Clutch mechanism of a VAZ 2106 car

A device with the simplest design that ensures the engagement of the power plant and gearbox. The mechanism is primitive, which makes its repair and maintenance as accessible as possible for the average motorist.

Description of design

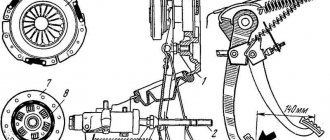

Here are the elements:

- clutch pedal;

- master cylinder;

- pressure main;

- working cylinder;

- clutch fork.

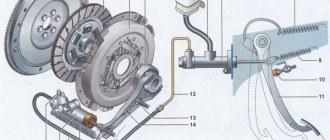

Inside the structure there is a special liquid that ensures the transfer of impulse from the pedal to the fork.

How does the clutch drive work?

- The driver presses the pedal.

- The master cylinder piston, connected by a hinge to the pedal lever, forces fluid through the cylinder, creating excess pressure inside the line.

- The oil passes through the pressure line and enters the working cylinder.

- Next, the piston is pushed out and the clutch fork moves.

- The mechanism comes out of the hook and the motor is disconnected from the gearbox.

The principle of operation is the same for all modifications and versions. Some car enthusiasts install a dry clutch. The actual difference is only in the working element - the classic one contains liquid, the dry one contains a cable.

Clutch failure

Among the most common “diagnoses” of auto mechanics are:

- Breakdown of the head or working cylinder seal. Liquid flows out of the system, causing it to become airy.

- The pressure line is clogged or coked. The problem is a consequence of using counterfeit oil or not replacing it in a timely manner.

- Mechanical damage to the fork or working cylinder. The parts are located at the bottom of the car. Typically, users can damage the mechanism when driving over off-road roads or curbs.

- The easiest problem is the spring stretching or falling out of the mounting groove.

Symptoms of malfunctions

Problems arising from improper clutch adjustment.

- The car jerks. This means that the disc does not move far enough from the basket and that when the drive is pressed, the motor is not completely disconnected from the gearbox.

- The gears don't want to turn on. The symptom that arises in the above problem is similar.

- When you press the gas pedal hard, the car does not respond or accelerates too slowly. Jerking may also occur during steady driving.

- The clutch pedal is falling/too hard and the gears will not engage.

About the selection of clutch master cylinders

If the owner of a “six” starts having problems with the clutch and decides to purchase a new cylinder, then he will inevitably be faced with the question: which cylinder is better to get? The answer is simple: the clutch master cylinder on all VAZ “classics” from VAZ 2101 to VAZ 2107 has undergone virtually no changes. Therefore, on the “six” you can easily install a cylinder from a “penny”, from a “seven” or from a “four”.

Drivers consider the best option to install standard VAZ cylinders on the “six”.

The cylinders on sale are also universal; they fit the entire range of classic VAZ cars. As a rule, car enthusiasts try to install original VAZ cylinders. The problem is that the VAZ “classic” was discontinued a long time ago. And there are fewer spare parts for it every year. This rule also applies to clutch cylinders. As a result, car owners are forced to use products from other manufacturers. Here they are:

- FENOX. This is the most popular manufacturer of spare parts for VAZ “classics” after VAZ. Cylinders from FENOX can be found in almost any major parts store throughout the country. These cylinders are reliable and in constant high demand, despite their somewhat inflated price. If a driver can purchase a standard VAZ cylinder for 450 rubles, then a cylinder from FENOX can cost 550 rubles or more;

- Pilenga. Cylinders from this manufacturer are much less common on store shelves than FENOX products. But with due diligence, you can still find such a cylinder. The price for Pilenga cylinders starts from 500 rubles.

And these are all big ones today. Of course, today there are many other, lesser-known brands on the aftermarket. However, contacting them is strongly discouraged. Especially if their cylinders cost half as much as the above ones. There is a very high probability of buying a fake that will not last very long. In general, clutch cylinders for “classics” are often counterfeited. Moreover, in some cases, fakes are made so skillfully that only a specialist can distinguish them from the original. But for the average car enthusiast, the only criterion for quality is price. You should understand: good things have always been expensive. And clutch cylinders are no exception to this rule.

As for installing cylinders from other cars on a VAZ 2106, such experiments are almost never practiced by car enthusiasts. The reason is obvious: the clutch cylinder from another car is designed for a different hydraulic system. Such a cylinder differs both in size and technical characteristics, the most important of which is the ability to create pressure. The level of pressure created by the “non-original” clutch cylinder may be either too low or, conversely, too high. Neither in the first nor in the second case does this bode well for the hydraulics of the “six”. Thus, the installation of “non-original” cylinders on a VAZ 2106 is an extremely rare occurrence. And this is done only when it is completely impossible to get a normal VAZ cylinder.

