Code P0122 Throttle Position Sensor A Circuit Low Signal

Code P0123 Throttle Position Sensor A Circuit High Signal

Code P0222 Throttle Position Sensor B Circuit Low Signal

Code P0223 Throttle Position Sensor B Circuit High Signal

Code P0122 is entered if the ignition is turned on and the throttle position sensor signal voltage is less than 0.25 V for 0.12 s.

Code P0123 is entered if the ignition is turned on; the throttle position sensor signal voltage is more than 4.75 V for 0.12 s

Code P0222 is entered if the ignition is turned on, the signal voltage of the throttle position sensor UDKP2 is less than 0.25 V for 0.12 s.

Code P0223 is entered if the ignition is turned on and the signal voltage of the throttle position sensor UDKP2 is more than 4.75 V for 0.12 s.

The malfunction indicator lights up 5 s after the fault code appears. Description of checks

1 Using a diagnostic tool, check whether code P0122 is active at the time of diagnosis. If only code P0122 is detected, then the fault must be looked for in the signal circuit of TPS A. If codes P0122 and P0222 are recorded simultaneously, then the fault must be looked for in the power supply circuit of TPS A and TPS B. 2 The circuit is checked from the contact “X1/K2” of the controller to contact “6” of the EDP. 3 The controller is checked: when you bridge contacts “6” and “2” of the block to the EDP using a probe, the TPS A signal on the diagnostic device should change. 4 The circuit is checked from contact “X1/K1” of the controller to contact “2” of the EDP. 5 The controller is checked: contact “2” of the block to the EDP should receive a reference voltage of 5 V from the controller. Diagnostic information If a malfunction is detected in the TPS A circuit, the engine control system will operate in emergency mode until the end of the current trip. The following emergency modes are possible: limiting engine power if the TPS B circuit is working; de-energizing the electric throttle drive and limiting engine speed (2500 rpm) if the TPS A and TPS B circuits are faulty. The diagnostic tool is in mode “1 Parameters; 6 Add. Options; 3 ADC inputs” shows the signals of TPS A (UDKP1) and TPS B (UDKP2) in volts. When the throttle valve is opened, the TPS A signal increases, the TPS B signal decreases. With the throttle valve fully closed, the TPS A signal should be in the range of 0.3...0.6 V, the TPS B signal should be in the range of 4.4...4.7 V.

What are the symptoms of a P0122 code?

- When this error appears, the Check Engine light will light up on the vehicle's dashboard. The ECM will put the engine into limp mode and stop current flowing to the throttle actuator. In this case, the opening angle of the throttle valve will be no more than 6 degrees.

- Problems may arise with the control of fuel injection and ignition timing.

- There may be a decrease in power as well as engine sensitivity to throttle opening.

- The engine may idle at higher speeds, but the vehicle will not accelerate as expected.

Note : Symptoms of this error may vary depending on the make and model of your vehicle.

Symptoms of malfunction

The main driver symptom of P0122 is the MIL (Malfunction Indicator Light) illumination. It is also called Check engine or simply “check light”.

They can also appear as:

- The “Check engine” warning light on the control panel will light up.

- Unstable or low idle speed.

- Increased engine speed at idle.

- The engine stalls or has trouble starting.

- The motor runs unevenly (pulsates).

- There is no response to the gas pedal.

Other symptoms may also be present.

How does a mechanic diagnose a P0122 code?

When diagnosing this error, the mechanic will do the following:

- Reads all stored data and error codes using an OBD-II scanner to find out when and under what circumstances the P0122 error code appeared

- Clear error codes from the computer's memory and test drive the vehicle to see if P0122 appears again

- Visually inspect the electrical wires and connectors related to the throttle position sensor “A” for looseness or damage.

- Compare the readings of throttle position sensors “A” and “B” using a scanner and, if necessary, replace the faulty sensor

- Clear the error code from the computer's memory again and test drive the vehicle to see if the problem is resolved

On which cars is this problem most common?

