Most often, the starter turns poorly due to low battery charge, poor ground contact, wear of the bushings on its body, breakage of the solenoid relay, short circuit of the stator or rotor (armature) windings, wear of the bendix, loose contact of the brushes with the commutator or their significant wear. .

Primary repair measures can be carried out without removing the unit from its seat, but if this does not help and the starter turns tightly, then it will have to be dismantled and additional diagnostics performed with its disassembly, focusing on its main malfunctions.

| What is the reason | What to do |

| Weak battery | Check the battery charge level, recharge if necessary |

| Check the condition of the battery terminals, clean them of dirt and oxides, and lubricate them with special lubricant. | |

| Battery, starter and ground contacts | Inspect the contacts on the battery itself (tightening torque), the engine ground wire, and the connection points on the starter. |

| Solenoid relay | Check the relay windings using an electronic multimeter. On a working relay, the resistance value between each winding and ground should be 1...3 Ohms, and between the power contacts 3...5 Ohms. When the windings fail, the relay is usually replaced. |

| Starter brushes | Check their level of wear. If the wear is significant, then the brushes need to be replaced. |

| Starter bushings | Inspect their condition, in particular, play. The permissible play is about 0.5 mm. If the free play value is exceeded, the bushings are replaced with new ones. |

| Stator and rotor (armature) windings | Using a multimeter, you need to check them for open circuits, as well as the presence of a short circuit to the body and an interturn short circuit. The windings are either rewinded or the starter is replaced. |

| Bendix starter | Check the condition of the Bendix gear (especially for old cars or cars with significant mileage). If there is significant wear, you need to replace the bendix with a new one. |

| Engine oil | Check the condition and fluidity of the oil using a dipstick. If summer oil is poured into the crankcase and it has thickened, then you need to tow the car to a warm box and change the oil there to winter oil. |

| The ignition is set incorrectly (important for carburetor cars) | In this case, you need to check the ignition timing and, if necessary, set its correct value. |

| Ignition switch contact group | Check the condition and quality of the contact group and connections. If necessary, tighten the contacts or replace the contact group completely. |

| Crankshaft | It is better to entrust diagnostics and repairs to specialists at a car service center, since it is necessary to partially disassemble the engine and check the condition of the liners. |

battery

If the car engine does not start when you turn the key, the first thing to check is the battery charge level. The electric starter requires high current and can drain the battery after a few unsuccessful starts. If the car battery is discharged below 10.8V, the power supplied to the brushes is not enough to turn the small gear on the large flywheel. Especially during a cold start.

Two more common problems associated with the battery: an error in the on-board system (if the brain does not have enough current, the battery will not allow the engine to start), as well as oxidized or loose terminals. Wipe the battery terminals from oxide, reconnect the wires, checking the tightness.

Oxidized battery terminal

Frequent malfunctions on popular cars

In most cases, the starter does not turn when the ignition key is turned due to oxidation and mechanical damage to the wiring. If there is poor contact with the “+” terminal of the battery, the control relay or ground, the starter does not receive enough current to crank the engine . Therefore, first of all, you need to look at the contacts in the engine compartment and check for voltage at the terminals with a tester. The most common malfunctions of specific car models, due to which the starter does not respond to the ignition key in the table.

| Why does the starter not work from the ignition key on popular car models? | |

| Auto | Weakness |

| VAZ 2110, 2111, 2112 | Wires of the central locking and ignition switch, which melt due to power surges. |

| VAZ 2108, 2109, 21099, 2113, 2114, 2115 (Lada Samara) | Oxidizing contacts of the control relay located in the engine compartment above the VUT, as well as the wiring extending from it. |

| VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107 (Classic) | The contact “nickels” of the solenoid relay often burn or oxidize. The contact group of the ignition switch fails. On later models, for example, 2107, problems with the control relay are similar to Samara (see above). |

| Niva | On old Nivas (before 21213), the ignition switch contacts burn and oxidize. On newer ones (after 21214), the starter control relay, located under the hood near the brake fluid reservoir, often fails. There is a drainage tube located nearby that drains water from under the glass, moisture from which gets onto the relay, which leads to oxidation of its contacts. |

| Lada Priora | Immobilizer problems due to which it does not see the key. |

| Lada Kalina, Lada Granta | Failure of the immobilizer, blocking the start, malfunctions in the contact group of the ignition switch and failure of the additional starter relay K3 in the fuse block. |

| UAZ | Malfunction of the 5-pin starter control relay and solenoid relay. |

| Gazelle | Poor contact of wires and failure of the starter relay. |

| Peugeot 307 | Solenoid relay fuse F8 blows, poor ground contact. |

| Kia Sid | The limit switch of the automatic transmission selector, which determines the P and N positions, is faulty. There may be poor contact at the starter terminals or at the point where the ground wire is attached to the body. |

