1. When diagnosing the cause of a problem with normal engine starting, open the car door and watch how the brightness of the interior lighting bulbs changes.

Note:

The brightness of the lighting lamp depends on its supply voltage. During normal starter operation, the brightness of the interior lighting decreases slightly.

If the brightness of the lighting does not change, then the cause of the problem is usually an open circuit in the starting system control circuit.

If the lighting almost or completely goes out, then the cause of the problem is most likely a short circuit or breakdown to ground in the starter field windings or a faulty battery.

2. Do not knock on the starter, as this may damage the starter parts.

Note:

In the past, it was not uncommon to see a technician banging on the starter to try to figure out why it wasn't working. Frequently, shock loads caused alignment or displacement of the current collector brushes, rotor, and bearing shells. In many cases, after a blow to the starter, its performance was restored, even if only for a short time.

But the design of most modern starters uses permanent magnets, which are fragile and can break if the starter is hit. A broken magnet disintegrates into several weak magnets. In some of the first designs of permanent magnet starters, the magnets were glued to the stator housing. With a strong blow to the starter, these magnets shattered into pieces, which, when they hit the rotor or in the bearing sockets, rendered the starter completely unusable.

Causes and methods of troubleshooting the starting system.

The starter does not turn on

1. Battery is faulty - check the battery.

2. Oxidation of the battery terminals and wire ends - strip, secure and lubricate the wire ends and terminals with petroleum jelly as described in this article.

3. Broken contacts in the connections, broken wires in the power supply and starter control circuits - check, clean, tighten or replace the contact connections in the power supply and starter control circuits.

4. Malfunction of the ignition switch (lock) - replace the contact group of the ignition switch (lock).

5. The traction relay is faulty - replace the traction relay.

6. Starter is faulty - repair the starter by removing it as described here.

The traction relay turns on, but the starter armature does not rotate or rotates too slowly.

1. The battery is very discharged - charge or replace the battery.

2. Oxidation of the battery terminals and wire ends - clean, secure and lubricate the wire ends and terminals with technical petroleum jelly.

3. Weak tightening of the nuts securing the wire lugs to the terminals of the traction relay - tighten the nuts using wrenches.

4. Starter is faulty - repair the starter by removing it as described here.

The traction relay turns on and off immediately (frequently repeating knocking)

1. The battery is very discharged - charge it with a stationary charger or replace the battery.

2. Increased resistance of the starter power supply circuit - strip and secure the wire ends. Replace faulty wires.

3. The ignition switch (lock) is faulty - replace the contact group of the ignition switch (lock).

4. The traction relay is faulty - replace the traction relay.

The starter turns on, but the crankshaft does not rotate

The starter is faulty - repair the starter by removing it as described here.

The starter turns on, but the gear does not engage

Gouges on drive gear teeth or flywheel rim - remove nicks or replace flywheel or starter drive.

The starter does not turn off after starting the engine

1. Key stuck in the ignition switch (lock) in position “D” - repair or replace the mechanical part of the ignition switch (lock).

2. Short circuit of the ignition switch (lock) contacts - replace the ignition switch (lock).

3. The starter is faulty - repair the starter by removing it as described here.

Increased noise level when rotating the starter armature

1. The starter fastening is loose - tighten the starter fastening bolts.

2. The teeth of the starter drive gear or the toothed rim of the engine flywheel are damaged - replace or repair the starter, replace the engine flywheel.

3. Starter is faulty - repair the starter by removing it as described here.

At the end of winter, my car began to have a problem with the starter: the retractor clicks, but the starter does not turn.

At first, simply turning the ignition off and on helped. Because of this, thoughts arose that the fault lay not in the starter, but in the ignition switch.

However, gradually, with each passing week, the problem progressed more and more and now turning the ignition off and on was no longer enough. I had to open the hood and move the wires going to the starter. When the car started up after such a procedure, I realized that the problem was not at all in the ignition switch.

I also noticed that if the battery is removed and fully charged, then. Conclusion: the starter does not have enough energy.

