Motor temperature

It turns out that the temperature regime in which internal combustion engines operate depends very little on the ambient temperature.

To a greater extent, this indicator is influenced by the design, as well as the operating features of a particular unit. From a design point of view, motors are distinguished by the cooling method, design, type of fluids used, materials, compression, presence of supercharging, operating speed, and level of wear. So, in each individual case the operating temperature of the engine is different. There are also quite a lot of factors that influence the regime.

High temperatures are very harmful to any motor, regardless of its design. Therefore, you need to maintain the correct temperature regime.

Their types and principle of operation

The operating principle of almost all outdoor air temperature sensors is the same. It is based on the effect of changing the resistance value of a semiconductor element depending on temperature. The temperature dependence of resistance for semiconductors is negative. This means that as the temperature increases, the resistance value decreases. For the VAZ sensor, the dependence table is as follows.

| Temperature, in degrees | Resistance, Ohm |

| -40 | 100922,67±2,96 |

| -30 | 53046,93±2,49 |

| -20 | 29092,08±2,13 |

| -10 | 16567,33±1,68 |

| 9773,24±1,21 | |

| +10 | 5953,85±1,73 |

| +20 | 3737,33±2,11 |

| +30 | 2411,98±2,39 |

| +40 | 1594,92±2,65 |

As can be seen from the table, the values are given with an error. Such great precision is necessary to ensure high reliability of the readings. Temperature measurement belongs to the field of measuring technology, and it should not “lie”. At manufacturing plants, selective verification of devices is carried out. It is doubtful that they do this in China, but Russian sensors accurately check. They “verify”, not “check”. Verification is a term used by surveyors and the military.

Video - replacing the outside air temperature sensor on a Peugeot 307:

If the sensor on the car starts to “lie”, you can check it yourself using a thermometer, a source of warm air (fan heater) and a multimeter in resistance measurement mode.

The accuracy of measurements depends not only on the sensor itself, but also on its location and design. The less the sensor is blown by oncoming air flows, the less moisture gets on it, the more accurate its measurements will be. For these reasons, the sensors are placed in special housings. This is what the BMW sensor looks like.

It is not necessary to purchase the sensor assembly if the housing is available. You can only buy the measuring element itself.

All sensors have different temperature dependence characteristics, so theoretically it is impossible to use sensors from other car models, even within the same model range. Temperature measurements will be taken, but the accuracy of the readings cannot be guaranteed.

How to find out what engine temperature is in a Lada Granta

The Lada Granta car is equipped with two instrument clusters. Let's call the first instrument cluster the old one; it does not have a temperature indicator, but only a warning lamp for engine overheating. Another model of the instrument cluster already shows the engine temperature, but only in the on-board computer.

Old dashboard

This instrument panel was installed before June 15, 2014.

Find the engine temperature indicator here?

There is no engine temperature indicator on the old instrument panel. There is only an overheating warning light. On my previous cars, which did not have a temperature gauge, there were at least two warning lights: “cold engine” and “engine overheating”.

On the Grant, as planned by AvtoVAZ engineers, the engine should not be warmed up, and you can immediately start driving. Interesting savings. A whole battle broke out on our website in the comments about this in the article: Is it necessary to warm up the engine before driving?

Car manufacturers allow the car engine not to warm up, citing global standards to prevent environmental pollution and save gasoline.

Read more about fuel consumption standards for the Lada Granta family of cars in the article: Grants fuel consumption on the passport and in reality, what is it like?

Ways to solve this problem

There are several ways to solve this problem. The simplest of them is to just hammer and drive like that. Most people do just that. You can flash the instrument panel, the result will be like this.

But in this car there is a hypothetical problem of the engine not heating up to operating temperatures, although AvtoVAZ management does not consider operating temperatures below 80 degrees a problem.

More on this a little later, when my diagnostic scanner arrives from China!

New instrument panel

New instrument panel combination (from June 16, 2014)

If your car was manufactured after June 15, then the engine temperature should be displayed in the on-board computer. If it is not there, then you need to reflash the instrument panel.

Your advantages when purchasing at Autocompas.ru

Range of auto parts in stock and on order

A wide variety of manufacturers and high-quality auto parts guarantee the mobility of your car and safety on the roads. A huge assortment is constantly available from stock online. Certified and reliable aftermarket suppliers, dealers, and regional market participants provide a full range of auto parts at reasonable prices. Our knowledgeable support staff is always available to assist you in your search.

Quality of service in our online store

The service and online offers from Autocompas.ru have already won several awards and made us a leader in the Russian market in the field of sales of auto parts for foreign cars, 40+ thousand people visit the site every day and many of them become our regular customers. Satisfied customers are our goal. Rely on Autocompas.ru as a reliable supplier of auto parts.

A review section has been introduced on the site, using the latest technologies, now each client can write a review from their personal account.

A completely new and intuitive returns system.

Global update of the “Delivery” section! Track numbers in your personal account and convenient cargo tracking.

Information letter AvtoVAZ (excerpt)

Excerpt from the “Information letter to AvtoVAZ dealers.”

4.3 Owners of cars of the Lada Granta (2190) and Kalina FL (2192, 2194) families state a fact: the average coolant temperature on their current cars is 7–10 degrees lower than on the previous Priora, Samara and Kalina models. Due to subjective “unusuality”, this fact has been elevated by consumers and service station personnel to the rank of a discrepancy (defect) called “underheating” of the engine.

4.4 Maintaining the coolant temperature on cars of the Lada Granta (2190) and Kalina FL (2192, 2194) families in the temperature range below the “usual” ones on previous car models Priora, Samara and Kalina does not lead to increased fuel consumption, increased wear of engine parts and no other negative consequences. Accordingly, in the absence of negative consequences and the absence of a coolant temperature standard, “underheating” of the engine according to clause 4.3 is not a non-compliance (defect).

4.5 A consumer’s claim for non-conformity (defect) “underheating” of the engine should not be accepted by service station personnel unless it is accompanied by a consumer complaint about any additional associated negative manifestation. If an unfounded claim is rejected, the consumer must be explained the features of the engine cooling system of cars of the Lada Granta (2190) and Kalina FL (2192, 2194) family.

That's the point of the whole guarantee! Rivet the cars from the beginning with defects, and they all went through the woods! Explaining this by saying that this is a design feature of the car's cooling system.

I have the same nonsense

The temperature does not rise above 80, even in the city or on the highway. I even put cardboard in the radiator, so I understand that it’s not just me who does this?

Yes, my engine temperature on Kalina was 85 87 from the beginning. The time has come to replace the thermostat, now the temperature does not rise above 80. It seems to say everything is fine, but it seems to me that now it has started to take oil. Not because the temperature has become lower.

see also

Comments 16

I jump from 80 to 105. Tell me, is this normal?

According to the manual, 77-82 is the norm.

The operating temperature of a 16-valve engine is 87-103 degrees Celsius.

I set the Luzar thermostat to 92 degrees. It's very hot in the car. The native was not a worker; his temperature did not rise above 80. After setting the thermostat to 92, fuel consumption decreased by 1.5 liters according to the on-board computer.

