Where is the speed sensor located?

The speed sensor (DS) on front-wheel drive VAZ cars reads pulses depending on wheel speed and transmits the data to the electronic control unit (ECU). When braking the engine, the fuel supply is turned off with the help of the diesel engine and the computer, thus achieving more economical operation of the internal combustion engine. If the sensor is faulty, an error code is recorded, gasoline consumption increases slightly, and idle speed decreases, especially during heavy braking. It is difficult to immediately detect where the speed sensor is located, since it is hidden under the air filter housing (AFC).

We find the part we need as follows:

- open the hood of the car;

- Using a 10mm wrench, unscrew the two KVF fastening bolts;

- loosen the clamp of the air “corrugation”, disconnect the “chip” with the wires;

- we take out the KVF, now the sensor has already appeared in the field of view, it is located on the gearbox (gearbox) housing, wires are connected to it, connected using a connector.

The DS can be easily unscrewed by hand, and the plug with wires can be pulled out even after the sensor has been unscrewed (but carefully so as not to damage the wiring during rotation).

Video.

Hello, dear car enthusiasts! All. But, especially car enthusiasts of VAZ models. VAZ starters, despite their reliability, durability and endurance, still fail sooner or later.

The average starter life is usually 5-6 years, which is half the life of the engine. And whether it’s a malfunction of the VAZ 21093, VAZ 2109 or 21099 starter, the problem will still have to be solved by diagnosing, repairing, and possibly even replacing this electrical component.

Since the VAZ starter design differs only slightly, we will take into consideration the situation when the VAZ 2109, 21099 starter does not turn.

After turning the key in the ignition, you may find that:

- VAZ 2109,21099 starter does not work after a single click;

- The VAZ 2109, 21099 starter does not work after a whole “trill” of frequent successive clicks;

- The starter response to turning the key is completely absent.

What to do if the starter does not work? Of course, look for the cause of this phenomenon and try to eliminate it.

VAZ 2109, 21099 starter does not work after one click

Reasons why the VAZ 2109, 21099 starter does not turn,

after a single click, there may be several.

Perhaps the power bolts on the . This defect leads to the fact that from the supplied 12V, only about 6-7V reaches the starter.

The fork that pushes out the starter bendix may be bent, broken, or otherwise deformed. In this situation, the bendix does not fully fit the flywheel; the cores only partially enter the coil, preventing the contacts from closing.

The teeth on the Bendix sprocket have worn out. Because of this, the solenoid relay cannot transmit voltage to the starter.

Also, the cause of the phenomenon of “one click” of the starter may be either the order of the armature bushings or a short circuit in the winding.

VAZ 2109, 21099 starter does not work after frequent clicks

A crackling noise from the starter in response to turning the key in the lock may indicate the need to check whether the terminals on it are oxidized or loose.

Repeated clicks are repeated due to the fact that the retracting winding retracts the core, and the holding winding cannot hold it and lets go. This can continue until the battery runs out completely.

Causes of malfunction

If the starter turns poorly when the battery is charged, then the breakdown, in most cases, is in the engine starting device.

The reason for the low engine speed, in this case, may be:

Before you begin to identify the above reasons, you should make sure that the battery produces sufficient current to start the engine. To do this, you can use a load fork. If the battery is serviceable, it is necessary to measure the density of the electrolyte.

Wiring faults

The starter of an internal combustion engine is the most energy-intensive piece of electrical equipment in a car, so poor-quality fastening of wires and terminals can reduce the efficiency of this device.

The current strength that occurs when the starter is turned on is so high that an electric arc can form in wires that are not well attached. Part of the energy will be spent on maintaining this effect, as a result of which the starter will rotate very slowly.

In addition to insufficient current in the circuit, an electric arc can lead to a fire, so if the battery does not turn the starter well, you should first inspect the battery connection terminals, and also check the quality of the connection of the positive wire, which is connected from the “+” battery to the solenoid relay.

You should also check the cable that connects the engine housing to the car body; there may also not be good enough contact in this place.