The starter turns poorly on a VAZ 2110

To start the combustion reaction, the car engine must spin up to a certain threshold level. When 40-50 rpm is reached, the gasoline engine starts, and at 100 rpm, the diesel engine starts.

A typical situation with sluggish starter operation is observed in winter, during severe frosts. The battery loses its charge when the temperature drops. A regular 55 Ah battery “tens” is usually only 70-75% charged. For each temperature drop, approximately 1% of the battery capacity is lost. Consequently, at a temperature of -20 degrees, such a battery is very often no longer able to start the car. As a rule, the starter on a VAZ 2110 does not turn well precisely for this reason.

At sub-zero temperatures, the car engine also has increased resistance to the starter. The lubricant does not freeze completely, but it thickens and the starter motor requires even more current to spin up.

A break or short circuit in the winding usually results in the VAZ 2110 starter not turning completely. No magnetic field is created at all inside the device, and the rotor does not spin. However, much more often the rotor still spins, but sluggishly. Such a short circuit is quite dangerous and can even lead to battery failure. If a car enthusiast notices that the starter is working especially hard, then you need to open the hood and see if there is smoke or a burning smell. These signs directly indicate a short circuit in the armature winding in the “tens” starter. It is highly not recommended to apply voltage to such a device in the future.

If, when starting the starter, a distinct noise and rumble is heard, then the reason may lie in the gearbox. The planetary gear in the BA 2110 starter is built using three satellite gears. When they wear out, serious vibrations appear during operation, which cause noise. Then the VAZ 2110 starter turns hard, and it is better to replace it.

The source of the noise may also be one of the jammed shafts. The 57.3708 gear starter is built using two shafts and four bearings in which they rotate. Over time, the liners break and the shaft begins to vibrate. If they are not replaced on time, the Bendix gear and flywheel crown begin to wear out. At some point, the shaft simply locks, and attempts to start the car lead to nothing. If the shaft is jammed, the armature winding can also easily burn out.

If the starter on a VAZ 2110 does not turn well, and no serious noise is heard, then the cause may also be wear on the brushes. Over time, the brush plates inevitably wear out, and at some point they lose contact with the commutator ring. In this case, the anchor spins weakly at first, and then stops rotating completely. You should unscrew the rear cover of the starter and replace the entire brush holder block. If the starter has been in service for more than one year and has undergone several repairs, then the commutator may also be worn out. This defect is corrected on a special machine in the workshop.

Even if the traction relay and DC motor are fully operational, the starter may still not spin the internal combustion engine to the required speed. The culprit may be the bendix, or the overrunning clutch. Bendix serves as a fuse in the starter. The VAZ 2110 starter itself is designed to give the internal combustion engine a speed of about 50 rpm. But when the car starts, the speed increases significantly. This is very dangerous for the starter. Therefore, the bendix spins on the shaft only in one direction, and only at the moment of excess speed between the engine shaft and the starter shaft. At the beginning of operation, this part of the device works as a single unit with the starter transmission shaft.

Bendix works on the principle of wedging between the ring and the shaft. Steel cylinders are placed between the two rings. If the shaft rotates in one direction, the cylinders rotate; if the direction changes, the cylinders jam. During operation, the cylinder cages are broken and the coupling does not occur completely. Very often the VAZ 2110 starter turns hard precisely because of a worn bendix. Changing it is not difficult, just remove the retaining ring on the shaft and it will come off.

Also read other reviews

- VAZ 2110 starter circuit

Units and design details

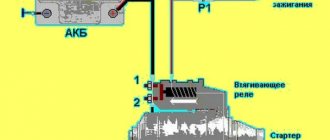

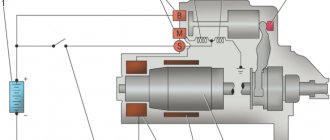

The function of the starter is to start the car engine by spinning its flywheel with an electric motor, creating temporary contact between the gears. Subsequently, the electric motor is turned off and physical contact with the flywheel gear is broken. The starter is located on the engine body closer to the battery and the cab.

