Error Code P0171 occurs when the mixture is too lean, when there is not enough fuel and too much air. This mixture occurs when the engine is taking in too much air from the environment and/or the fuel system is not injecting enough fuel. This state of the mixture entails misfires, delays in the car's response to the accelerator, jerking during acceleration, idle failures, and unstable engine operation. In engine management systems Euro 2 and higher, the lambda probe controls the quality of the mixture in which there should be 14.7 parts of air per part of fuel. When the permissible range for increased air presence is exceeded, which is 20-30% of the norm, error P0171 appears.

Injector problems

It doesn't take an expert to figure out that the problem here is with the injector. And first of all, before we begin to study the Lenten mixture, we will try to find out what it is. This is only important because such a cause can lead to costly repairs.

Why do jerks happen?

The presence of jolts when the car is moving is a problem that directly or indirectly indicates the presence of malfunctions in the engine, or more precisely, a loss of power. In total, there are two features that affect the development of power in the engine: fuel supply and the ignition system.

If everything is more or less clear with the ignition, due to inspection of the generator, spark plugs, ignition cables for malfunction and the battery for charging, then in the case of the ignition system everything seems much more complicated.

High voltage cables are marked with arrows

Inspecting the condition of the spark plugs

To ensure a good engine start, it is necessary to mix the mixture of fuel and air in ideal proportions, and the injector is responsible for this.

It happens that when mixing these proportions, a malfunction occurs and the mixture turns out rich or lean.

A clear example of the air-fuel ratio.

In order for a car to get maximum power when burning fuel in the cylinders, it is necessary to bring its indicator to the level of 0.85 - 0.9, with an excess of oxygen => 1 (at this indicator, gasoline burns completely without residue - about), and when there is not enough oxygen and readings coincide The main reasons for the lack of mixture

The main and most important sign that the system will be lean is a stalled or unstable engine. And if the mixture is completely lean, it is possible that there are factors that will not start at all.

The most common cause of these problems is a clogged air filter (see "Replacing the Air Filter"), clogged injectors, worn fuel pump and possibly air leaks in the installation. All these reasons are somehow related to the stable operation of the engine.

What do spark plugs tell us?

One of the main checks for the condition of the mixture will be to assess the condition of the spark plug.

So, a light brown tint will indicate that the system is working normally, too dark a tint, a deficiency (enriched mixture - about), too light, an excess of the mixture (depletion - about.

Candles with different types of soot

Please note that if, in the presence of such malfunctions, the consumption decreases by at least 10-15%, this may lead to further failure of the lambda probe (lambda probe, if present - approximately), or worse, lead to an increase detonation.

And this, as you already understand, will directly affect the operation of the engine. Engine power readings can be changed by cleaning the injectors, provided the ignition elements are functioning properly.

A regular wash, every 20-30 thousand kilometers, can keep it in a condition close to ideal.

Diagnostics of the throttle valve block on a VAZ-2114

If you have never performed such a procedure, first of all we recommend checking the condition of the throttle valve for carbon deposits and other deposits, because it is in this place that fuel vapor from the intake manifold settles, accumulating in weather conditions.

And the already deposited carbon does not allow the damper to close completely, allowing more air into the system, thereby changing the composition of the mixture, making it leaner. Since large traces of carbon deposits can be detected visually, cleaning should be done with regular carburetor cleaner, which is sold in cylinders of different capacities.

We disassemble the throttle valve

How to clean the injector yourself!

If you do not want to take your car to a specialized workshop to clean the injector, you can do it yourself. This work can be done both on the removed mechanism and directly on it.

To clean the injector (nozzle - approx.) on a VAZ-2114, you need to read this article and do everything as indicated in the detailed instructions.

P0171 Possible solutions

There are many different solutions for the P0171 code. We will describe them, starting with the most common. Diagnostic tools that can help you troubleshoot problems are described in the diagnostics section below.

- Replace faulty vacuum hoses or gaskets around the intake manifold.

- Repair other intake leaks.

- Replace the PCV valve.

