A car fuel pump is a device designed to provide an uninterrupted supply of fuel to the installation in which the fuel mixture is formed. Even the slightest malfunction leads to interruptions in the operation of the engine, and in the event of more serious problems, you simply will not start it.

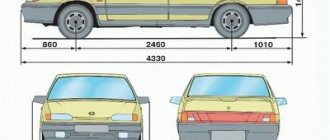

In this article we will look at situations where the gas pump does not pump fuel at all, or pumps it, but not in the amount required by the power unit for normal operation. We will also try to understand the possible causes of this or that malfunction of the fuel supply device and discuss methods for eliminating them independently using the example of domestically produced cars carburetor VAZ-2109 and injection VAZ-2114.

What types of fuel pumps are there?

Cars with gasoline engines, depending on the make, model and modification, can be equipped with gasoline pumps of different designs. But they all fall into two main categories: mechanical and electrical. Most carburetor engines are equipped with mechanical fuel delivery devices. If we take the VAZ 2109 (carburetor), then from the factory it was equipped with a diaphragm pump manufactured by DAAZ. The main difference of this device is its simplicity of design, which is easy to understand even for a beginner. In the carburetor "nine" the fuel pump is located in the engine compartment of the car. It is easy to recognize by its characteristic hemispherical cap and fuel line hoses.

VAZ 2114 injection engines are equipped with electric fuel pumps. Their design is also based on a membrane, but unlike “mechanics”, the fuel supply devices in cars with automatic fuel injection are not under the hood, but directly in the tank.

Measure the fuel pressure in the rail

As mentioned above, in order to measure the pressure of the fuel pump in the rail, you need to screw the pressure gauge sequentially into the fuel supply. Measurement is carried out in different modes, depending on the symptoms of the malfunction:

- The car won't start. We take measurements when the ignition is turned on. Using the diagnostic scanner, you can turn on the fuel pump through actuators. Working pressure from 3 to 4 atm.

- The craving is gone. First you need to measure the fuel pressure at the ignition, if it gives a normal reading, measure it at idle. The pump should produce 2.5 - 4.2 atm, depending on the type of engine. 2.5 - RTD on the ramp, 4.2 - RTD in the tank.

- There are cases when the owner complains of loss of traction for a short time or in the heat. In this case, you need to check on the go. We attach the pressure gauge, check the tightness of the contact with the fitting so that there is no leakage of gasoline. We attach the device to the windshield, maybe under the wiper, and off we go. If the fuel pressure drops while driving, you need to replace the fuel pump, filter, and bleed the lines.

- How to check a fuel pump in the wall. This procedure is necessary to eliminate a clogged filter or fuel pressure regulator lines. The pressure value on the injector into the wall should be from 6 atm.

Design of a carburetor fuel pump VAZ 2109

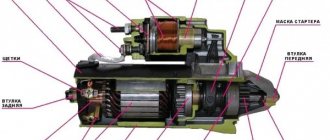

To understand why the VAZ 2109 fuel pump (carburetor) does not pump, let’s briefly look at its design. So, the “nine” fuel supply device consists of:

- housings;

- pusher with mechanical pumping lever;

- diaphragm assemblies;

- covers with valves and fittings for attaching hoses;

- mesh filter;

- manual pumping lever.

Self-diagnosis and repair

The simplest way to check the operating condition of the pump, proven by more than one generation of drivers, is to disconnect the hose from the outlet and manually pump it. You just have to take into account

In order for the bleeding lever to move, the diaphragm must be at its highest point, and the pusher at the bottom of the eccentric.

If they are stopped in the reverse position, one turn of the manual winding handle will be enough to return the diaphragm and pusher to the desired position.

When manually pumping, fuel should be supplied from the pump in a stream in time with the movement of the hand lever. The main thing when carrying out this procedure is to place a rag on the engine.

so that gasoline does not splash around the engine compartment.

To correct internal defects, the pump must be dismantled. The procedure is not complicated. It is enough to disconnect the supply hoses of the fuel line and unscrew the two fastening nuts with a “13” wrench.

While removing the pump

Care must be taken not to damage the gaskets. There are three of them under the fuel pump. First comes a gasket with a thickness of about 0.3 mm, then comes a gasket that provides thermal insulation of the pump from heating the cylinder block, after which a thin gasket-seal is laid again, but only 0.75 mm thick.

Method of selecting the thickness of gaskets

The height of the pusher exit is set, which should be within 0.8 mm. up to 1.3 mm. But between the base of the gas pump and the thermal insulating gasket there should always be a gasket with a thickness of no more than 0.33 mm.

Beginning drivers need to remember that when the fuel pump on a VAZ 2106 does not pump and it has been disassembled for repairs, reassembly does not guarantee its functionality. For correct assembly installation of this part, certain experience and skills are required, especially in terms of removing gaps between mating parts.

