December 29, 2014 Lada.Online 662 394 78

In the event of malfunctions in the operation of the vehicle, the engine electronic control unit (ECU) stores errors in memory. In the future, Kalina ECU errors can be read using an on-board computer or special equipment for car diagnostics. In addition to controller error codes, it is possible to perform Kalina self-diagnosis on the dashboard.

Advice

: To read errors in electronic units, car owners often use the ELM327 adapter (buy on Ali) and the OpenDiag application in their smartphone.

VAZ (LADA) errors via OBDI protocol. Self-diagnosis.

1 — Malfunction of the engine control unit.

2 — The voltage in the on-board network is too high.

3 — Malfunction in the electrical circuit of the fuel level sensor.

4 — Malfunction in the electrical circuit of the antifreeze controller.

5 — Error in external temperature controller.

6 — Overheating of the engine (power unit)

7 — Emergency oil pressure in the engine.

8 — The voltage in the vehicle's electrical network is too low.

9 — Low battery level (battery is discharged)

12 — Malfunction in the electrical circuit of the malfunction indicator located on the instrument panel.

13 — No data (loss of communication) from the oxygen sensor (lambda probe)

14 — High signal level of the coolant temperature sensor (antifreeze).

15 — Malfunction in the electrical circuit of the coolant temperature controller.

16 — Increased voltage in the vehicle’s electrical network

17 — Low voltage in the on-board network

19 — Malfunction in the electrical circuit of the crankshaft position sensor.

21 — Malfunction in the throttle position regulator.

22 — Low signal level of the throttle position sensor

23 — High signal level of the intake air temperature sensor

24 — Malfunction in the electrical circuit of the vehicle speed sensor.

25 — Low signal level of the intake air temperature sensor

27 — Incorrect signal from the exhaust gas system sensor

28 — Incorrect signal from the exhaust gas system sensor

33 — Malfunction in the electrical circuit of the air flow meter

34 — Malfunction in the electrical circuit of the air flow meter

35 — The ECU has detected a deviation in idle speed

41 — Incorrect signal coming from the phase regulator

42 — Malfunction in the electrical circuit of the electronic ignition system

43 — Incorrect signal coming from the knock sensor

44 — The mixture in the engine cylinders is too lean or rich

45 — The mixture in the engine cylinders is too lean or rich

49 — Vacuum leak

51 — Malfunction of one of the memory modules of the control unit - RAM or PROM

52 — Malfunction of one of the memory modules of the control unit - RAM or PROM

53 — Incorrect signal coming from the exhaust gas sensor

54 — No signal from the octane corrector regulator

55 — Poor air-fuel mixture at low load on the car engine

61 — Malfunction in the electrical circuit of the oxygen sensor (lambda probe)

E - Determining an error in a data packet stored in EEPROM

Diagnostics

If you notice that something is wrong with the operation of the Lada Kalina vehicle, then it makes sense to diagnose the car. As a rule, all breakdowns appear immediately after checking the car. You can ask for help in carrying out diagnostics at a service station, where you will pay a certain amount for this service, or you can do everything yourself. Of course, with the help of special equipment there is a greater chance of identifying a malfunction, since when checking independently there is a possibility of obtaining inaccurate data.

So, let's start diagnosing the car ourselves. For this:

- Turn off the ignition.

- Press and hold the daily mileage reset button.

- While holding the button, turn the key in the ignition.

- Having done this, all sensor indicators on the dashboard will light up, and the arrows of the tachometer, speedometer, antifreeze temperature sensor and gasoline level in the fuel tank will move on a scale from zero to maximum. Next, press the button located on the steering column wiper switch. This way you can switch the data on the instrument panel screen. On the first one you can see the process of checking the functionality of the instrument panel. The second will show the version of the software installed in the car, and the third will show combinations of faults.

To check your car for breakdowns, hold down the daily mileage button and hold it while turning on the ignition key. At this time, all arrows will go from zero to maximum.

Then press the button located on the steering column wiper switch. This is done in order to switch the data mode on the instrument panel screen.

To read combinations of faults in a car, you will need the last screen. It will display clear codes. To obtain four-digit combinations of faults, use special equipment or the services of specialists at a service station.

