TPS is a critical component in the intake tract of the Chevrolet Niva engine. The throttle valve itself is controlled by the gas pedal (DZ control pedal). The purpose of the throttle position sensor is clear from its name.

A properly functioning throttle position sensor ensures that the fuel-air mixture is obtained in the concentration required for uniform and economical operation of the engine in all modes. The device is mounted on the throttle body.

Attention! An idle speed sensor (a cylindrical elongated part, rather difficult to access) is also mounted on the DZ housing. Don't get confused!

general information

The throttle valve is an important component of the fuel supply system to the cylinders of a vehicle engine. It regulates the volume of supplied air when creating a combustible mixture and is responsible for maintaining the optimal proportion of gasoline and oxygen for ignition.

According to its design features, the TPS is a kind of valve that regulates the level of air pressure in the fuel system when opening and closing. In the open position, the pressure increases to atmospheric pressure, and in the closed position it approaches a vacuum state. The throttle position sensor consists of two passive elements, one of which is constant and the second is variable, the total resistance of which is 8 kOhm. A constant voltage is supplied to one of the resistor outputs, and the second is connected to ground. Thus, by changing the voltage value, a signal is transmitted about the current location of the throttle valve at a specific moment in time and the position of the throttle valve is controlled.

Removing the knock sensor

The knock sensor (DS) is mounted on the front upper part of the cylinder block.

The piezoceramic sensing element of the sensor generates an AC voltage signal, the amplitude and frequency of which corresponds to the vibration parameters of the engine.

When detonation occurs, the amplitude of vibrations of a certain frequency increases.

At the same time, to dampen detonation, the controller adjusts the ignition timing.

We remove the generator.

With the ignition off, disconnect the sensor connector.

Using a 13mm spanner, unscrew the bolt securing the sensor to the cylinder block and remove the sensor. In photos 1–3, the exhaust pipe and air filter housing have been removed for clarity.

Before installing the sensor, clean the surface of its contact on the cylinder block

Install the sensor in reverse order. The tightening torque of the sensor mounting bolt is 20–25 Nm.

Removing the oxygen sensor

We carry out the work on an inspection ditch or a lift.

Disconnect the oxygen sensor connector.

Using a 22 key, unscrew the sensor and remove it

When installing the sensor, do not allow grease or dirt to get on the slotted tip of the sensor and on the wiring harness connector.

We tighten the sensor with a torque of 30–45 Nm.

Varieties

Depending on the design features, there are two types of throttle sensors: mechanically or electrically driven. The first option is used in cars of the cheap price segment, and the second - in more expensive models. It is worth noting that the TPS is a separate unit of the fuel system, which consists of the following elements: - housing; — throttle valve; — sensor; — idle speed regulator.

The throttle body is integrated into the vehicle's ventilation system, which also includes pipes through which fuel vapors are captured. The idle speed regulator is an electronic element responsible for adjusting the crankshaft speed in idle mode when the power unit is started. These parts supply air to the fuel system, which is necessary to create a combustible mixture.

It is worth noting that many automobile manufacturers are gradually moving away from mechanical-type TPS, each year giving preference to electrically driven elements. The main difference between these parts is the presence of an electronic control system that controls the amount of torque in various engine operating modes. The use of electronically controlled sensors allows not only to increase the efficiency of using the power of the power unit and increase the dynamic characteristics of the car, but also to significantly reduce gasoline consumption.

Signs of sensor failure

The operation of a vehicle is associated with a high level of wear and tear on all parts and assemblies, as a result of which each element, sooner or later, becomes unusable. The TPS is no exception and, on the contrary, breaks down much more often than other parts, since its operation takes place under conditions of extreme temperatures.