You can delve a little deeper into history, since now we will talk about why the fuel pump does not work on a VAZ 2107 car. And the conversation will be about the carburetor engine. Consequently, the fuel pump is driven by a rod installed in the cylinder head. But first you need to consider the design of the device and understand what can fail.

Operating principle of a mechanical fuel pump

The fuel pump is driven by the camshaft cam, which moves the pusher in a horizontal direction, causing it to perform reciprocating movements. The pusher, in turn, acts on the mechanical pumping lever, and it already raises and lowers the membrane rod.

Thus, a certain pressure is created inside the fuel pump, which is maintained by the valves of the device cover. One of them lets fuel in without letting it back in, and the second pushes it into the fuel line going to the carburetor.

As you can see, the design is very simple, therefore, to determine the reason that the fuel pump does not pump, it is enough to disassemble it and check the condition of the main elements.

Pusher

Since the housing does not affect the operation of the fuel pump in any way, unless it is damaged, of course, we will start with the pusher. This element is made of steel and cannot simply break. But wear and tear is welcome, especially if it is not original, but purchased as a separate spare part. As soon as its length decreases by a few millimeters, the fuel pump does not pump fuel.

Or rather, it pumps, but the amplitude of movement of the diaphragm is significantly reduced. This results in low fuel pressure in the system, and, as a result, interruptions in engine operation. The standard pusher length for DAAZ pumps is 84 mm. Measure its length and, if necessary, replace the worn part.

Pump filter and manual pumping lever

The first thing you will see when you disassemble the fuel supply device is the strainer. It is made of thin perforated plastic. The reason why the fuel pump does not pump can also be if it is deformed or severely contaminated.

In the first case, the filter must be replaced, in the second, it must be washed with carburetor cleaning fluid.

The manual pumping lever has nothing to do with the fact that the fuel pump does not pump fuel when the camshaft rotates. The only thing that can break in it is the spring that tilts it back to its original position.

Power check

You can establish the presence of voltage at the TN connector using a simple test to check electrical circuits. To check the fuel pump, in the electrical diagrams for your car model, find the pinout of the electrical connector of the fuel module. For the pump motor to operate, “–” and “+” are required. If, after turning on the ignition and connecting the control contacts to the corresponding pins of the block, the light comes on, then everything is in order with the supply voltage. Using this method, you can check for the presence of +12V and ground in the fuel pump relay connector, and establish the presence of supply voltage from the ECM to the relay. If the fuel pump does not turn on, but there are no problems with the components of the electrical circuit, the reason is in the fuel pump itself.

The most convenient way to determine why there is no power to the fuel pump is to use a multimeter. Let's say that + 12V to the pump comes from the relay, but does not reach the fuel module connector. In this case, it is necessary to ring the wires from the relay to the fuel section. In ohmmeter mode, you will not only find an open, but you will also be able to see the parasitic resistance in the circuit. When considering possible reasons why the fuel pump does not pump, do not forget about the immobilizer failure. Often in such cases the engine starts, but stalls after a few seconds.

The fuel pump does not pump: injector

As already mentioned, pumps in carburetor and injection engines have different designs. In cars with forced fuel injection, all processes associated with its supply to the combustion chambers are controlled by an electronic control unit, so breakdowns of various types of electronic devices can occur here.

The main reasons why the fuel pump of an injection engine does not pump include:

- malfunction of the device's electric drive;

- pump filter clogged;

- relay failure;

- fuse blown.

Connection diagram

Fuel pump relay diagram

Above is a standard connection diagram for a fuel injection pump engine. The ECM (controller), after successfully polling the immobilizer, energizes the coil winding of the fuel pump relay (pins 85, 86). Under the influence of electromagnetic induction, power contact 30 (constant “+” from the battery, protected by fuse X) and contact 87 close, which leads to the inclusion of the fuel pump. Main faults:

- fuse blown; Attention! Replace the burnt-out fuse-link with a fuse of standard rating. Installing an insert designed for high current may result in a vehicle fire.

- formation of oxides inside the connectors, burning of the power contacts of the fuel pump relay. Parasitic resistance leads to a drop in current in the circuit and a decrease in the performance of the nose;

- chafing, breaking wires;

- breaking off the latch of the power connector going to the fuel module. Often in this case, contact is broken when driving over uneven surfaces.

Video: Fuel pump does not work. How to find and eliminate the cause.

How to understand that the cause of engine interruptions is the fuel pump

Diagnosing problems with the fuel pump in a car with an injection engine is much easier than in a car with a carburetor engine. The fact is that when you turn on the ignition, you can clearly hear the sound of the electric motor of the fuel module. It lasts for several seconds. This sound indicates that the fuel pump is turning and pumping fuel.

If this happens when you turn the key, then there is nothing wrong with the device itself, and the cause needs to be looked for elsewhere. Well, if when you turn on the ignition you do not hear the characteristic sound of the pump, you can be sure that the problem is in it, or in the elements of its energy supply.