- Replace the fuel pump/fuel filter/fuel pressure regulator or repair the wires.

- Replace EVAP valve.

- Replace oxygen sensors.

- Replace the EGR valve.

- Replace the mass air flow sensor (MAP/MAF).

- Repair exhaust leak.

- Replace the coolant temperature sensor.

- Repair of faulty wires.

- Replace the ECU (ECM/PCM, rare).

Causes of excess air

If, after carrying out this work, instability in the operation of the system is also observed, pay attention to possible places where excess air is present, since it also affects the depletion of the mixture, and the main reasons are as follows:

- Presence of dirt or marks on the mass air flow sensor.

And to eliminate the above reasons, it is necessary to conduct a thorough diagnosis.

Troubleshooting

Mass Air Flow Sensor: The mass air flow sensor can become clogged due to natural causes, as well as fumes from the throttle body when the car is not running. And then, over time, accumulating in a thick layer on the thin sensor wire, it forces it to send inaccurate data to the ECU, which in turn negatively affects the flow and intake air parameters of the system.

When diagnosing its malfunction, it is better not to rush into purchasing it, since it is not cheap, but it is better to check its performance on a known-good device. And when it is determined that this is the reason, you can try to clean it or then replace it with a new one.

Vacuum leak

Vacuum Leak - These words mean any form of air leakage, such as being sucked into a system, mainly through a manifold or pipe gasket.

The vacuum pump and return line may cause

Pay attention to the condition of the pipeline going from the air filter to the throttle valve, pipes going to the crankcase ventilation. There should be no visible damage to them, as well as large cracks through which excess air could get in.

In addition to all of the above, you may want to check the engine oil dipstick and the oil filler cap on the fuel filler neck because if these connections are not completely sealed, they can cause excess air.

Self-adjustment

Most drivers are very glad that they know how to adjust the throttle angle, as they are completely confident that this will help regulate fuel consumption. In addition, some resort to flashing the vehicle's electronic control unit. In order not to damage some units or ECUs, it is worth seeking help from qualified technicians who can, using special programs, without affecting the quality of the mixture, improve some of the car’s performance. Otherwise, the risk of “killing” the engine of your vehicle increases. Thus, a lean mixture is formed on the injector, the reasons (2114 is no exception) for which lie in the independent adjustment of the angles or the intervention of an inexperienced car owner in the operation of the engine system.

Error 0171 “lean mixture”

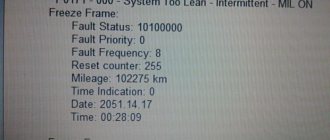

With this error, the check engine light does not light up. It can only be detected using diagnostics, for example through the ELM327. This error directly indicates a malfunction in the ignition system.

But this can also occur as a result of using low-quality fuel. If, when resetting, it appears in the future, after refueling on a good distributor, then be prepared to look for the faults that we wrote about above.

The modern injection system is most popular in cars. There were practically no cars with carburetors; everything switched to electronic or electronic-mechanical control. However, this did not eliminate the inconvenience and the problems did not decrease. Today we will find out why a lean mixture forms at the injector.

Clogged injectors

If you do not change the fuel elements of the car system on time, a lean mixture may form on the injector, the reasons for which will lie in the incorrect operation of the injectors. That is, fuel is supplied, but supplied in fairly low quantities. An injector is a special device related to the injection system of a car. There are many elements: electromagnetic, electrohydraulic or piezohydraulic. Vehicles with gasoline engines use electromagnetic parts.

To solve the problem, you can restore the previous injection by washing the injectors, which is carried out only using special equipment.

By the way, to avoid contamination of fuel filters and injectors, you should clean the fuel tank at regular intervals, since there is a large accumulation of dirt, sand or other substances there.

Symptoms of a lean fuel assembly

ATTENTION! I found a completely simple way to reduce fuel consumption! You do not believe me? Even a mechanic with 15 years of experience didn’t believe it until he tried it. Now save 35,000 rubles a year on gasoline! Know more"

A fuel mixture or group is a certain amount of gasoline and air. A lean mixture means there is less fuel in the fuel block than needed. There is also an enriched mixture, when there is much more fuel.

