It often happens that all standard units are working properly, but the engine does not start. At the same time, the error indicator on the “Check” dashboard does not light up.

It is extremely difficult to immediately name the most likely reason, since there can be at least a dozen of them. It is not advisable to try to find and fix a breakdown on your own without experience. It is better to contact a professional workshop.

Reasons why Chevrolet Niva does not start

- Crankshaft, camshaft position sensor

During vehicle operation, both sensors often fail.

The reasons for this are different: manufacturing defects, natural life, third-party mechanical damage. Since the equipment cannot be repaired due to the design features, the craftsmen install new ones. The replacement process is not long, the cost of consumables is cheap.

- Coolant temperature sensor

By analogy with the crankshaft sensor, the DTOZH cannot be repaired. The installation is quite simple and straightforward. You can do it yourself without involving service station workers.

To a greater extent, the electrical component of the breakdown. The design of the IAC sensor allows for maintenance, cleaning, and blowing with compressed air. Replacement in case of mechanical damage or deformation.

First of all, you need to remove the cap from the spark plug (any one) and install spark plug A17 DVRM. Holding it with pliers, turn on the starter.

To remove the cap, hold the spark plug by the hexagon (pliers with insulated handles are suitable). It is necessary that the spark plug body touches the “ground”. As a result, you will be able to see a spark. In the case where there is no spark, this indicates:

- malfunction of the ECM or lack of voltage;

- combustion of the ignition coil module;

- damage to high-voltage wires.

By the way, a spark “in the air” does not guarantee its presence in the engine. Spark plugs can be faulty, there is a gap violation, etc.

Bottom line

Although the Niva-Chevrolet bears a somewhat American name, it is still assembled in Russia. That is why the quality is no different from other Russian models. Because of this, such breakdowns occur, after which it is impossible to start the engine. However, having thoroughly studied the nodes, you can easily eliminate the problem that has arisen in a short period of time and without huge costs. In case of a serious breakdown, you can contact any car service center where they know the device and can completely repair the Niva-Chevrolet.

Spark plugs Niva Chevrolet

Unstable spark plug operation and untimely spark supply contribute to engine detonation. First signs:

- Reduced acceleration dynamics;

- Increased fuel consumption;

- The engine is not running properly;

- Difficulty starting the engine.

Also interesting: Chevrolet Niva central locking - Auto repair shop online

Since candles are a disposable consumable, they cannot be prevented.

The engine does not start in the cold - the first sign of failure of the spark plugs. When in good condition, candles heat the space from the inside. In the event of a breakdown, starting the engine is complicated by low temperatures and the formation of condensation.

We check the spark plugs with a multimeter and replace them with new ones as necessary. We also inspect the spark plug start relay. It should make a slight clicking sound.

The method described above is effective for the injector. In the case of a carburetor, the checking mechanism is as follows:

- open the hood, wait until the engine cools down to a safe temperature;

- remove the cradles one by one, unscrew the spark plugs, check them for a spark;

- install new spark plugs, replace them if defective ones are found;

- assembly in reverse order.

The procedure for returning the car to “life”

Let's say you find yourself in circumstances where the injection engine starts poorly or refuses to do so at all. There is no need to hesitate in such a situation - it is advisable to immediately begin resuscitation procedures. If you don’t have time to figure out the exact reason why the car doesn’t start well, then you should quickly carry out the following algorithm of actions:

- First of all, we check the availability of gasoline and battery charge. Is there something missing? Fill it up and light it up. Let's try to start. If there is no result, proceed to the next step;

- Next, we quickly analyze under what circumstances the car malfunctions. If it takes a long time or is difficult to start when hot, we first check the spark plugs for overheating (light carbon deposits) and the functioning of the fuel system. Otherwise, when the car malfunctions both cold and hot, a more comprehensive approach is required. As a rule, the following procedures are sufficient: checking spark plugs, wiring the ignition system, assessing the operation of the injector and fuel system;

- Note that most motorists manage to solve the problem, so to speak, with little loss, that is, by implementing the actions described above. If you are not one of the lucky ones and your car still takes a long time, starts poorly or refuses to work at all, you will have to act globally. Here it is better to take the car to a service station or a convenient garage and check the compression, timing adjustment, clean the injector, assess the condition of the fuel system and ignition devices. If there are any malfunctions, they must, of course, be eliminated.