Structurally, the device can be divided into two functional blocks:

Solenoid relay. When 12 volts are applied directly to the control contact, the electromagnet pulls in the core. The core pushes the bendix through a lever to engage the gear with the flywheel teeth. At the final point of retraction, the armature, with a contact plate through the rod, closes the contact of the nickels, providing a direct connection of the electric motor to the “+” of the battery.- Electric motor. When voltage is applied, it begins to rotate, spinning the flywheel through the Bendix to the operating speed of the car engine.

After starting the engine, the key is returned from the ignition position, de-energizing the relay. The relay opens the contacts, the spring returns the bendix to its original state. When starting, the electric motor requires several tens of amperes of current from the battery. After starting the car engine, the generator restores the battery charge.

The starter may have malfunctions, determined by the nature of the manifestation, visible signs, and tester readings.

Prevention for starter

If there is no time and opportunity to monitor the starter, and minor problems already exist, then it is recommended to carry out a little preventive maintenance. This will not help avoid significant damage, but will improve the condition of the device.

It is important to remember that during operation the car finds itself in various unfavorable environments. Due to such conditions, the metal used in mechanisms oxidizes and corrodes. Because of this, problems with the operation of the starter, as well as other elements, are possible.

Because of this, problems with the operation of the starter, as well as other elements, are possible.

To troubleshoot problems due to corrosion and oxidation, it is recommended to pay attention to the integrity of wires and contacts. To do this, you should regularly carry out the following actions:

- Disconnect the battery from the system.

- Clean all contacts with sandpaper.

- Treat all contacts with solvent or other special agent.

- Return the contacts to their place and securely fix them.

During the preventive maintenance process, it is worth checking the battery charge and the condition of the generator. If problems arise with the power system, this will affect the start and many other elements of the car.

You can check the battery using a simple multimeter, and do not forget to pay attention to the wires. It is also worth looking at the condition of the crankshaft and other components of the car. This approach will allow you to detect problems at an early stage and eliminate them without significant time and financial costs.

This approach will allow you to detect problems at an early stage and eliminate them without significant time and financial costs.

By following these rules, the risk of problems when starting the system is significantly reduced. But it is worth remembering that breakdowns can occur against the background of many other defects. Therefore, it is necessary to regularly diagnose all systems, not just the starter.

And for a better understanding of diagnosing and repairing the starter, it is recommended to watch this video. This describes the process of repairing a device if it does not spin well, and also explains some of the nuances of this task, which will allow you to independently disassemble and eliminate possible problems in the system that lead to low efficiency of the device:

Common Causes

Before checking, it is worth conducting a simple test for the operation of the starter, namely, checking its performance in cold and hot conditions. Based on this feature, you can exclude a lot of possible causes of problems. To check, it is enough to test the mechanism on a cold car, then start it and warm it up. Next you need to perform the same test.

Among the common problems it is worth noting:

- insufficient battery charge;

- thick oil;

- wear of bushings or brushes;

- problems with the solenoid relay;

- bad mass;

- Bendix failure;

- loose contact between brushes and commutator;

- short circuit of the element winding to ground.

The first point is the most common. Insufficient charge causes problems with the operation of the starter, due to which it cannot spin the shaft normally - there is simply not enough traction. Therefore, it is necessary to carefully examine the circuit with a multimeter. The check should affect not only the battery, but also all wiring elements.

The second problem is observed in cold regions when thick summer oil is used in the car. It is not designed for low temperatures, which is why it hinders the operation of various connections, including the crankshaft. In addition, during cold operation, the efficiency of the battery decreases, which also affects the operation of the starter.

Next comes wear on the bushings or brushes. Often the device wears out evenly, so this sign is a hint at replacing the starter. Damaged parts can be replaced, but other damage may occur.

Solenoid relay problems are also a common cause of starter problems. This is often due to pinhole contacts, so it is important to check them immediately and replace them as necessary.

Often problems with the starter arise due to the “mass” of the battery. It is important to check its contact to the solenoid relay, as well as the integrity of the wires. If it shorts to the windings of the elements, this significantly reduces the efficiency of the device.