What is the most common cause of this problem? Acidified contacts.

After simply using analogue WD-40 did not help, it was decided to remove the starter:

Having previously removed the negative terminal from the battery, I unscrewed the two bolts that hold the starter and now the engine starting device is in my hands.

It was quite dirty, both outside and inside. The contacts were also dirty:

What interested me was the thick, small, stranded wire that comes from the pull-in relay into the housing of the starter itself. After all, the retractor clicks, which means current is flowing to it, but it does not reach the starter through this wire.

I cleaned all the contacts with 180-grit sandpaper, treated them well with analogue WD-40, and then installed them in place.

Next is the verification stage. The situation has definitely gotten better; now you don’t need to turn the ignition on and off, much less climb under the hood.

However, not everything is perfect, quite often, after turning the key, the following situation arises: the starter turns, then stops, then there is a pause of 1-2 seconds, after which it starts turning again, after which the engine usually starts. During this entire time, the key is turned to the “start” position.

Here the problem is most likely in the spark plugs, they need to be cleaned or replaced, which is what I will do. If you have other assumptions, write them in the comments, I’ll take a look, maybe I really have something different.

In any case, the problem is no longer as identified as it was before, so the result is positive in any case. And its cost is quite small, I think everyone has sandpaper and something like WD-40 in their garage.

Let us consider such cases in more detail to know what to do if such an unenviable situation does occur.

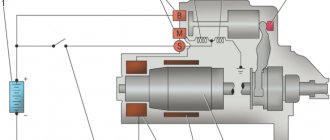

To find out why the starter clicks but does not turn, it is necessary to disassemble its structure and switching circuit, including the components on which its operation depends. Let us divide the entire structure we are interested in into three elements:

- power supply system - for the starter it is, first of all, a battery;

- switching – all connections (wires and relays);

- the starter itself.

Originals, analogues, articles and prices

| Name / article / OEM | Price, rub.) |

| LADA Largus 8 cl Romania Original 8200815083 | From 9650 |

| LADA Largus 16 valves 8200266777 | From 6750 |

| LADA Largus engine .16 valves K4M Valleo 233009141R | From 9100 |

*check the price with your official representative at the time of purchase.

- The control unit starts on the second or third attempt: the contact board of the traction relay burns out;

- The starter rotates with great effort: wear of the brushes and pressure spring;

- The drive shaft disengages due to some delay: wear of the bendix and flywheel teeth.

As in many models of the Lada family, the control unit is located in the engine compartment, closer to the flywheel, at the end of the cylinder block wall.

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Alternative ways to start the engine

You can start a car with problems in the starter/ignition switch system by towing or using a pusher. To do this, you need to turn on the ignition, depress the clutch with the gearbox in second gear, accelerate the car to a speed of 10-15 km/h and release the clutch. If the engine starts, turn off the gear and stop smoothly.

There are situations when it is not possible to push the car to the required speed. In this situation, if the problem is not in the starter winding or jamming of its elements, you can start the car simply by short-circuiting the contacts with a screwdriver or a large wrench. To do this, you need to turn on the ignition and turn off the gearbox. Next, find the starter under the hood, remove the protective rubber casing from the wires and close two large opposite contacts. After the engine starts, open the indicated contacts.

Such actions must be carried out after making sure of your own safety and the safety of others.

Source

How to replace the starter on a VAZ 2101-VAZ 2107?

Note! Before you start replacing this unit, be sure to make sure that its performance is not due to other reasons, for example, the battery is discharged, or its terminals are oxidized, or the wiring that goes to the starter is not working properly!

And also take into account the fact that the starter must be replaced in an inspection ditch, otherwise it will be inconvenient and very problematic to remove from the car!

Removal: 1) First, loosen the clamp that secures the warm air supply hose to the air filter housing.

2) Then loosen the clamp that secures the hose to the air intake itself.