The presence of a low-quality fuel assembly can be determined by its characteristics:

- occurrence of misfires;

- delay in engine response during acceleration and sudden pressing of the accelerator pedal;

- engine interference;

- automatic shutdown of the internal combustion engine at idle;

- twitching when maneuvering or accelerating;

- change the engine sound when starting;

- unstable operation of the engine as a whole.

As you can see, the presence of a spent fuel group can only be determined by signs of engine operation.

Mixture rate

Norm is an important concept. Today it may differ depending on what the European standard is. For example, for cars of Euro 2 standard and higher, a special sensor or lambda probe is installed on the engines. Thanks to this, quality control of produced fuel assemblies is carried out. According to standards, 1 part fuel should be 14 parts air. With a minimal deviation from the values, the on-board computer immediately generates an error, since if a lean mixture enters the cylinders, there is a risk of failure and overheating of the engine. It is obvious that a group of spent fuel cannot contribute to the jerk of the power unit to a given speed.

Overheating the engine will not lead to anything good. After a while, the motorist will encounter the following:

- engine pistons, valves and rings will burn out;

- the engine will lose traction;

- the consumption of antifreeze, oil and gasoline will increase.

Causes

Because it happens. It turns out that the reasons for poor fuel assembly are quite simple; they need to be looked for in the operation of the car itself. They can be determined using tests. And first of all, the elements that generate sparks are analyzed - candles. If any of them fails, the appearance of a faulty fuel assembly is, of course, a priori.

Injection system

Errors occurring in the injection system are said to be the main cause of mixture tilt. As you know, the injectors are “controlled” here, injecting fuel into the engine and controlling the preparation of fuel groups. Over time, the injectors tend to become clogged and therefore require flushing.

Incorrect injector operation is always a problem, and one of them is creating a lean mixture. Fuel is injected, but in very small quantities, as one or more injectors are clogged or clogged.

One of the reasons for clogged injectors is premature filter replacement. They allow foreign particles and debris to pass through, which settles in the nozzle holes.

It is also important to monitor the condition of the fuel tank. Over time, a lot of deposits also settle inside, and the incoming fuel gradually begins to become dirtier, which clogs the filters and injectors.

In addition to the injectors, the injection system also includes various sensors that control the opening angle of the air valve. Regulators that report incorrect information must be replaced.

The most common causes of a lean mixture include a malfunctioning fuel system. This usually happens due to:

- consumption of low-quality gasoline at Russian gas stations;

- clogging of car fuel cells.

Filters and airing

The latter mainly concerns fuel filters. As you know, on modern cars there are two of them: a large mesh and FTO (fine mesh). Both filters are extremely important; clogging one of them leads to difficulties in the operation of the entire machine. Therefore, it is so important to change filters in a timely manner and monitor their condition. The coarse mesh is located inside the submersible injection pump, and the FTO is installed separately, usually under the threshold of the car.

It is also possible that ventilation has occurred in the injector system. Air is sucked in from the fuel pipes or other places, which ultimately causes the percentage to increase. A certain amount of air gets into the mixture, depleting it. That’s why it’s so important to monitor tightness.

On some vehicles, the intake manifold can break down over time. If it is not replaced, air will begin to penetrate in large quantities. Another common occurrence for aspiration is the XX sensor. It must be replaced along with the torn o-ring.

Fuel system malfunction

Other causes of a lean mixture on the injector are due to improper operation of the vehicle's fuel system. As a rule, operational disruptions occur due to low-quality fuel, which is filled at little-known gas stations. One of the options for unstable engine operation and the formation of a lean mixture is clogged fuel cells of the car. In such cases, there is a misfire in the engine. As a result, the car may jerk. To prevent this from happening, it is necessary to purchase fuel only from trusted gas stations. Both fuel elements should also be replaced in a timely manner. Remember that one filter is presented on the injector in the form of a mesh and is installed directly into the fuel pump. The second element is most often located near the tank on the bottom of the car, less often in the engine compartment. To avoid over-leaning the mixture, it is necessary to change them at least once every 40,000 km. Sometimes this figure may be lower, since it all depends on the quality of gasoline.