Voltage blocking alarm

Modern security systems fully control the car, its elements and assemblies. In emergency situations, the alarm will prevent theft, but the alarm may be false.

The reasons for the “false call” are caused by:

- manufacturing defects;

- short circuit in the circuit;

- violations in the operation of the electronic control unit;

- damage to electrical wiring, insulation;

- poor terminal contact.

In order to be able to start the car in the future, you need to deactivate the alarm. However, you need to know what to turn off. To carry out work at a professional level, visit a service station.

Operating principle of TPS

There are two types of devices: resistive and non-contact. They differ in design, operating principle and service life.

- Resistive TPS is a variable resistor, the resistance of which changes as the slider moves along the tracks. Due to their simple design and affordable price, they are most common in the automotive industry. The Chevrolet Niva rolls off the assembly line with just such resistive devices.

- Non-contact TPS is based on a circuit that includes a magnetic field sensor and a microcontroller. They last longer and consume less electricity than resistive ones. However, contactless devices are more expensive, and the semiconductor microcontroller can burn out due to sudden voltage surges in the on-board network.

The installation location and operating principle of the TPS does not depend on the design. It is mounted on the throttle shaft. When the throttle position changes, the output voltage at the sensor changes from 0.7 to 4 volts. Due to this, the ECU receives information from the degree of opening of the damper. Based on the information received from the sensor, the composition of the air-fuel mixture is formed. Therefore, the throttle response and efficiency of the engine depend on the performance of the TPS.

When the immobilizer is activated, one way or another, it will block the engine from starting. This happens when, with the ignition on, the indicator starts flashing for 15 seconds and then goes out. Next, the system sends sound signals.

It’s time to disable the module on the Chevrolet Niva APS-4. Here you will need a training key (red), but APS-6 cannot be turned off. Basically, the ECM is forced to flash. There is no need to panic: the blocking is probably due to a broken reader in the cable.

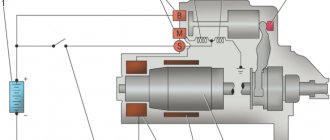

Checking the starter circuit

For starter malfunctions , see the section Diagnosing engine malfunctions: “The crankshaft does not turn with the starter”, “Loud noise when the starter is running”

How to check the functionality of the starter circuit

If the starter does not crank the engine when the ignition key is turned to the appropriate position, then there are four possible reasons:

1. the battery is discharged;

2. the electrical connections between the starting relay, battery and starter are broken, i.e. current from the battery is not supplied to the starter;

3. the starting (traction) relay is faulty;

4. the starter is stuck or its electrical part is faulty.

• To check the battery, turn on the headlights. If they go out after a few seconds, the battery is discharged or damaged. If the headlights are bright, turn on the starter and see what happens to the headlights. If the headlights dim, voltage is supplied to the starter, but it does not rotate. The starter needs to be removed for inspection. If the starter rotates very slowly, proceed to the next test.

• If the headlights still shine brightly when you turn on the starter, then there is no voltage reaching it. Check all connections from the battery to the start relay and starter for tightness and cleanliness. If the car has a good battery, then the most likely cause is a malfunction of the starter itself. Check that the flexible ground wire between the engine and the body is tightly screwed - this sometimes helps eliminate an apparent malfunction.

• If no results are achieved, turn off the headlights to avoid draining the battery. You may hear a clicking sound each time you turn the ignition key to the starter position. These are the sounds of the solenoid (traction relay) operating, but this does not mean that the main contact is operating properly. (If you do not hear a click from the relay, it may be faulty.) The solenoid contact can be checked by connecting a voltmeter or test light to the main wire connection (battery to starter) on the "starter" side of the relay and to ground. When you turn the ignition key, the voltmeter should show voltage, or the light should light up. If this does not happen, then the traction relay is faulty. (Do not connect a light bulb to the two relay contacts. If the starter is working, the light will light up.) If, in the end, it is determined that the relay is working properly, and voltage from the battery is supplied to the starter, then most likely the starter itself is faulty.