Tips to make diagnosis and repair easier

To diagnose a malfunction in a Lada Largus car, you may need special tools and devices. If there are problems with the fuel supply, it is necessary to measure the pressure in the fuel rail; for this you will need a special pressure gauge with an adapter. If it is missing, you can unscrew the gasoline supply hose from the rack, lower it into an empty container, turn on the ignition and measure how many liters of fuel the pump will pump in one minute. A working Lada Largus pump pumps approximately one and a half liters of fuel in one minute.

The performance of the crankshaft position sensor can be checked using an ohmmeter - a device that shows electrical resistance. The working sensor has a resistance of about 250 Ohms, and when a piece of metal approaches the sensor, this value should change.

The presence of a spark can be easily checked by removing the high-voltage wire or ignition coil from the spark plug and bringing the contact closer to a distance of 2-3 mm to the iron element of the engine. When starting the internal combustion engine, an electric charge - a spark - will jump between the wire/coil and the motor element. During the procedure, you must use special insulating gloves or tools.

Lada 4×4

Remove the rear support bracket for the intake pipe by unscrewing the two bolts with a 13mm wrench.

We remove the starter protective shield by unscrewing its fastening nuts with a “13” wrench.

From the bottom of the car, unscrew the two bolts securing the starter. From the engine compartment side, move the starter forward and disconnect the block with wires.

We unscrew the nut and disconnect the wire tip from the contact bolt of the traction relay. Remove the starter from the engine compartment.

By the way, do you know that the ignition system of LADA cars can be improved, for example, by abandoning the ignition key in favor of a start/stop button.

Starter malfunctions and methods for eliminating them Lada Largus

Tool:

- Open-end wrench 10 mm

- Open-end wrench 13 mm

- Multitester

- Driver for socket attachment

- Extension for the end attachment on the wrench

- 8mm wrench attachment

- 10mm wrench attachment

- 13mm wrench attachment

- Medium flat screwdriver

- Stationary charger

- Pliers

Parts and consumables:

- Vaseline technical VTV-1 in aerosol packaging

- Sanding paper with a grain size of no more than P220 or felt with abrasive paste PMA-2

- Starting system contact connections

- Egnition lock

- Starter traction relay

- Flywheel

- Starter drive

Notes:

To confirm a malfunction of the engine starting system, the following deviations in the operation of other mechanisms must appear, which can be seen by performing a series of actions described below.

1. When diagnosing the cause of a problem with normal engine starting, open the car door and watch how the brightness of the interior lighting bulbs changes.

Note:

The brightness of the lighting lamp depends on its supply voltage. During normal starter operation, the brightness of the interior lighting decreases slightly.

If the brightness of the lighting does not change, then the cause of the problem is usually an open circuit in the starting system control circuit.

If the lighting almost or completely goes out, then the cause of the problem is most likely a short circuit or breakdown to ground in the starter field windings or a faulty battery.

2. Do not knock on the starter as this may damage the starter parts.

Note:

In the past, it was not uncommon to see a technician banging on the starter to try to figure out why it wasn't working. Frequently, shock loads caused alignment or displacement of the current collector brushes, rotor, and bearing shells. In many cases, after a blow to the starter, its performance was restored, even if only for a short time.

But the design of most modern starters uses permanent magnets, which are fragile and can break if the starter is hit. A broken magnet disintegrates into several weak magnets. In some of the first designs of permanent magnet starters, the magnets were glued to the stator housing. With a strong blow to the starter, these magnets shattered into pieces, which, when they hit the rotor or in the bearing sockets, rendered the starter completely unusable.

Causes and methods of troubleshooting the starting system.

The starter does not turn on

1. The battery is faulty - check the battery.

2. Oxidation of the battery terminals and wire ends - strip, secure and lubricate the wire ends and terminals with petroleum jelly as described in this article.

3. Broken contacts in the connections, broken wires in the power supply and starter control circuits - check, clean, tighten or replace the contact connections in the power supply and starter control circuits.

4. Malfunction of the ignition switch (lock) - replace the contact group of the ignition switch (lock).

5. The traction relay is faulty - replace the traction relay.

6. The starter is faulty - repair the starter by removing it as described here.

The traction relay turns on, but the starter armature does not rotate or rotates too slowly.

