Measured (estimated) the pressure in the fuel rail

I’ve never done anything like this, but in order to collect evidence in the investigation of the case “why in the morning, when starting the engine, a new car stalls (or there is a drop in engine speed),” I decided to measure the pressure in the fuel rail.

The pressure gauge was taken from an old foot compressor for inflating wheels. I didn’t find a gas-resistant tube, as it should be, but I found a tube from a shower stall and decided to take a chance in the hope that it would withstand 3...3.5 ATM for a short time... I took off the adsorber valve to make it easier to get to. I removed the plug and unscrewed the nipple. I tightened the tube to the ramp and pressure gauge with clamps. When I unscrewed the nipple, gasoline flowed out of my nose.

At first glance, the pressure in the system is normal. I suspect that the old pressure gauge is lying, its needle is not even at zero, so let’s call this experiment not a measurement, but an assessment.

1. When the ignition is turned on, the pressure reaches approximately 3 atm, but then gradually drops. When the ignition is turned off, it drops quickly.

2. When starting the engine at idle, the pressure remains about 2.8 atm, which is close to normal.

3. If, with the engine running, you drop the vacuum tube from the manifold to the fuel pressure regulator (I seem to have a traditional fuel circuit with a return line), then the pressure increases to 3.4 atm.

My thoughts. The pressure regulator (at least IN THE EVENING) works normally. Why does the pressure in the rail drop when the ignition is turned on and off, if the engine is not running? This is a question: is it supposed to be like this or is the check valve in the fuel pump poisoning? So, I have another suspect...

Mass air flow sensor (MAF)

This sensor is located near the Niva air filter box. Air flows through this sensor, which is necessary to form the air-fuel mixture. The sensor records the amount of air passing through it and sends signals to the electronic engine control unit (ECU).

Signs of a DMRV malfunction:

- Loss of vehicle dynamics;

- Increased fuel consumption;

- Unstable idling (speeds fluctuate);

- Difficulty starting the engine when the engine is warm;

Troubleshooting

No pressure in the fuel rail? Causes:

If the pressure in the fuel rail gradually drops, the cause may be:

Let's check it like this. We clamp the leading rubber hose of the fuel rail:

Checking the RTD. Connect the pressure gauge hose to the outlet fitting of the fuel pump and turn on the ignition:

If the pressure in the fuel rail is within normal limits, we look for the causes of engine malfunctions elsewhere.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

What elements make sense to repair?

O-rings, clamps and flexible hoses are typical consumables. Their service life is short, and repairs are impractical. Connecting hoses cost within a few hundred rubles, connecting elements are even cheaper, so it is much easier to replace them with new ones.

Steel pipelines are a completely different matter. The Chevrolet Niva user manual states that the damaged part of the fuel line can be repaired. Repairs are made by replacing the damaged area with a reinforced hose. The decision on the feasibility of repair is made based on measuring the length of the damaged section of the gas pipeline.

Checking the pressure in the fuel rail on VAZ and Lada cars with an injection engine

The article will describe a testing technique that does not require special devices.

From the tool you will need:

1. We took a regular gas pressure gauge with a scale of up to 1.0 MPa. It has a threaded connection and screws perfectly onto a 9 mm oxygen hose. You can use a mechanical one to check tire pressure. They are usually inserted into the fuel hoses by 8 mm.

2. Screw it into the hose and tighten it with a clamp:

3. Unscrew the plastic cap from the fuel rail. It should unscrew by hand, but if it hasn’t been touched for a long time, you may need pliers:

4. If the car has just been turned off, then the gas in the ramp is under pressure. First, it is recommended to release the pressure by pressing on the spool and placing a rag or a plastic “bottle” with the neck cut off. It is more convenient to bleed using a wheel cap.

5. Unscrew the nipple with the cap. It is similar to a wheel nipple:

6. We put a hose with a pressure gauge on the threaded part and tighten the connection with a clamp:

7. Start the car and first of all make sure that there are no gasoline leaks from the connections. Then we look at the pressure gauge readings.

8. For fuel systems with “return” (a pressure regulator is installed on the fuel rail, from which a tube goes back to the tank), a pressure of 2.7 atm is considered normal (when re-gasping it should jump up to 3 atmospheres). However, a pressure of 2.5 atm is also acceptable. If the pressure is less, then the fuel system is faulty. Pressure pulsation (0.2 atm) indicates a clogged coarse mesh (located in the tank with the fuel pump).

9. Next, we check the pressure regulator. To check, disconnect the hose going from the regulator to the intake manifold. The fuel pressure should increase to 3.2 atm (at 2.7 initial). Up to 3.0 atm is also acceptable. If the pressure has not changed or changed only slightly (0.1-0.2 atm), then you need to check the fuel pump.