Video

Air lock in the fuel line of Niva Chevrolet

There is a control fitting 3 on the ramp with regulator 5. The latter is hidden by a cap; you need to unscrew it and carefully press the spool. Fuel poured out - therefore, it entered the ramp. However, it is possible that the required pressure is not generated. The reasons may be clogged filter cylinder, damage to the pump, etc.

The pressure must show 350 kPa, that is, 3.5 bar. To control it, unscrew the spool and then install a pressure gauge. On the eve of the test, you should reduce your blood pressure. If there is no fuel supply, you need to pay attention to whether the pump turns on or not when turning the key to the “I” mark. When cold, the pump should operate for 10 seconds with the engine running.

The intake of air into the fuel circuit from the outside creates plugs, as a result of which the fuel mixture does not burn in full. A copious amount of carbon deposits is formed, which settles inside the exhaust system and exhaust manifold.

Carbon deposits clog the catalyst, which reduces power, increases fuel consumption, and exposes the engine to unstable idle speed.

You can remove air from the system by connecting a rubber hose to the “return” and grinding off the fuel until the air is removed. Subsequently, the fuel can be reused.

Story

In the 80s of the last century, AvtoVAZ produced a car called “Niva”. The management and engineers of the enterprise began to understand that the model was becoming outdated and losing popularity. Then they started working on updating the Niva. For the first time, the restyled model was presented to a wide audience in 1998 and had the VAZ-2123 index. However, at this time the company was suffering from some economic problems, due to which mass production of the new model could not be carried out in full. At AvtoVAZ itself, the model was produced only from 1998 to 2002, and, as a rule, in small batches. In 2002, it bought the rights to produce the car. From that moment on, the model began a completely different future. The company's specialists began improving the car. The start of production of the Niva-Chevrolet occurred in September 2002. It is worth noting that AvtoVAZ wanted to continue producing the car under the Lada brand, but at . However, the American company compiled the documents in such a way that this became impossible.

A record number of cars produced was recorded between November 2006 and April 2008. Then about 1000 copies rolled off the assembly line. The car was equipped with an Opel Z18XE engine and a 5-speed Aisin manual transmission.

In 2009, the model was restyled. Thanks to this, the appearance of the Niva-Chevrolet has changed significantly. Design elements from BERTONE were installed on it. Changes also affected the chassis and engine.

Damage to the starting system

The main task of the fuel filter is to timely supply fuel to the combustion chambers. It is difficult to physically check the flow of fuel to the ramp without special equipment.

First, we check the flow of fuel through the filter. The presence (absence) of fuel will be visible through the transparent body. We replace the cleaning element with a new one as needed.

We check the limit switches, terminals on the contacts, injectors, and fuel pump. We clean, remove oxidation, tighten the clamps. We check the fuel pump for serviceability by turning the key in the ignition. A clicking sound is heard from the fuel pump. If there is none, then there is a malfunction in the “pump”.

Failure may manifest itself in improper operation of the starter device. Let us highlight 5 main malfunctions of this mechanism:

- The starter does not turn. The reason lies in a violation of the contact units, a break or short circuit in the starter circuit, or damage to the traction relay.

- When starting the starter on a Chevrolet Niva, there are repeated clicks. This indicates a malfunction of the traction relay, which is held by the winding, a discharge of the battery, or loose contact connections in the starter circuit.

- The starter starts, but the armature either does not rotate or rotates slowly. The cause may be a discharged battery, broken contact connections, burnt contacts of the traction relay, worn brushes, dirty commutator, interturn/short circuit of the windings.

- The starter turns on, the armature rotates, but the flywheel does not move. The problem may be loosening of the starter to the clutch housing, breakage of the flywheel teeth or drive gear. This would also include slipping of the freewheel of the drive and damage to the lever.

- The starter does not turn off after starting the Chevrolet Niva engine. The reason is a malfunction of the freewheel of the starter device, sintering of the contacts of the traction relay. If this damage occurs, stop the engine immediately.

Also interesting: Pump for Chevrolet Niva - Auto magazine Akord-Auto

The above reasons require the intervention of specialists at a service station or upon arrival at an equipped garage. You can only check in advance with a voltmeter how discharged the battery is, and also pay attention to the tightness of the contact connections in the starter circuit.

Electrical faults

- First of all, for all types and models of cars, you should pay attention to the battery - it can be worn out or simply discharged.