1. The battery is very discharged - charge or replace the battery.

2. Oxidation of the battery terminals and wire ends - clean, secure and lubricate the wire ends and terminals with technical petroleum jelly.

3. Weak tightening of the nuts securing the wire lugs to the traction relay terminals - tighten the nuts using wrenches.

4. The starter is faulty - repair the starter by removing it as described here.

The traction relay turns on and off immediately (frequently repeating knocking)

1. The battery is very discharged - charge it with a stationary charger or replace the battery.

2. Increased resistance in the starter power supply circuit - strip and secure the wire ends. Replace faulty wires.

3. The ignition switch (lock) is faulty - replace the contact group of the ignition switch (lock).

4. The traction relay is faulty - replace the traction relay.

The starter turns on, but the crankshaft does not rotate

The starter is faulty - repair the starter by removing it as described here.

The starter turns on, but the gear does not engage

Gouges on drive gear teeth or flywheel rim - remove nicks or replace flywheel or starter drive.

The starter does not turn off after starting the engine

1. The key is stuck in the ignition switch (lock) in position “D” - repair or replace the mechanical part of the ignition switch (lock).

2. Short circuit of the ignition switch (lock) contacts - replace the ignition switch (lock).

3. The starter is faulty - repair the starter by removing it as described here.

Increased noise level when rotating the starter armature

1. The starter is loose - tighten the starter bolts.

2. The teeth of the starter drive gear or the toothed rim of the engine flywheel are damaged - replace or repair the starter, replace the engine flywheel.

3. The starter is faulty - repair the starter by removing it as described here.

The article is missing:

- Photo of the instrument

- Photos of parts and consumables

Source:

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

The cause of a stalled engine is a power supply failure

In this type of problem, 3 reasons may be involved:

- Poor contact with the terminals of the new battery;

- Detection of poor contact or breakdown along the entire length of high-voltage wires;

- The appearance of malfunctions in the generator or ignition coil system of the car.

If the problem lies in damp high-voltage wires, then it is best to replace them completely along with the battery contacts. If the terminals make poor contact, you need to carefully clean them with sandpaper and try to reconnect them. If the generator is found to be inoperable, the problem usually boils down to problems in the following parts:

- Broken timing belt;

- There is a malfunction inside the housing of the unit itself.

A problem with the generator is easily detected when the corresponding indicator on the dashboard turns on. In addition, if there is insufficient energy supply, the backlight of the on-board panel will gradually fade, and a set of other diagnostic sensors will show incorrect values.

From the list of reasons that are directly related to the car engine, you need to move on to problems that arise in the fuel and air supply systems, as well as malfunctions of components responsible for exhaust gas removal.

Lada Largus does not start, the starter turns

To start a car engine, it is necessary to have a spark and a fuel mixture in the cylinders at the right time. Problems with starting the Lada Largus engine may occur if one or more elements of the vehicle systems fail. This article lists the reasons and solutions for cases where the starter turns, but the engine does not start.

| Possible malfunction | Diagnostics | Remedies |

| There is no gasoline in the tank | On the instrument cluster the fuel level arrow is at zero. | Pour gasoline |

| Battery is low | The voltage at the battery terminals with consumers turned off is less than 12V. When trying to start the engine, a cracking noise is heard from under the hood. | Charge the battery or replace it with a new one |

| Oxidation of battery terminals or wire terminals, their fit is not tight | When you try to start the car, the voltage in the on-board network drops much more than at the battery terminals. In this case, a crash may be heard under the hood. | Clean the contacts, lubricate them with petroleum jelly and tighten the terminals |

| Unreliable connection of electrical circuits of engine control and power supply systems | Check the connections of the connectors and the reliability of the contacts in the blocks. | Fix faulty wire connections |

| Increased resistance to rotation of the crankshaft (scores on the shafts, bearing shells, cylinder-piston parts, deformation of the shafts, frozen engine oil, jammed generator, jammed coolant pump) | The crankshaft turns slowly. If the engine is started in severe frost, and the engine was working properly the day before, then most likely the engine oil has frozen. If you hear extraneous noise when starting the engine, check the free rotation of the pump and generator pulleys. | Use the recommended engine oil. Repair the engine. Replace the pump and generator. |