Well, I don’t know who has it - EVERYONE. I'll write for myself. If I see a temperature below 85 on mine, I grind it or change the insert. My native one lasted for 2 years, Luzara for 3, now Metal-INKAR is standing. No pipe insulation. The temperature rises to 88, drops once to 83 and then stays at 88-86.

It's like that for everyone, don't worry about it. Grants and Kalinas 2 are cooler in engine temperature than previous VAZ cars.

Read an interesting article on this topic! www.drive2.ru/l/8447404/

I dropped to 73, that was already a problem. www.drive2.ru/l/463796545658028259/ Consumption is higher and the cabin is colder.

And your temperature is still within adequate tolerances.

Not a grant but a viburnum 2, the temp was 74, coldly closed with a corton, it became 85 and Tashkent

If it’s -30 outside and the air intake is from the street, then while driving the temperature can be less than 70 when you’re rolling down a hill, it’s cold in the cabin. If the fence is from the interior, then the temperature is 80-82, the interior is very warm, but the windows quickly fog up. The holes are closed only in the bumper. If you drive for an hour, it doesn’t matter where the fence is from, it’s hot in the cabin. But there is blowing from the glass seals.

Like constructive know-how. People change the thermostat, but as a rule it doesn’t help much as I understand it. I scored, I skate like this. Only in winter from -10 I put pipe seals in the radiator so that the engine is not at all cold.

Have you heard about pipe insulation inserts in the bumper? put them here. The temperature will rise to 85. In winter, the radiator cools excessively when driving. You can somehow even attach cardboard like on a Zhiguli. The main thing is to reduce the radiator airflow

Yes, they have a crap thermos and it holds it like that. If you don’t worry about the heat, if it gets cold in the future, change it to 92 degrees and that’s it

The first year of operation, both in winter and in summer, the temperature was 84-85, and in the second year in winter it showed a temperature of 79-81. I replaced the thermal insert at 85, but in fact it did not help. The most important thing is to install springs in the trunk from classic clutches if you have a sedan, remove the handbrake cable from the eyelets and replace the front mudguards so that the sills are not sandblasted, and install RKI 19 and 135. Good luck!

The operating temperature of the engine in a Lada Granta car should be 90 degrees , but most owners complain that the temperature does not rise above 80 degrees . Even despite the above-zero temperature outside.

Apparently AvtoVAZ decided to further protect itself by installing a thermostat that opens already at 85°. The most interesting thing is that AvtoVAZ defines the tolerances for the opening temperature of the thermostat as: (85±8.3) ºС, i.e. from 77 to 93 ºС

. This is a scatter, isn't it?

The operating temperature of the engine must be at least 90ºС.

To learn how to find out the engine temperature when your car is not equipped with a temperature indicator on the instrument panel, read the material: how to check the engine temperature.

Replacing the Lada Granta temperature sensor (VAZ Granta)

The sensor is installed in the engine cooling system. The sensitive element of the sensor is a thermistor, the electrical resistance of which varies inversely with temperature.

The Lada Granta coolant temperature sensor is a thermistor (a resistor whose resistance changes depending on the temperature).

The sensor is screwed into the thermostat housing and connected to the controller input, connected to an internal voltage source of 5 V through a 2 kOhm resistor. At low temperatures, the resistance of the sensor is high, and at high temperatures it is low (Table 1). The controller calculates the coolant temperature from the voltage drop on the sensor.

On a cold engine the voltage drop is high, and on a warm engine it is low. Coolant temperature affects most of the characteristics controlled by the controller.

To remove the sensor you will need: a 19mm wrench and a multimeter.

If you have a 21126 engine, then you can see the algorithm for removing the sensor in the article “Replacing the coolant temperature indicator sensor in Lada Priora”

1. Disconnect the wire from the negative terminal of the battery.2. Partially drain the coolant from the radiator.3. For ease of operation, remove the air filter (see “Removing and installing the air filter, air supply hose and air intake of the Lada Granta”).4. Release the wiring harness block clamp

5. and disconnect the block from the sensor.

6. Unscrew the sensor from the thermostat housing.

7. Remove the sensor.

Check the sensor in ohmmeter mode, connect probes to the sensor terminals and measure its resistance. Measure the current air temperature with a thermometer and compare the obtained values with the data in the table. 1. If the resistance deviates from the norm, replace the sensor.

9. To measure the resistance at the sensor terminals at different temperature conditions, lower the sensor into hot water and check the change in its resistance as the water cools, monitoring the water temperature with a thermometer. Nominal resistance values at various temperatures are shown in table. 1.10. Install the sensor in the reverse order of removal

Tools:

- Ratchet wrench

- Extension

- 8 mm head

- 10 mm head

- 19 mm head

- Medium Phillips screwdriver

- Ohmmeter (tester)

Parts and consumables:

- Coolant temperature sensor

- Technical capacity

- Container for hot water (glass, mug)

- Water thermometer

- Household thermometer

- Hot water

- Rags

1. Disconnect the wire from the negative terminal of the battery.

2. To access the radiator drain holes, remove the middle mudguard as described here.

3. Partially drain the radiator coolant as described here.

4. To make it easier to replace the DTOZH sensor, remove the air filter as described here. Take him aside.

5. Press the lock of the DTOZh sensor wiring harness connector and disconnect the connector from the sensor (it is located on the cooling system thermostat).

6. Using a wrench with an extension and a 19 mm socket, unscrew the DTOZH from the thermostat.

7. Remove the sensor.

8. Cool the DTOZh sensor to ambient temperature.

9. Connect the tester in ohmmeter mode to the terminals of the DTOZH sensor and measure its resistance.

10. Measure the current air temperature with a thermometer and compare the obtained values with the data presented below.

11. To measure the resistance at the terminals of the DTOZh sensor at different temperature conditions, lower the coolant temperature sensor into hot water and check the change in its resistance as the water cools, monitoring the water temperature with a thermometer. Nominal resistance values at various temperatures are indicated in the table (see paragraph 10).

12. If the resistance deviates from the norm, replace the DTOZh sensor.

13. Install the coolant temperature sensor on the vehicle in the reverse order of removal.

First, it’s worth understanding why temperature meters are needed in a car. It is completely clear what internal and external air temperature meters do. They carry out their measurements, transmit a signal to the car’s ECU, and thanks to their work, the car either carries out climate control, or regulates the operation of the car’s mechanisms, or simply displays the obtained measurements on the dashboard (however, this is often done bypassing the ECU altogether).

Why, for example, do you need a coolant temperature sensor (DTOZH)? His work, although it seems just as obvious, is actually deeper in nature.

After all, the coolant travels a long way, through the engine to the radiator, and then, wobbling through its tubes, returns to the engine, where it is re-measured.

The radiator is designed in such a way that air flows counter to the car cool the antifreeze without unnecessary costs on the part of the car. However, in hot weather or standing in a traffic jam, this may not be enough, and then the computer decides to turn on additional cooling in the form of fans located inside.

At the same time, the Lada Granta DTOZH, with its measurements, helps the computer determine the need for additional fuel injection. Although more often devices that measure incoming air or outgoing air (exhaust) are responsible for this.