- The starter has become wet or has become unusable.

- The terminals may have oxidized, resulting in poor battery contact.

- Malfunctions are often due to defects in spark plugs, which occur when using low-quality fuel. Also, the spark plugs could simply wear out, forming a large gap.

- Another reason is a blown fuse.

- Broken ignition relay.

- It is possible that the wire supplying the starter or injector has been torn off.

- The immobilizer is not working.

Fuel supply filter

There is always a small amount of moisture in the fuel. When this amount is increased, this is what can happen:

- the first start always goes without problems;

- After leaving the car in the parking lot, after 2-3 hours the driver will no longer be able to start the engine without repairs.

Everything mentioned should be attributed to the injection internal combustion engine. And here the fuel filter will be a candidate for failure. So, in the Chevrolet Niva it is located under the bottom in aluminum form. By the way, this is thought out on many machines.

Video diagnosing the causes of an uncertain cold start

Along with high efficiency and relative reliability, fuel-injected cars have one unpleasant drawback - the difficulty of repair. It happens that the injector suddenly stops starting, and it becomes difficult to do anything with it. It’s good if you have the opportunity to call a tow truck or show the car to a professional, but what should those motorists do who are left with the problem alone? Let's figure it out by examining in detail all the reasons why the injector starts poorly or refuses to start at all, as well as how to “treat” such a malfunction.

Tips for care and maintenance of Niva Chevrolet

- Observe technical inspection intervals every 20,000 km;

- Buy original parts with factory catalog numbers. Avoid buying cheap analogues of dubious origin;

- During the warranty period from the manufacturer, visit a service station to undergo routine diagnostics with a note in the service book;

- Remember that the length of its service life depends on the driving style of the car;

- Observe the timing of the transition to the summer/winter tire seasons, check the tire pressure.

How to troubleshoot problems on a Niva Chevrolet

| Sign | Elimination |

| The starter rotates but the flywheel does not move. | Wear of flywheel teeth cannot be prevented. Installing a new |

| The starter rotates very slowly and engages intermittently | Low battery voltage. Recharging, replacement. |

| The starter does not turn over in cold weather | The battery is severely discharged and has become unusable. Installing a new |

| The engine starts the second and subsequent times when cold. | Unstable supply of current, spark, fuel. It is necessary to comprehensively check the fuel system, as there can be many reasons |

| The engine takes a long time to start when hot and then immediately stalls. | Clean the throttle valve, check the fuel filter, fuel pump |

| The immobilizer lamp lights up on the dashboard, indicating a breakdown in the power system. | Check the tension of the drive belt, the reliability of the generator, contacts, terminals |

| When starting the engine, a metallic grinding or creaking noise is heard. | Most likely the shaft bearing is worn out, the spring is deformed, the flywheel teeth are damaged |

Regardless of the type of breakdown or the availability of technical equipment maintenance skills, use the services of a service station, where they provide a quality guarantee for the work performed.

Independent intervention in repairs does not always bring positive results. Use the services of handicraft workshops less often.

Read news about the new Niva

- Chevrolet Niva won't start; the starter doesn't turn: it just clicks.

- How to connect a speed sensor in a field

- Phase sensor Niva Chevrolet symptoms of malfunction, DPRV high signal level

- Chevrolet Niva camshaft sensor

- Fuses for Niva 21214: where are they located, replacement

- Relays and fuses Lada 4×4 (VAZ 21214, 21314) » Lada.Online || Niva sensor under the hood

- Niva Chevrolet knock sensor: where is it located, replacement

- Chevrolet Niva idle speed sensor

Pumping up excess air

As you know, a Chevrolet engine sometimes does not want to spin because too much air is drawn into the intake manifold. Therefore, it is worth checking the fixation of all pipes and more.

The cause of excess air is damaged VUT. The engine on a Chevrolet Niva does not start while the starter is turning, which means you need to look for the problem in the brake system. But you can do it simpler:

- remove the vacuum supply hose (from the amplifier side);

- close the hose gap with your finger by performing a test run;

- the engine starts, which means the problem has been found.

Despite its apparent simplicity, damage to the air supply is difficult to see. It is worth checking how the hoses are seated on the fittings and making sure the clamps are tight.