| Malfunction in the ignition system | Check for spark. | Check the circuits and devices of the ignition system. Replace faulty system elements. |

| HV wires are connected in the wrong order or the wire is disconnected (on K7M engine) | Inspect. | Connect the wires in the correct order |

| The timing belt is broken or the belt teeth are cut off | Open the front timing cover and check. | Replace timing belt |

| Disturbed valve timing | Check the marks on the crankshaft and camshaft pulleys. | Set the correct shaft position |

| Malfunction of the ECU (electronic engine control unit), its circuits, crankshaft position sensor or coolant temperature | Check the supply of +12V to the ECU, the sensor circuit, and the absence of damage to the sensors themselves. | Replace ECU, sensors. |

| The idle air regulator (IAC) or its circuits are faulty | Check IAC. When starting the engine, lightly press the gas pedal. If the car starts and stalls when you release the gas pedal, then the sensor is faulty. | Replace sensor |

| The fuse is blown or the main relay of the control system is faulty | Check fuse and relay. | Eliminate the cause of the blown fuse. Replace fuse and relay |

| Fuse blown, fuel pump relay. Circuit, relay or pump is faulty. | When the ignition is turned on, there is no sound of the pump running. Check the fuse. Apply voltage to the pump from the battery. | Clean contacts, replace faulty circuits, replace fuse, pump and relay. |

| The fuel filter is dirty, the water in the fuel line is frozen, the fuel line is damaged | Check the pressure in the fuel rail and the condition of the fuel lines. | Replace the filter, blow out or replace the fuel lines. |

| Insufficient pressure in the fuel rail | Check the pressure in the fuel rail, the pump strainer and the condition of the fuel lines. | Clean the filter. Replace the pump, fuel pressure regulator (RDT) |

| Faulty injectors or their power supply circuits | Check the injector windings with an ohmmeter. Check the chains for breaks. | Replace injectors, replace chains |

| Air leak into the intake tract | Inspect the joints and fittings of the hoses and clamps. During start-up, turn off the vacuum brake booster (VUT) and plug the receiver fitting. | Eliminate air leaks, replace vacuum booster |

Probable Causes

When the starter does not turn when trying to activate the engine, this often indicates problems with the battery. Insufficient charge of the latter interferes with the functioning of the device in question, because it consumes a lot of energy.

Also, the Lada does not start due to damage to the starter electrical circuit or individual elements included in it. Inspect all wires leading to the device. Also check the fuse and relay if not already done.

The next obvious problem: oxidation of the battery terminals. Over time, a film of high resistance forms on them, which prevents the supply of current of the required strength. Clean them with fine sandpaper and tighten them with a wrench so that the wires do not dangle.

The ignition switch often prevents the Grant from starting. It is easy to make sure that it is faulty - just short-circuit the wiring leading to it. After this, the power plant should start.

When none of the above helped, and the Grant still does not start, it is permissible to assume the worst - a malfunction of the starter itself. Here, in particular, the following may fail:

- the electric motor itself (armature or winding);

- traction relay;

- flywheel;

- drive unit.

It is difficult to perform diagnostics in the field, because the starter will have to be dismantled and disassembled. Failed elements are not repaired, but replaced with serviceable ones. All that can be done on the spot is to inspect the wires going to the device, remove them and clean them. Before doing this, do not forget to disconnect the negative cable from the battery. As practice shows, the most common reason why the engine refuses to start and the starter does not turn is a weak battery charge, poor contact in the terminals or a breakdown of the Lada ignition switch. Other malfunctions occur much less frequently. Next we will tell you how to check.

