the pump may turn on sporadically. This means that the relay contacts are dirty. Proceed as follows:

- unscrew the block into which the element is inserted;

- pull it out (do not touch the wires);

- close the two opposing contacts.

This simple technique will allow you to check the operation of the fuel pump without any pinout. You simply supply power to it, bypassing the relay. If the motor turns on directly, it will have to be replaced.

Car won't start after replacing fuel pump

Sometimes, after installing a new pump, the car cannot be started. There may be several reasons for this problem.

A defective product has been installed. It needs to be replaced.

The fuel inlet and outlet pipes are not connected correctly.

The power plug is not connected correctly.

The terminal contacts have oxidized. They need to be cleaned.

Proper connection of wires and fuel supply pipes guarantees proper operation of the fuel pump

The fuel pump is the main element of the fuel supply system. Any malfunction leads to the impossibility of further operation of the vehicle. You should pay attention to all symptoms of decreased performance of the mechanism, immediately identify them and take appropriate measures. Good luck on the roads!

A car fuel pump is a device designed to provide an uninterrupted supply of fuel to the installation in which the fuel mixture is formed. Even the slightest malfunction leads to interruptions in the operation of the engine, and in the event of more serious problems, you simply will not start it.

In this article we will look at situations where the gas pump does not pump fuel at all, or pumps it, but not in the amount required by the power unit for normal operation. We will also try to understand the possible causes of this or that malfunction of the fuel supply device and discuss methods for eliminating them independently using the example of domestically produced cars carburetor VAZ-2109 and injection VAZ-2114.

Adjusting the pressure in the fuel system

A simple way to regulate the operation of a worn-out fuel pump is to install a fuel pressure regulator. It connects to the fuel rail and shows the pressure, allowing you to change it either up or down.

The device allows you to adjust the fuel pressure in the system depending on the situation

To measure the fuel pressure in the system, you can also use a pressure gauge by connecting it to the fuel rail.

Repair work

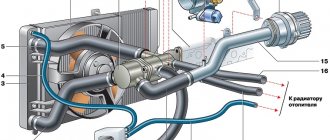

On a carburetor VAZ 2110 it is easier to replace the fuel pump if necessary. It is located under the hood and is not difficult to get to. It is enough to disconnect the pipelines, then unscrew the pump itself.

The electric fuel pump installed on an injection machine is located directly in the gas tank, so it is more difficult to get to it; this is done from the passenger compartment by removing the rear seat.

All fuel pumps are dismountable. After removing the cover, the mesh is removed and its condition is assessed. Of course, you can wash it, but it’s even better to replace it right away. Before starting repairs, you should purchase a repair kit, which must be equipped with a mesh.

Pump filter and manual pumping lever

The first thing you will see when you disassemble the fuel supply device is the strainer. It is made of thin perforated plastic. The reason why the fuel pump does not pump can also be if it is deformed or severely contaminated.

In the first case, the filter must be replaced, in the second, it must be washed with carburetor cleaning fluid.

The manual pumping lever has nothing to do with the fact that the fuel pump does not pump fuel when the camshaft rotates. The only thing that can break in it is the spring that tilts it back to its original position.

Design and operation of fuel supply

The system that provides the engine with the required amount of gasoline operates according to the following algorithm:

- After turning on the ignition, the electric fuel pump starts, raising the pressure in the line after itself to a certain level. The electrical power supply circuit of the unit is protected by a fuse.

- The fuel pressure regulator (common abbreviation - RDT) is located on the line after the pump and limits the upper pressure threshold, dumping excess fuel back into the tank through a separate pipeline.

- When the crankshaft is rotated by the starter and the engine continues to operate, fuel enters the fuel rail, mixes with air and is directed to the injectors built into each cylinder. The amount of mixture supplied to the combustion chambers is controlled by an electronic unit.

- On the way to the fuel rail, gasoline goes through 2 stages of filtration. The first is a mesh installed in the tank on the suction pipe of the pump, the second is a fine filter on the gas supply line.

Reference. In various car models, 2 schemes are used for installing the RTD and laying the return pipeline - in the engine compartment or directly in the gas tank. In the first case, the standard fuel pressure in the system is 2.7...3.0 Bar, in the second - 3.8...4 Bar.

A common mistake made by ignorant car enthusiasts: if the combustible mixture does not enter the cylinders, then the fuel pump is definitely not working. Knowing the design of the fuel supply, we can assume other problems:

- the protective fuse in the electrical circuit has blown, the pump is in good working order, but does not receive power;

- the primary or secondary filter is clogged (sometimes both at once), fuel flows in small quantities or does not flow at all;

- the pressure regulator has become unusable, dumping the lion's share of the fuel back into the tank, the engine gets nothing;

- One or more injectors have failed.

To accurately determine the source of the problem, you need to check the operation of the electric fuel pump and other elements. It is not necessary to go to a service station - diagnostic work can be carried out in your own garage.