10. The maximum pressure developed by the pump is checked. To do this, use pliers to pinch the return fuel line (coming from the regulator). Different pumps show different pressures, but a new one should have at least 6 atm. A pressure of 5 atm indicates severe wear, but will still serve. If the pressure is less than 4.0 atm, the pump is faulty or the pipeline with the fine filter is clogged. If the fuel pump is working properly, and the pressure in the rail drops after the “return” is restored to less than 2.5 atm, and/or does not change when the regulator hose is disconnected, then the regulator is faulty. If, when the return line is pinched, the pressure rises slightly, and engine performance deteriorates significantly, then there is a high probability of injector leakage.

11. To eliminate the influence of the injectors, it is better to measure the pressure on the supply line itself by disconnecting it from the ramp and inserting it into a hose with a pressure gauge. If the pressure has risen to 5-6 atm, and with the “return” compressed it is significantly less, then the injectors are allowed to pass through. It is necessary to remove the ramp and check the condition of each individually.

12. You can check for clogging of the pipeline as follows. Remove the rear seat and unscrew the hatch. We see the fuel pump assembly underneath it. If the pipeline has quick-release connections, then we buy such a connection in the store (50 rubles).

13. If the pipeline is installed on threaded connections, you will have to buy the entire tube and cut off the tip:

14. Connect it to the pump outlet, and put a hose with a pressure gauge on the other end. Let's check the pressure again. If the pressure gauge readings increase to the normal 6 atm (after pumping gasoline several times by turning the key), then change the fine fuel filter and bleed (or flush the entire system).

15. Replacing the fuel filter is shown here: replacing the fuel filter on Lada Priora, Kalina and Granta cars. The only difference is that after removing the filter, we direct the fuel supply hose into a plastic bottle (preferably transparent) and turn on the ignition with the key (the fuel pump turns on and fuel spills into the bottle). We inspect the condition of the fuel in the bottle. Then we install a new filter, remove the hose from the ramp and direct it into the bottle. We turn on the ignition several times and spill gasoline. We inspect the fuel in the tank again. If dirt is found after the filter, then washing the injectors is also required. We assemble the entire system and measure the pressure readings again. If the readings have not changed, then check the correct clamping of the “return” (you can try connecting a pressure gauge to the output of the regulator). If this does not help, then perhaps the blockage is serious and requires blowing with air under high pressure. It would be a good idea to check the entire pipeline from the tank for mechanical damage (dents, kinks).

16. Fuel systems without a return line are diagnosed in almost the same way. The main difference is that here the fuel regulator is located on the pump body. The fuel goes from the pump to the fine filter, and then goes to the regulator. Near the body, the fuel pipe bifurcates. One tip goes to the regulator, and the second goes to the fuel rail.

17. The main difference in the readings is the normal pressure at the ramp is 3.8 atm. When over-gassing it should jump up to 4 atmospheres. If the pressure is less, immediately check the pump. We connect a pressure gauge to the pump outlet and check the pressure. The pressure should also be at least 6 atm for a new one.

18. If the pressure is working, then check if the fuel filter is clogged. To do this, we restore the fuel line from the pump and connect to the tube suitable for the regulator. The easiest way to do this is to cut off the old tip from the fuel filter, install one end of it in a clip, and put a hose with a pressure gauge on the other. If the pressure is identical to the pump pressure, then the filter is clean. If a significant drop is visible, the filter must be replaced.

19. Next, we check the supply line to the ramp. Shut off the fuel supply to the regulator. It is easier to do this by inserting a soldered (twisted/crumpled) tip from the filter into the quick-release connection. If there is no difference here, then change the regulator. If losses are detected, then we check the entire pipeline - there may be leakage or crumpling of the pipeline, it is also possible that nozzles are leaking.

Speed sensor (DS)

The speed sensor of the Niva car is installed in the transfer case. The function of the sensor is to transmit vehicle speed readings. The sensor also forms the fuel mixture; when the car is moving at neutral speed, you can notice that the speed is slightly higher than when the car is running at XX while standing still. Increased speed when driving is necessary to avoid dips when turning on the speed and sharp acceleration.

Signs of DS malfunction:

- Increased fuel consumption;

- There are no increased speeds when driving at neutral speed;

- Dips during acceleration;

- The speedometer does not work;

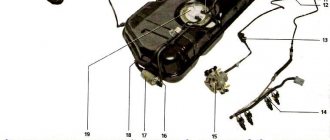

Checking the pressure and replacing the pressure regulator in the VAZ-21214 engine power supply system

Checking the pressure in the fuel system of the VAZ-21214 injection engine

We carry out the work on a cold engine.