Causes of clicking noises when starting the engine, checking and solving the problem

Solenoid relay malfunctions

Thus, it is not difficult to think of reasons why the click of the retractor relay may not be accompanied by activation of the starter. The simplest of them is power problems: dead battery, oxidized terminals. At the moment when the solenoid relay turns on the starter winding, a sharp drop in voltage occurs, and with it, in strict accordance with Ohm’s law, the current in the holding winding. The energy of the magnetic field is no longer enough to counteract the retractor return spring, and the core moves outward, breaking the starter circuit. Depending on the condition of the car and the battery, this results in either a single click from the starter or a “machine-gun burst” of clicks from under the hood.

Therefore, the first thing you should check is the battery charge, inspect the terminals on the battery and, if necessary, clean them. Having already guaranteed the supply of electricity “as intended,” we proceed to further verification.

Starter not working

After turning the key to the “Engine Start” position, the starter begins to rotate the car’s flywheel and within 5 seconds, under normal temperature conditions, the Largus engine should start. If the starter does not work, some elements may have failed:

- Low voltage in the on-board network - the voltage at the battery terminals must be at least 12V. When the voltage is lower, it is necessary to charge the car battery.

- Faulty contact group of the ignition switch or start relay - after turning the key, power is not supplied to the starter solenoid relay - you can measure the voltage at its contact with a voltmeter. A broken ignition switch or relay needs to be replaced.

- Faulty starter solenoid relay - when 12V is supplied to its contact, the relay does not operate (you cannot hear a characteristic click) and the starter does not turn. The retractor will need to be repaired or replaced.

- Faulty starter - after applying voltage to its winding, the engine does not turn over. The first reason is wear of the brushes; to eliminate the breakdown, it is enough to replace them. The second reason is that the starter winding has burned out, in which case the assembly part needs to be replaced. The third reason is jamming of mechanical elements; to eliminate it, it is necessary to disassemble the electrical part of the starter and the overrunning clutch (Bendex), wash all parts and lubricate them with graphite lubricant.

Starter design

Regardless of the specific design (geared/gearless, with or without a stator winding), the electric starter includes a solenoid relay. This electromechanical unit performs two functions simultaneously:

- It pushes the bendix and drive gear forward, allowing it to mesh with the flywheel ring gear.

- It relieves the load on the ignition switch contacts: the current consumed by the starter is large, and the solenoid relay allows you to control the starter using a relatively small current.

The design of the solenoid relay is simple: its body houses two windings of different power, which draw in (hence the name) the core. A fork is installed on the core, which moves the bendix through a lever, and at the end of the stroke the core closes power contacts (“nickels”) that supply power to the starter directly from the battery. Two windings are used to reduce current consumption: more force is required to retract the core than to hold it in place. As soon as the core of the pull-in relay closes the “nickels”, the pull-in winding is bypassed, and only the holding winding works.

Electrical causes of failure

If it is determined that the VAZ-2105 starter does not turn, or the speed is too low, then you must check the electrical circuit. Troubleshooting starts with the battery. The driver must ensure that:

- the battery is well charged;

- the wire connecting the terminals of the solenoid relay is securely fastened;

- the ignition switch contact group is not damaged;

- The wire between the starter and battery is good.

At this stage of identifying problems, you need to pay attention to how the retractor operates and the armature rotates. Sometimes the winding of the traction relay is damaged, at the same time a short circuit occurs between the turns

Then the VAZ-2105 does not start, but the starter turns. Another cause of starter failure, which is classified as electrical, is slow rotation of the flywheel.

If no visible problems are found, the starter will need to be removed for further inspection. Most likely, the commutator burned out due to the short circuit of the plates. Other electrical causes of starter failure are:

- failure of the traction relay;

- brushes that do not fit tightly to the commutator;

- armature commutator wear.

Largus 16 valves won't start, clicking

With the arrival of winter, I encountered a problem that the car stopped starting the first time.

When you turn the ignition key, you hear a click, but the starter does not turn. It only appears when it’s cold! After 10-20 attempts to manipulate the ignition key, the car starts up safely. Everything is fine with the battery (they checked it for both charge and electrolyte density). Where to look for the problem? When hot it always starts the first time. Mileage 155000 km.