In addition to electrical leakage and loose nuts and bolts, the starter may lack electrical power due to oxidation of the battery terminals. In this case, a layer is formed of a substance that poorly conducts electric current, which is the reason for the deterioration of the starter’s performance.

This problem can be easily solved if you use a soda solution to remove the resulting oxidation layer:

Defective solenoid relay

A very common breakdown that can cause poor performance of the car’s starting mechanism.

If a short circuit occurs in the electromagnet winding, then this part will need to be completely replaced, but in most cases the reason for the unsatisfactory operation of the solenoid relay is a malfunction resulting from burning of the relay contacts.

In order to restore the functionality of the device, it is necessary to remove the solenoid relay from the starter housing and remove the ebonite cover to which the wires are connected.

Inside the device, there will be a copper plate that closes the relay contacts. It is this part that is most damaged. The surface of the plate that comes into contact with the contacts must be cleaned of irregularities that arise due to elevated temperatures during contact closure. To do this, you should use a velvet file, but remove the metal very carefully so that the plate does not become too thin, otherwise there will not be good contact between the electrical conductors.

The contacts located on the ebonite cover of the solenoid relay also need to be cleaned. To carry out this operation, you need to unscrew the bolts to which the wires are connected and clean them on the side where they come into contact with the contact plate. The surface of the bolts is cleaned with a file. It is necessary to remove a minimum amount of metal so that the contacts are in sufficient contact with the contact plate of the electromagnet.

When cleaning of the contacts is completed, assembly and installation of the solenoid relay is carried out in the reverse order. The bolts of the retractor relay must be well fixed in the ebonite housing, but the threaded connection should not be twisted, otherwise the fragile material of the cover of this device may be damaged.

Starter failure

Despite the high service life of the starter, this device does not last forever and sooner or later fails.

1. The difficulty of diagnosing the technical condition of the electric motor, which is located inside the starter housing, is complicated by the fact that some common “diseases” of this device can only appear when the engine is completely warmed up.

A characteristic “symptom” of such a breakdown is easy starting of a cold engine, and very slow cranking of the crankshaft when the coolant temperature reaches the operating value. If the starter turns poorly only on a hot engine, then if this problem occurs, it is necessary to remove the part from the car engine within a short period of time, disassemble it and use an ohmmeter to measure the resistance between the winding and the housing.

If the indicator is less than 10 kOhm, then electric current leaks into the device body, which significantly reduces the power of the electric motor. If the starter winding is in order, it is necessary to measure the resistance between the armature winding and its body.

2. If there are no leaks in this part of the starter electric motor, you should very carefully inspect the output wires of the commutator, which may be sealed off, as a result of which the contact is broken and the starter either does not turn the engine completely, or the crankshaft rotates at insufficient frequency.

3. The most important element of the starter is the brushes.

If this part has completely exhausted its service life, then the starter will turn the car engine poorly, both in a cold state and after the engine has warmed up.

If the amount of brush wear is not large, then they should be checked for current leakage. This operation can be carried out using any device for measuring resistance, or an ordinary twelve-volt light bulb.

When the “+” power source is applied to the brushes, and “-” to the light bulb, which is connected to the ground of the brush block with another terminal, the glow of the filament should be completely absent. When checking with an ohmmeter, the resistance indicator should tend to infinity.

What to do if the starter turns poorly

When the starter turns poorly, it is necessary to perform diagnostic and repair measures. You should always start with the battery and check the quality of the contact, and only then dismantle and possibly disassemble the starter and perform diagnostics.

Check battery charge

It doesn’t matter whether the gearbox turns poorly or a regular battery needs to be charged. This is especially true in winter, when the air temperature outside at night drops below zero Celsius.

Accordingly, if the battery (even if it is new) is at least 15% discharged, then it is advisable to charge it using a charger. If the battery is old and/or has exhausted its service life, it is better to replace it with a new one.

— **Make sure the contact between the battery terminals and the starter power supply is reliable. If there are pockets of oxidation (rust) on the battery terminals, then this is definitely the problem. Also make sure that the power wire clamp is securely tightened. Pay attention to the contact on the starter itself. It makes sense to check the “ground pigtail”, which directly connects the engine housing and the car body. If the contacts are of poor quality, they need to be cleaned and tightened.