Breakage of the bendix, loose contact of the brushes and commutator, as well as some other reasons for the incorrect operation of the starter should also be checked in the process of solving the problem. It is only important to note that some problems occur only in a cold or hot system. This is also worth considering.

The starter turns the engine, but the engine does not start

Malfunctions that appear when the engine is started are a fairly common occurrence during vehicle operation, regardless of the type and design features of the installed power unit (gasoline, diesel, naturally aspirated or turbocharged engine, hybrid engine, etc.). One of the most common situations is that after turning on the ignition and turning the key in the lock to the engine start position, the starter turns normally, but the engine does not start.

A feature of this type of breakdown is a certain difficulty in localizing the fault. The fact is that it is much easier to look for a problem if, for example, the starter makes a sound but does not turn the engine, or the fuel pump does not pump after turning on the ignition. In any case, the existing problem needs to be solved. Next, we intend to talk about why the engine may not start when the starter turns the crankshaft well.

Crankshaft wear

The reason why the starter does not turn on a hot engine may also be the crankshaft bearings - liners. Due to wear, oil starvation, poor-quality assembly and increased longitudinal (axial) play of the crankshaft, the liners may wear unevenly, which will give them an “wrong” shape, especially as a result of scoring on the surface. As a result, when the engine cools down, gaps appear between the crankshaft bearing journals and the liners, which makes it easier to crank the engine. When it warms up, the presence of these defects, on the contrary, can lead to complete jamming of the engine. In any case, when operating a car, it is advisable to respond as quickly as possible to its seemingly random “whims”.

Problems with the fuel system

Even the most “vigorous” battery and a new, working starter will not be able to start the car if problems arise with the supply of fuel to the cylinders. For this reason, the next thing to check is the engine power supply system.

1.Fuel pump

For carburetor and diesel engines, this unit is located directly next to the cylinder head or block. Injection power plants are equipped with an electric pump, which is installed in the fuel tank. Their operation is judged by a short buzzing sound that appears after the ignition is turned on. As for fuel pumps in carburetor engines, they are mechanically driven by a cam mounted on the camshaft.

It is easy to check the functionality of the fuel pump - to do this, remove the hose from the carburetor inlet fitting and lower it into a suitable container. After this, you should pump up the fuel using the manual pumping lever or by turning on the starter. If the result is negative, check the passage of gasoline through the fuel line and clean the mesh located in the top cover of the pump. If this does not help, then inspect the membrane and valves of the fuel pump. After replacing damaged and worn parts, the functionality of the device will be restored.

2.Fuel filters

Along the path of fuel passing from the tank to the engine there are several filter units - coarse meshes located on the fuel receiver, in the fuel pump and carburetor, and in addition, paper filters located in the section of the fuel line. The intensity and even the possibility of supplying fuel to the internal combustion engine depends on their purity. If you find a blockage, clean or replace the filter elements.

Throttle and injectors

Gasoline internal combustion engines operate on a fuel mixture, which is prepared in the carburetor or in the intake manifold (for fuel-injected cars). In the first case, the fuel passes through a whole system of channels, jets and nozzles that are located in the carburetor. In the second, it is supplied by injectors according to signals received from the electronic engine control unit (ECU).

The air supply is metered using a throttle valve, which, depending on the engine design, can be mechanically or electrically driven. Clean the parts of this assembly and the throttle itself. Also check if fuel is being supplied to the cylinders. If you are dealing with an injection car, then press the fitting spool located at the bottom of the fuel rail - gasoline should flow out from there under pressure. If the stream is too weak, then check the filters, fuel line and pressure reducing valve of the fuel pump.

In carburetor engines, the fuel supply can be judged by sharply opening the throttle - in this case, a portion of fuel will be injected from the accelerator pump nozzle into the diffuser. In addition, for gasoline power units, inspect the spark plugs - they should not be dry. Otherwise, check for the presence of a control signal at the injectors. If everything is in order with this, then you should unscrew the ramp fastening and move it away from the manifold in order to inspect the spray nozzles when starting the engine. The absence of fuel streams or their weak intensity indicates the need to clean or replace the injectors.

As for diesel engines, fuel is supplied to them under high pressure, and a much more complex pump (fuel injection pump) and specially designed injectors are responsible for this. To repair these components, special equipment is required, so in this case it is better to contact specialists.