As a result, the main positive criteria for the work of the DTOZh include:

- reduction in fuel consumption;

- reducing wear on machine mechanisms;

- improving vehicle performance and avoiding overheating.

This can also include bonuses such as notification to the driver or analysis of the operation of one or another form of coolant. But this already depends on the ability of the drivers themselves to recognize such signals.

The coolant temperature detector in the Lada Granta is installed on the thermostat housing. To work with it, you will need standard tools like a Phillips screwdriver, two pairs of hands, and perhaps a 19 mm deep socket to simplify the work.

The dismantling of the meter in the Lada Granta itself takes place in several stages:

- we find where the device is located, remove the air filter that prevents us from getting to it;

- disconnect the wires from the meter;

- remove the connector from the detector;

- Let's start unscrewing the device.

Before dismantling, be sure to turn off the power to the car by removing the terminal from the battery. After this, be sure to drain the coolant. Failure to comply with any of these conditions poses a threat to your life and health.

Installation of a new device occurs in reverse of its dismantling. That is, they screwed it in, put the wires back in place, and put the air filter back. After that, we poured back the antifreeze and connected the electricity. However, two installation nuances should be remembered. The first is to convince yourself of the quality of the seal of the new sensor or add your own sealant (coolant should not leak out while the car is running). Well, the second comes out of the first - start the car and make sure there is no antifreeze leakage.

Repairing the Lada Granta DTOZ is easy and simple. At the same time, the benefits of the device are difficult to overestimate. Therefore, the logical conclusion is made that you should not neglect replacing a failed meter. Replacement should be done immediately.

The absence of a working DTOZh leads to the immediate activation of the additional cooling system, even if there is no need. As a conclusion, this leads to unjustifiably high fuel consumption during vehicle operation.

Replacing the DTOZH sensor REASONS and a little about air leaks.

Speed sensor

The DS is intended to measure the speed of a vehicle, with subsequent transmission of the received data to the ECU. The speed sensor is a small part; it is located in the upper part of the clutch housing, near the front wheel on the right. Its malfunction is usually directly related to a breakdown of the speedometer. However, the sensors installed on Grants are distinguished by fairly high quality and durability.

By the way, initially three types of speed sensors were installed on Grants: VAZ-2170 PEGAS, 2190 AVAR Russia and 21700-3843010-02.

More details about the speed sensor on Grants.

If the DS malfunctions, the electric power steering most often stops functioning, and at the same time the instrument panel begins to display error P-0501. As a rule, the steering wheel fails precisely because the car detects a breakdown of the speed sensor; the DS itself may show zero speed.

If the sensor fails, the following symptoms of failure are noted:

These parts have their own markings, their price ranges from 300 to 600 rubles.

Rules for operating motors

According to car owners, the biggest disadvantage in its design is the lack of an engine temperature sensor. This indicator is necessary to monitor the quality of the engine.

Overheating is the main enemy of the cylinder-piston system. The reasons for the increase in temperature in the engine may be a lack of antifreeze, insufficient cooling, etc. If the sensor is on, all of the above situations can lead to breakdown. To prevent this from happening, experts recommend installing a digital engine temperature indicator, which will accurately reflect the state of affairs.

Thus, the recommended frequency of engine checks is 15 thousand km. In this case, you do not need to wait for the indicator on the panel to inform you about any problem: it is easier to eliminate the prerequisites for a malfunction than the malfunction itself.

When the mileage reaches 30 thousand km, you will need to replace not only the oil, but also the power system filters and spark plugs, which will also be indicated by the indicator. Often, at this mileage level, the indicator begins to inform about problems in the engine. This could be a failed timing pulley or a faulty valve cover gasket. After a mileage of 45 thousand km, the indicator will indicate the need for an oil change.

If you take a responsible approach to car operation, the resource of the power unit can be increased by thousands of km.

Despite the fact that the Lada Granta is a budget car, the manufacturer offers a wide range of engines for it:

- VAZ 21126-77.

Of course, the volume of the engines listed above is approximately the same and is 1.6 liters, but each of the listed power plants has its own advantages and disadvantages. For this reason, many car enthusiasts who want to purchase a Lada Granda often cannot decide on the type of engine they need, and therefore below we will try to consider each of them.

Malfunctions

The main malfunctions include tripling, low-quality spark plugs, poor cooling system, floating speed and failure of sensors. These vehicles are often subject to diagnostics by electricians. Even chip tuning can't save you.

The repair is quite simple. To correct tripping, the spark plugs are replaced. Next, it is worth diagnosing and replacing faulty sensors. This is especially true for DMVR and TPS.

Many owners of 16-valve engines ask the question whether the valves on the Grant are bent. Of course, valves bend when the timing belt breaks. Therefore, it is necessary to change the belt mechanism in a timely manner, namely after 60-70 thousand kilometers or due to wear.

If there are problems with maintaining the temperature, then it is worth diagnosing the thermostat or the presence of leaks in the cooling system. The engine operating temperature is 87-103 degrees Celsius. Some car enthusiasts, in winter, when the cooling system does not heat up, install cardboard on the radiator grille to help the power unit warm up.

Error codes

Often, malfunctions of the power unit can be determined by the appearance or accumulation of errors in the electronic control unit. To understand what error occurred, you need to know the decoding. Let's look at deciphering the error codes that are present on the Lada Granta 16 valve:

| Error code | Description of the error |

| P0030 Oxygen sensor before the converter, checking the open circuit of the heater P0031 Oxygen sensor before the converter, checking the short circuit of the heater circuit to ground P0032 Oxygen sensor before the converter, checking the short circuit of the heater circuit to the on-board network P0036 Oxygen sensor after the converter, checking the open circuit of the heater P0037 Oxygen sensor after converter, checking the short circuit of the heater circuit to ground P0038 Oxygen sensor after the converter, checking the short circuit of the heater circuit to the on-board network P0101 Mass air flow sensor, signal output is out of the permissible range P0102 Mass air flow sensor, low output signal level P0106 Intake absolute pressure sensor circuit manifold, signal output out of acceptable range P0107 Intake manifold absolute pressure sensor circuit, low signal level P0108 Intake manifold absolute pressure sensor circuit, high signal level P0103 Mass air flow sensor, high output level P0112 Intake air temperature sensor, low output level signal P0113 Intake air temperature sensor, high output signal P0115 Incorrect coolant temperature sensor signal P0116 Coolant temperature sensor, signal out of range P0117 Coolant temperature sensor, low output signal P0118 Coolant temperature sensor, high output signal P0122 Throttle position sensor, low output (sensor No. 1) P0123 Throttle position sensor, high output (sensor No. 1) P0130 Pre-converter oxygen sensor faulty P0131 Pre-converter oxygen sensor, low output P0132 Pre-converter oxygen sensor , high output signal level P0133 Oxygen sensor before the converter, slow response to enrichment or lean P0134 Oxygen sensor before the converter, signal circuit open P0135 Oxygen sensor before the converter, heater faulty P0136 Oxygen sensor after the converter, open signal circuit P0137 Oxygen sensor after the converter, low signal level P0138 Oxygen sensor after the converter, high signal level P0140 Oxygen sensor after the converter, open signal circuit P0141 Oxygen sensor after the converter, heater faulty P0171 Fuel supply system too lean P0172 Fuel supply system too rich P0200 Injector control circuit faulty P0201 Injector control circuit of cylinder No. 1 , open P0202 Injector control circuit of cylinder No. 2, open P0203 Injector control circuit of cylinder No. 3, open P0204 Injector control circuit of cylinder No. 4, open P0217 Engine overheating, engine temperature above the threshold value P0222 Throttle position sensor, low output signal (sensor No. 2) P0223 Throttle position sensor, high output signal (sensor No. 2) P0261 Cylinder No. 1 injector control circuit, short to ground P0262 Cylinder No. 1 injector control circuit, short to +12V P0264 Cylinder No. 2 injector control circuit, short On Earth P0265, the cylinder nozzle control circuit No. 2, closing at +12V P0267 Control circuit cylinder nozzle No. 3, Closing to Earth P0268 Control circuit of the injector of cylinder No. 3, Closing a +12V P0270 Control circuit No. 4, Closing to Earth P0271 circuit circuit injector control of cylinder No. 4, short to +12V P0300 Random or multiple misfires detected P0301 Misfire detected in cylinder 1 P0302 Misfire detected in cylinder 2 P0303 Misfire detected in cylinder 3 P0304 Misfire detected changes to 4 th cylinder P0325 Knock sensor break P0326 Knock sensor, signal is outside the permissible limits P0327 Knock sensor, low signal level P0328 Knock sensor, high signal level P0335 Crankshaft position sensor, no signal P0336 Crankshaft position sensor, signal is outside the permissible limits P0337 Crankshaft position sensor, circuit short to ground P0338 Crankshaft position sensor, open circuit P0340 Camshaft position sensor faulty (Phase sensor error) P0342 Camshaft position sensor circuit low P0343 Camshaft position sensor circuit high P0346 Phase sensor circuit incorrect signal P0351 Ignition coil, open circuit check, primary circuit current is less than the threshold value P0352 Ignition coil, open circuit check, primary circuit current is less than the threshold value P0353 Cylinder 3 ignition coil, control circuit open circuit P0354 Cylinder 4 ignition coil, control circuit open circuit P0363 Random detected or multiple misfires to protect the converter P0422 The effectiveness of the converter is below the threshold P0441 Incorrect air flow through the valve P0443 The canister purge valve control is faulty P0444 The canister purge valve, checking for open circuit P0445 The canister purge valve circuit is short to ground P0458 The canister purge valve, checking the short circuit for " ground" P0459 Canister purge valve, checking the short-circuit circuit to the on-board network P0480 Fan relay control circuit 1; open circuit check P0481 Fan relay 2 control circuit; open circuit, check for open circuit P0485 Cooling fan, check supply voltage P0500 Vehicle speed sensor, no signal P0501 Vehicle speed sensor error P0503 Vehicle speed sensor, intermittent signal P0504 Brake pedal sensor, sensor signals change inconsistently P0505 Idle speed controller error P0506 Idle speed controller blocked , low speed P0507 Idle speed control blocked, high speed P0522 Oil pressure sensor circuit, low signal level P0523 Oil pressure sensor circuit, high signal level P0560 On-board voltage below the system operability threshold P0562 On-board voltage is low P0563 On-board voltage is high P0601 Malfunction ROM of the control unit P0603 Malfunction of the RAM of the control unit P0604 Checksum error of the internal RAM of the controller P0606 Controller, faulty ADC P0607 Incorrect signal of the detonation channel of the controller P0615 Starter relay control circuit, open P0616 Starter relay control circuit, short to ground P0617 Starter relay control circuit, short to ground +12V P0627 Fuel pump relay, checking open circuit P0628 Fuel pump relay, checking short circuit to ground P0629 Fuel pump relay, checking short circuit to the on-board network P0642 Sensor power bus, low signal level P0643 Sensor power bus, high signal level P0645 Air conditioning clutch relay, checking open circuit P0646 Air conditioning clutch relay, checking short circuit to ground P0647 Air conditioning clutch relay, checking short circuit to on-board network P0660 Intake system channel length control valve, open circuit P0661 Intake system channel length control valve, circuit short to ground P0662 Control valve the length of the intake system channels, short circuit of the on-board network P0691 Fan relay control circuit 1; open circuit, checking short circuit to ground P0692 Fan relay control circuit 1; open circuit, checking the short circuit to the on-board network P0693 Fan relay control circuit 2; open circuit, checking short circuit to ground P0694 Fan relay control circuit 2; open circuit, checking the short-circuit to the on-board network P0830 Clutch pedal switch, circuit faulty P1102 Low resistance of the oxygen sensor heater P1115 Faulty oxygen sensor heating control circuit P1123 Additive component corr. by air the composition of the mixture exceeds the threshold. Composition “rich” P1124 Additive component corr. by air the composition of the mixture exceeds the threshold. Composition “poor” P1127 Multiplicative. the mixture correction component exceeds the threshold. Composition “rich” P1128 Multiplicative. the mixture correction component exceeds the threshold. Composition “poor” P1135 Malfunction of the oxygen sensor heater circuit to the converter P1136 Additive component corr. fuel exceeds the threshold. Composition “rich” P1137 Additive component corr. fuel exceeds the threshold. Composition “poor” P1140 The measured load differs from the calculated one P1141 Malfunction of the oxygen sensor heater circuit after the converter P1171 Low signal level from the CO correction potentiometer P1172 High signal level from the CO correction potentiometer P1301 Misfires detected to protect the converter in the 1st cylinder P1302 Misfires detected to protect the converter in the 2nd cylinder P1303 Misfire detected to protect the converter in the 3rd cylinder P1304 Misfire detected to protect the converter in the 4th cylinder P1335 Monitoring the throttle control, throttle position out of range P1336 Monitoring the throttle control , checking the mismatch of signals from the throttle position sensors, the sensor voltages differ by the value of the threshold P1384 Monitoring the control of the throttle valve drive. Engine torque is out of range P1385 Monitoring throttle actuator control. Engine load signal is out of range. P1386 Knock detection channel, internal test error P1387 Throttle actuator control monitoring. Injection time is out of range. P1388 Monitoring the throttle drive control, checking the accelerator pedal position, sensor voltages differ by the threshold value P1389 Monitoring the throttle drive control, engine speed is outside the permissible range P1390 Monitoring the throttle drive control, there is no response to a malfunction in the system P1410 Canister purge valve control circuit, short to +12V P1425 Control circuit for the canister purge valve, short to ground P1426 Control circuit for the canister purge valve, open P1500 Open circuit for the control circuit of the electric fuel pump relay P1501 Control circuit for the fuel pump relay, short to ground P1502 Control circuit for the fuel pump relay, short to +12V P150 9 Control circuit idle speed regulator, overload P1513 Idle speed regulator control circuit, short to ground P1514 Idle speed regulator control circuit, open or short to +12V P1541 Fuel pump relay control circuit, open P1545 Throttle valve drive, deviation of the actual throttle position from the desired one is greater than the threshold value P1558 Throttle actuator, return spring faulty P1559 Throttle actuator, valve rest position out of range P1570 Immobilizer, no positive response or open circuit P1578 Throttle actuator, adaptation value out of range P1558 Throttle actuator, throttle return time to position limp home above the threshold value P1559 Throttle valve actuator, valve position outside the permissible range P1600 No communication with the immobilizer P1602 Loss of on-board network voltage P1603 Malfunction of the control unit EEPROM P1606 Rough road sensor, incorrect signal P1612 Processor reset error P1616 Rough road sensor, low signal P1617 Yes tchik rough road, high signal P1620 Malfunction of the ROM of the control unit P1621 Malfunction of the RAM of the control unit P1622 Malfunction of the EEPROM of the control unit P1640 Court controller, error reading-writing EEPROM memory P1689 Malfunction of the error memory P2070 Length control valve of the intake system channels, constantly open P2071 Length control valve intake system channels, constantly closed P2100 Throttle valve actuator, checking open circuit P2101 Electric throttle actuator, control circuit faulty P2102 Throttle valve actuator, checking short circuit to ground P2103 Throttle actuator, checking short circuit to on-board network P2105 Controller, faulty monitoring module P2122 Pedal position sensor A circuit high P2123 Pedal position sensor A circuit high P2127 Pedal position sensor B circuit low P2128 Pedal position sensor B circuit high P2187 Fuel system too lean (at idle) P2188 Fuel supply system too rich (idling) P2135 Throttle position sensors “A”/”B”, signal mismatch P2138 Accelerator pedal position sensors “A”/”B”, signal mismatch P2176 Throttle valve drive control system, zero position adaptation valve not completed P2178 Throttle valve actuator, adaptation has never been carried out P2187 Fuel supply system too lean at idle P2188 Fuel supply system too rich at idle P2270 Oxygen sensor after the converter, no response to enrichment of the mixture P2271 Oxygen sensor after the converter, no response to lean mixture P2301 Ignition coil of cylinder 1, short circuit of the control circuit to the on-board network P2304 Ignition coil of cylinder 2, short circuit of the control circuit to the on-board network P2307 Ignition coil of cylinder 3, short circuit of the control circuit to the on-board network P2310 Ignition coil of cylinder 4, short circuit of the control circuit to the on-board network P2500 Alternator Excitation (LT) Control Circuit Low P2501 Alternator Excitation (LT) Control Circuit High | |

