Last updated April 2, 2022 at 11:57 am

When operating gas fueled vehicles, drivers often encounter incorrect operation or breakdowns of the gas equipment. The efficiency of this equipment largely depends on the serviceability of gas injectors. Their operation takes place under conditions of high temperatures and sometimes low-quality fuel.

Owners of gas-powered vehicles are advised to know how to repair, clean and adjust 4th generation LPG gas injectors with their own hands. This will help in some situations and save money.

First, a little introduction...

Everyone knows that it’s not just gasoline and diesel fuel that we’re running out of. A long time ago, gas stations learned to “inflate” our brother, not with gas, but with air, mixing various nasty things into the gas fuel, which adversely affects the condition of the gas equipment and the entire engine as a whole.

So one day it was noticed that the engine was unstable on gas; when switching to gas, the engine stalled, and there was simply no idle. Among other things, the dynamics deteriorated, traction disappeared, gas consumption increased and dips appeared during acceleration. Moreover, the above-described “glitches” appeared, as a rule, “in the cold”. Some time after the engine warmed up to the optimal temperature, all these “sores” practically disappeared.

The problem did not allow me to live and drive any car. Having scoured the Internet, I found similar cases, as well as reviews from those who “overcame” this problem. Suspicion fell on the filter (how to change filters and drain condensate is written here and here), as well as gas injectors. The filters were replaced, by the way, during the replacement a large amount of resin was discovered in the filter elements, this alarmed me and made me think. If there is so much “poop” in filters, then what is in gas injectors? The decision was made - it was necessary to clean the gas injectors, as well as their further calibration. What came of it - read on...

That's when I encountered the problems of HBO.

The car is equipped with Lovato LPG with Matrix injectors. To be honest, I didn’t appreciate this package at the time, because... I was far from all this equipment and had never encountered it. Now I can already say that Matrices are cool injectors, although they are no longer produced.

Initially, the car switched to gas and because of the HBO, it was running. But after working a little, the engine began to work normally. The former owner of the car immediately made me happy, saying that the injectors needed to be changed, because... The gas at our gas stations is bad and it’s time for them to be replaced. When I went to the LPG service station, they immediately changed the filters (they really had some tar in them), and the master told me not to bother with replacing the injectors, but to drive until the LPG stops working completely. Well, that's what I did. Naturally, the further we went, the more problems there were with HBO.

When switching the LPG, the car was shaking and twitched while driving, but after a couple of hundred meters the operation of the LPG leveled out, and you could drive around calmly. Although due to the HBO, the revs fluctuated for some time.

So autumn passed unnoticed and winter began.

While warming up in the morning, the car switched to HBO and stalled. Although no. At first, she was Troil, specifically Troil. Well, a month later she was completely deaf. Only specific warm-up saved the day, and after a few kilometers, it was possible to switch to gas. But the HBO really didn’t want to switch, the car almost stalled.

Well, when the frosts came, you yourself understand what happened: I switched to gasoline.

Equipment for home use

Ideally, you can buy a professional washing stand for chemical cleaning, but its price deters many car owners. In addition, such specific equipment will only have to be used periodically, and the costs will never be recouped. However, you can ask your friends - some have a homemade installation, which they will probably provide free of charge. If there are no such people in your immediate environment, you will have to, with patience, desire and available materials, assemble an improvised washing stand yourself. Here are its components.

Liquid pump with pressure gauge.

PET mineral water bottle.

Rubber hose - 2 m is enough - and 4 clamps to secure it.

Two "nipples" similar to those used in a tubeless tire.

Wires with terminals and other small devices.

Despite its simplicity, such a “homemade” installation in most cases is not inferior in efficiency to industrial equipment. Especially if high-quality chemicals are used for washing. As for the use of various additives, which are simply added to the fuel tank, and then supposedly the injector is cleaned “automatically,” this is not so. Of course, in this case, the fuel itself somewhat cleans the injection system, in addition removing carbon deposits from the valves. But still, this method rather belongs to the category of preventive measures, rather than effective methods of cleaning injectors.

Cleaning the engine without removing the injectors

You can clean the injectors without removing them. To do this, you will need a flushing cylinder - made from a two-liter plastic bottle. A hole is drilled at the bottom to which the compressor is connected. A hose is attached to the neck, which is connected to the ramp. We operate without removing the engine.