Something else useful for you:

Video: The starter hums, but the engine does not turn over

To check the ignition system, unscrew and remove the spark plug from one engine cylinder. Having installed the tip of the high-voltage wire on its contact nut, touch the spark plug skirt to the cylinder head and crank the engine with the starter. In this case, a powerful spark of a purple or blue hue should appear on the contacts. If the spark is too weak (or there is none at all), then we check the operation of the computer, ignition coils and distributor (for an old-style internal combustion engine).

Advice to a car owner

All external contacts of the starter should be cleaned before checking, since this is a fairly common malfunction and there is no need to remove it from the engine.

Even an initial check of the starter without removing it from the vehicle usually indicates a breakdown, reducing repair time, reducing costs and not taking much time.

A large number of problems associated with a car's electrical system can be caused by poor contacts. Their appearance is associated with processes of chemical origin, in particular oxidation, or as a result of mechanical action. Thus, if problems are detected in the operation of the vehicle’s electrical system, manifested, for example, by malfunctioning headlights or the inability to start the car, you first need to very carefully check the connection to the battery ground. But in order to find out the reason for the poor performance of the starter, you should check for the presence of all possible causes that cause it.

Reasons for slow and ineffective starter operation:

Insufficient battery charge

A dead battery is not capable of cranking the engine for a long time. After a couple of cranking attempts, the starter goes silent and you can only hear relay clicks, which indicate that the battery is completely discharged. In this case, you need to charge the battery; if the problem occurs in cold weather, warm up the battery, use another battery or a special device, or replace the battery.

2. Use of thick engine and transmission oil at sub-zero temperatures.

In severe frosts, using engine oil that is not intended for use in extreme temperatures is accompanied by the problem of oil thickening. This can also happen with transmission oil poured into the gearbox.

Problems connecting the ground to the starter

It is necessary to check the reliability of the connection of the negative battery ground wire with the starter solenoid relay. If necessary, strip the ground wire, then connect it to the solenoid relay. Additionally, you should check the condition of the wires and contact connections in the direction from the battery to the starter.

Worn bushings

If you find wear on the starter bushings, they must be replaced. But it should be noted that if the starter wears out excessively, this will not help for long. By placing washers under the bushings, you can eliminate the axial play that occurs on them.

There is a malfunction in the solenoid relay

Malfunction of the relay may be associated with burnout of the contact plates located in the relay, combustion of the relay winding, destruction or fatigue of materials.

Short circuit of the starter winding or armature to ground

The starter brushes are not making good contact with the commutator.

What to do if the starter turns poorly

When the starter turns poorly, it is necessary to perform diagnostic and repair measures. You should always start with the battery and check the quality of the contact, and only then dismantle and possibly disassemble the starter and perform diagnostics.

Check battery charge

It doesn’t matter whether the gearbox turns poorly or a regular battery needs to be charged. This is especially true in winter, when the air temperature outside at night drops below zero Celsius.

Accordingly, if the battery (even if it is new) is at least 15% discharged, then it is advisable to charge it using a charger. If the battery is old and/or has exhausted its service life, it is better to replace it with a new one. Make sure there is reliable contact between the battery terminals and the starter power supply. If there are pockets of oxidation (rust) on the battery terminals, then this is definitely the problem. Also make sure that the power wire clamp is securely tightened. Pay attention to the contact on the starter itself. It makes sense to check the “ground pigtail”, which directly connects the engine housing and the car body. If the contacts are of poor quality, they need to be cleaned and tightened.

Did the above recommendations not help? Then you will have to remove the starter to inspect and check its main elements. The only exception may be if the new starter turns poorly, then if it’s not the battery and contacts, then you need to look for the reason in the engine. Checking the starter should be performed in the following sequence:

- Solenoid relay. You need to ring both windings using a tester. The resistance between the windings and the ground is measured in pairs. On a working relay it will be about 1...3 Ohms. The resistance between the power contacts should be about 3...5 Ohms. If the indicated values tend to zero, it means there is a short circuit. Most modern solenoid relays are made in a non-disassembled form, so if the unit fails, it is simply replaced.