The problem with code P0122 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Chery

- Chevrolet (Chevrolet Aveo, Impala, Cruz, Lanos, Lacetti, Malibu, Silverado, Spark, Traverse)

- Chrysler

- Citroen (Citroen Berlingo)

- Daewoo (Daewoo Leganza, Matiz, Nexia)

- Dodge (Dodge Ram)

- Ford (Ford Galaxy, Mondeo, Transit, Focus)

- Geely

- Honda (Honda Accord, Jazz, Fit, Civic)

- Hover

- Hyundai (Hyundai Santa Fe, Solaris, Sonata)

- Jeep (Jeep Liberty)

- Kia (Kia Magentis, Rio, Sorento)

- Lifan (Lifan Solano)

- Mazda

- Mercedes

- Mitsubishi (Mitsubishi Colt, Lancer)

- Nissan

- Opel (Opel Astra)

- Peugeot (Peugeot 206, 307, 308, Partner)

- Skoda (Skoda Yeti, Fabia)

- Subaru

- Suzuki

- Toyota (Toyota Corolla)

- Volkswagen (Volkswagen Golf, Jetta, Crafter, Passat, Polo Sedan, Tiguan)

- VAZ 2107, 2109, 2110, 2112, 2114, 2115

- Gazelle Business, umz 4216

- Zaz Chance

- Lada Granta, Kalina, Niva, Priora

- UAZ Bukhanka, Patriot

With fault code P0122, you can sometimes encounter other errors. The most common ones are: P0102, P0108, P0113, P0118, P0222, P0223, P0300, P0335, P0341, P0343, P0452, P0463, P0719, P1122, P1381, P1403, P1961, P2135, C0242, U210 0.

Common errors when diagnosing code P0122

- Failure to visually inspect the throttle position sensor “A”, as well as the associated electrical wires and connector

- Neglecting to check for an error code using a scanner, clearing the code from the computer's memory, and rechecking the system before performing any repair work

- Hasty replacement of throttle position sensor “A”

- Neglecting to check the voltage of throttle position sensors “A” and “B” before starting repair work and after its completion

Why was the throttle valve equipped with a sensor?

The injector is equipped with flaps that change the angle of location, opening/closing the gap for the passage of air flow. Its volume should be enough to create a mixture with fuel in optimal proportions (ideally 14.7 parts of air per 1 part of gasoline). The mixture is then injected in portions into the engine cylinders, where it is burned.

In order to successfully regulate all stages of fuel supply (and this is a huge number of parameters), the electronic unit needs a reliable assistant who will collect and send truthful and timely information to the central authority.

Such functions are assigned to a miniature device - the PDZ sensor, the trouble-free operation of which determines the proper and efficient functioning of the engine.

The data from this sensor forms the basis for the calculation parameters for many electronic systems controlled by the ECU:

Additional comments for troubleshooting P0122

- Along with the P0122 code, there may also be other error codes related to the throttle position sensor that need to be investigated and resolved.

- The most common cause of P0122 is a faulty throttle position sensor or a loose sensor connector.

- As a rule, when errors related to the throttle position sensor appear, emergency mode is activated, and the symptoms of such errors are almost the same.

Diagnosis and problem solving

Carefully check the Throttle Position Sensor (TPS), wiring connector and wiring for opens, etc. Repair or replace as necessary to resolve P0122.

Check the voltage at the TPS (see your vehicle's service manual for more information). If the voltage is too low, this indicates a problem. Replace the sensor if necessary.

If recently replaced, the TPS may need to be adjusted. On some vehicles, installation instructions require proper adjustment (see repair manual for details).

If there are no symptoms, the problem may be intermittent and cleaning the code may temporarily resolve it. In this case, you should definitely check the wiring to make sure that it is not rubbing, worn out, etc.

Other trouble codes related to the TPS sensor and circuit: P0120, P0121, P0123, P0124.

Causes of malfunction of contact sensors

The main reason for failure is wear of the resistive tracks, leading to a complete or partial break in the electrical circuit. This leads to the transmission of incorrect data to the ECU.

Causes of malfunction of contact sensors:

- Wear of the resistor layer leads to loss of electrical contact. This can happen either at the beginning of the slider’s movement (typically when the voltage at the sensor output is low), or on another section of the tracks.

- Broken or worn tip.

- Wear of drive gears.

- Short circuit of signal or electrical circuits.

- Broken wiring, especially for VAZ cars, whose wires are not reliable.

- Oxidation of contacts and contamination of connectors.

Most causes can be diagnosed visually after disassembling the device and using a multimeter.