Did the above recommendations not help? Then you will have to remove the starter to inspect and check its main elements. The only exception may be if the new starter turns poorly, then if it’s not the battery and contacts, then you need to look for the reason in the engine. Checking the starter should be performed in the following sequence:

- Solenoid relay. You need to ring both windings using a tester. The resistance between the windings and the ground is measured in pairs. On a working relay it will be about 1...3 Ohms. The resistance between the power contacts should be about 3...5 Ohms. If the indicated values tend to zero, it means there is a short circuit. Most modern solenoid relays are made in a non-disassembled form, so if the unit fails, it is simply replaced.

If you are sure that the starter is working properly, then pay attention to the engine. Engine oil

Sometimes car owners have difficulty identifying oil viscosity and its service life. So, if it becomes thick, then the starter needs to spend additional effort to turn the engine shaft. That is why it can spin tightly “in the cold” in winter. To get rid of this problem, you need to use one suitable for a specific car, used in winter (with low temperature viscosity, for example, 0W-20, 0W-30, 5W-30). Similar reasoning is also valid if the engine oil is used much longer than the required mileage without a complete change.

Engine oil. Sometimes car owners have difficulty identifying oil viscosity and its service life. So, if it becomes thick, then the starter needs to spend additional effort to turn the engine shaft. That is why it can spin tightly “in the cold” in winter. To get rid of this problem, you need to use one suitable for a specific car, used in winter (with low temperature viscosity, for example, 0W-20, 0W-30, 5W-30). Similar reasoning is also valid if the engine oil is used much longer than the required mileage without a complete replacement.

Crankshaft. If problems are observed in the operation of the piston group, they can be noticed by a number of other changes in the operation of the engine. In any case, it is better to go to a service center for diagnostics, since self-checking in this case is hardly possible due to the fact that you will need additional equipment. Including, you may have to partially disassemble the engine to perform diagnostics.

If the starter turns poorly, and even more so when cold, then first of all you need to check the charge of the battery, the quality of its contacts, terminals, the condition of the wires between the starter, battery, ignition switch, especially pay attention to the ground. When everything is in order with the listed elements, then it is necessary to remove the starter from the car and perform detailed diagnostics

It is necessary to check the solenoid relay, brush assembly, stator and rotor windings, condition of the bushings, quality of contacts on the windings. And of course, use low-viscosity motor oil in winter!

Possible faults

The starter consists of more than 20 parts. The electric motor consumes hundreds of kW of power from the battery, converts it into rotational motion of the flywheel, overcoming the resistance of a car engine frozen on a winter night. In this mode, there is something and why to break. How to check if the starter is working - there is a method for finding out the location of the breakdown in order of complexity of the work - from diagnostics without removing the starter to its complete disassembly.

Low on-board voltage

A sign of a malfunction - the engine started and the car drove 5-10 kilometers. When trying to start, the starter turns weakly, the battery is charged before the trip. When you turn on the high beams, the headlights shine dimly. You can verify that the voltage is low by measuring it at the battery terminals with a tester with the key in the ignition switch and without it.

Probable reasons:

The generator must power on-board consumers and provide charging current to the battery, otherwise the headlights and engine will quickly discharge the battery. With such a malfunction, the engine spins weakly when starting, although the battery was charged shortly before the trip. To check, you can disconnect the positive terminal of the battery after starting the engine by lighting it; if the generator is working, the engine will run. You can check other on-board devices without starting the engine - turn them off one by one by removing the fuses until the battery tester shows an increase in voltage.

Now it's time to start checking the starter itself.

Quality of contacts

Electrical malfunctions are caused by only two reasons - either the required contact is missing, or an unnecessary one has appeared . To check for current leakage through the starter, without removing it from the car, disconnect the power wire from its terminal. If the on-board voltage rises, then the starter is faulty, and why should be clarified after disassembly.