Source

The role of cooling in creating a favorable temperature regime

The operating temperature of the engine depends on the efficiency of the cooling system. It is a complex of all devices that supply coolant to technological areas and then remove heat to the atmosphere.

The purpose of the coolant is to provide the most favorable conditions for the functioning of engines. And also so that when working in any conditions, the temperature regime is maintained at the same level. When the fuel burns, the temperature at this moment is about 2000 degrees. And the cooling system allows you to reduce it to 90 degrees. This is considered the optimal temperature.

The principle of operation of the cooling system

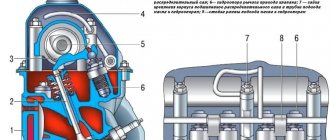

Lada Granta cars use modified ODS. When the engine starts, the thermostat is in the closed position, the antifreeze is forced to move by the water pump in a small circle: pump, water jacket, heater radiator - an expansion tank is also built into the system in parallel. On the first Granta models, the stove radiator was also installed in parallel, but at the moment its inclusion in the system is sequential - the liquid in the small circle necessarily passes through it.

For this reason, the radiator has a single-pass design, meaning coolant circulates in only one direction. As the antifreeze heats up at a temperature of 60 degrees or more, the thermostat valve begins to open slightly, and the coolant begins to circulate in a large circle: pump, water jacket, radiator, heater core. The liquid begins to circulate through the radiator, a small circle works in parallel with the expansion tank. The pressure in the system is maintained by two pipes and points on the top of the radiator in place of three return pipes: from the radiator, from the heater and from the pump.

After the coolant warms up above 110 degrees, the fan is activated, forcibly cooling it to operating temperature - 95-100 degrees. An indicator above 110 degrees is considered critical - the motor overheats.

The series-connected heater core, thanks to its single-pass design, increases the efficiency of heating the interior. There is an improvement in circulation and a decrease in hydraulic resistance. If previously the coolant was mixed in the thermostat housing, now it flows from the jacket directly to the control valve. It always opens at the right moment, reacting not to the general, but to the real temperature of the antifreeze. Overheating is practically eliminated; on the contrary, insufficient heating is noted, but this does not affect engine operation and fuel consumption.

Replacing coolant in the SOD

The antifreeze level in the tank is checked only after the engine has cooled down. You cannot add coolant to the maximum mark - during operation the liquid heats up and increases in volume, after topping up the valve cover is screwed on tightly.

It is necessary to constantly monitor the level of antifreeze; a sharp decrease in its volume can cause a malfunction of the cooling system, which should be eliminated immediately. Every motorist can add antifreeze to the expansion tank:

- The car must be on a flat surface, all work is carried out with the engine cooled down.

- Unscrew the cap of the expansion tank.

- Check the condition of the antifreeze; there should be no oil film or other contaminants on it. If the color of the coolant is dark or rusty, the ODS needs to be flushed.

- If the fluid level is below the minimum level, all connections should be inspected for leaks. If they are missing, add antifreeze between the two marks and tighten the valve cover tightly.

The procedure is simple and can be performed by anyone without seeking help from a car service center. The price of the work does not exceed 100-200 rubles, depending on the region.

Preparing for replacement

According to the regulations, the coolant is replaced after reaching 75 thousand km or after 5 years of operation. In other cases, the procedure is carried out when antifreeze is contaminated or leaks. Lada Granta engines use ethylene glycol-based coolant without the addition of borates, silicates and other synthetic additives. To change the entire coolant, you will need to purchase at least 8 liters of fluid. It is not necessary to use the antifreeze used at the factory for this. As an alternative, you can take products from the brands Sintek, Felix, G-ENERGY.

For work, a 13 mm wrench, screwdrivers, rags, a container for draining the coolant and new antifreeze are used.

How to drain coolant

First of all, the engine must cool down. Then, by unscrewing the cap of the expansion tank, relieve pressure in the system. The engine protection is removed. A suitable container is placed under the radiator drain plug, and the valve cover is screwed on - this way the antifreeze will drain more slowly and will not flood everything around. Then the drain plug is unscrewed and the coolant is drained into the container. This way, not all the liquid comes out - you also need to drain it from the water jacket.

On an engine with 8 valves, the container is placed below the ignition module under the front part of the BC. Using a 13 mm wrench, unscrew the drain nut on the block and wait until the antifreeze drains from the jacket. Then tighten the nut.

On an engine with 16 valves, due to design features, the starter prevents the fluid from draining from the jacket. For this reason, you must first remove it and only then unscrew the drain nut. If this is not done, the coolant will flood the starter, and this will lead to the failure of the starter. The drain nuts use tapered threads so no O-ring is required.

Why is overheating dangerous?

If the engine gets very hot, this can ultimately lead to dire consequences for the car owner. Overheating leads to increased wear of parts and components.

