One of the most important elements of the fuel injection system of a gasoline engine is the electric fuel pump, which is located in the fuel tank of the car. The fuel pump pumps fuel into the system from the gas tank, creating a certain pressure.

Auto repair experts identify the following common fuel system problems that are related to the fuel pump:

- The fuel pump pumps poorly and does not create the required pressure;

- the fuel pump does not pump when the ignition is turned on;

Considering that the fuel pump is an electromechanical device, the most common fuel pump malfunctions are related to both the mechanical and electrical parts. Next, we will look at what signs indicate a breakdown of the fuel pump and why the fuel pump stops pumping partially or completely.

Read in this article

Signs of fuel pump malfunctions

The main symptoms of fuel pump failure, as well as malfunctions in its operation, are:

- the car starts with difficulty, the engine runs unstable, there are dips, jerking when pressing the gas pedal, etc.;

- the pump does not pump after turning on the ignition, does not turn the starter and does not pump the fuel pump, the engine does not start;

There have also been cases when the fuel pump stops pumping while driving. In such a situation, the engine begins to malfunction and stalls immediately after the remaining gasoline in the fuel line is used up. The problem can occur either regularly or periodically.

Video on the topic

The fuel pump is one of the main components of a car. Without it, it is simply impossible to start the engine, much less operate it. Therefore, if you have any problems starting or operating the engine, you first need to check the fuel pump. To find out how to check a gas pump, you must first determine the basic principles of operation of this unit and possible breakdowns. As a rule, the fuel pump is not repaired and is replaced by a working one. However, it is necessary to identify that this is where the problem lies.

The fuel pump does not pump: causes and diagnostics

Let's start with the fact that if the gas tank is full, the battery is charged, the spark plugs are dry and there is a spark, the starter turns the engine normally, but the engine does not seize, then you should pay attention to the gas pump. A common problem is that there is no power to the fuel pump after the ignition is turned on. In a similar way, the malfunction manifests itself in motion, when the power to the fuel pump is lost and the engine suddenly stalls.

An equally important point is how much the fuel pump pumps. In other words, the pump may hum and buzz (power is being supplied), but not create the required pressure in the fuel line. The pressure in the fuel system with a working fuel pump must be more than 3 bar (which depends on the specific car model). The indicated pressure is accumulated in the fuel rail and has an indicator of 300 kPa and above.

To check, you need to measure the pressure in the fuel rail with a pressure gauge, taking into account the indicators that are the norm for a specific car model. Using the example of injection VAZs, the pressure when the ignition is turned on is 3 atmospheres, at idle the figure is 2.5 atmospheres, when you press the gas 2.5-3 atmospheres. This method will help you accurately determine:

- malfunction of the fuel pressure regulator in the rail;

- breakdown of the fuel pump or a noticeable decrease in its performance due to wear;

- severe contamination of filters (fuel filter and/or fuel pump mesh);

In the second case, when you press the gas, the pressure does not increase; in the latter case, the pressure gauge needle rises, but very slowly or jerkily.

A decrease in pressure below the norm will lead to the fact that the engine may not start or start with difficulty, stall, jerk, operate unstably and with failures. If this happens due to the fault of the pump and not the fuel filter, then there is a high probability that the coarse filter screen of the fuel pump is clogged. In this case, there is no need to change the fuel pump itself, since it will be enough to replace or even clean the mesh.

If you suspect that there is no voltage to the fuel pump, there is a quick way to check. It is enough to turn the ignition key and listen, as when you turn the key you should hear a slight hum from the fuel pump. If such a buzzing noise is not heard, it means there is no power to the fuel pump, there are problems with the wiring, etc.

Also in the general list of possible reasons why the fuel pump does not pump, the following are noted:

- failure of the fuel pump fuse;

- fuel pump relay failure;

- problems with the ground of the fuel pump;

- malfunction of the electric motor of the fuel pump;

- oxidation or damage to fuel pump contacts and terminals;

- the fuel pump itself is faulty;

Wiring to the fuel pump

On most cars, the wiring to the fuel pump consists of three wires: “plus”, “minus”, and also a wire for indicating the amount of fuel in the gas tank. If the fuel pump does not pump, then the cause may be a lack of power.

To check the power to the fuel pump, just take a 12-volt light bulb and supply it with power from the external connector of the fuel pump. After turning the ignition, the control lamp should light up. If this does not happen, then the problem is in the external circuits. If the lamp comes on, it will indicate the need to check the internal contacts of the fuel pump.

How to check fuel system pressure

Once you know the fuel pump is delivering fuel, a fuel system pressure test can sometimes identify the source of the problem. In the next series of tests, you will use the fuel pressure sensor to check the pressure in the system.

1. Relieve pressure in the fuel system.

If your vehicle's fuel system has a Schrader valve or test port (similar to the air valve on your tires), cover the valve with a shop rag and gently press the valve with a small screwdriver. Use a rag to catch the fuel. This valve is similar to the air valve on your tires. If your fuel system does not have a test port, you can remove the fuel pump fuse and start the engine. He will die in a few seconds due to lack of fuel. Reinstall the fuel pump fuse.