Bad contacts will manifest themselves as unstable operation - either the solenoid relay does not click when starting, or the rotation speed of the electric motor changes. Checking the battery starter will help identify the most common faults.

To check the voltage supply to the relay control electrode, remove the ignition key from the lock. Without dismantling the starter, remove the positive contact of the battery and the wire from the control terminal of the solenoid relay (it does not have a thread). Use a separate wire to connect the freed contact to the battery positive. A working relay will have a noticeable operation sound and the bendix will move into the operating position.

If previously there was no sound when starting with the key, but now it appears, you need to eliminate the faulty wiring from the ignition switch to the starter. If there is no sound, thoroughly clean the ground contacts on the housing and the control relay terminal. If after cleaning the sound does not appear, the solenoid relay is at fault.

In terms of frequency of failure of the retractor relay unit, it is less common than bad contacts. To check, you will need to dismantle the entire starter and remove the relay cover. The breakdown is manifested by the absence of a characteristic click of the retracted armature when the ignition is turned on. Visually, the Bendix gear will not move into the working position until it hits the limiter.

For all subsequent checks, the starter housing should be secured in a vice on a workbench, since the reaction to the supply of electricity will be a strong torque, at which it is very difficult to hold it in your hands.

Node diagnostics consists of checks:

Having compressed and fixed the spring of the lever, you should try to move the anchor along the line of its movement. It should move freely. Possible dirt deposits should be washed off before moving smoothly. In case of physical deformation, it is better to take a new armature or relay completely.

The lever may jam at the connection points with the anchor, bracket or drive coupling as a result of dirt or metal wear in the friction areas. This means that you need to clean off the dirt, sand out scratches, or replace a worn-out part of the assembly.

The relay windings are checked with a tester. For a working winding, the resistance between the control contact and the housing will be shown by the tester to be about 1.5 Ohms. It is impossible to diagnose an interturn closure of a relay at home, therefore, if all the tests were successful, but when +12 V is applied to the relay, the armature does not retract, the relay should be replaced.

The gear can wear out, especially at the ends of the teeth. The gear cannot be restored. The bendix should be replaced.

Motor assembly

The malfunction is manifested by a click of the relay and full output of the bendix, but the rotation of the gear does not begin or may occur jerkily, slowly, with a weak torque.

Without disassembling or even removing, you can find out the functionality of the contact coins. To do this, you must first turn off the power to the on-board network and connect the plus of the battery to the starter wire that goes from the threaded terminal into the housing. If the engine begins to rotate much faster, to repair the starter, you need to remove the starter, disassemble the relay and clean the contacts of the coins and the contact plate.

To clarify other faults, the electric motor must be disassembled and the condition checked:

A malfunction that requires replacement of the brushes is determined by their appearance - high wear, when the force and stroke length of the springs are insufficient for reliable contact with the commutator. It is possible that the brushes are simply dirty - washing will solve the problem. Be sure to measure the lack of conductivity between each brush and the body, in which case the part will have to be replaced.

A commutator that comes into direct contact with the brushes during rotation may have unacceptable wear or contamination. But sometimes the malfunction is in the nature of bridging nearby lamellas with conductive material - metal or coal dust. For repairs, you should clean the gaps between the lamellas and measure the resistance of each pore of adjacent contacts.

The starter clicks but does not crank due to a faulty engine

If, when you try to start the internal combustion engine, you hear a strong click, but the crankshaft does not turn, it is likely that the engine itself is jammed. It must be said that this is one of the most unpleasant things that can happen to a car, but there are many different options here too, and not all of them are very sad. How do we diagnose in this case:

- set the gear to neutral, remove the starter;

- Using a large flat screwdriver, we try to turn the crankshaft by the teeth of the flywheel in one direction or the other;

- look carefully to see if there are any foreign objects or pieces of metal between the teeth and the flywheel housing.

In practice, various defects occur, for example, the aluminum Bendix housing may crack and get between the flywheel and the crankcase. It also happens that some bolt or other metal object flies into the intake manifold, then gets stuck between the cylinder head and the piston. If the bolt gets into the cylinder head, the crankshaft will easily scroll backwards, against rotation, and jam as the crankshaft moves. If a foreign object gets into the cylinder, you cannot start the engine, as there will be a strong knock in the engine, and the piston heads and combustion chambers may be damaged!