If the sensor fails, it is necessary to eliminate the malfunction in a timely manner, however, to do this, you need to have knowledge of the signs that accompany the malfunction. The main one among them is the stability of the power unit in idle mode. If it is accompanied by a sharp drop or increase in torque, then this indicates that there are clearly some problems with the electronic element responsible for the operation of the throttle valve. Another indicator of TPS failure is a constantly stalling engine when the gas pedal is released. The need to replace the device may also be indicated by a drop in the dynamic characteristics of the car, which will already pick up speed or there will be no effect at all from pressing the gas pedal. Very often the crankshaft does not drop speed below one and a half thousand per minute at idle. This is only a small part of all the possible symptoms of a unit failure, however, they are all united by unstable engine operation. Therefore, if you are faced with a problem when your car’s engine begins to behave extremely suspiciously, troubleshooting should begin with the throttle sensor. It is worth noting that the failure of this unit is accompanied by identical symptoms in almost all VAZ car models, so diagnosing the malfunction will not be difficult.

Phase sensor - DF

It's also a camshaft sensor. The VAZ phase sensor is designed to determine the angular position of the camshaft. The main function is that when the engine is running, the phase sensor provides a pulse signal to the controller synchronizing fuel injection with the opening of the intake valves. Failure of the phase sensor switches the fuel supply to pairwise-parallel mode, which leads to a slight (up to 10%) increase in fuel consumption. And I’ll also add this “miracle of nature” is a headache and a source of a lot of errors, for example the famous 0301, 0302.... In my humble opinion, this is the same disgusting and abomination as the old-style hydraulic compensators. But what has grown has grown. (How to get rid of it forever, lambda, roll sensor - will be written in the article about chiptuning). The only normal manufacturer of this sensor is Avtovazagregat. The logo is visible in the photo.

Fault diagnosis

If you encounter one of the above problems, then you need to check the throttle sensor for functionality. This is very easy to do, so there is no need to contact a car service center for help. All you need for this is a multimeter. If, when you turn on the ignition system, the engine malfunction indicator lights up on the measuring device, then the problem most likely lies in the TPS.

Next, open the hood and use a multimeter to check for the presence of a minus. To do this, we find ground in the compartment of wires of the car's power supply system and connect the measuring device. If it shows that power is supplied to the sensor, then the reason is its failure.

After this, turn off the throttle sensor and check for openness at the contacts of the electronic element. If the sensor is working properly, then during the movement of the damper the voltage will change to the value of the battery voltage. If no changes are observed, then there is a high probability of failure of the variable resistor.

TPS adjustment

If, during the diagnostic process, unstable engine operation caused by a malfunction of the throttle sensor was detected, then it is necessary to adjust this electronic element. The first step is to disconnect the pipe through which the air is supplied. After this, you should wash it with strong solvents, such as gasoline or alcohol. To remove stains better, it is recommended to use a piece of thick fabric. Once the pipe is finished, a similar procedure must be done with the intake manifold and throttle valve. When cleaning is complete, inspect all elements for possible mechanical damage.

If everything is in order with the damper, then you can proceed directly to the adjustment itself. First of all, loosen the fixing screws. To do this, we sharply lift them and sharply release them. When they loosen, you will hear a knock against the stop. After this, we adjust the degree of tension of the screws until the gas pedal stops biting. Now, you need to unscrew the nuts securing the sensor and turn it a little until a position is reached where the voltage changes only when the damper is opened. When the desired result is achieved, tighten the nuts until they stop so that the sensor sits securely while driving and enjoy the stable operation of the power unit.

The operation of the engine of a modern car is completely controlled by electronics. The controller collects readings from several sensors, prepares a mixture of fuel and air and supplies it to the cylinders in the required quantity. Failure of any of these meters leads to problems with the engine: failures, increased fuel consumption and loss of power. This publication proposes to consider the signs of a malfunction of the throttle position sensor (abbreviated as TPS), since it fails more often than others, making car enthusiasts nervous and looking for problems in the power unit.

Details about the Chevrolet Niva TPS, which one to choose and how to replace it yourself?

- The throttle position sensor (TPS) is an important element in controlling the dosing of the fuel-air mixture.