- Connect the fuel pressure sensor to the test port. If you do not have the correct adapter to connect the sensor to the Schrader valve, try removing the valve and connecting the sensor to the fitting; however, if there is no test port, disconnect the fuel line from the rail (this is the line coming from the fuel filter) and connect a T-adapter to the line so you can reconnect the line to the fuel rail and connect the sensor as well.

- Start the engine and let it idle. NOTE: The repair manual for your specific vehicle may include a power-on test. Check your manual if necessary.

- Compare fuel pressure to specifications. Check the pressure reading on the pressure gauge and compare it to the specification in your vehicle's repair manual (if the vehicle does not start, turn the ignition key to the ON position and read the fuel pressure. Compare the reading to the specification in your manual for the pressure switch). The injection system typically produces 15 to 40 pounds per square inch (psi) (100-280 kPa) or more, depending on the application. The reading includes pressure from the fuel pressure regulator (FPR). So if your readings are out of specification, you may have a problem with your FPR, so keep measuring.

NOTE. New modern fuel systems do not use FPR in the injection system; rather, they vary the voltage at the pump or use an internal pump valve to regulate system pressure.

A. What to do if the pressure is correct

- With the fuel pressure sensor still connected and the engine idling, disconnect the vacuum line from the fuel pressure regulator (FPR - the small metal cylinder that connects to the fuel rail).

- Make sure the vacuum line is completely dry. If you find traces of fuel inside the hose, it is sucking fuel from the pressure regulator because the diaphragm is torn. Replace the fuel pressure regulator.

- Fuel pressure should increase from 3 to 10 psi. Otherwise, check the vacuum line: if there is no vacuum in the line, check that the hose is properly connected and not damaged, and that the vacuum port is not restricted; If there is vacuum in the line, but the pressure does not increase when you disconnect the vacuum hose, replace the fuel pressure regulator. For best results, perform the test described in the next section, Testing FPR with a Vacuum Pump.

- Stop the engine and wait at least 5 minutes. Compare the pressure reading with the specification (for pressure holding) in the repair manual. If the pressure drops below the specified value within five minutes, you may have detected a leak somewhere: check the fuel lines, fuel pump, injector or pressure regulator for leaks.

- What to do if your blood pressure is low

- Place a rag over the fuel return line.

- Pinch the hose using suitable pliers to block the flow.

- Watch the pressure gauge; If the pressure remains low, the fuel pump is not getting enough voltage or the pump is worn out. However, if the pressure increases, replace the FPR.

- What to do if your blood pressure is high

- First, perform the test described in the next section, “How to Test FPR with a Vacuum Pump.”

- Then turn off the engine.

- Disconnect the fuel return line.

- Blow through the return line to ensure it is not blocked. If the return line is blocked, find where it is.

NOTE. The video below provides an idea of how to check the voltage and ground at the fuel pump electrical connector.

Other causes of fuel pump malfunctions

Quite often, unprofessional installation of additional electrical equipment or security anti-theft systems leads to the fact that the power to the fuel pump is lost due to mixed up contacts or other connection errors.

Finally, let’s add that the gas pump in the gas tank is immersed in gasoline, in which it is actively cooled. The habit of driving with an empty tank can quickly damage the electric motor of the fuel pump, as it burns out.

What functions does the fuel pump relay perform, signs of breakdown. Where is the fuel pump relay installed, how to properly check the fuel pump relay.

Why does the starter turn normally, but the engine does not catch and does not start? Main causes of malfunction, checking fuel supply and ignition systems. Adviсe.

Diagnose faults that may indicate problems with the fuel pump. Self-check of the device, measuring the pressure in the fuel rail.

The causes of whistling and increased noise during operation of the fuel pump are overheating of the pump. How to diagnose and fix the problem yourself. Tips and tricks.

How to change a fuel pump. Location of the fuel pump, releasing pressure in the system, unscrewing the fuel lines, removing the pump, reassembling.

What to do if the car accelerates worse, does not pick up speed, or has failures during acceleration. Why the engine does not pull, how to find the reason for the decrease in power.

The Kalina fuel pump relay is an important element for ensuring stable operation of the car. The internal combustion engine is the main unit for the movement of road transport. With the advent of electric vehicles, the share of cars with internal combustion engines is decreasing, but the vast majority will be provided with cars powered by hydrocarbon raw materials for the coming decades.

For stable operation of the flaming engine of any car, including the Lada Kalina, a stable supply of a sufficient amount of fuel is necessary.

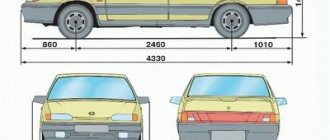

The main element of the fuel system on Kalina is the fuel pump. The fuel tank on the Lada Kalina is located in the rear of the body, therefore, the delivery of gasoline through the supply pipes to the injector sprinklers must be constant and forced.