If you are sure that the starter is working properly, then pay attention to the engine. Engine oil

Sometimes car owners have difficulty identifying oil viscosity and its service life. So, if it becomes thick, then the starter needs to spend additional effort to turn the engine shaft. That is why it can spin tightly “in the cold” in winter. To get rid of this problem, you need to use one suitable for a specific car, used in winter (with low temperature viscosity, for example, 0W-20, 0W-30, 5W-30). Similar reasoning is also valid if the engine oil is used much longer than the required mileage without a complete change.

Engine oil. Sometimes car owners have difficulty identifying oil viscosity and its service life. So, if it becomes thick, then the starter needs to spend additional effort to turn the engine shaft. That is why it can spin tightly “in the cold” in winter. To get rid of this problem, you need to use one suitable for a specific car, used in winter (with low temperature viscosity, for example, 0W-20, 0W-30, 5W-30). Similar reasoning is also valid if the engine oil is used much longer than the required mileage without a complete replacement.

Crankshaft. If problems are observed in the operation of the piston group, they can be noticed by a number of other changes in the operation of the engine. In any case, it is better to go to a service center for diagnostics, since self-checking in this case is hardly possible due to the fact that you will need additional equipment. Including, you may have to partially disassemble the engine to perform diagnostics.

If the starter turns poorly, and even more so when cold, then first of all you need to check the charge of the battery, the quality of its contacts, terminals, the condition of the wires between the starter, battery, ignition switch, especially pay attention to the ground. When everything is in order with the listed elements, then it is necessary to remove the starter from the car and perform detailed diagnostics

It is necessary to check the solenoid relay, brush assembly, stator and rotor windings, condition of the bushings, quality of contacts on the windings. And of course, use low-viscosity motor oil in winter!

Reasons for a cold or hot system

Since system temperature can affect the causes of starter problems, it is necessary to test its operation in both states - cold and hot. In the first case, the following problems may appear:

- thick oil;

- reduction in battery efficiency.

In a cold system, such a set is extremely small, because the low temperature here is dangerous only for liquids. However, when hot, the following problems are possible:

- bushing wedge;

- crankshaft failure (rubbing of liners, axle displacement, etc.);

- bushing wear.

Such problems more often arise on a well-developed system where the temperature has risen. If such a tendency is observed, it is recommended to check the system at a car service center. There may be problems with the crankshaft, which can lead to expensive car repairs.

If there is no difference between the operation of the starter in both cases, then it is recommended to look for reasons among the general ones. Most often, the problem is in the starting device itself or the power system.

High voltage part of the system

If the VAZ-2107 starts poorly or does not work at all, you need to check the center wire. It connects the distributor to the coil. To do this, the tip of the wire is carefully removed from the cover. Next, it is brought closer to any part that is in close contact with the mass of the machine. It does not matter whether this surface is painted or not.

Next, you need to secure the wire in such a way that there is a small space between the selected part and its tip (5-7 mm is enough). If the car has an electronic ignition, the conductor must be secured especially carefully. After all, if it falls on ground, all electronics will most likely fail.

You should also not scratch the central wire across the body. Do not hold the conductor with your hand. The electric shock will be quite strong. If there is a spark in this system, then the problem is in another system.

Common types of starter failures

The above reasons allow us to identify the following starter failures:

- oxidation of battery terminals or poor fastening of wire tips;

- short circuit or burnout of the starter relay winding;

- violation of the integrity of the power supply chain;

- malfunction of the switching relay;

- defects in graphite brushes.

Starter diagnostics

Dismantling. Once we are convinced that this is the cause of poor rotation of the starter when cold, it will need to be removed from the car for diagnostics. It is advisable to carry out the procedure when the engine is cold, so as not to get burned on the elements of the exhaust system. Before dismantling the starter, you need to remove the terminal from the battery. Depending on what brand of your car it may be more convenient to first unscrew the mount of the starter itself, and then disconnect the power wires and the solenoid relay wire, and possibly vice versa.

Inspection. After dismantling the starter, we need to inspect it. If it is heavily soiled, we clean it. First of all, we check the solenoid relay. If we observe signs of severe wear or any visible damage, the relay should be replaced. Naturally, the new relay must be installed with the same parameters.