If the motor has been running for a short time at high temperatures, then there is nothing to be afraid of. Nothing will happen to him in 5 minutes. The reasons for this are various malfunctions with the fan or incorrect operation of the thermostat. If you stop the car in time, the maximum consequences are melting of the pistons. For a new car, short-term overheating is not at all scary.

If the engine operating temperature exceeds the norm for about 20 minutes or more, then there is a serious risk of cylinder head deformation and gasket burnout. Inter-ring partitions may also become unusable.

If the engine is completely overheated, this is a real disaster. This leads to damage to every part, every unit. The motor could even explode if the components were a little more reliable. If there is severe overheating, the piston group will certainly melt, and liquid metal will fall on the cylinders. This will make the piston stroke much harder, which means more wear. Also, engine diagnostics after overheating often reveals inevitable problems in the operation of the lubrication system. Overheated oil will not have its original properties, and rubbing vapors will destroy themselves. Pistons can puncture the cylinder head, and the crankshaft often breaks in two.

New instrument panel

On a Lada Granta with a new instrument panel, the temperature indicator should already be built-in. However, not all cars have it. Therefore, many car owners have to reflash the panel.

Since overheating alarms are no longer installed, the temperature should be displayed on the instrument panel when requested by the car owner. If it is not there, then perhaps the manufacturer installed old firmware and therefore the car owner cannot find the engine temperature on the instrument panel screen.

The instrument panel also displays other values of vehicle parts. For example, gasoline consumption, amount of gasoline, errors in operation of the automatic transmission or engine.

Firmware for instrument cluster on Kalina2Granta

Since the USBDM programmer had already tested it at home (CAN recovery) and found out that it can also flash instrument clusters (gearboxes), I decided to flash it myself.

My gearbox costs 219240 and came with firmware 007 and did not display engine temperature readings. I decided to upgrade to version 009. But as always, the first thing is lumpy, an error popped up during the firmware and the result was a brick. Again, study the internet and figure out what’s wrong. I found my mistake, reflashed it with a new one - everything worked.

But the mileage readings became “000” and the IMMO was lost. There were no problems with retraining the keys (IMMO), the Internet is full of information, and I’ve already done it myself. But it was not easy to restore the mileage; the car is under warranty and also needs mileage. MrRararai for help

, he helped restore my mileage, for which I thank him very much.

Now I have firmware 012 on my gearbox.

Now I have also learned to change the mileage.

I surfed the Internet and this is what I found about instrument clusters:

how to view the CP firmware

- press the mileage switch button, then turn on the ignition without releasing the button (without starting the engine), the test will begin, press the button again - we see the software version (top line) and equipment (bottom line).

There are two firmware options:

1) with mileage and IMMO reset (it will be necessary to retrain the keys)

2) with preservation of mileage and IMMO.

— The gearbox seal is broken (warranty).

— When flashing the firmware, there must be a training key nearby, if something goes wrong and the IMMO is jammed, the car will not start, you need to train the keys (IMMO)

015

- on the old board, there is not a single temperature.

029 — 040

- updated board. there is no temperature.

All panels from the standard have a different display installed; to flash the firmware, you need to change it to a display from the standard. And add a bunch more elements. The old and new versions are different, each has its own improvements.

053, 060, 076, 087

- there is no temperature.

090, 091

– it is possible to connect an ambient temperature sensor (TOS), but there is no coolant temperature (TOZH)

092-095

– there is TOZ and TOS

053, 060, 076

– Old boards, to flash them you need to modify the board with a soldering iron or sew adapted 092 firmware

087-095

– New boards. Sewn without any modifications.

046

– has everything (same as 009 from Kalina)

009

– has everything (same as 046)

012

– everything is there, the latest version. It differs from 009 in the presence of a gear shift prompt.

Hardware PCs of configuration 40 (Lux) from configuration 20 (Normal) differ in the presence of an LED for indicating PPTF and the color of the glasses

— 219220(40)-007 and higher, there will be software: 009 or 012 — BC of the “Lux” configuration + engine temperature + removed the glitch with the outside air temperature + corrected the clock

On the 012 firmware of the gearbox and the firmware “i427ge05”, “i427GKA1” of the ECU, only on the luxury PC (219240), only on the manual (127 engine) - a hint about gear shifting appeared.

— 219020-060, 076 will be software: adapted 092, TOS and TOZH will be added

— 219020-087 and higher, there will be software: 092 or 046 (unlike 092, it will additionally show the engine operating time, fuel consumed and average speed. All parameters are resettable) or 009 from Kalina (in addition to 046, the squeak of the turn signals).

— 219040-032 and higher, there will be software: 046 — BC of the “Lux” configuration + engine temperature + removed the glitch with the outside air temperature + corrected the clock

Some data on firmware versions was taken from Goffka

Comments 32

Kalina 2 after flashing from T007 to T012, the sounds of turn signals and emergency lights disappeared

There is a sound from the turn signals when the ignition is turned on...

I also had a gearbox from 007, now 012 - there is a sound from the turn signals.

there is no sound and the same thing while driving

So I did something wrong...

I have a grant from 2013. 1.6 98hp engine, automatic transmission, instrument panel 219020 - 076. Is it possible to install modified 092 firmware on it so that the technical specifications and TOC are displayed, will there be any problems with the automatic transmission indication.

Good day. Guys, tell me, the grant standard is 13 years old. Manual transmission. The firmware costs 219020_090. Which one can you upgrade to and how to have both the identity and technical specifications. If you can be more detailed because This is my first time encountering this, are there any nuances? I would be grateful! :)

You can flash it on software: 092

Instrument panel Lada Kalina, 11186 (2192380101020) can I install the automatic transmission standard on a grant?

No, from Kalina1 they do not fit to Kalina2/Granta

009 firmware from Kalina, and it definitely has TOZH. May not show TOC if sensor is not installed.

Oh, I wrote 090 incorrectly, but if I set 009, it will show the automatic transmission switching? Can you tell me?

But now doesn’t it show - D, R, etc. ?

On Granta they put 046, analogue 009

Good afternoon) Can you tidy me up? Kalina 2 does not show temperature.

Good afternoon. Tell me about the Grant standard with the new board, what extras. functions will need to be done, in addition to replacing the screen.

What causes engine overheating?

In most cases, the engine heats up in the summer. But similar cases are also observed in winter and autumn. The reasons can be very different. Overheating can be external or internal.

External overheating can be determined by the increase in temperature of the cooling mixture. The driver can notice this and react immediately. And when the engine heats up from the inside, it is difficult to notice right away. The high temperature remains inside the engine, the coolant temperature does not increase. And the unit suddenly loses power.

The first reason is the lack of cooling mixture in the system. Liquid may leak from the system due to depressurization. Engine cooling in modern cars consists of many different pipes, pipes, clamps, and gaskets. A leak can happen anywhere. Leaks can be easily diagnosed. These are white spots or streaks on the outer parts of the motor. This includes drops of liquid under the car after parking. But the leak is nonsense. It's worse when the coolant goes into the lubrication system. There is a risk of getting a water hammer or - even worse - a jammed crankshaft.