Causes and their identification

The reasons why the fuel pump does not work may be: violation of the integrity of its diaphragm, accumulation of dirt in the valve area, contamination of the filter, if the spring has lost its elasticity, the housing has become leaky, normal natural wear and tear of pump parts. Electrical malfunction occurs only when exposed to it. Now on modern cars it is quite reliable. Several can be highlighted. Faulty wiring (dirty or rusty wires can cause interruptions in operation), dirt in the tank, clogged fuel filter, frequent and long-term driving of the car with a minimum amount of fuel and, of course, the usual natural wear and tear of pump parts.

Wiring fault

To diagnose a pump in electrical systems, you will need to find the pinout of the electrical connector of the fuel module that is suitable for the car model. To understand that there is no power to the fuel pump, connect the “control” contacts to the corresponding pins and start the car.

The light coming on will mean that everything is normal and there are no problems with the supply voltage.

Using exactly the same method, you can at the same time check +12 V and the ground located in the electrical switch, which is designed to close. If the fuel pump does not turn on when the ignition is turned on, but there are no defects in the electrical circuit, the reason is in the fuel pump.

Electric motor malfunction

If you hear that the pump hums but does not pump, you need to check the pressure in the steering rack and external wiring. If everything goes well and no failures are detected. Try to look for the problem in the electric motor of the pump. This device moves gasoline inside the pump. It is worth understanding that the terminals may oxidize, and as a result, the power supply and operation of the pump stops. Therefore, you need to take the time to check both devices. Be sure to clean/resolder the terminals.

Fuel pump relay

This part is located next to the fuel pump ground. In theory, proper operation of the relay assumes that when the ignition is turned on, the pump creates pressure and then turns off. After which a click should be heard, indicating that the relay is turned on. Afterwards there is a click indicating it is turned off. A sign of a problem will be that the relay does not click, that is, it does not work. To fix this, the relay needs to be replaced.

Circuit breakers

When checking, do not forget about the fuse. It is located in the block. It must be marked FUEL PUMP. We pull it out and inspect the contact. If it is whole, then there is no reason to worry. A damaged one will indicate a burnout and it is worth replacing such a fuse.

Start with the relay and fuse

Considering that the fuel supply module is located in the car tank, and it is not so easy to get to it, it is better to start diagnostics with the relay and fuse:

- Unscrew the screws securing the cover of the mounting block located to the left of the steering column.

- Underneath it, find fuse F3 (15 A) and relay R2. These are the elements that we need to check.

- As for the fuse, it needs to be “ringed” with a tester. If unusable, replace it.

Checking the relay in a garage is quite difficult. But you can take a similar one (from an adjacent socket), a known good relay, and install it instead of the one being diagnosed. Now turn on the ignition. Is the fuel pump pumping? The reason has been found! Well, if nothing has changed, move on.

Replacing the fuel pump

If all the above elements function as they should, then all that remains is to clean the filters or install a working pump.

Before you begin this procedure, you will need to pump out the fuel in the tank. To replace the pump you will also need a screwdriver and a set of wrenches.

The procedure is performed in the following sequence:

- the car is de-energized by disconnecting the negative wire from the battery;

- the back seat will be removed;

- the protective plastic cover located under them is dismantled;

- All wires are disconnected from the pump;

- disconnect the fuel hoses;

- unscrew the fixing plate with a 7 key;

- pull out the pump itself.

It should be remembered that it is necessary to remove it from the gas tank very carefully, since in the process it is easy to damage the fuel sensor (float).

Electric drive and filter

The fuel pump in the injection VAZ 2114 is an element of the fuel module, which is located in the car’s tank. It also includes:

- coarse filter;

- fuel level sensor;

- pipes for connection to the fuel line.

To get to the module, you need to remove the lower part of the rear seat, disconnect the wiring harness and unscrew the 8 screws securing its cover. Remove the entire device assembly. First of all, inspect the coarse filter. If it is clogged, replace it.

To test the electric motor, you will need to connect it directly to the battery terminals. If it is operating normally, “ring” the wiring and check the contact of the ground wire on the module cover. If the electric motor shows no signs of life, the question “why the fuel pump doesn’t pump” has finally found its solution.

It is not advisable to try to repair it yourself. Just buy a new motor and install it in place of the old one. And yet, you shouldn’t spend money on buying the entire module, which now costs about 3 thousand rubles. Buy the electric motor and a new filter separately. All this will cost you three times less.

Causes of malfunction

- Fuses under the dashboard on the ECU. The top one is 15 A (pump) and the bottom one is 7.5 A (goes to the ECU, to the ignition module).

- Faulty fuel pump relay. It is located there under the torpedo - the very top (below the top fuse).

- Poor fuel module mass. It is mounted under the dashboard, where the handbrake is. The mass needs to be cleaned and re-secured. If it disappears, the fuel level indicator will also not work.

- Lack of positive contact. Removing the back seat. We check the presence of contacts in the wire block. If there is no positive, then the reason is either the relay or the fuse.

- Fuel pump motor not working.