Error p0118 stands for “coolant temperature sensor - high signal level.” It occurs if the electronic engine control unit (hereinafter referred to as the ECU) detects that a voltage above the threshold is supplied from the specified sensor, that is, above 4.91 Volts. Most often, the cause of error p0118 is an open circuit of the sensor or failure of the sensor itself. Eliminating the error code and the problem itself in general consists of one of the following options - replacing the wires of the sensor circuit, replacing the sensor connector, replacing the sensor itself with a new one.

What are the symptoms of a P0118 code?

- When this error appears, the Check Engine light will light up on the vehicle's dashboard. The ECM will put the engine into limp mode, replacing the incorrect coolant temperature sensor reading with a value of 80°C (176°F).

- The car engine may be difficult to start when cold. When warm, the engine starts normally.

- The car engine may run rough until it warms up.

- After warming up, the engine usually runs normally.

Note : Symptoms of this error may vary depending on the make and model of your vehicle.

Symptoms of malfunction

The main driver symptom of P0118 is the MIL (Malfunction Indicator Light). It is also called Check engine or simply “check light”.

They can also appear as:

- The “Check engine” warning light on the control panel will light up (the code will be stored in the ECM memory as a malfunction).

- The engine stalls or has difficulty starting (especially when starting from cold).

- Floating speed, as well as attempts to stall at idle.

- Car engine overheating.

- Black smoke from the exhaust pipe when running on a rich mixture.

- On a lean mixture, increased NOx emissions may occur.

- Incorrect operation of cooling fans.

Error P0118 is not serious, the car will be able to start and continue driving. But it is better to solve it as soon as possible, since improper heat transfer can lead to more serious consequences.

How does a mechanic diagnose a P0118 code?

When diagnosing this error, the mechanic will do the following:

- Visually inspect the coolant temperature sensor and related electrical wires and connector

- Reads all stored data and error codes using an OBD-II scanner to find out when and under what circumstances the P0118 error occurred

- Clear the error codes from the computer's memory and test drive the vehicle to see if the P0118 code appears again

- Check the electrical wires and coolant temperature sensor connector for corrosion and damage.

- Observes the coolant temperature sensor readings in real time using a scanner

- If necessary, replace the coolant temperature sensor, associated electrical wires and connector, or engine control module (ECM)

Diagnosis and problem solving

The first step in the process of troubleshooting P0118 is to review the Technical Service Bulletins (TSBs). For known problems with a specific vehicle.

Perform a thorough visual inspection to check the wiring for obvious defects such as scratches, scuffs, exposed wires, or burn marks. Next, you should check the connectors and connections for safety, corrosion and damage to the contacts.

Be sure to carefully check the integrity of the wire harnesses and secure any loose wires. If you find a burnt wire, solder it and make sure it is properly insulated.

Checking the coolant and thermostat

Make sure the coolant level is correct, both in the radiator (when cold) and in the coolant overflow reservoir. Make sure there are no leaks and that the sealing cap is working properly.

If there is not enough coolant in the system, the engine may not warm up properly. Because if the temperature sensor is not in contact with the coolant, it will not read the temperature.

Using a non-contact thermometer or scan tool with real-time data streaming, check to see if the engine is warming up properly. Typically, the upper radiator hose should remain relatively cool until the thermostat opens. After which it will heat up quickly.

If the thermostat is open, coolant will flow continuously, preventing the engine from reaching operating temperature. This may also be the reason for the P0118 trouble code.

Using a thermometer or scan tool, check the engine temperature after 10-15 minutes of operation. If the temperature does not reach operating temperature, check the ECT sensor.

Checking the coolant temperature sensor (ECT)

Visually check the sensor for damage to the wiring or connector and repair if necessary. Then connect the OBD2 scanner, if the engine temperature is excessively high, about 140°C, it is not normal.

Disconnect the sensor on the engine and see if the readings drop by, for example, 10°C. If so, then the sensor is most likely faulty, shorted internally, causing a low resistance signal to be sent to the PCM.

But, if you want to be completely sure that it is the sensor and not the wiring, you can run a test. Check the sensor's resistance to ground using an ohmmeter. The resistance of a normal sensor will vary slightly depending on the vehicle.