VAZ (LADA) errors via OBDII protocol

Fuel system and air supply

P0000-P0099, P0100-P0199, P0200-P0299

P0030 - Malfunction in the electrical circuit of the oxygen sensor heater

P0031 - Oxygen Sensor Heater Circuit Low Voltage

P0032 - Oxygen Sensor Heater Circuit High Voltage

P0100 - Malfunction in the electrical circuit of the mass air flow sensor (MAF)

P0101 - Incorrect operation of the mass air flow sensor (MAF)

P0102 - Low signal level of the mass air flow sensor (MAF)

P0103 - High signal level of the mass air flow sensor (MAF)

P0112 - Intake air temperature sensor signal low

P0113 - Intake air temperature sensor signal high

P0114 - Insufficient contact of the electrical circuit of the intake air temperature sensor

P0115 - Malfunction in the electrical circuit of the coolant temperature sensor

P0116 - Incorrect operation of the coolant temperature sensor

P0117 - Low signal level from the coolant temperature sensor

P0118 - High signal level from the coolant temperature sensor

P0119 - Insufficient contact of the electrical circuit of the coolant temperature sensor

P0120 - Malfunction in the electrical circuit of the throttle position sensor

P0121 - Incorrect operation of the throttle position sensor

P0122 - Low signal level from the throttle position sensor

P0123 - High signal level from the throttle position sensor

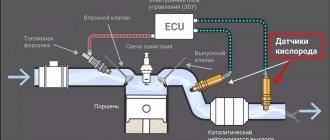

P0130 - Malfunction in the electrical circuit of the oxygen sensor

P0131 - Oxygen sensor voltage low

P0132 - Oxygen Sensor Voltage High

P0133 - Low speed oxygen sensor

P0134 - No response from oxygen sensor

P0135 - Heated Oxygen Sensor Circuit Malfunction

P0171/171 – Air/fuel mixture too lean

P0201 - Malfunction in the electrical circuit of injector 1

P0202 - Malfunction in the electrical circuit of injector 2

P0203 - Malfunction in the electrical circuit of injector 3

P0204 - Malfunction in the electrical circuit of injector 4

P0222 - Throttle Position Sensor 2 Low

Ignition system

P0300-P0399

P0300/300 – Multiple misfires (ignition)

P0301 / 301 - Misfire (ignition) in cylinder No. 1

P0302 / 302 - Misfire (ignition) in cylinder No. 2

P0303 / 303 - Misfire (ignition) in cylinder No. 3

P0304 / 304 - Misfire (ignition) in cylinder No. 4

P0326 - Incorrect operation of the knock sensor

P0327/327 – Knock sensor signal low

P0328/328 – Knock sensor signal high

P0335 / 335 - Malfunction in the crankshaft position sensor electrical circuit

P0336 - Incorrect operation of the crankshaft position sensor

P0337 - Low signal level from the crankshaft position sensor

P0338 - High signal level from the crankshaft position sensor

P0343/343 – Camshaft Position Sensor High Signal

P0351 - Malfunction in the electrical circuit of the ignition coil "A"

P0352 - Malfunction in the electrical circuit of the ignition coil "B"

P0363 - Misfire (ignition) - lack of fuel supply

Emission control

P0400-P0499

P0422 / 422 - Low catalyst performance

P0441/441 - Evaporative Emission System - Flow Incorrect

P0442 - Evaporative Emission System - Minor Leak

P0443 - Malfunction in the electrical circuit of the evaporative emission solenoid valve

P0444 - Evaporative Emission Solenoid Valve Circuit Open

P0480 - Malfunction in the electrical circuit of the engine cooling fan

P0485 - Malfunction in the electrical circuit of the engine cooling fan

Speed and idle control

P0500-P0599

P0500 - Malfunction in the electrical circuit of the vehicle speed sensor

P0501/501 – Vehicle Speed Sensor Malfunction

P0504 / 504 - Incorrect brake pedal position sensor signal

P0505 - Malfunction in the idle speed control system

P0506 - Engine idle speed below acceptable values

P0507 - Engine idle speed is higher than permissible values

P0511 - Idle Air Bypass Control Circuit Malfunction

P0560 - System voltage (on-board network) - malfunction

P0562 - Low voltage in the system (on-board network)

P0563 - High voltage in the system (on-board network)

Electronic control unit (ECU) and its subsystems

P0600-P0699

P0601 - Electronic Engine Control Module - Memory Checksum Error

P0603/603 – Engine control module external RAM module error

P0615 - Starter relay circuit malfunction

P0628 - Fuel Pump Control - Low Signal

P0650 - Malfunction indicator circuit malfunction

Transmission

P0700-P0799, P0800-P0899, P0900-P0999

P0830 / 830 - Malfunction in the electrical circuit of the clutch pedal position sensor

Other errors

P1135 - Malfunction in the electrical circuit of the oxygen sensor heater

P1140 - Measured engine load differs from calculated load

P1141 - Malfunction in the electrical circuit of the oxygen sensor heater installed after the converter