The washing liquid is poured into the bottle. The fuel pump in the car is turned off and the compressor is started, which will supply flushing to the system. When all the liquid has been used up (and it was supplied instead of gasoline), the engine is turned off and everything is put back together. Install new spark plugs. The disadvantage of the engine cleaning method is the lack of visual control of the result.

Checking the tightness of the system

Next you need to check the tightness of the system:

- All gas lines are connected.

- All connections are washed.

- The flow valve on the gas cylinder opens.

- The car ignition is turned on.

- If bottled gas leaks are detected, they must be repaired immediately.

The leak test procedure must be carried out to avoid accidents on the road and ensure the safe operation of gas equipment.

Repair of gas automotive equipment

Before proceeding to a detailed analysis of specific symptoms caused by the malfunction of certain parts of the gas equipment: gearbox, injectors, electronic unit, cylinder and multi-valve, it is worth noting three associated factors:

Some of them cause intense corrosion, while other resinous substances clog passage tubes and rubber valve plugs that are difficult to clean. By skipping the next change of gas filters in a car, the owner will reduce the gas filter of any manufacturer and generation to a terrible state, even with first-class installation and fine tuning.

DON'T WASTE MONEY ON REPAINTING! Now you can remove any scratch from the body of your car in just 5 seconds.

Repair of VALTEK gas injectors

It happens that the life of one or several gas injectors comes to an end. This manifests itself in the fact that the machine, when operating on a gas mixture, begins to stall, there is a loss of power, unstable engine operation and a characteristic “clatter” of one or more gas injectors. It is this “clatter” that appears after the sealing rings and rubber bands on the rods wear out and means that it is time to repair the gas injectors.

What do we have to do

Repairing VALTEK gas injectors involves several simple steps, namely:

- removing the ramp from the car;

- dismantling the ramp and all its components;

- replacement of rods, springs and rubber rings with new ones from repair. kit;

- subsequent assembly of injectors and their adjustment;

- installing the ramp back onto the car.

Disassembling gas injectors

The first step to removing the ramp from the car is to shut off the gas supply to the LPG line by closing the flow valve on the gas cylinder.

- Exhaust all the gas from the line; to do this, start the car with the valve closed and wait until it switches to gasoline, then force the system to switch to gas two or three more times.

- Before disconnecting the wires and removing the ramp, be sure to mark which wire belonged to which of the gas coils. This can be done using a marker or multi-colored electrical tape. When assembling, you must accurately determine whether the wire belongs to one or another coil.

- Unscrew the fasteners and remove the ramp. When unscrewing the clamps, you will hear residual gas escaping - this is a normal situation.

- Using a 12mm wrench, unscrew the calibration jets.

Remove the corkscrew rings, carefully folding them so as not to lose them. Remove the coils. If you made marks on the coils with a marker, mark which coil was in which place so as not to confuse them during assembly. If you made marks on the ramp itself, the order of installing the coils may not be followed.

Using a 14 key, unscrew the guides and carefully remove them. If one rod is being replaced, during disassembly, it is imperative to mark the rod-seat pair so that they are not confused during reassembly. If all parts are replaced, the order may not be followed. Remove the rods and springs from the guides.

Conduct a visual inspection of the rods and rubber bands, determining whether you need to use a repair kit or not. If the rubber band is completely worn out, metal comes into contact with metal, resulting in a characteristic “clicking” sound.

If the rod itself has a satisfactory appearance, you can replace only the rubber band and the spring (also in case of wear); to do this, remove the old rubber band from the rod with a sharp object (an awl) and place a new one in its place. If the mileage of the injectors is significant, the rod should also be replaced.

Carefully inspect and replace worn parts with new ones on all injectors, then reassemble the ramp in reverse order.

Signs and possible causes of malfunctions

Symptoms of a malfunction of one or more injectors may include:

- high fuel consumption;

- deterioration of the dynamic characteristics of the machine;

- unstable engine operation, internal combustion engine is tripping (one or a couple of injectors do not work);

- dips when pressing the gas pedal;

- malfunctions of various sensors, appearance of “Check engine” errors (for example, MAP sensor);

- knocking in the injectors (they “click” loudly);

- gas leaks through injectors (pouring/poisoning);

- The car stops idling and the injectors do not turn on.