A bad option for engine jamming is turning the crankshaft liners; here, when you try to turn it manually, the shaft moves tightly, springs back, but still turns with difficulty. Melting of the liners always leads to a major overhaul of the internal combustion engine; there is no other way out; in the worst case, the cylinder block may be punctured.

Nothing brought early cars closer to mass appeal than the invention of the electric starter: the starting handle was both inconvenient and unsafe. Over more than a hundred years of use, the design of automobile starters has been “polished” almost perfectly, but even now it causes problems. The most typical of them is clicking noises under the hood when starting the engine, but the starter does not turn the engine.

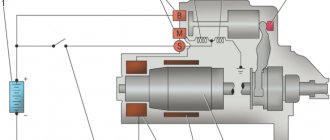

Regardless of the specific design (geared/gearless, with or without a stator winding), the electric starter includes a solenoid relay. This electromechanical unit performs two functions simultaneously:

- It pushes the bendix and drive gear forward, allowing it to mesh with the flywheel ring gear.

- It relieves the load on the ignition switch contacts: the current consumed by the starter is large, and the solenoid relay allows you to control the starter using a relatively small current.

The design of the solenoid relay is simple: its body houses two windings of different power, which draw in (hence the name) the core. A fork is installed on the core, which moves the bendix through a lever, and at the end of the stroke the core closes power contacts (“nickels”) that supply power to the starter directly from the battery. Two windings are used to reduce current consumption: more force is required to retract the core than to hold it in place. As soon as the core of the pull-in relay closes the “nickels”, the pull-in winding is bypassed, and only the holding winding works.

Internal reasons why the starter may fail

A rare malfunction of the starter on a VAZ is the armature burning out. In this case, the winding breaks due to excess current. Such a breakdown cannot be repaired - all that remains is a complete replacement of the armature or the entire starter.

Mechanical failures may include:

- grinding of teeth;

- coupling wear;

- flywheel ring gear wear.

In all cases, the same symptom is present: a sharp metallic crackling sound during operation. The teeth slip, the resulting chips get stuck and create a characteristic sound.

Mechanical breakdowns cannot be repaired, because... It is impossible to restore the teeth. The cause of the malfunction, as a rule, lies in improper operation of the car, for example, in driving on the starter.

Also a characteristic feature: when you turn the key, the VAZ makes characteristic relay clicks, i.e. The electrical part is in perfect order.

There are often problems with brushes. If the relay clicks but the starter does not turn, this may indicate wear.

Brushes are graphite columns that transmit voltage from the stator to the rotor. An electromagnetic circuit appears inside, creating that same rotation. Over time, they wear off, causing the current to stop moving. Because Brushes are consumables; they can simply be replaced with new ones.

By the way, if these are brushes, try hitting them with the handle of a screwdriver. The blow will move them a little and the starter will start working again, but this is a temporary solution.

Types of solenoid relays and their manufacturers

Let's briefly touch on the solenoid relays used on VAZ cars. They are divided into four types:

- for non-geared starters of VAZ 2101-2107 (“Classic” models);

- for non-geared starters of VAZ 2108-21099 models;

- for VAZ gear starters of all models;

- for AZD starter gearboxes (used in VAZ 2108-21099, 2113-2115 models).

In addition, as mentioned above, they are divided into collapsible and non-collapsible. Older models are collapsible. New and old are interchangeable.

For VAZ cars, solenoid relays are produced by the following companies:

- Plant named after A.O. Tarasov (ZiT), Samara, Russian Federation. Relays and starters are produced under the KATEK and KZATE trademarks.

- BATE. Borisov Automotive and Tractor Electrical Equipment Plant (Borisov, Belarus).

- Kedr Company (Chelyabinsk, Russian Federation);

- Dynamo AD, Bulgaria;

- “Iskra” A Belarusian-Slovenian enterprise whose production facilities are located in the city of Grodno (Belarus).