The pressure in the fuel frame is checked with a special pressure gauge, but if you don’t have one, you can use a regular pressure gauge.

We put an oil and petrol resistant hose (with an internal diameter of 12 mm) onto the threaded fitting of the pressure gauge and secure it with a clamp.

We unscrew the protective cap on the rear end of the fuel rail.

Using the wheel valve cap, unscrew the spool from the fuel rail fitting (for clarity, we show the operation on a removed ramp)

Gradually releasing the fuel pressure, remove the spool.

We put the pressure gauge hose on the ramp fitting and secure it with a clamp.

We start the engine and when it is idling, check the fuel pressure, which should be 2.8–3.2 bar (2.8–3.2 atmospheres)

Remove the vacuum hose from the fuel pressure regulator.

If the regulator is working properly, the fuel pressure should increase by 0.2–0.7 bar (0.2–0.7 atmospheres).

If the regulator is faulty, then see below how to replace it.

Replacing RTD Niva Chevrolet

To work you will need:

- Hexagon 5.

- Open-end wrench 24.

- Screwdriver.

Before removing the regulator, it is necessary to relieve the gasoline pressure in the fuel hose. To do this, unscrew the gasoline drain nut and lower it down the tube.

The device can be removed in literally four steps:

After dismantling the old device, use a screwdriver to remove the O-ring and check its integrity. A damaged seal should be replaced with a new one.

Installation of the fuel pressure regulator is carried out in the reverse order of removal.

Before you start using the car, you should make sure that the RTD is working properly by checking the pressure in the fuel rail in different modes. This will help you ensure that the problem is resolved and the machine is ready to use.

Removing the fuel pressure regulator

A small announcement on the design of the regulator:

The regulator consists of a valve with a diaphragm, pressed by a spring to a seat in the regulator body.

When the engine is running, the regulator maintains the pressure in the injector rail in the range of 284–325 kPa.

The regulator diaphragm is affected by fuel pressure on one side, and pressure (vacuum) in the intake pipe on the other.

When the pressure in the intake pipe decreases (the throttle valve closes), the regulator valve opens at lower fuel pressure, allowing excess fuel to flow through the return line back into the tank.

The fuel pressure in the rail decreases.

As the pressure in the intake pipe increases (when the throttle valve opens), the regulator valve opens at a higher fuel pressure and the fuel pressure in the rail increases.

We carry out the work on a cold engine. Disconnect the negative cable from the battery

Disconnect the fuel pressure regulator vacuum hose from the receiver.

Using a 17mm wrench, unscrew the drain tube nut, gradually releasing the pressure.

Hold the hose fitting with a wrench of the same size

The connection between the hose and tube is sealed with a rubber ring

Using a Phillips screwdriver, unscrew the clamping bar screw.

Using a 24mm wrench, loosen the nut securing the drain tube to the pressure regulator

Use a 5mm hex to unscrew the two screws securing the fuel pressure regulator to the rail.

Separating the regulator from the ramp

Unscrew the nut and remove it.

The connection between the ramp and the regulator is sealed with a rubber ring.

In photos 6–10 the receiver is removed for clarity

The connection between the fuel pressure regulator and the pipe is sealed with a rubber ring

Install the regulator in reverse order

If necessary, replace the O-rings and lubricate them with engine oil.

The tightening torque of the regulator mounting screws is 8–11 Nm, and the drain pipe mounting nuts are 20–34 Nm

Location, structure and principle of operation

The fuel pressure regulator (FPR) is located between the fuel pump and the rail. It consists of the following parts:

- Three fittings: inlet, outlet (to the ramp) and for supplying fuel to the tank.

- Frame.

- Membrane.

- Valve.

- Spring.

- Valve holder.

The diaphragm divides the regulator into a fuel chamber and a spring chamber. The first receives gasoline, and the second is connected to the intake manifold.

The membrane is pressed against the valve by a spring. On the other hand, it is affected by the fuel pressure in the system.

The regulator works like this:

- Gasoline presses on the membrane.

- If the pressure force exceeds the force of the spring, the latter is compressed.

- The membrane moves back, opening the bypass valve.

- Part of the gasoline is sent to the tank through the return pipeline.

- The pressure decreases and the valve closes.

No pressure in the fuel rail, reasons

The presence of a certain pressure in the fuel rail of an injection engine is one of the conditions for its operation.

Using the example of the fuel rail of the fuel injection system 2111 of the VAZ 21093 (21083, 21099) car, we will consider the signs and reasons for the disappearance or decrease in gasoline pressure in it.