I think the problem has been identified correctly - in the starter. Clicking sound - this is the starter relay turning on, but not turning because the solenoid relay is not closing. With such a mileage, either the lubricant has thickened, or the heels of the relay are already burnt. Most likely the first, because appears when cold.

In any case, remove the starter.

The officials removed the starter and I went with it to a specialized workshop for starters and generators. The experts said that for such a long mileage it is in very good condition. They cleaned, lubricated and installed a grommet and a nut on the output of the Bendix power stud, explaining that they are often used by new cars that have the same problem with the starter. At the end of the power wire that is attached to the starter there is a washer with a nut rolled into it, and a backlash is created between them, resulting in poor contact after the vehicle has been in use for a long time. This nut needs to be drilled out and the shad remaining on the wire must be secured through a screwdriver and a new nut. I’ll write about whether this corrected my situation later, but I hope that the situation should change.

Today, after 20 hours of inactivity, it started up the first time, and the starter turned very vigorously. Let's see what will happen next.

Source

Do-it-yourself spare wheel for the Lada Largus car door

The Largus spare wheel is installed on the door using a special basket called a bracket. Fixation is carried out in the luggage area. Installing the rim causes problems for many car enthusiasts, so they prefer to carry a spare tire in the trunk.

Bracket for spare wheel

Lada Largus is a small car, and the spare wheel at the rear makes it look massive. Factories began to produce special baskets that allow the wheel element to be fixed outside rather than inside the car. Mass production appeared due to the high demand for products. The bracket allows you to hold not only the wheel, but even the tire. Bracket specifications:

- length, width – 55 cm each;

- height – 30 cm;

- weight – 5 kg.

The basket will allow you to fix the spare wheel on the surface of the stern door without damaging the body. The bracket does not need to be registered like a trailer. Its cost starts from 4,000 rubles. The price will be higher if the product is equipped with fasteners. It is better to purchase the Lada Largus spare wheel mount for the rear doors separately, since the factory element has a lot of shortcomings: short pins, lack of nuts, weak steel.

If previously the wheel was moved due to the desire to install a gas cylinder in the luggage compartment, now it is the final touch of the upgrade. For this purpose, several options for car brackets are used:

- Rotary type. It is installed on the right door.

- Product screwed to the bottom.

Fastenings are made to standard points on the body; technologists have provided special holes for fixing.

Advantages and disadvantages

Not all Largus are equipped with baskets, since additional fastening has advantages and disadvantages:

| pros | Minuses |

|

|

Some manufacturers provide fasteners, a cover for the spare tire, or a hard plastic cap with a company logo along with the product, but drivers assure that it is more profitable to buy each element separately.

Bracket selection and installation

It is better to purchase the original, but if the driver wants to save money, then you can buy an analogue. The basket is made of metal and has a chrome-plated or painted surface. Chrome is preferable as the paint will peel off over time.

When installing a spare wheel on the Largus rear door, you should take care of reliable fastenings, since they will hold the part and the spare wheel. It is better to purchase bolts with massive nuts and a cross-shaped tip. Such hardware can be found in any automotive store.

Along with the hardware, you should prepare a screwdriver, a ratchet wrench, and take care of an assistant who will support the device while another screws the structure. Algorithm of actions:

A special sealing gasket is provided with the basket, so the protective part is installed first using bolts. The bracket is attached to the top with three screws

It is important to ensure that the gasket is securely clamped between the body and the basket. The hook is fixed in the central hole and handle. The levers that will hold the spare tire are being installed. The wheel is installed.. The hardware should be tightened using a wrench with a special pad that allows you to firmly fix the fasteners

The hardware should be tightened using a wrench with a special pad that allows the fasteners to be firmly fixed.

Removing and installing the spare tire on the Largus door

On the Lada Largus, the spare wheel bracket on the trunk door looks organic, which cannot be said about the bottom. The central hook is the main element that takes the weight of the spare tire. For dismantling you will need screwdrivers, a wrench and an assistant. The wheel is fixed according to the instructions:

Fastenings become loose. The handle, which is located next to the hook, is removed

The handle is the main protection for the wheelbase from falling out of the basket. The wheel tilts a little, it is important to hold it with your hands while the lower bolts are unscrewed. After this, the spare tire is easily removed.