Instructions for adjusting the clutch with your own hands on a VAZ 2106

To do this, you need to perform a simple sequence of actions, without the use of highly specialized pullers or clamps. A standard set of tools is pre-prepared:

- flat screwdriver;

- ruler or corner;

- wrenches No. 10, 13, 17;

- clean rags.

The following is what the repair looks like.

- The machine is driven onto an inspection hole or overpass and securely secured with support shoes to prevent rolling away.

- Inside the cabin, behind the clutch pedal there is a travel limiter (marked with the number 1). This element sets the working gap between the pusher and the main hydraulic unit. Pedal loosening is considered normal with fluctuations of 0.5-2 millimeters.

- The second step is to set the working play of the clutch fork pusher (number 2) - the part deviates away from the piston. In this case, the gap is considered normal when its value is 4-5 mm.

Important! The working stroke of the clutch pedal before the unit is engaged should be 25 - 35 mm.

You can also watch the repair procedure in the video.

Tools, accessories, consumables

To perform the operation you will need the following set:

- standard ruler for 25-30 cm;

- wooden or plastic stop;

- pliers;

- set of open-end wrenches No. 10, 13, 17.

You will also need a rag if pumping is carried out, you will need a container for draining the waste and a set of syringes with hoses of a suitable size.

Preparing for self-adjustment

Before getting into the car, you should carefully study the manual and read the theory. Next, the operation is performed like this.

- Warm up the car and drive it onto an inspection pit, overpass or lift.

- Turn off the engine. Secure the vehicle in a stable position to prevent it from moving.

- Prepare in advance the necessary keys, tools and rags for cleaning up dirt.

Repair and replacement of coupling

Hydraulic system repair involves identifying and eliminating the malfunction. Thus, if the working fluid leaks, it is necessary to eliminate the cause of the leak. This could be a worn cuff, a development on the cylinder running surface, or a sludge hose. 2106 hose coupling , respectively. In any case, after repairing the hydraulic clutch

, it is necessary to remove air from it. pumping the system.

The situation with direct coupling repair is more complicated. This type of work involves partial or complete dismantling of the checkpoint, which cannot but affect the duration and complexity of the repair work, so it is better to carry it out with an assistant.

Start work by installing the car on an inspection pit, overpass or on an elevator. After this, to ensure access to the coupling, the following preparatory work is carried out approximately in this order:

- In the cabin, the gear shift lever is disconnected from the gearbox;

- in the luggage compartment from the battery, the terminals are removed, the starter mounting bolts are loosened.

Also, if the car is on a lift. he rises. Then, in order:

- the terminals from the backup sensor are disconnected;

- from the resonator. exhaust pipe;

- from the gearbox housing. clutch control cylinder;

- the driveshaft, traverse and starter are dismantled;

- The clutch cover and mount bolts on the gearbox are loose.

Preparations for removing the gearbox are complete, and after that there are two options: remove the gearbox completely (which is more labor-intensive) or simply move it to a distance that allows you to unscrew the bolts securing the clutch basket to the flywheel. I must say that if the need to replace the clutch fork or release bearing of the VAZ 2106 is not available, then the option of incompletely disassembling the gearbox is quite suitable. In this case, the box will rest on the receiving tube after the change.

After this, after unscrewing the bolts, the basket is moved away from the flywheel, the clutch drive disc is removed, and after moving the basket towards the engine again, it can be removed from the input shaft of the gearbox. By removing the basket, in addition to inspecting the drive disk for faults, you can check the condition of the release bearing and clutch fork. More details about replacing the VAZ 2106 clutch can be found by watching the video on the Internet.

Reassemble in reverse order. When installing a driven drive, it is important not to make mistakes. its protruding side relates to the gearbox. Before screwing in the basket bolts, a mandrel is used as a guide, which facilitates the centering of the clutch elements, which is the end of the gearbox input shaft.

After assembly is complete, if the repair does not affect the hydraulic clutch system, you only need to adjust the free movement of the clutch slave cylinder pusher. Finally, we can say that when replacing a VAZ 2106 clutch during its service period, the price of the product will be affected, which in most cases indicates quality.

Setting up the VAZ 2106 clutch

You can check whether the clutch position on a VAZ 2106 is set correctly in this way.

- Place the car in neutral and warm up the engine to operating temperature. With the engine running, without touching the accelerator lever, turn on the “R” position. The response to the action should be a smooth movement of the lever without extraneous sounds or excessive force.

- During the operation of the car, all gearbox positions work clearly, there are no crashes, squeaks, or crunches.

- During sharp acceleration, the increase in engine speed is proportional to the acceleration. If the clutch disc slips, the engine starts to spin up without a manual transmission.

If any malfunctions or malfunctions are detected, it is necessary to perform more detailed diagnostics of the unit. You may need to replace the disk or repair the basket.