Signs that there is no pressure in the fuel rail

Car engine does not start

The starter turns, but there are no or infrequent sparks in the cylinders.

The car engine starts and immediately stalls

After starting, the engine makes a few revolutions and stalls.

Unstable engine speed at idle

The engine jerks, shakes, and tries to stall when idling.

Dips, jerking and jerking after pressing the gas pedal

When pressing the gas pedal, instead of the expected increase in speed and pickup while the car is moving, the driver feels that the engine is trying to stop and stall - failure or several such attempts extended over time - jerking and jerking.

Reduced power and throttle response of a car engine

The car's former agility and engine traction have disappeared somewhere; the car can barely pull.

Causes of the “no pressure in the fuel rail” fault

Fuel pump faulty

The electric fuel pump cannot create the required pressure in the fuel system due to its malfunction or a malfunction of the electrical switching circuit. If the pump fails completely, then there can be no question of any pressure in the fuel rail.

Fuel filter clogged

When the fuel filter of the fuel injection system becomes clogged, its throughput decreases (in some cases it disappears altogether). As a result, gasoline cannot be pumped into the fuel rail by the gasoline pump with sufficient pressure, or maintaining the required pressure at different engine operating modes becomes impossible. See “Signs of a clogged fuel filter in the fuel injection system.”

The pressure regulator on the fuel rail is faulty

Due to the loss of mobility (freezing) of the diaphragm inside the pressure regulator, gasoline from the fuel rail is constantly discharged into the return line (and not only when it is needed). Therefore, it cannot provide the required level of fuel pressure. The pressure on the injectors drops, and the less pressure on the injectors, the less efficient they work.

The fuel lines of the engine power supply system are clogged

Low-quality gasoline containing various additives that create deposits, a fuel filter that has ceased to cope with its functions, and dirt in gasoline and in the fuel tank allow a car with high mileage to first narrow the clearance of the fuel lines and then close it completely. Accordingly, the fuel supply weakens or stops altogether. There is no pressure in the fuel rail or it is below normal.

There is a fuel leak in the engine power supply system

It turns out that despite all the efforts of the fuel pump to catch up with the required level of pressure, it is constantly being released, reducing the norm. The signs of malfunction listed above appear in the operation of the car's injection engine.

What to do if there are signs of a “no pressure in the fuel rail” malfunction?

First of all, you need to check the pressure in the fuel rail using a pressure gauge. It should correspond to 2.5 - 3.5 bar (250-350 kPa) after the engine has been stopped.

Fitting for checking the pressure in the fuel rail of the injection engine 2111 of the VAZ 21093 (21083, 21099)

If it meets the standard, but there are problems with the operation of the engine, then we check and, if necessary, replace parts of the power system.

First, you should inspect the fuel lines for gasoline leaks or damage (kinks, flattening).

Then we check the strainer on the fuel module in the gas tank for clogging and replace the fuel filter next to the gas tank.

Next, check the fuel pump in the gas tank. After turning on the ignition, you should hear a click from the activation of its relay under the panel and the hum of the pump in the tank (you can open the filler cap of the tank and listen). Of course, in this way it is impossible to completely assess the serviceability of the pump, but in most cases this is enough.

If necessary, replace the pressure regulator with a new one or a known good one.

Brake pedal sensor

The brake pedal sensor is installed on the pedal assembly under the Niva's steering column. In cars without the E-GAZ system, it is only responsible for turning the brake lights on and off. In cars that have an electronic throttle and therefore an electronic gas pedal, this sensor affects the operation of the pedal. If the brake sensor breaks down, the gas pedal stops working.

Signs of malfunction:

- The gas pedal does not work;

- Jerking when moving at a constant speed;

- Loss of power and vehicle dynamics;

Ignition module (IZ)

The ignition module is installed on the left side of the engine on a bracket. This sensor is involved in the formation of ignition. It is this that produces the high-voltage voltage necessary to create a spark in the combustion chamber of the internal combustion engine. The module has two coils, they are also autotransformers, which produce a spark in pairs, each coil for two cylinders. If one of the coils fails, two cylinders fail at once.

Source

Oxygen sensor (DC, lambda probe)

An oxygen sensor, also known as a lambda probe, is installed in the exhaust system of a car. In some versions of cars, two sensors are installed before the catalyst and after the catalyst. Two sensors are installed in Niva with EURO-4 standards. The sensor captures exhaust gases and transmits readings to the ECU. If there is a large amount of unburned gasoline in the exhaust gases or, on the contrary, a small amount, then the DC makes changes to adjust the fuel mixture.