But basically, if the motor temperature is around 95 degrees Celsius, then the resistance will be around 200 ohms. At a temperature of about -20°C, the resistance will be more than 10,000 Ohms.

This test will help you determine if the sensor resistance matches the engine temperature. If it doesn't match your engine temperature, then you probably have a bad sensor.

How serious is P0118?

When P0118 occurs, the vehicle's ECM will put the engine into limp mode. Staying in limp mode may result in unstable engine operation, which will continue until the engine warms up to normal operating temperature. Possible increased fuel consumption and excessive carbon buildup on engine components. Driving a vehicle in limp mode for long periods of time can lead to a number of other problems, including problems with the ignition system. Also, the cooling system fans can run continuously.

On which cars is this problem most common?

The problem with code P0118 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Audi (Audi a4, Audi a6, Audi TT)

- BMW

- Chery

- Chevrolet (Chevrolet Aveo, Camaro, Cruz, Lacetti, Malibu, Silverado)

- Chrysler (Chrysler Voyager, Town Country, 200)

- Citroen (Citroen C3, C4)

- Daewoo (Daewoo Nexia)

- Dodge (Dodge Caravan)

- Ford (Ford Transit, Focus, Fusion, Explorer)

- Honda (Honda Accord, Odyssey, SRV, Stream, Fit, Civic)

- Hyundai (Hyundai Accent, Santa Fe, Solaris)

- Jeep (Jeep Grand Cherokee)

- Kia (Kia Rio)

- Lexus

- Mazda (Mazda 3, Mazda 6)

- Mercedes

- Mini (Mini Cooper)

- Mitsubishi

- Nissan (Nissan Almera, Altima, Qashqai, Murano, Note, Patrol, Primera)

- Opel (Opel Astra, Corsa)

- Peugeot (Peugeot 206, 308, Partner)

- Pontiac (Pontiac Grand AM)

- Renault

- Saturn (Saturn SC)

- Skoda (Skoda Octavia, Fabia)

- Subaru (Subaru Tribeca, Forester)

- Suzuki

- Toyota

- Volkswagen (Volkswagen Golf, Passat, Touareg, Transporter)

- Volvo

- VAZ 2105, 2107, 2110, 2112, 2114, 2115

- Volga Chrysler

- Gazelle Business, Chrysler, Sobol, ZMZ 405, UMZ 4216

- Lada Granta, Kalina, Niva, Priora

- UAZ

With fault code P0118, you can sometimes encounter other errors. The most common ones are: P0108, P0113, P0119, P0123, P0138, P0301, P0340, P0351, P0453, P0507, P0708, P1400, P1406, P1557, P2305.

VAZ fault code P0118 check.

This can be done if you have a multimeter, on-board computer or a device for reading fault codes. Before starting the test, it is necessary to check the reliability of the connection of the plug to the sensor and the integrity of the wires.

To check, you need to disconnect the contact block from the sensor, turn on the ignition, and check for the presence of fault code PO117: low signal level of the coolant temperature sensor. The appearance of this code indicates that the circuit and controller are working properly and the sensor needs to be replaced.

If the code does not appear, it means that wire 17 O is shorted to ground or to wires 7 Z and 53 ZP, connecting the sensor to pin 26 of the controller. The controller may also be faulty.

If there is no diagnostic tool available to read error codes from the controller’s RAM, and the car is not equipped with an on-board computer, it is necessary to check the serviceability of the sensor. To do this, we heat it, any heated container with water is suitable for this, and check the resistance between its terminals. The resistance must correspond to the temperature indicated in the table. It is enough to check the readings corresponding to a cold and warm engine. If the temperature and resistance do not match, the sensor is replaced with a working one.

If the fault code is not permanent, that is, it disappears periodically, it is necessary to check the reliability of the sensor connector connection and check the sensor ground circuit, wires 7 Z and 53 ZP.