Clutch replacement

Please note that it is imperative to install new clutch basket mounting bolts. On old ones, the threads already have minor deformations, therefore, the connection will be very unreliable. The price of all elements will be approximately 2000-2500 rubles.

If you prefer foreign-made units, it will be more expensive. However, it is worth wondering about a simple truth: the service life of imported ones is sometimes shorter than domestic ones, and the price can be twice as high. Why pay extra money? And in general, if the price of a car is 20-40 thousand rubles, why invest a lot of money in it?

But let's return to the replacement procedure. Unscrew all the bolts from the basket, remove it and the clutch driven disc. Install new elements in the same way, but tighten the bolts, do not tighten them. It is advisable to look at the condition of the crown before installation. If it is deplorable, then you should immediately install a new one.

In stores, its price is about 200-250 rubles, which is not very expensive. But you can reduce the cost of repairs by simply removing the crown, heating it and installing it on the reverse side. But you will have to buy a new one if this procedure was previously performed.

Pay attention to the VAZ 2106 clutch fork; if it is damaged, be sure to replace it. A new release bearing is installed in any case. You can apply CV joint grease to it, for example. This can slightly increase its resource.

Almost finished, all that remains is to take the guide sleeve and install it in the hole of the clutch disc. Without removing the shaft, tighten all the basket mounting bolts crosswise. Do not allow distortions, otherwise the clutch will not work correctly and its service life will decrease.

That's all, the clutch replacement was completed successfully, now all that remains is to assemble the car. But here no difficulties will arise, since all the actions are the opposite of those that were described in detail in this article. If you also need to replace the brake fluid in the drive system, then read on.

How to properly bleed the clutch on a VAZ-2106

The sequence of the operation is as follows.

- Drive the car into a pit or put it on trestles. Securely secure the car.

- Clean the expansion tank and bleeder fitting from dirt. The latter is located on the working cylinder.

- Open the RB cover.

- Check that the fitting can be unscrewed and put a pre-prepared hose on it. Place the other end of the tube into the waste container.

- The assistant sits behind the wheel and pumps up the pressure 4-5 times by pumping the pedal. At the end you need to pinch and hold it.

- Next, the shut-off fitting is unscrewed and the liquid, along with the air, goes into a container for draining the waste. At the same time, you need to monitor the oil level in the RB and add it if necessary.

- When the bubbles are completely released, the fitting closes.

- To eliminate any remaining air in the line, it is recommended to repeat the operation 2-3 times.

Adjusting the pusher on the working cylinder

The clutch adjustment of the VAZ-2106 is carried out in the following order:

- Clean all elements from corrosion and dirt. Treat threaded connections with penetrating lubricant.

- Unscrew the nut located on the working cylinder pusher.

- Use one wrench to hold the bolt for adjustment, and use the other to loosen the locknut.

- Secure the pusher so that it cannot turn.

- Adjust the free play empirically and tighten the locknut.

- Reinstall the spring.

Check the operation of the entire clutch system, measure the free play of all elements. If it is larger than expected and there are gaps, you need to repeat the adjustment.

We change the clutch with our own hands without removing the transmission

- Place the machine on a viewing hole or a lift and securely secure it to prevent it from rolling away.

- Disconnect the cardan and slave cylinder from the gearbox.

- Remove the protective cover of the mechanism and the traverse.

- Unscrew the box cushion.

- Using your hands or using a lever, push the gearbox housing away from the power unit until it stops. For insurance, you can install a support under the box.

- Next, you will need to unscrew the 6 bolts securing the basket from the flywheel.

- The box basket needs to be moved all the way and the clutch disc pulled out through the resulting gap.

- Similarly, slide the basket back and remove it.

- The last step is to dismantle the release fork and remove the bearing of the same name from the gearbox input shaft.

- Installation of new parts is carried out in reverse order.

Work under the car

This is perhaps the most difficult part of the entire repair, since there are many more steps to be taken here. So make yourself comfortable and proceed to the following operations:

- Unscrew the last (lower) nut securing the starter and remove it. This nut is the nastiest, since it is difficult to get to it using simple wrenches; you will need to use a socket, a ratchet and a cardan. True, it was possible to work with an ordinary open-end wrench installed in the end.

- Unscrew the suspension bearing mount.

- Disconnect the cardan and rear axle flange. Hold the bolt head from turning with a 12mm open end wrench.

- Apply sharp blows to the driveshaft to dislodge it from the rubber coupling on the transmission shaft. Move the cardan to the side.

- Unscrew the mounting of the pillow, install a support under the gearbox.

- Remove the slave cylinder from the clutch fork. Be careful not to lose the bar underneath and the spring.

- Remove the speedometer cable.

- That's all, now all that remains is to unscrew the four bolts that secure the box to the engine block.