What to do

If an error is detected, it can be eliminated manually or by contacting specialists. Why this needs to be done is described in detail above. Of course, it would be better to take the car to a service station, where experienced technicians will check other breakdowns, check and adjust all elements of the automotive system in accordance with the standards.

Self-adjustment

Experienced motorists themselves know how to adjust the throttle position angle. With the help of proper settings, it will be possible to regulate fuel consumption and normalize the mixing of fuel groups.

Thus, self-regulation of the injector in case of problems with the fuel mixture comes down to the following steps.

- Check the connectors for dirt deposits.

- Inspect the supply pipes for air leaks.

- Check the operation of the nozzles, wash them if the procedure has not been carried out for a long time.

- Pay attention to the sparkling elements. If one of the candles is too lit, this is a clear sign of excess air.

- Check the ignition coils.

- Check the drain, which can easily indicate the presence of a lean mixture. Consequently, when lean, the muffler tends to make an automatic popping sound.

- Check the operation of the fuel pump, which fails over time. It also happens that it works reluctantly and still needs to be changed.

And finally. Remember that if the injector has mechanical injection, the cause may also be hidden in the RTD. This is a sensor installed on the fuel rail to monitor and control the amount of fuel.

If you take care of your car, carry out timely maintenance, and install original spare parts, problems can be minimized.

Forget about camera fines! An absolutely legal new product - Jammer for traffic police cameras, hides your license plates from cameras that are found in all cities. More details at the link.

- Completely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter socket;

- It does not interfere with radios or cell phones.

List of reasons for poor mixture at the injector. What to check and how to do it?

The reasons, among other things, are not so varied and are often quite easy to eliminate. The main thing is to understand what is going on with your car and take action before it gets offended and completely refuses to drive, and your nerves begin to subside.

The reasons for a lean mixture at the injector, as mentioned above, are quite trivial. Anyone who has a fuel injected engine in their car knows that it can regulate the ratio of gasoline vapor to air. However, not everyone thinks about their fair balance. For people who are not inclined to go into technical details, we explain: the norm is considered to be the proportion of one kilogram of the same vapor per 15 kilograms of air.

At the same time, parity between fuel economy and engine power is maintained. If the weight of air is reduced to 13 kg, then gasoline will correspondingly increase, the engine will receive more power, but fuel consumption will also increase significantly.

In the opposite situation (often admitted with full knowledge of what you are doing), when you introduce 16 kg of air, power is reduced by 10 percent compared to a rich mixture, but savings increase by 15-20%. However, further dilution of gasoline leads not only to a decrease in engine thrust, but also to an increase in fuel consumption: when trying to climb a mountain, you press the gas, burn more fuel, and the efficiency is zero.

Therefore, no one installs an injector of up to 20 kilograms of air per 1 gasoline. That is, there are some disagreements with the node itself.

The primary and main symptom of a lean mixture is a stalled engine. A very weak mixture means that the engine does not start at all, and if it does, then when you try to move, it immediately turns off. It’s just that the mixture is not rich enough and the car jumps and jerks when driving. However, this style of movement is not limited to the slender mixture.

The car can behave like this and have problems with any part of the ignition: coils, spark plugs, distributor cap, wires, carbon or slider. Therefore, it is necessary to pay attention to other signs, indirect or less obvious. Experienced drivers recommend the following.

Unscrew the spark plugs and look at their color. If they are light brown, the injector is working properly; dark - not enough air; light is its excess. However, carbon deposits cannot serve as an accurate indicator: its shade does not correspond to the norm both when the ignition is set incorrectly and when there are errors in the selection of the spark plugs themselves. More details in the article "".

… If the mixture is lean, the muffler produces an automatic explosion without much recoil, and if the mixture is too rich, isolated, noticeable explosions occur.