Disassembly. If everything is in order with the relay, we move on to the starter. It is worth considering that starters come in different designs. It is necessary to remove the rear cover of the starter, under which the brush assembly is located. The back cover at the same time protects the rotor. We evaluate the condition of the brushes and replace them if necessary. Brushes can be attached either by bolts or by soldering

In addition to the brushes, we pay attention to the bushings. If there is severe wear, the rotor warps at the moment of starting, a lot of force is created, the starter consumes a lot of current and therefore turns hard

If there is 0.5 mm play on the bushings, they should be replaced with new ones. To ensure good contact between the brushes and the rotor, the rotor must be cleaned of dust.

One of the important points is the correct diagnosis. Some people succeed easier, some more difficult, some don’t succeed at all. Much also depends on experience and whether the person has encountered this problem before. There are also car owners for whom such words as “starter” and “generator” are something completely incomprehensible. The article is intended for those who have decided to independently search for the causes of poor engine starting with a starter and eliminate them.

Friends, remember: despite the fact that a car is just hardware, it nevertheless requires periodic attention. Only in this case can we talk about reliability and be confident in your car. Good luck to everyone on the roads!

https://youtube.com/watch?v=zeRAuG0uEns

Hello everyone! Ford sierra 88 2.0 carb. An unpleasant incident happened to me the other day, while leaving a gas station, I heard that when starting the car, the starter was barely turning, but thanks to the fact that the car was still warm, it started. I drove away from the gas station and parked the car. on a descent (in case something happened) and turned off the car, but it didn’t work to start. I came home, started racking my brains (pulling the wires where I cleaned it) and voila it started as usual. After about 30 starts of the car, the situation repeated itself. I cleaned the terminals on the starter, removed the + and - from the battery and cleaned it with WD40 - in the end nothing has changed. Then, purely by chance, I noticed the ground wire screwed to the battery holder, unscrewed this terminal, cleaned it, sprayed it with WD40, tried to start and it started up fine , that is, the starter turned as expected. I tried 15 times and I calmed down, I thought that everything was resolved, but the next day in the morning I couldn’t start again. I don’t know what to do anymore. The battery is 4 months old, charged. Anyone who knows can give me advice. Thank you in advance

By the way, removing the terminals from the battery, tugging the ground wire solves this problem every once in a while—————————————————The solution to the problem in my case; I cleaned all the terminals and their attachment points, including on the starter, no longer with sandpaper and sandpaper

I paid special attention to the weight, thoroughly cleaned the attachment point to the body and to the engine. I replaced the high-voltage wires (they needed replacement, the car was jerking while driving) Well, I forgot about all the problems. Thanks to all those who responded. Gone are the days when you could start a car engine using a crank handle.

Gone are the days when you could start a car engine using a crank handle.

Therefore, in a situation where the battery is charged, but the starter does not rotate the crankshaft well, there is nothing left but to find out the cause of such a malfunction on the spot. What to do in such a situation, and how to find a breakdown, will be described in detail in this article.

Main reasons and methods for solving them

Healthy! Maybe you are lucky and resetting the injector errors will help. To do this, you first need to remove the negative terminal from the battery. If after 5-10 minutes the car starts as well, then this is not the problem.

Difficulty starting the engine is influenced by a number of simple reasons, which you can eliminate yourself in the garage, having a standard set of tools with you.

Starter mechanisms (brushes, bendix)

In the process of rebuilding the starter. The arrow indicates worn brushes.

- On used cars, the brushes on the starter wear out. In this case, you need to remove the cover and replace them with new ones;

- A starter that has been in use for a long time can be sorted out, cleaned all the mechanisms, washed with WD-40 and filled with new lithol, since the old one is most likely coked and formed into balls;

Fuel problems

In the process of replacing the fuel pump grid. On the right is the old one, and on the left is the new coarse mesh

Small particles of debris getting into the gas tank . This problem is treated by cleaning the fuel system and replacing the filter.

Incorrect sensor readings

Failure or incorrect signal supply from the sensors to the ECU (their diagnostics are required, and if a malfunction is detected, replacement with new ones):

- Speed sensor.

- Crankshaft position sensor.

- Idle speed sensor.

- Phase sensor.

Wires, filter and spark plugs

Clogged air filter

- High-voltage wires are broken , poor contact on the tips (oxidation). During a visual inspection, it is rarely determined whether the best option is to replace it with new or known good ones. Before replacing, you can clean (blow out) the contacts on the old wires.

- The spark plugs are flooded , mechanically damaged, or the gap is set incorrectly. If necessary, the following is done: new ones are screwed in, the required gap is set, or the old ones are returned to their place.