- It detects the position and transmits information about the position of the gas pedal to the engine ECU.

- This allows you to form the composition of the fuel-air mixture corresponding to the operating mode of the engine.

Operating principle of TPS

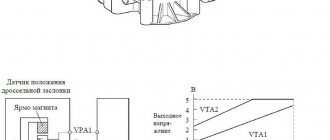

There are two types of devices: resistive and non-contact. They differ in design, operating principle and service life.

- Resistive TPS is a variable resistor, the resistance of which changes as the slider moves along the tracks. Due to their simple design and affordable price, they are most common in the automotive industry. The Chevrolet Niva rolls off the assembly line with just such resistive devices.

- Non-contact TPS is based on a circuit that includes a magnetic field sensor and a microcontroller. They last longer and consume less electricity than resistive ones. However, contactless devices are more expensive, and the semiconductor microcontroller can burn out due to sudden voltage surges in the on-board network.

The installation location and operating principle of the TPS does not depend on the design. It is mounted on the throttle shaft. When the throttle position changes, the output voltage at the sensor changes from 0.7 to 4 volts.

Due to this, the ECU receives information from the degree of opening of the damper. Based on the information received from the sensor, the composition of the air-fuel mixture is formed.

Therefore, the throttle response and efficiency of the engine depend on the performance of the TPS.

Symptoms of a problem

You can accurately determine the condition of the throttle position sensor only using a scanner or voltmeter. However, malfunctions also have external manifestations:

- Decrease in engine power.

- Deterioration in engine response when pressing the accelerator.

- Gasoline consumption is increasing.

- The engine runs unstably at low or high speeds.

- The car accelerates jerkily.

- Idle speed changes randomly or the engine stalls when the gas pedal is released.

- The yellow “Check engine” light on the instrument panel is on.

Most often, problems arise with resistive type devices. In them, the conductive layer on the tracks is erased or contaminated.

As a result, the voltage changes nonlinearly when the damper is turned.

Also, the moving core in the sensor may break. In this case, it does not respond to throttle movements at all.

How to check TPS?

To diagnose the throttle position sensor, you will need a multimeter or scanner that reads the on-board computer.

The test consists of monitoring the voltage at different throttle positions. To do this you need:

- Disconnect the wires from the sensor connector.

- Turn on the ignition.

- Connect a multimeter in voltmeter mode to the contacts.

Tip: you can find out the functionality without measuring instruments in a simple way - install a known working part from another car. If the symptoms disappear, the problem is in the sensor.

When the accelerator pedal is released, the device should show 0.7, and when pressed all the way - 4 volts. You also need to make sure that when you smoothly change the position of the accelerator pedal, the voltage changes smoothly.

If the multimeter readings do not correspond to the nominal values or change abruptly when the damper position is gradually changed, the part needs to be replaced.

Choosing TPS for Chevy Niva

The stores offer parts from different manufacturers:

- Bosch;

- General Motors;

- "Auto kit";

- "Autoelectronics";

- "Astro" and others.

Sensor article number: 2112-1148200. The cost depends on the manufacturer and type.

The price of resistive ones starts from 250 rubles, contactless ones are more expensive - up to 800 rubles.

Replacing TPS on VAZ-2123

Replacing the sensor does not require any special tools. All you need is a Phillips and flathead screwdriver. If you want to solve the problem once and for all, buy a contactless device from Bosch or General Motors.

To replace the throttle position sensor, proceed as follows:

- Use a screwdriver to pry up the rubber clips and remove the decorative engine cover.

- Remove the wire block from the connector.

- Use a Phillips screwdriver to unscrew the fastening screws.

- Remove the sensor and insert a new one.

- Tighten the screws.

- Put on the wire block.

- Return and secure the decorative engine cover.

Tip: if the voltage on the resistive sensor changes jerkily, there is a chance to restore its functionality. Remove the part, insert a flat-head screwdriver into the hole that fits onto the throttle shaft and twist it back and forth without any extra effort for a minute. This will help remove contamination from the resistive tracks and the device will begin to work correctly.