Source

VAZ fault code P0118

The fault code of the VAZ MP7 vehicle controller, RO 118, high signal level of the coolant temperature sensor, is entered into the controller’s RAM if, within 0.2 seconds while the engine is running, the sensor voltage supplied to the controller corresponds to +135 degrees. In this case, the “Check engine” lamp lights up on the instrument panel and the controller calculates the engine temperature based on its operating time. If this fault code is in the memory, do not rush to change the sensor. First you need to check the sensor circuit and the serviceability of the controller.

Formation and purification conditions

An error with code p0118 is generated in the memory of the electronic control unit when the following conditions are met (may differ for different machines, average data are given):

- engine operating time is at least 120 seconds.

- within 0.2 seconds, the signal voltage from the sensor corresponds to a coolant temperature of less than – 38°C (the value may differ for different machines);

- If the breakdown occurs regularly, the Check Engine light and the corresponding error code are generated after two drive cycles.

Conditions for deleting error information from the memory of the control unit (averaged data are shown similarly):

- the check on the panel is automatically turned off if the ECU has not detected such a problem after four engine start cycles;

- the archive of diagnostic trouble codes is cleared after 40 consecutive coolant heating cycles, provided there is no specified fault;

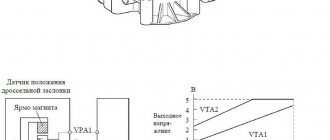

Types of engine temperature sensors: what type is used on Priora

It is important to understand that there are two types of engine temperature sensors. They differ in the principle of operation, and you need to know the operating features in order not to make a mistake when choosing such an element for your car.

The following types of DTOZH are distinguished:

- With a negative temperature coefficient

(NTC - negative temperature coefficient) - it works as follows: when the temperature rises, the resistance decreases, and vice versa. - With a positive coefficient

(PTC - positive temperature coefficient) - it has the opposite principle of operation. When the temperature increases, the resistance increases.

The most common types are negative temperature devices. It is these sensors that are used on Priora cars.

When the engine is cold, the maximum resistance of the Priora DTOZH thermistor reaches 100.7 kOhm (this value will be at a temperature of -40 degrees). When the engine warms up, the temperature increases, which means the resistance drops. At a high temperature of +130 degrees, the thermistor resistance is about 70 Ohms. These readings are the operating range. When the engine is cold, the voltage drop in the circuit will be large (drops to 18%). As it warms up, it will increase (up to 90%).

This is interesting! If the engine is cold, then the voltage in the circuit will be about 3.4V, and when it warms up, the value decreases to the minimum (0.15V)

It is important to know what type of sensor is used on the car in order to diagnose it and check for serviceability or correct operation.

Verification methods

Recommended verification algorithm:

Caution: there is a risk of making a mistake and replacing the working sensor if the reason lies in the wiring (break or short circuit). Upon completion of the repair, it is imperative to clear the ECU’s error memory, otherwise the data will trigger an error code until the end of the full cycle included in the program’s update algorithm.

When P0118 is output, clearing the controller memory from it

Sensor signal error P0118 (its code) appears in the ECU controller memory under the following conditions (generalized, there may be differences for some brands):

- The internal combustion engine runs from 120 seconds;

- 0.2 sec. voltage from the detector as at t° below -42 or -38 (may vary slightly for different vehicles);

- if the malfunction is persistent after 2 drive cycles, then CHECK ENGINE is displayed.

We summarize the conditions under which the code is deleted from the ECU controller (the memory is cleared):

- CHECK ENGINE disappears (turns off) if the control system does not detect a malfunction after 4 cycles of starting the engine;

- The diagnostic history becomes clear after 40 consecutive heating cycles of antifreeze in the absence of a problem.

Decoding error codes Lada Kalina 2

Most of the indexes and encodings are similar to the first generation model, before restyling. Therefore, in 80% of cases, the above list will be relevant here too. However, the new generation has acquired a large number of on-board systems that were missing on the old car, which forced the manufacturer to adjust the standard table.

Note! Below, only newly introduced or updated codes are indicated; ciphers that have not undergone changes are ignored here - you can use the existing list.

Oxygen supply to the engine (0100)

- 101 – the mass air flow sensor may be shorted, the permissible indication limits are exceeded;

- 106-108 – incorrect data from the intake manifold absolute pressure sensor;

- 130 – failure of the oxygen sensor before the catalytic converter is broken;

- 131-134 – power supply problems with the above sensor.