- The air filter is clogged , causing the air supply to the engine combustion chamber to deteriorate. It is recommended to replace with a new one.

Gasoline pump

The fuel pump is located under the rear seat

The fuel pump does not provide the required pressure , which is why the injectors do not spray fuel, but simply splash it. In order to discard this option, you need to measure the fuel pressure with a pressure gauge (the nominal one should correspond to the norm of 3.2 bar).

If the result is different, the situation requires replacing the fuel pump.

Engine failure

Reduced compression in the cylinders is one of the most terrible situations for a car owner. In this case, flammable gases enter the crankcase, and new vapors do not ignite.

The battery is charged - the starter does not turn at all

In practice, there are much more often cases when the starter struggles or shows no signs of life at all due to a discharged battery. Here the repair is as simple as a door - charged the battery and started. However, it is not so uncommon for a situation where the battery is new, fully charged, but the starter still stalls or completely refuses to do its job. This is where you should start.

How to check the battery charge level

In order for a working starter to work reliably, the battery must be charged at least 30%. This is if it is new or purchased relatively recently. If the battery is already “tired”, then being charged and at 50-60%, providing the starter with the necessary current within a few seconds may be an impossible task for it.

How can you quickly and without a specialist check whether the battery is charged and by what percentage? There are only three ways to do this:

- Voltage measurement. This method is suitable only for those cases when the battery has not received a charge for at least 8, or even 12 hours. If you recently drove a car, just started the engine, recharged the battery from the charger, this method is useless. If the battery was at rest for the specified time, then by the voltage at its terminals you can easily determine its charge level. If the device (multimeter in voltmeter mode) shows 12.7 V, the battery is 100% charged. Voltage 12.6 V is already 90% and so on. Accordingly, if the voltmeter shows 12 V, or even less, then the battery is charged 30% or less.

- Electrolyte density measurement. The advantage of this method is that to assess the charge level of the battery, you do not need to “wait” for 8-12 hours, which is necessary to equalize the voltage. The charge determined by the density of the electrolyte will be correct, even if you take the measurement directly while charging the battery from a stationary charger. This method also has one significant drawback - not all modern batteries have liquid electrolyte or access to it. A 100% charged battery will have an electrolyte density of around 1.26-1.27 units. Indicators at the level of 1.1-1.2 indicate that the battery is almost “dead”. You can also focus on a clear percentage scale, which is probably found on any car hydrometer (a device for measuring electrolyte density).

- Load fork test. Not every car enthusiast has such a device. But if there is one, the instructions for it describe in detail and clearly how to check the condition of the battery using a load plug.

- So, the battery is sufficiently charged...

But the starter still doesn't turn over

In such a situation, there can be, offhand, three reasons:

- Retractor mechanism jammed. This unit is part of the starter itself. With its help, the starter drive gear is brought into engagement with the engine flywheel. When the retractor jams, then when you try to start the engine, nothing happens at all - that is, no sounds are heard - clicking, rotation, and so on.

- Broken retractor mechanism. The node works, but does not work as it should. The retractor seems to be trying to bring the drive gear to the flywheel, over and over again. But the crankshaft does not rotate. This problem can be easily diagnosed, since if it occurs, characteristic clicking sounds or even a metallic ringing can be heard when trying to start the engine.

- Starter malfunction. When, when turning the ignition key, a clicking sound is heard once, after which nothing happens, the starter takes over or its main unit, which is a conventional electric motor, does not work. That is, the drive gear is brought into engagement with the flywheel (the same clattering sound), and this is where all the work ends. As a rule, at this moment there is a severe voltage drop in the on-board network, which can be seen by a flashing or dimming dashboard.

What to do if you experience one of the problems described is described below in the section on repairing and servicing the starter yourself.

Possible consequences of long starter operation

When the starter is turned for a long time, the greatest damage is caused to the battery and starter. The first one loses its charge very quickly. When starting the engine, the starter consumes a lot of current, so the battery consumes most of its charge, which is then (after the engine has been started) replenished by charging from the generator.

Bendix failure

With each such idle start, voltage from the battery is supplied to the bendix, which begins to rotate the shaft until the engine starts. At this moment, the splines on the bendix are severely worn out, and the bearing may also crumble or hum.

In these cases, there is only one way out - replacing the starter with a new one.