To return the spare tire to its place, you need to reattach the handle and tighten the hook screws well.

DIY starter repair

The starter is a regular electric motor that requires periodic cleaning and lubrication. You should start with the solenoid relay, the cost of which is not high, and therefore you just need to replace it.

To repair the starter itself, it is necessary to disassemble it and necessarily replace the brushes, which are consumables.

The commutator on the armature can be easily cleaned using a soft material, such as an eraser, which will not damage the working surface but will remove dirt.

In case of malfunctions associated with the windings, the entire armature is replaced.

On starters used with Lada engines, special attention should be paid to the bushings on which the armature axis is supported. Worn bushings allow the axle to move freely, which leads to jamming of the electric motor.

It is also better to replace the Bendix with a new one.

The last stage is cleaning and lubricating the mechanism. After this, the starter can be assembled and installed back on the car.

Almost all starter parts are available for free sale, and with self-repair, restoring the electrical part of the car will be much cheaper than replacing it.

Recommendations for starter maintenance

Adhere to the technical inspection schedules established by the manufacturer - every 15,000 km. Buy original parts and components at official points of sale.

Use the services of certified workshops for diagnostics and repairs. Remember that unprofessional intervention in the operation of the car is more likely to harm than help.

Don't skimp on consumables. Check the catalog numbers with the actual data specified in the instruction manual.

Keep the control unit active while starting the engine for no longer than 15 seconds, then 30 seconds. break. After starting the engine, release the key from the ignition switch as soon as possible. Excessive retention eats up the teeth on the drive shaft and flywheel.

Lada Largus won't start

To properly start an internal combustion engine, it is necessary to have a prepared fuel-air mixture, in the correct proportion, in the cylinders, which is ignited by a spark from the spark plug at a strictly defined moment.

In addition, all parts and components associated with the starter/ignition switch must be in good working order. Lada Largus may experience problems when starting the internal combustion engine if some elements of the system are broken or not working correctly.

Problems with the starter, ways to solve them on Lada Largus

It is customary to divide breakdowns into electrical and mechanical based on the nature of their origin.

Electrical

The most common type of failure. The section of electrical wiring from the steering column to the starter must be inspected.

Signs:

- Slow rotation of the rotor,

- The control unit does not respond when current is applied,

- The starter clicks but does not turn. Most likely there is an interturn short circuit, a broken wiring, a faulty solenoid relay,

- Wear of armature, brushes.

To make diagnostics as productive as possible, rule out the following breakdowns. To do this you need to check:

- presence of charge in the battery,

- tightness of battery terminals,

- wiring integrity. First of all, we inspect the area from the steering column to the control panel, and then the remaining ones,

- serviceability of the ignition switch. Backlash, poor contact, and delays in turning are unacceptable.

Mechanical

A stationary crankshaft with a working starter is a sign of a malfunction of the overrunning clutch, pressure spring, wear of the retaining ring, or flywheel. A metallic grinding noise during rotation indicates wear on the flywheel teeth and possible breaks. If the starter does not start, then the reason is a faulty electrical part.

After starting the motor, the launcher continues to rotate:

- jamming of the spring, drive shaft,

- contact board sticking,

- wear of the solenoid relay,

- The bearing race is damaged.

Option one - battery

This is perhaps one of the most common types of malfunctions of this kind. Its essence lies simply in a discharged or inoperative battery. Determining discharged is simple:

If the cause is the battery, then it would seem that everything is simple - just charge it (or light it) and you can hit the road. But not everything is so simple, because the unclear reason that caused the consequence in the form of an unsuccessful launch will cause the same consequence again. Therefore, it is worth figuring out why the battery was discharged.

Everything is elementary if a light was simply left on somewhere, or another consumer was left on. But if everything was turned off, then it is necessary to check the quality of the generator, as well as the serviceability of the battery itself.

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at