Supplying fuel to the cylinders (0200)

- 200 – malfunction of the fuel injector control network;

- 222-223 – incorrect indicators of the TPS network.

Ignition circuit malfunction (0300)

- 326 – critical fluctuations in the signal level from the fuel mixture detonation sensor;

- 363 – there are misfires of the mass to protect the catalyst.

Auxiliary equipment units not related to the primary circuit of electrical equipment (0400)

- 458/459 – checking the short circuit of the KPA lines to ground and 12V, respectively;

- 485 – diagnostics of the main fan supply line is required.

Throttle and brake drive VAZ Kalina 2 (0500)

- 500 – speedometer sensor network interruption;

- 501 – the above sensor is faulty;

- 503 – speed sensor indicators are floating;

- 504 – incorrect response of the brake sensor – ABS may not respond correctly;

- 505 – the XX adjustment indicator is broken or out of order;

- 506-507 – the XX regulator is jammed, accompanied by too low or high speeds;

- 522/523 – incorrect data from the oil pressure sensor inside the crankcase compartment of the internal combustion engine.

Incorrect data from the vehicle’s on-board networks (0600)

- 606 – ADC unit failed;

- 642/643 – incorrect signal from the sensor power bus;

- 660-662 – the channel length control valve is faulty or there is an open circuit with a short to 12V or ground;

- 691-692 – the power supply to the relay of the first radiator cooler is disrupted with a possible short circuit;

- 693-694 – similar, only for the second element.

Clutch line (0800)

- 830 – the switch sensor of the corresponding pedal does not respond to the ECU request; the sensor may fail or the wiring may be damaged.

Additional system error flags (1000)

- 141 – failure or damage to the DK2 heater circuit;

- 301-304 – misfires to protect the catalyst for all cylinders in series;

- 335 – incorrect position of the remote control;

- 336 – failure to synchronize the sensors and the actual throttle position;

- 384 – remote control drive control, internal combustion engine torque exceeds permissible limits;

- 385 – similar, only for the engine signal;

- 386 – the line indicating the presence of detonation of the mixture fails;

- 387 – violation of synchronization of the injection moment with the position of the remote control;

- 388 – TPS does not respond correctly to pressing the gas pedal;

- 389 – also only with exceeding the power plant speed thresholds;

- 390 – the throttle valve does not respond to the ECU request;

- 410/425/426 – malfunction of the canister purge valve circuit with a short circuit to ground or 12 volts;

- 513/514 – open circuit of the XX sensor network with a short circuit;

- 545 – synchronization failure or slow response of the remote control to the TPS pulse;

- 558 – wear or breakage of the throttle spring;

- 559 – remote control drive is faulty;

- 570 – immobilizer circuit open;

- 578 – malfunction or jamming of the remote control drive;

- 600 – no response from the immobilizer;

- 602 – power supply to the on-board network is lost, it may be necessary to tighten the battery terminals;

- 603 – EEPROM failure;

- 689 – error memory data is displayed incorrectly.

Peripheral BU system (2000)

- 70-71 – the channel size diagnostic valve is faulty (jammed);

- 100 – break in the PDZ line;

- 101 – similar value to the previous paragraph;

- 102/103 – short circuit of the remote control control line;

- 105 – control unit failure;

- 122/123 – incorrect pedal position signal;

- 127/128 – similar to the above code;

- 187/188 – excessively rich or lean mixture at idle;

- 135 – sensors A and B, designed to control the position of the remote control, do not respond correctly;

- 138 – similar value for the corresponding accelerator lever position sensors;

- 176 – throttle drive position failure;

- 178 – complete failure of adaptation of the above block;

- 187/188 – incorrect mixture formation;

- 270/271 – lack of reaction of DK2 to enrichment or depletion of the mixture after the catalyst;

- 301/304/307/310 – short circuit of the ignition coil for all cylinders, respectively;

- 500/501 – incorrect generator power readings.