P1301 - Cylinder 1 - Converter critical misfire detected

P1302 - Cylinder 2 - Converter critical misfire detected

P1303 - Cylinder 3 - Converter critical misfire detected

P1304 - Cylinder 4 - Converter critical misfire detected

P1335 - Throttle Actuator Control Monitoring - Position Out of Range

P1336 - Controller type does not match standard

P1425 - Malfunction in the electrical circuit of the canister purge control valve

P1426 - Malfunction in the electrical circuit of the canister purge valve

P1513 - Malfunction in the electrical circuit of the idle speed sensor

P1514 - Malfunction in the electrical circuit of the idle speed sensor

P1541 - Fuel pump relay control circuit malfunction

P1545 - Throttle position is out of operating range

P1570 - Immobilizer control circuit malfunction

P1578 - Invalidity of throttle valve relearning results

P1600 - No communication with immobilizer

P1602 - Interruption of on-board network voltage

P1603 - Malfunction of the internal microprocessor memory module

P1612 - Electronic control unit processor memory reset error

P1617 - High signal level from rough road sensor

P1620 - Incorrect operation of the internal memory module of the control unit

P1621 - Incorrect operation of the control unit RAM module

P2020 - Incorrect operation of the drive position sensor of the intake manifold geometry changing system

P2122 - Low signal level from the gas pedal position sensor

P2127 - Low signal level from the gas pedal position sensor

P2135 - Accelerator Pedal Position Sensor - Voltage Correlation

P2138 - Accelerator pedal sensor voltage correlation

P2187 - Air/fuel mixture too lean at idle

P2188 - Air/fuel mixture too rich at idle

P2302 - Malfunction in the electrical circuit of the ignition coil "A"

P2305 - Malfunction in the electrical circuit of the ignition coil "B"

How to check errors on Niva

You will need to connect a special scanner to OBD2. The device reads all the codes and displays them on the display. If you don’t have access to such equipment, you can use the self-diagnosis mode. It's done like this.

- Turn off the ignition.

- Open the fuse box cover at the driver's left knee.

- Find the diagnostic block and close the two outermost contacts of the top row.

- Next you need to turn on the ignition.

- After this, the check engine light will flicker on the instrument panel.

- The number of indicator blinks will help you read the code.

DTC Engine or automatic transmission error P1141

On our resource you can ask questions and share your own experience in troubleshooting problems associated with error P1141. By asking a question within a few days you will be able to find the answer.

Taking into account the fact that OBD2 errors in the operation of the engine or other electronic systems of the car do not always directly indicate a non-functioning element, and the fact that for different brands and models of cars the same error can arise as a result of a malfunction of completely different elements of the electronic system, we have created this algorithm for assistance and exchange of useful information.

We hope, with your help, to form a cause-and-effect relationship for the occurrence of a particular OBD2 error in a specific car (make and model). As experience has shown, if we consider a specific make and model of a car, then in the vast majority of cases the cause of the error is the same.

If the error indicates incorrect parameters (high or low values) of any of the sensors or analyzers, then most likely this element is working, and the problem must be looked for, so to speak, “upstream”, in the elements whose operation is analyzed by the sensor or probe.

If the error indicates a constantly open or closed valve, then you need to approach the issue wisely, and not thoughtlessly change this element. There may be several reasons: the valve is clogged, the valve is jammed, the valve receives an incorrect signal from other faulty components.

Errors in the operation of the OBD2 engine and other vehicle systems (ELM327) do not always directly indicate a non-functioning element. The error itself is indirect evidence of a malfunction in the system, in a sense a hint, and only in rare cases a direct indication of a faulty element, sensor or part. Errors (error codes) received from a device or scanner require correct interpretation of the information, so as not to waste time and money on replacing working elements of the car. The problem often lies much deeper than it seems at first glance. This is due to the fact that information messages contain, as mentioned above, indirect information about the disruption of the system.

Here are a couple of general examples. If the error indicates incorrect parameters (high or low values) of any of the sensors or analyzers, then most likely this element is working, since it analyzes (produces certain parameters or values), and the problem must be looked for “upstream”, so to speak, in elements whose operation is analyzed by a sensor or probe.

If the error indicates a constantly open or closed valve, then you need to approach the issue wisely, and not thoughtlessly change this element. There may be several reasons: the valve is clogged, the valve is jammed, the valve receives an incorrect signal from other faulty components.

Another point that I would like to note is the specifics of a particular brand and model. Therefore, if you recognize an error in the operation of the engine or other system of your car, do not rush to make hasty decisions, but approach the issue comprehensively.

Our forum was created for all users, from simple car enthusiasts to professional auto electricians. A drop from each will be useful to everyone.