The design of the Chevrolet Niva does not require adjustment of the throttle position sensor. If the voltage at its output differs from the nominal one, the part is faulty and must be replaced.

Symptoms of sensor malfunction

The main control unit contains a program: if one of the important meters stops working, the air-fuel mixture is prepared and supplied according to average indicators, and the Check Engine warning sign turns on on the dashboard. Emergency operation with increased fuel consumption is a clear sign of a breakdown of any sensor.

The insidiousness of the TPS is that it does not break in the usual sense. When the resistive film begins to wear away, the resistance of the device changes unpredictably. The controller either “sees” a working sensor in the circuit, or notes incorrect voltage surges and tries to switch to emergency mode. From here, the main sign of a malfunctioning throttle valve is determined - a periodically flashing Check Engine display.

The problem is accompanied by a change in the behavior of the engine, or more precisely:

- “shaking” and spontaneous stops of the engine idling;

- there is no acceleration dynamics; after pressing the gas pedal, jerks and dips are observed;

- increased idle speed of the power unit (1500–2500 rpm);

- the car “does not pull” due to loss of power;

- jerks are also felt while driving;

- Fuel consumption increases by 10–25%.

The listed symptoms can be caused by a dozen reasons, ranging from malfunctions of the ignition system to wear and tear of engine parts. That is why it is important to weed out problems that lie on the surface, including incorrect operation of the throttle position sensor.

How to check TPS?

To confirm or refute the symptoms of a malfunction of the meter, you will need a multimeter or other device with a voltmeter function. The kit must contain pointed probes, otherwise you will have to strip the wires connected to the sensor. It is highly undesirable to strip the insulation from the conductors, so if there are no sharp contacts, make them yourself - they will come in handy in the future.

The sensor is diagnosed by measuring the voltage between the output wire and the machine ground. The operation algorithm is as follows:

- With the ignition off, remove the TPS connector and use the diagram to determine which of the three wires is the output. In VAZ cars, the required conductor is connected to the upper contact of the block.

- Put the connector in place and pierce the outside of the found wire with a pointed probe. Connect the second clamp to the negative terminal of the battery.

- Set the multimeter to measure voltage and turn on the ignition. Record your readings.

- Open the throttle all the way and remove the second voltage reading.

- Smoothly turn the damper, observing the voltage increase. The values should change gradually, without jumps or drops to zero.

What does the throttle position sensor do?

A part such as a throttle position sensor (TPS) is created in order to transmit information to the electrical engine control unit about the specific state of the bypass valve at a given point in time. In fact, it is a combination of a fixed and variable resistor, and its maximum total resistance is approximately 8 ohms. Throttle position sensor symptoms. The TPS has three contacts in its design, two of them are supplied with voltage (usually its value is about 5 V), and the third is a signal and is connected to a suitable controller.

Removing the coolant temperature sensor

The sensor is a negative temperature coefficient thermistor, meaning its resistance decreases as the temperature rises.

The controller supplies the sensor with a stabilized voltage of +5 V through a resistor (about 2 kOhm) and, based on the voltage drop across the sensor, calculates the coolant temperature, the values of which are used in most engine control functions.

If a malfunction occurs in the DTOZh circuits, the engine control system malfunction indicator lights up, the controller turns on the cooling system fan to constant operation and calculates the temperature value using a bypass algorithm.

We carry out the work on a cold engine.

Partially drain the coolant.

With the ignition off, disconnect the sensor connector.

Use the 19mm key to unscrew the sensor.

We take out the sensor along with the sealing ring

To check, lower the sensor into a vessel with coolant and heat the vessel.

We control the temperature with a thermometer. We measure the resistance of the sensor at different temperatures

Install the sensor in reverse order. The tightening torque of the sensor is 9–15 Nm. Add coolant to normal level.