When choosing a particular manufacturer, it is necessary to take into account that the highest quality and most common brands are “KATEK” and “KZATE”. Also remember that if an AZD starter is installed on your car, then “native” relays manufactured at the same enterprise are suitable for them. That is, they are not compatible with products from other factories.

Results

The starter retractor relay is a simple device. However, its failure is critical, as it will not allow the engine to start. Even an inexperienced car owner with basic plumbing skills can check and repair the relay. The main thing is to have the appropriate tools at hand. If the relay is not removable, we still advise you to replace it, since, according to statistics, after repairs are completed, its service life will be short. Therefore, if the solenoid relay does not work in your car, buy a similar device and replace it.

A faulty starter relay is often the reason why the car refuses to start when the key is turned in the ignition. Perhaps these are not the most pleasant moments in the life of any driver.

Therefore, in such cases, it is important to know how to check the starter solenoid relay, and how to start the car if it does not work

We will tell you about the purpose of the starter solenoid relay and its structure, how you can check it and perform simple repairs yourself.

At the end of this article, watch the video that shows how to start your car if the starter solenoid relay is not working.

Also on our website you can find information about other common causes of starter malfunction with step-by-step instructions on what to do if the starter does not work.

When, when you turn the key in the ignition switch, you can clearly hear that the starter is idling, then the cause of this malfunction may be the solenoid relay. But before you start diagnosing it, you should know the purpose of this electrical unit.

Diagnostics

If the problem is not initially found, it is worth diagnosing the starter by disassembling it. To do this, you must first remove it from the system and carefully examine it.

During the removal process, it is worth checking adjacent parts. It is especially recommended to inspect the retractor relay, because this is where problems can arise. If there are oxidized contacts at the connection points, you need to clean them. It is also worth checking all connections for oxidation, because inappropriate operating conditions can cause destruction of the metal. This leads to wiring problems.

Next you need to grab the starter again. The following elements are checked in turn during the analysis process:

- bushings and brushes;

- armature winding;

- stator winding;

- bendix.

The remaining elements are not so important, because checking them is difficult, breakdowns often occur due to these parts. It is important to carefully diagnose their condition and interaction with other elements in order to detect possible traces of problems.

In particularly severe cases such as massive oxidation, destruction of several parts and other malfunctions, it is recommended to completely replace the starter. Even after repair, the reliability of such a device will be low, and a comprehensive repair will be more expensive than purchasing a new part.

Possible causes of failure of the VAZ 2109 starter.

So, there are actually quite a lot of situations in which the starter stops working. For example, if you are trying to start your car and you hear a clicking noise, there may be a problem with the car's fuse or wiring. It may also not work yet, or the reason may lie in the wear of the bushings. In such a situation, I recommend checking the contacts on the relay, since they may simply oxidize. But first of all, make sure the battery is working, I advise you to read my articles:

To do this, simply turn on the lights and/or hazard lights. If you can do this, it means the battery is charged and working properly.

Why do you need a starter?

For many years, since the appearance of the first “self-propelled strollers,” which later became known as cars, the engine was started by rotating the starting handle. As long as the engine had one or two working cylinders, this was not difficult to do. An increase in the number of cylinders and their volume required a significant increase in effort to start the power unit. Therefore, the efforts of designers were aimed at solving this problem. The result of their work was the invention of the electric starter.

The appearance of such an “assistant” made it possible to start the engine without leaving the car, simply by turning the ignition key or pressing a special button. The starter is a complex electrical device in which the energy accumulated by the battery is converted into rotational movement of the armature. A gear is mounted on the armature shaft, which, when engaged with the engine flywheel, starts it.

The starter clicks or buzzes, but the engine does not catch: the main causes of the malfunction

If there is a malfunction that manifests itself in the form of clicks from the starter when the engine starts, then analysis of the nature of the clicks can indicate the causes of the breakdown. If the starter traction relay clicks constantly:

- the battery is discharged, it is necessary to check the charging current;

- you should check the tightness of the battery terminals;

- there are problems with the “ground”, it is necessary to check the place of contact of the ground with the body or internal combustion engine, it may be necessary to implement additional demining;

We also recommend reading about what engine demining is. From this article you will learn about why it is necessary to install additional weight in a car and what advantages this solution has.