Remove the gearbox carefully, try to move it as far as possible from the engine block. The fact is that you can damage the VAZ 2106 clutch drive disc. And this is quite easy to do.

If we take nines and newer VAZs as an example, then the clutch drive discs on them are more reliable and durable. It is advisable to set the gearshift lever to the position corresponding to the third speed.

Pro Tips

Experienced auto mechanics recommend following the advice.

- When pumping, only high-quality fluid should be used.

- Operations related to the clutch must only be carried out cleanly. Dirt entry is unacceptable.

- It is recommended to check the clutch settings every 3-4 months of active use. The maximum permissible deviation from the working position is 10% of the range width.

Specialization : Graduated from the State Automobile University, worked for 20 years at GAZ-56, now I drive a Zhiguli.

Source

When is clutch adjustment necessary?

It is not difficult to understand that the mechanism needs to be adjusted. The machine itself will tell you this. The following factors are clear signs of disorder of the unit.

- Pedal dips - when you press, you feel your foot drop to a certain level.

- Loss of elasticity under pressure.

- The car begins to move at the beginning or end of the pedal stroke.

- Loose lever or complete lack of working play.

- Difficulty shifting gears.

- Slipping of the clutch disc during acceleration and braking of the car.

Other deviations in the normal operation of the gearbox unit and unit are also acceptable.

Clutch adjustment options

If it is necessary to adjust the mechanism, the machine begins to behave inappropriately. The pedal sinks, changing gears becomes more difficult, jerking and jerking appear.

There are factory recommendations that establish strict tolerances for backlash.

What pedal stroke is considered normal?

In the correct position and in fully working order, the movement of the pedal until the mechanism disengages is 2.5-3.5 centimeters. The reference standard is established by the manufacturer and is considered a recommendation value.

Some car enthusiasts reconfigure the system to suit themselves, adjusting it within the range of 45-55 mm.

How to measure your car's pedal travel

Experienced craftsmen recommend measuring the stroke like this.

- A ruler is applied to the pedal at an angle of 90 degrees.

- Next, note the pedal height in centimeters.

- Press the lever until it stops.

- Make a mark on the ruler.

Measure the difference in values; normally, free play is limited to 25-35 mm.

Frequency of setting

There is no strictly established time interval for servicing the mechanism. The manufacturer insists that clutch adjustment is mandatory after performing any repair and service work related directly or indirectly to the device.

Eg:

- replacing the clutch disc/basket;

- pumping of highways;

- installation of new cylinders.

Replacement of electrical wiring of VAZ 2104

If there is a failure in the power supply to electrical equipment, you should first check the integrity of the electrical circuit. To do this you need:

- De-energize the area being tested by disconnecting the negative terminal of the battery or the corresponding fuse.

- Connect the contacts of the multimeter to the ends of the problem section of the circuit, and one of the probes to ground.

- If there are no readings on the multimeter display, there is a break in the circuit.

- The wiring is replaced with a new one.

Selection of wires and replacement of wiring is carried out according to the VAZ 2104 power supply diagram. In this case, standard components or components from another model with suitable characteristics are used.

Video: replacing wiring, fuses and relays of classic VAZ models

To replace the wiring, the front part of the cabin is disassembled. Wires of insufficient length are extended, and connections are soldered and insulated.

Video: replacing electrical wiring in the cabin and under the hood

It is almost impossible to completely replace the electrical wiring of a VAZ 2104 with your own hands. If such a situation arises, it is better to contact a car service.

How to center a clutch disc without an input shaft

A little about clutch disc alignment. And a popular myth:

If you do not center the disc, the clutch will “beat”. Is it true.

If you do not center the disk, you will not be able to install the gearbox in place, because the centers of the holes in the basket, disk, seat on the flywheel must coincide, otherwise the shaft will not go all the way.

In general, there are 2 official methods for centering a disk.

1) Centering the disk on the seat of the input shaft.

This method is routinely used in service centers for opulent cars, incl. and Lanos. A mandrel according to the dimensions of the input shaft is used. For Lanos like this

2) Centering the disc on the basket.

This type of tool is used

There are many unofficial methods - using a shovel handle, a finger, other parts of the body and any other crap that comes to hand.

But I will describe 2, which are very simple, do not require investment, and can be made from scrap materials in 5 minutes

1 Method. Bolt and blue electrical tape.

In general, blue electrical tape is a unique thing. She can repair anything. And not only to repair.

We will need an M10 bolt or a 10 or 11 mm drill. — a roll of blue electrical tape First, wrap a certain amount of electrical tape around the end (of the bolt) and try it on so that it (the end of the bolt) fits into the seat of the input shaft on the flywheel with a slight interference. Then, we measure the distance at which the clutch disc will be located and wrap the required amount of electrical tape so that the disc can fit with a slight interference fit. Those. we get an analogue of the device from the official 1st method.