The second reason is ineffective cooling of the radiator. There are several possible problems here. If the fan is not electric, but is powered by the crankshaft, then it is worth checking the belt tension. If the airflow is electric, then problems should be looked for in the thermostat. Another culprit is the engine radiator. Dirt easily gets into its ribs and it becomes clogged. This can be diagnosed if the temperature returns to normal slightly after parking.

Malfunctions in the thermostat also lead to overheating. Various deposits accumulate in the cooling system, and this leads to deterioration in the performance of the elastic element of the thermostat. It simply no longer records the temperature of the coolant mixture. If it is installed in one position, it will pump the mixture in a large circuit or in a small one. The thermostat also really doesn’t like the effects of our hard water.

How effectively the cooling will work depends on the level of coolant flow that is pumped through the system. Its consumption depends on the crankshaft speed. But it’s summer, it’s hot, it’s a highway. There is a long and serious climb ahead and a KamAZ. It is impossible to overtake him due to oncoming traffic. The internal combustion engine is boiling. And why all? There is no speed, the air flow is weak, the speed is low, cooling has virtually no effect, and the engine operates in hard mode despite the fact that the optimal operating temperature of the VAZ engine is 90 degrees. Everything is here at once.

There are other reasons, but these are the most popular.

Camshaft

The Niva Chevrolet camshaft sensor creates stable engine operation. The work is based on the Hall effect. Thanks to it, the tilt of the gas distribution device is controlled according to the crankshaft. The system that controls the operation of the spark plugs and the flow of gasoline receives a corresponding signal. It works based on monitoring the potential difference of the required electricity, and is associated with the operation of the crankshaft position analyzer. Simply put, it informs the location of the piston of the internal combustion engine cylinder, while all cylinder stroke cycles occur sequentially. If it stops working, the device and indicator turn on, thanks to which a mixture of air and fuel occurs, dosing is suspended and the reserve mode is activated. Replacement is recommended every five years. If it is faulty, the on-board computer will display the following errors, PO343, PO342, PO340.

Operating temperature of 8-valve

The normal operating temperature for eight-valve engines on Kalinas and Grants is exactly 90 ºC. But owners complain that sometimes it has difficulty reaching 80 degrees even in warm weather. The reason lies in the thermostat - it opens fully at a temperature of 85 degrees. Moreover, the permissible deviation from this value is very large - (85±8.3) ºС.

In other words, the run-up is 77..93ºС.

But the fuel mixture can only ignite normally if the engine temperature is about 90 degrees. This is the value stored in the electronic control unit. If the temperature is too low, the mixture becomes richer (the amount of gasoline increases). This is the main problem that occurs when the temperature drops. And in winter the heater works worse.

Your case

Temperature diagram. Normal operating temperature is at 90 on the instrument panel.

In your case, the thermostat is most likely stuck, usually stuck in the middle. In this case, either repairing or replacing the thermostat will help.

A stuck thermostat valve is a typical malfunction of the engine cooling system.

That is, the liquid that has not yet been heated is supplied to the cooling radiator and blown by a strong wind flow. Indeed, with an increase in air temperature, the problem will partly go away. That’s why they used to put cardboard on it and drive like that for years. But we don't recommend doing this.

Solution

The problem of low temperature of the engine cooling system can be eliminated by installing a thermostat that opens at 92ºC. The WAHLER 3091.92D element performs excellently.

You just have to disassemble it and transfer the inside to Kalina’s original thermostat.

There is a downside: in summer the temperature will be higher, and there is a risk of boiling in a traffic jam. To be more precise, this risk is higher when installing a thermostat with a late opening time!

Be sure to use new gaskets and lubricate them with a small amount of sealant - this will prevent coolant leaks.

Possible causes of failure

Before replacing the sensor, you should also check the circuit from it to the warning light. To do this, disconnect the pressure sensor terminal, and then lean it against the engine (to ground). If the circuit is in working condition, the lamp will stop lighting. Otherwise, the network is interrupted or damaged.

An important factor to remember when replacing is its condition.

When you pull out the grant oil pressure sensor, pay attention to whether it is oily or not. If it is oily, it means it is broken and needs to be replaced.

If it is not in oil, it is most likely not the problem.

A pressure gauge will help you determine the condition of the system. Screw it into the DDM cell, turn on the engine and at idle speed the pressure gauge should ideally show 0.65 kgf/cm2. Or even more. This indicates that the problem is only in the sensor.

Lada Granta engine cooling system: malfunctions and methods for eliminating them

The cooling system maintains a certain temperature inside the engine by removing excess heat generated as a result of fuel combustion in the cylinders. During operation, parts can become very hot. Without heat removal, the engine will overheat and collapse.

Elements of the Lada Granta cooling system

On Lada Granta cars with an injector, a closed liquid ODS with forced circulation of antifreeze is used. It removes heat and acts as a lubricant and does not freeze in severe frosts in winter. In a working system, the temperature of the Lada Granta engine is maintained at 95-100 degrees. Regardless of the body type, configuration, or the presence of air conditioning, the cooling system remains the same, without any changes.

Thus, a recall program has started in Russia to return 145 Bentley Continental GT cars. All models were released in 2018-2019. The recall is due to an issue related to insufficient battery voltage, which can cause the center console switch assembly to fail.

The list of VIN numbers of cars that are subject to recall is published on the Rosstandart website. Moreover, each owner will receive an official letter, according to which they need to provide the car to official dealers for repair work.

During the repair process, dealers will update the center panel switch assembly program or replace the assembly. All work will be carried out at the expense of the manufacturer. After the repairs are completed, the cars will be returned to the owners, with the necessary documents completed confirming the fact that the repairs were completed under the car recall program.

Dealers will not need much time to complete repair work, so owners can wait for their cars in the waiting room.

Recently, legendary cars “from the past” have been put up for sale in various parts of the world - well-known sports cars in factory configuration and in perfect condition.

Of course, the question is: how did such legendary cars survive to this day? Because they look as if time and years have passed them by.

Nissan Skyline GT-R Nismo, 1990. Up for auction in America. For this rare car, they are asking relatively little, just some 820,000 rubles. But since this car is up for auction, its price could undoubtedly increase. By the way, this example is for sale in the same form in which it left the assembly line: the 2.6-liter engine is still capable of producing 280 horsepower, and the appearance is not at all spoiled. Only a couple of changes - lowered suspension, a new exhaust pipe and the absence of rear axle steering.

Toyota Supra, 1997 release. By the way, this anniversary version is black, has a removable roof panel and is in exactly the same perfect condition as the previous example. But only its price is also “anniversary” - during the auction it flew up to 11,227,000 rubles! Someone is really in love with this car and wants to buy it. By the way, it is also up for auction in the States.

Buick GNX, 1987 release. And again we are pleased with the decent condition. Inside, you can note that the interior is still wrapped in factory wrap, and the tires are still filled with air from 1987. We can say that there is no mileage at all - 79 kilometers. 3.8-liter turbocharged engine with a power of 300 hp, rich finishing and power accessories. And the price tag is modest - only 4,514,000 rubles. The ad was posted in America.