Lada Kalina errors, interpretation for automatic transmission (P0000)

- 720 – failure of the output shaft rotation sensor;

- 717 – turbine rotation sensor;

- 705-706 – no selector signal or multiple values;

- 973/974 – solenoid on/off, open circuit or short circuit to ground;

- 962/963 - the same element responsible for pressure - there is a break or short circuit;

- 740/743 – LOCK UP SOL open or closed;

- 17AB/AA – L/C SOL;

- 17АЭ/AD – 2-4/B SOL;

- 17B1/B0 – H/C and L and R/B;

- 1735-1738 – the 1st-4th gear lock is closed, respectively;

- 744/1744 – LU CLUTCH;

- 731-734 – incorrect ratio for positions 1-4;

- 17A0-A4 – reverse and forward gears do not work alternately in accordance with the last digit of the code;

- 711-713 – network malfunction or DTM failure;

- 863 – connection failure with the diagnostic computer;

- 062F – memory error;

- 1701 – main controller power failure.

Malfunction of data transmission from the BC to the diagnostic unit (U0000)

- 1 – test tire is broken;

- 9 – similar value with a short circuit in the line;

- 73 – connect the CAN connector;

- 0100 – connect the engine check connector;

- 305 – software incompatibility with EBKK.

Important! The specified data is similar to the VAZ Granta car.

Where is the sensor located

The location of the described unit is the engine compartment near the cylinder head (on the exhaust pipe), the thermostat. This is a standard location, for example, like the VAZ 2114. Appearance - plastic, rectangular box, plug with a metal part with a thread and a contact segment. There are 2, less often 3, wires going to the device.

What does code P0118 mean?

Modern cars have an electronic monitoring system (ECM) of the state of the internal combustion engine with a control unit (ECU). By connecting a diagnostic scanner-adapter to the unit, you can find out about the operation of the motor. Data is displayed in brief alphanumeric notifications. These codes include P0118, which indicates that excessive voltage has been detected on the coolant temperature sensor (CTS) circuit. Appears when 4.91 V is exceeded.

So, if the output voltage of the coolant sensor (detector, detector) that monitors the temperature level of antifreeze exceeds 4.91 V, then the ECM registers a problem in its circuit and signals this with code P0118, which can be seen on the display of the diagnostic adapter connected to the ECU.

Explanation of the described error: “high signal level”. The coolant sensor is a thermistor; a 5 V power supply is supplied to it from the ECU. The detector returns a voltage that decreases as t° increases. In this way, monitoring and feedback from the system occurs. Code P0118 shows that the internal combustion engine control unit detects an excessively high incoming voltage from the device, the normal level of which is 1.5 - 2 V. For most vehicles, the threshold is 4.91 V. The ECU forcibly deactivates the sensor, following its programmed algorithm, and makes a switch to emergency condition. Plus, the impellers of the cooling system can be activated; they are constantly running on the radiator.

Re: M9R won't start

The chain slipped on the car, after repairing and replacing 3 injectors (we managed to get one intact), the car started up, ran for about 5 minutes, turned it off, assembled the attachment and did not start again. Then I prescribed the injectors (Delphi scanner) I thought it might help, but it didn’t help. When diagnosing an error in the camshaft sensor DF119, I removed the timing cover and installed the camshaft and crankshaft lock, that is, the phases are not shifted. Starts on air. One specialist said that it should start if you disconnect the chip from the camshaft sensor, but no. Then I took out one injector and when I cranked the starter there was no injection!

How to carry out repairs

If OBD P0118 is detected in the ECU memory, do the following:

- The ignition is activated, but the engine does not start.

- A diagnostic vehicle error scanner is connected to the ECU (to its connector), and it also receives data on the parameters of the entire system. Select “t° cooling” in the menu. liquid."

- If the temperature of the antifreeze on the instruments is below +135°, then if there are no other errors in the control unit’s memory, check the grounding of the sensor (integrity of wiring, contacts). The electrical circuit diagram is in the technical documentation of the vehicle and the device. At the same time, check all connections.

- Snap off the block (chip) with the conductors. If the device continues to show above +42°, then its signal wire is shorted to ground or the ECU is broken. If it is lower, then there is a problem in the sensor itself, in which case there is only one way out - replacement (but after preliminary additional testing).

The coolant sensor is in direct contact with the cooler, so if there are signs of overheating, it should not be removed.