Regarding error P2135, which was mentioned in the previous section, its causes:

- poor ECU contact ground;

- oxidation of contacts in the connector;

- main relay malfunction;

- short circuit and other reasons.

How does the remote sensing position sensor work?

Most manufacturers equip cars with moving (contact) sensors, which are ponetiometers with a moving element. This is its weak point, because it experiences friction, which leads to rapid wear. Now there is an active transition to a contactless option. It has great operational potential and high accuracy of parameter measurement.

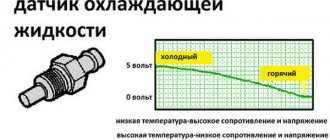

Using the mobile type as an example, we will consider the design features and operating principle of the PDZ sensor. It is rigidly fixed to the axle, into the throttle body. One end is connected to the battery, the other is connected to the negative electrode. They are supplied with voltage (5V). The third end moves along an axis on which the voltage changes when the damper changes position. The change interval is from 0.7 to 4V. This is indicated by the sensor in the ECU. This signal is fundamental in regulating the fuel system. Electronic control is carried out through sensors that transmit the following data:

- Crankshaft rotation indicators

- Air flow and temperature

- Antifreeze temperatures

- Throttle position

- Feedback system (exhaust gas composition)

- Detonation in the engine

- Mains voltage

- Travel speeds

- Camshaft position

- Activating the air conditioner

- Irregularities in the road surface

Primary sources of sensor failure

The most obvious reason for the incorrect operation of such a device is wear. Moreover, the wear of different parts has different effects on the system.

- Erasing conductor coating. Therefore, it becomes impossible to fix the voltage indicator.

- Exhausted wear reserve of the moving element of the sensor. When the gap between it and the axle conductor becomes too wide, contact between them is lost. At the same time, the check does not pop up. You can guess about it by the intermittent operation of the engine in different modes.

- Oxidation, rust coating, accumulation of a layer of contamination on the contacts.

After detecting such design changes, you have no choice, the device cannot be repaired, it must be replaced. Of course, it is better to purchase a contactless device. It is much more reliable, because it has no rubbing elements.

Error P2135 dpdz

Along with this error, the ECU produces some others that reflect deviations from the norm in the operating parameters of the throttle valve and their sensors - P0120, 0122, 0123, 0220, 0223, 0222, 01578.

The test comes down to measuring the voltage of the sensor signal, as well as the resistance of the wires, especially the state of the ground pin of the electronic unit.

Possible reasons could be:

- Poor condition of the “mass”. If necessary, clean, solder, eliminate breaks

- Faulty relay. This problem can be solved by replacing the part (it is better to purchase a part from a European manufacturer with a current of 40 amperes)

- Unsatisfactory condition of the sensor's electrical outputs. You can try bending them in the connector, this is often enough.

- A short circuit is detected between VTA contacts 1 and 2. Voltage measurements in this zone show a deviation from the same 5V by more than 0.2V

- Problems in the electromechanical throttle mechanism (EMDU). The malfunction is eliminated by replacing the device.

Cleaning the damper

If the cause of poor engine performance is contamination of the throttle, it is necessary to clean it. To do this, you need to purchase a special engine cleaning product and start doing the work:

It is also recommended to remove and clean the idle speed control and the channel in which it is located. Be sure to check the condition of the air filter, since an unsuitable filter can not only cause contamination of the throttle body, but also affect the operation of the engine as a whole and cause you a lot of trouble. Good luck on the roads!

Errors during diagnostics

In order to accurately determine the cause of the error and methods for eliminating it, diagnostics are carried out. It can be done with the help of a car mechanic or yourself if you have the proper experience. An OBD-2 scanner is used for operation. Common errors that occur when diagnosing a P0122 code include:

- sensor “A”, which is responsible for the throttle valve, connector and electrical wires, is not inspected;

- the scanner is not checked, the code is not cleared from the computer memory, the system is not re-checked before repair;

- sensor “A”, responsible for the correct position of the throttle valve, is not inspected properly;

- The voltage of sensors “A” and “B”, responsible for the throttle valve, is not checked before and after repair work.

Trouble P0122 will cause the vehicle's ECM to set the engine to limp mode. This is fraught with numerous problems until it is eliminated. Even though the engine is running at high idle speed, the vehicle will not accelerate properly. Its operation becomes unstable or the engine begins to fail altogether.