Source

Fixing breakdowns

After the diagnostic procedure, and determining why the VAZ Kalina 8 valves are capricious, it is necessary to completely check the entire line of the unit, which is indicated by the decoding of the index. This must be done by testing the main line and replacing the blocks with known good ones. Additionally, the specifics of operation should be taken into account - due to constant shaking on broken roads, the standard terminals can become loose, which provokes a breakdown in contact. In this case, the computer will also indicate the presence of a malfunction. In order to prevent this, experienced craftsmen recommend treating connectors with special impregnations that repel water and carry out preventive maintenance in a timely manner.

Diagnosing Lada Kalina errors requires the necessary equipment and knowledge of how to decipher the indices generated by the program. In the absence of proper experience, information can be misinterpreted, which will lead to unnecessary procedures and waste of time. If necessary, you can contact a qualified specialist, but the services of service station masters are not cheap.

Source

Checking with a plug-in tester

More accurate and comprehensive diagnostics can be performed using a connected computer or a special tester. However, the data displayed on the screen is alphanumeric. The letters have the following meaning:

In addition, the number 0 means OBD code 2, numbers 1 and 2 indicate the enterprise code, and 3 is the backup password.

Basic ignition system

(the letter P precedes the digital designation):

Fuel-air system

(the letter P is located before the numbers):

In principle, diagnostics using BC makes it possible to identify the main faults. Basic error codes for Priora 8 and 16 valves using a plug-in tester provide significantly more information. To understand it, you should study the decoding of indicators, which is not so difficult.

Modern Lada model

Like any modern foreign car, the Lada Priora has many different sensors installed. The condition of important vehicle systems depends on their correct operation. The problem is that if some sensors fail, the Priora can continue to move. Faults of this kind can lead to increased fuel consumption, unstable engine operation, and increased wear of parts, but the car will drive, and you will only find out about the fault when it means you have to make expensive repairs.

In order not to go into the engine compartment with a multimeter, the Priora has a controller that allows you to check faults using a special tester, a plug-in or built-in on-board computer. In order to diagnose the systems, just press 2 buttons and look at the error codes.

Replacing the device

Technical properties of the sensor:

Checking the ADC pulse of the VAZ rough road sensor can be carried out using the DST-2M device or its analogues. The BSMW indicator is analyzed and diagnosed in the form of acceleration configuration g. If the sensor is subjected to a slight impact with a click or knock, then there is a change in acceleration values with a different spectrum, from instantaneous to small values. In principle, this device is very sensitive, changes are observed even by the body's rocking.

Error codes for VAZ rough road sensor:

To dismantle the Priora rough road sensor you will need a Phillips head screwdriver:

Self-diagnosis of the instrument cluster Kalina/Priora

Decoding error codes in the dashboard:

How to reset errors on Kalina? You can reset the errors yourself using the on-board computer, or contact a service station with special diagnostic equipment.

Let us remind you that you can find detailed photo reports in the Lada Kalina repair category.

Keywords: instrument panel Lada Kalina | dashboard of Lada Priora | on-board computer Lada Kalina | on-board computer Lada Priora | Lada Kalina engine | Lada Priora engine | ECM Lada Kalina | ECM Lada Priora

Found an error? Select it and press Ctrl Enter..

"Bipek Auto - Asia Auto" is the largest LADA dealer in Russia

Replacement

Installing a new sensor is not a difficult job. To carry it out you will need a minimum of tools, as well as a little time:

Thus, work to replace the sensor is carried out on Lada Kalina and Lada Priora. On machines of other brands and models, this work may be performed differently.

Manufacturers

. If you have a foreign car, then it is better to purchase an original sensor from official suppliers. Even the most expensive models will cost relatively little. You shouldn’t save money and buy a Chinese “pig in a poke”; no one will guarantee the service life of the part.

Several of our companies produce DND for domestic production. The most famous are Kaluga sensors and those produced in Zelenograd. Connoisseurs of German quality can purchase a device manufactured by BOSCH.

Checking using a connected computer or tester

Driver Information Panel

Checking system malfunctions using connected devices gives more accurate results, but at the same time requires deciphering special codes. For example, the monitor displays code p0441 or p0130 or error p0422. Oh, these car manufacturers, in human language they could write “replace the oxygen sensor” instead of P0130 or “check the canister valve” instead of P0441. But nothing can be done, the Lada Priora is also intended for export, so it is easier to write p0441 in the program than to give explanations in Russian, Kazakh, Arabic, Armenian and 10 other languages. And then attach special tables that indicate the meaning of certain codes. Just look at them and everything will become clear. But these tables are not included with the operating instructions. Either way, you can check them out below.

All fault codes for Lada Priora car systems consist of 5 characters. Here is a breakdown of Prior's errors.

The Latin letter comes first:

The system indicates an error

The next digit indicates the system in which the malfunction was found:

The last 2 digits indicate the serial number of the fault.