Other elements of the car's fuel system, in addition to the tank and fuel pump, are a fine filter and fuel supply pipes.

Possible causes of fuel supply system failure

The fuel pump on Kalina is electric. The use of this design and operating principle is justified by a number of advantages. These are simplicity and reliability, compliance with the required characteristics in terms of fuel supply volumes and a high level of safety ensured by turning off the system when the engine stops running.

On the other hand, for high-quality work you need excellent gasoline and cooling of the fuel pump, and the process is also accompanied by an increased noise level.

- As a rule, poor quality gasoline and dirty filters lead to incorrect operation of the gasoline pump or its failure.

- If there is no response from the engine when you turn the ignition key, the problem may be due to a broken fuel pump.

- Since the main unit of the fuel system is powered by current, to troubleshoot it is necessary to check the electrical circuit going to the fuel pump.

Replacing the fuel pump relay

The Kalina fuel pump relay is located in the cabin just below the dashboard near the air duct grille. To access the fuel pump relay, you need to remove the cover by prying it off with a regular flat-head screwdriver.

How to remove the fuel pump relay? Before replacing the relay, you should check the fuse box, which is located next to the gear lever and the ashtray. By opening the cover, you can visually evaluate the fuel pump fuse based on the integrity of the jumper. To remove parts, it is convenient to use tweezers, which can firmly and accurately fix the fuse.

While maintaining the integrity of the jumper, for final confirmation of operability, the part must be tested with an ohmmeter, since the point of contact of the wire with the legs may be open. If the fuel pump fuse is good, then the relay is not working. There are some nuances here. The fuel pump relay is removed using a socket wrench.

Having verified the integrity and operability of the electrical network and made the necessary replacements of parts, the Kalina fuel pump should start working again. If the fuel system still does not work, then the car owner will have to become more familiar with the components of the Kalina fuel supply system.

Troubleshooting the Kalina fuel pump

If the electrics are working correctly, the fuel pump remains the object of close study. Replacing the fuel pump assembly is an extreme, and not at all mandatory, measure.

Electrical diagram for connecting a fuel pump

If the fuel pump does not turn on during normal electrical operation, remove the device to check the fuel pump. To check the functionality of the fuel pump, you need to remove the cover, which is located in the rear of the car, and remove the unit itself.

If the pump does not pump or pumps intermittently, it may be necessary to replace the Kalina fuel pump mesh. We remove the cover, disconnect the hoses and wires, use screwdrivers to press out the retaining ring and gain access to the pump. The device itself is located in the gas tank and takes gasoline directly from the tank.

Routine work, which would include replacing the mesh, is not specified in the operating instructions for the Lada Kalina. Repairing the fuel pump in order to replace the mesh should usually be carried out after 50 thousand kilometers, since the fuel at Russian gas stations is generally of low quality.

During dismantling, this can be assessed visually; the mesh turns from white to dirty brown interspersed with mechanical residues of metal, dirt and oil. At the bottom of the glass, when dismantled, you can see solid particles of unknown origin, which could only get into the tank when refueling.

There is also the opinion of some experts about the possibility of washing the mesh without replacing it. But taking into account the cost of this part, which does not exceed 100 rubles, the feasibility of flushing during the rather complex procedure of removing and installing the fuel pump is highly questionable.

Separately, it is worth pointing out the culture of repair work: after disassembly, all parts must be cleaned of dirt and foreign impurities, thoroughly washed and installed in their original place without the use of excessive force. When replacing the mesh, it is advisable to replace the fine filter, which is located in the rear right wheel arch near the jack cup. Routine work to replace the filter is provided for during maintenance every 30 thousand km.

When pumping gasoline to the nozzle, 2 more grids are installed along the way to clean the fuel. One is located in front of the fuel pressure regulator, and the last cleaning line is installed before the injector inlet. But before these filters, gasoline arrives in a dirt-free state and fault diagnosis based on these barriers is practically not carried out, due to the low probability of the need for replacement.

The fuel system of the Lada Kalina car is a reliable and well-functioning combination of units that can ensure uninterrupted operation of the car for a long period of time with timely and correct maintenance. They include a mandatory replacement of the fine filter every 30 thousand km and, highly desirable, replacement of the fuel pump mesh after approximately 50 thousand km.

#1 sonnic

- Users

- Messages: 2,547

- Samara city

About work culture and regulations

The fuel system of LADA Kalina (and not only) requires cleanliness of both the gasoline itself and the components involved in its supply to the engine. All dismantled parts of the system must be perfectly cleaned and washed before reinstallation. When replacing the mesh, we also recommend replacing the filter used for fine fuel purification. Where is this filter located? It is located inside the right stern wheel arch near the jack stand cup. According to the regulations, this element requires replacement no less than after 30 thousand kilometers.

Note that there are two more mesh filters along the fuel path in the circuit, one of which is installed in front of the fuel pressure regulator, and the second directly in front of the injectors. These filters “take over” fuel that has already been practically purified in the preliminary stages, so the need to replace them is extremely rare.