Advice to a car owner

All external contacts of the starter should be cleaned before checking, since this is a fairly common malfunction and there is no need to remove it from the engine.

Even an initial check of the starter without removing it from the vehicle usually indicates a breakdown, reducing repair time, reducing costs and not taking much time.

Originally posted 2018-03-28 15:11:04.

Source

Reasons why a car won't start.

In any case, all the questions of car enthusiasts like “the starter clicks the car cannot, by and large, be combined into one - the car will not start. So, if your car does not start, the reasons for this may be the following:

- violation of the integrity of fuses,

- corrosion on the battery or discharged battery,

- defective ignition switch,

- corrosion on any electrical part, especially the starter,

- there is no spark from the ignition coil (in this case it is worth replacing the coil),

- condensation under the hood,

- problems with the fuel system (in this case, qualified assistance from auto mechanics is required).

One of the most common malfunctions in the car starting system is starter failure. At the same time, you should know how to check the starter in order to determine its serviceability. It is noteworthy that in modern foreign cars, the starter often fails due to the depletion of lubricant or the presence of any contaminants. Of course, to carry out diagnostics, it is best to remove the starter, then it must be cleaned and new lubricant applied (the old one should be removed as thoroughly as possible). If you think that such work is too complicated for you, you can always turn to specialists.

Reasons why the engine may overheat.

Another serious nuisance that can deprive you of driving pleasure for a long time is engine overheating, the reasons for which may be the following:

- Leakage of coolant (antifreeze or water) from the cooling system. To avoid this, you must carefully monitor the integrity of all tubes. You should know the approximate coolant consumption and be wary if this value suddenly increases sharply or after a long stay you see a puddle under the hood,

- ineffective air cooling of the radiator. The reason for this can be even simple dirt under the hood, so you should still keep your car clean,

- malfunction of the thermostat (change in its readings in one direction or another due to its failure),

- faulty adjustment of the ignition or injection system,

- prolonged operation of the engine in off-design modes or, even worse, in conditions of detonation,

- exhaust valve burnout, which leads to an increase in exhaust gas temperature.

These reasons lead to the so-called “external” overheating, that is, one that your existing devices will definitely inform you about. However, there is also “internal” overheating, which is much more dangerous, since temperature sensors do not respond to it. This type of overheating is possible if the engine has accumulated a large amount of foreign deposits in the combustion chamber or on the cylinder head. This can happen due to the use of low-quality coolant (“antifreeze” of unknown origin) or due to the driver’s excessive enthusiasm for chemical additives supposedly to “improve” engine performance. That is why all automobile manufacturers strongly recommend not to skimp on the liquids poured into your car, and also to determine the advisability of using a particular additive specifically for your case. The best option would be to choose one reliable manufacturer and try to purchase only its products all the time.

Communities › Auto electrics › Blog › The starter turns as if the battery was dead (problem solved)

Hi all! Ford Sierra 88 2.0 carb. The other day, an unpleasant incident happened to me: while leaving a gas station, I heard that when starting the car, the starter was barely turning, but thanks to the fact that the car was still warm, it started. I drove away from the gas station, parked the car on a downhill slope (in case something happened) and turned off the car, but it was no longer possible to start. I arrived home, started racking my brains (pulling the wires where I cleaned them) and voila it started up as usual. After about 30 starts of the car, the situation repeated itself. I cleaned the terminals on the starter, removed the + and - from the battery and cleaned it with wd40 - in the end nothing has changed. Then, purely by chance, I noticed the ground wire screwed to the battery holder, unscrewed this terminal, cleaned it, sprayed it with some water, tried to start and it started up normally, that is, the starter turned as expected. I tried 15 times and I calmed down, I thought that everything was resolved, but the next day in the morning I couldn’t start again. I don’t know what to do anymore. The battery is 4 months old, fully charged. Give advice who knows. Thank you in advance

Comments 31

How nice it is when the Japanese have mass for the starter through the body

When you turn the engine with the starter, does the “positive” cable from the battery to the starter not heat up?