Porsche 911 Strosek, 1977. The appearance of the car is still from that era - small front optics and streamlined wings have long become the hallmark of this car. As for the area under the hood, it is filled with a luxurious 2.7-liter six-cylinder engine with Strosek additions. The condition of the body is as if the car had just been picked up from the assembly line. Amazing!

Lotus Esprit Turbo, 1983. Compared to the above cars, this “James Bond car” is being auctioned for a relatively small amount - 1,175,000 rubles. The car is in good condition, 2.2 liter engine with a five-speed manual transmission. By the way, this car is one of the limited editions, as only 50 pieces were produced. This example is for sale in Ohio.

ZAZ-968 A, manufactured in 1977. Exhibited not in the states, but here, in Russia. It sells today for a very substantial amount, but it's worth it. According to the seller, this car has been in the garage for about 30 years, so its mileage is low, and the body has never felt any rust.

Bottom line. If you are a connoisseur of iconic cars, and your finances allow you to purchase something similar, then take the time to spend a little time searching for ads on the Internet. Perhaps luck will smile on you and you will find a car in good condition.

The driver and the car have been together for almost 150 years. And during this time, automobile statistics have managed to accumulate interesting facts. Some of them arouse curiosity, while others make you think.

About the number of cars. Automotive companies are actively developing production. This has led to a bit of an oversaturation of cars in the world. Today the indicators are:

- The total number of cars on the planet is about 1 billion.

- Daily vehicle production is at 165,000 units.

- The number of parts to assemble a machine is about 30,000 positions.

From the life of a car. Despite all the love for his car, not every driver has a caring attitude towards his car. Although there are exceptions:

- about 95% of the time the car is in use is parked or in a garage;

- 75 of the 100 Rolls-Royce badged cars produced are still in service;

- the highest mileage by car during its life was recorded at 4,586,063 thousand kilometers;

- in the United States, the average owner spends $8,876 a year on maintaining one vehicle—over 50 years, that’s almost $0.5 million;

- in Turkmenistan from 2008 to 2014, each driver received 120 liters free of charge every month. fuel.

Highly dangerous product. Over time, the car has turned from a comfortable means of transportation into a source of environmental danger. On the roads, in the hands of a careless driver, it is also a source of danger to life and health for passengers and pedestrians. No less interesting facts are revealed here:

- At the beginning of the century, mechanical carriages were more environmentally friendly transport compared to horse-drawn carriages.

- Up to 50 odors of various organic compounds were detected in a new car.

- An American driver spends up to 38 hours in traffic jams throughout the year.

- The first traffic accident with a car was recorded in the US state of Ohio in 1891.

- Currently, the risk of dying in a car accident is estimated at 1:5000.

- About 40% of drivers do not have time to press the brake pedal moments before an accident on the road.

- According to traffic accident statistics in the United States, road accidents are the No. 1 cause of death for young people under 35 years of age.

- In many countries around the world, sounding the horn is permitted only to prevent accidents.

- A seat belt with 3 attachment points was patented by Volvo. Access to the right to use the development was made free of charge. Today, a seat belt saves someone's life every 6 minutes.

Other interesting facts.

-There are more and more cars in the world. In Los Angeles, America, there are already more cars than people. Moreover, they win not only by numbers.

— The fastest production car reached a speed of 431 km/h. It was a Bugatti Veyron with the Super Sport prefix. If you go at this speed to the Moon, it will take only 1 month and 7 days for the entire journey.

Bottom line. The era of fossil fuel cars is coming to an end. Perhaps electric cars will bring their own records and new historical facts.

Checking the radiator for leaks

The diagnostic process is not at all complicated; we carry it out ourselves, and if you don’t have free time, visit a service station to have the work performed by professionals.

Checking the radiator from the engine compartment side

- We place the car within the perimeter of the repair area, on the inspection hole, and open the hood.

- From the engine compartment side, we inspect the surface of the radiator for drips and traces of antifreeze (antifreeze) leakage.

- We carry out similar actions from under the bottom of the car;

- We inspect the antifreeze supply/return lines, upper and lower circuits.

The most common places for depressurization: corners around the perimeter, joints, ties with clamps.

How to drain antifreeze from the cooling system of a Lada Granta

- The hood is open, the car engine has cooled down to a safe temperature so as not to damage the skin.

- We unscrew 6 screws from under the bottom and remove the oil pan protection.

- Unscrew the drain plug in the lower circuit of the radiator.

- At the same time, unscrew the drain plug on the wall of the cylinder block. We substitute the container.

Unscrew the plastic drain plug of the radiator tank

Note to the driver!

- After the liquid is completely drained from the water jacket, screw in the drain plugs. Fill in new antifreeze in a volume of 7.5 liters to about or 8.0 liters to the recommended average level.

Not just overheating...

In addition to overheating, there is also hypothermia. But this does not harm the engine components as much. Often this phenomenon occurs due to low temperature outside the car. In a supercooled unit, the oil thickens and has weak lubricating properties. This is the reason for increased wear. Hypothermia also causes fuel to enter the crankcase. As fuel flows, it washes lubricant off important parts. There is increased wear of the piston and cylinder group. With all this, the engine loses its power.

What temperature sensors are installed on the Lada Granta, where are they located and the price

Now let's see what devices are installed on Russian cars and where they can be found.

- Lada Granta engine coolant temperature sensor is installed in the thermostat cover - 300 rubles;

- detonation device at the front of the cylinder block wall. Between the second and third;

- the device for determining the location of the crankshaft is found in a special opening in the tide of the oil pump cover;

- device for determining phases or camshaft - 2000 rubles;

- air and pressure measuring device;

- lambda probe - 1000 rubles;

- device for calculating mass air flow - 1800 rubles;

- device for determining speed - 310 rubles;

- oil pressure.

Attention! Experienced mechanics do not recommend buying equipment on open markets. It is best to make purchases in specialized stores or service centers.

Catalog items

The serial number for the engine temperature gauge of a vehicle from a domestic manufacturer is 2190-94. It is not being repaired. Experienced mechanics advise checking this device before replacing it. At the service center, the procedure is carried out at special stands. But you can check it at home.

Replacement

To install a new cooling sensor on the LADA 2115 Samara, you need to select a flat area. You will need a tool: open-end and spanner wrenches (19 mm, 13 mm, 10 mm, 8 mm), as well as a large medical syringe 100–250 ml, and a 15–20 cm dropper tube to it. It is recommended to buy the original sensor itself, here its number is 21120–3851010–05. It is easy to replace the DTOZH yourself. The step-by-step process looks like this:

- Allow the engine to cool to at least 40 °C.

- Use a syringe to pump out antifreeze/antifreeze from the expansion tank (so as not to drain the coolant).

- Unscrew the negative terminal of the battery (10–13 mm wrench).

- Disconnect the plug from the air flow sensor.

- Unscrew the air filter housing (8 mm wrench).

- Carefully removes the “pan” and moves it to the right.

- Disconnect the plug from the DTOZH.

- Unscrew the sensor (19 mm spanner).

- Cleaning the landing area.

- We screw in the new DTOZH.

Let's collect everything in reverse chronology. It is not recommended to use sealant, as the copper ring is perfectly crimped, ensuring a tight seal.