Separately, symptoms may indicate various malfunctions; in general, they may indicate malfunctions in the injector. Ideally, of course, it would be worth getting a gas analyzer, but few people have one lying around on a shelf in the garage.

There are only 3 of them and we will look at each in detail.

- The most common type is dirt. It clogs injectors and filters, so that the fuel supply to the engine is not complete;

... Either a crack has formed on one of the pipes and nozzles connected to the manifold, or the pressure in it has been depressurized, or some connections are not tightened well;

- The fuel pump died silently. Or he is still alive, but works for a quarter of his own, that is, he will still have to change.

How is the check carried out?

Check sensors . One of the most common causes of the P0171 code is a clogged air flow sensor (MAF). The sensor's response to changes in air flow may be slow due to dirt accumulated on its wire. It can also be contaminated by fuel vapors that escape through the intake manifold and throttle body when the engine is not running. These vapors deposit a waxy layer on the sensor wire, which causes a signal to be sent indicating that there is not enough air in the mixture. And the engine control unit, in turn, does not add fuel when the amount of air increases and the overall balance of the mixture is disrupted. All this leads to a lean fuel mixture and the appearance of error P0171. Often, along with this error, errors p0100 or p0102 may appear, which clearly mean a malfunction of the mass air flow sensor. To solve the problem, the sensor itself must either be cleaned using a special cleaner for electrical appliances or carb cleaner (spraying onto the sensitive element), or a new one must be installed.

For cleaning, use only carb cleaner or electrical cleaner. Other substances may damage the sensor.

Check for vacuum leaks . If the cause is not the mass air flow sensor, then you should check for a vacuum leak. Depressurization can occur at any point in the inlet pipe, as well as at the outlet of the throttle body - at the connection point between the vacuum hoses and the intake manifold, in the throttle body gasket, in the inlet manifold gaskets. It is also worth inspecting the hoses of the crankcase ventilation system, fuel vapor recovery system and plugs on the intake manifold for physical damage. The entire exhaust system near the oxygen sensor, half a meter before and after it, must be sealed. In another case, the sensor readings may be incorrect (for example, an error may occur when a corrugation burns out). The easiest way to check for leaks is using an auto scanner (by checking the fuel balancing value).

If your vehicle is equipped with a differential pressure sensor in the exhaust gas recirculation system (DPFE), then the code P0171 may appear if it is faulty. Such sensors fail quite often when the car has high mileage. You should check it if the car's mileage is already more than 90 thousand kilometers.

This sensor is mounted on the engine and is connected by two hoses to a pipe through which exhaust gases are discharged to the recirculation valve (EGR). Corrosion in the sensor leads to its sensitivity decreasing, as a result of which it transmits information about the lack of gases and the EGR valve remains open longer, which leads to an increase in the air level in the mixture and its leanness.

Check the fuel system . As already mentioned, the lean mixture error code P0171 can also appear if there is insufficient fuel volume with which the mixture is saturated. To check the health of the fuel system, the following tests are performed:

These tests can also be performed using an in-vehicle scanner. The fuel pressure parameter and fuel balancing value are checked. If error P0171 occurs intermittently, but with some frequency, the reasons may be unreliable connection of the sensor and controller harness contacts, mechanical damage to the harness, or poor grounding of the controller.

Author: Ivan Matieshin

Subscribe

to our

Yandex channel.

Zene More useful tips in a convenient format Subscribe Didn't find the answer to your question?

Ask in the comments. We will definitely answer!

The reasons for this error are in many ways a mirror image of the reasons for the appearance of error P0172 in the controller memory.

A lambda probe that degrades over time may physically stop working - that is, deviations in the oxygen balance “from different sides” of the sensitive element will no longer lead to a change in voltage at its terminals (here we are talking about the classic version of a platinum oxygen sensor, which is precisely the source of voltage). For the ECU, this is equivalent to a constantly lean mixture; accordingly, the “fuel supply correction” parameter will begin to constantly go positive.