Alarm Signals

The starter is the highest-loaded electrical consumer in a car. If, when starting the car, an extraneous sound, noise, or crackling appears, or it becomes clear that there have been changes in the operation of the starter, action must be taken without delay. On a VAZ 2109, problems with the starter can be different, some of them can be fixed with your own hands by reading how to do it or watching a video. Here is a small instruction on faults.

Malfunctions

So:

- If the starter on a VAZ 2109 does not start, first you need to do a basic check

- Check if the battery is dead.

- Check the fuse in the fuse box for the starter.

- Check the relay responsible for the starter, it is located in the engine compartment (photo 2).

If, however, the starter does not work on the VAZ 2109 and the problem is different, you need to contact a specialist.

- On VAZ 2109 the starter barely turns

- you need to make sure that the battery charge is normal

- won't they overtighten?

- On a VAZ 2109, the starter sticks (by turning the key to the “engine start” mode, the starter is activated for 1-2 seconds, which is not enough to start the engine and stops)

- you need to make sure that the terminals on the battery are not heating up, and that the positive wire leading to the starter is not heating up. If it gets hot, it means there is a bad connection.

- The armature bushings may need to be replaced.

- On a VAZ 2109 the starter sticks, in other words on a VAZ 2109 the starter does not turn off (releasing the key after starting the engine, the starter continues to work)

- The additional starter relay (not the solenoid relay) may have failed.

- It is possible that the contacts (nickels) of the starter solenoid relay are sticking.

- Or there is a malfunction in the contact group of the ignition switch - the contacts have fused.

- On a VAZ 2109, the starter does not turn in the cold (the starter turns a little, but with a lot of tension, or does not turn at all)

- Most likely, in the cold, the chemical processes in the battery have stopped. You need to turn on the light for a few minutes; this will help accelerate the battery.

- Another option involves heating the battery in a warm room (do not make the temperature difference too large, for example, placing it in hot water)

- You can also start the car by throwing power from another car

- If the previous options did not help, the battery needs to be replaced.

- On a VAZ 2109, the starter does not turn, the relay clicks (when you hold the key in the “engine start” mode, the relay automatically turns on and off)

- Dead battery

This happens because there is enough battery charge to work. When the contacts close, the starter consumes a lot of current, but this current is not enough for it to work. The voltage on the battery drops and the solenoid relay returns to its original position. There is no more load, again there is enough current for the retractor to work. The actions are repeated. So:

- On a VAZ 2109, the starter does not turn on (the retractor relay turned on, but the starter did not turn on) The starter brushes are worn out (photo 3)

- The starter may have burned out

- starter jammed

- On VAZ 2109 the starter is cracking

- Flywheel teeth are broken or worn. (photo 4)

- The bendix (the mechanism that engages with the flywheel) is worn out.

Solutions

So:

- We select a suitable tap, screw it into the bushing and pull it out.

- Or cut the bushing with a sharp object (screwdriver, small chisel, etc.)

At first glance there is a lot, but nothing is impossible. What is made by human hands can definitely be repaired, and with the necessary knowledge and skills, this can be done much faster and with better quality. Good repair.

If the VAZ 2109 starter does not turn, the driver must immediately diagnose it and also carry out the required repairs, since malfunctions of this mechanism of the automobile starting system can lead to dire consequences.

Units and design details

The function of the starter is to start the car engine by spinning its flywheel with an electric motor, creating temporary contact between the gears. Subsequently, the electric motor is turned off and physical contact with the flywheel gear is broken. The starter is located on the engine body closer to the battery and the cab.

Structurally, the device can be divided into two functional blocks:

After starting the engine, the key is returned from the ignition position, de-energizing the relay. The relay opens the contacts, the spring returns the bendix to its original state. When starting, the electric motor requires several tens of amperes of current from the battery. After starting the car engine, the generator restores the battery charge.

The starter may have malfunctions, determined by the nature of the manifestation, visible signs, and tester readings.