The reasons for this may be:

- wear of the damper rubber rings on the valve stems (this causes the injectors to knock);

- development of the seat (seat) of the valve or its locking rubber;

- wear of the rod (also called piston, anchor) or sleeve (also called core, cylinder, bulb);

- armature jamming in the cylinder;

- weakening of the elasticity of the piston return spring;

- failure of the electromagnetic coil (solenoid);

- violation of the integrity of the electrical wiring.

All of the above reasons can appear naturally or due to low-quality parts, untimely maintenance of gas equipment, or violation of the rules for installing injectors. For example, if gas filters are not replaced on time, gas condensate (oily liquid, water, dirt) can get into the injectors, which can cause them to jam or accelerate wear.

Also, the horizontal position during installation affects uneven wear (ellipse) of the liner body and rod. And simple non-compliance with the rules for installing wires (twisting instead of soldering, mixing, improper fastening) can cause problems over time. One way or another, injectors of this type rarely survive up to 70 thousand km. mileage without repair (repair kit change). It all depends on the conditions of their use.

Do-it-yourself step-by-step repair of gas injectors

To repair 4th generation LPG injectors type Valtek or OMVL, you will need to remove the entire rack assembly:

- shut off the gas supply to the cylinder. To do this, you need to tighten the corresponding multi-valve tap;

- start the engine for a while to remove any remaining fuel from the system;

- disconnect the battery terminals;

- disconnect the hoses and power supply;

- Unscrew the vibration dampers and remove the gas train.

Disassembly and washing

In order to disassemble and wash the nozzle (let’s look at the example of Valtek type 30), you need to:

- Using a 12mm wrench, unscrew the calibration jets/nozzles from the bottom of the ramp;

- Using round pliers or a screwdriver, remove the retaining rings of the coils;

- remove the coils;

- unscrew (key 14) the valve cores and remove the pistons from them.

Disassembling Valtek type injectors

Next, you need to check for wear: rubber parts, valve seats and rods with sleeves.

Wear of the valve sealing rubber

Carry out troubleshooting of parts. Identify squashed rubber rings, bumpers and seals, and also check the cylinders and anchors for wear. The valve rubber should not have large indentations from the seat. The saddle also tends to shrink over time. Discard unusable parts.

Then clean the injector parts from dirt deposits; this can be done conveniently using a rag or cotton swabs. Using carburetor cleaner (carbocleaner), acetone, gasoline or other similar products. Rubber products (if a decision is made not to change) must be removed and cannot be washed with aggressive substances. Rubber can swell from such compounds. For the same reason, it is not advisable to clean/rinse injectors (non-removable) such as Hana, Barracuda, Brc, the effect of such cleaning does not last long, if they work at all after that.

Selecting and replacing a repair kit

The repair kit for gas injectors, as a rule, is equipped only with rubber products (RTI), a rod and a spring, for one injector or the entire ramp. You can also buy a complete set of parts (rods with core bodies and return springs assembled). Everything happens separately. On average, the price of a standard repair kit for one rail will be about 500 rubles.

Based on numerous reviews from drivers, for Valtek injectors, and these are LPG Tech, GREEN GAS (Green Gas), Atiker (Atiker), WentGas (ventgas), Tomasetto (Tomasetto), Yota (iota), Digitronic (Digitronic) even Lovato ( Lovato), original repair kits from RAIL are best suited.

The peculiarity of r/k is that their piston has a hole in the body; this solution reduces the effect of the syringe

If the choice fell on another manufacturer, you should pay attention to the lack of magnetic properties of the metal parts (this should not happen), dimensions, weight

The entire replacement process involves assembling the mechanism block in the reverse order:

- if the pistons are not changed, then remove them from their seats on the rods and replace the rings (rubber dampers/bumpers);

- install (new/old) armatures and return springs into the sleeves;

- change the O-rings of the rod stroke adjusting screw, as well as under the coil and core;

- screw the sleeves into the rail;

- put on the coils and retaining rings.

All seals are recommended to be used once. The outlet calibration nozzles/fittings do not need to be installed at this stage.

General information

Gas injectors are special gas equipment units that are responsible for the dosage of fuel, essentially being high-speed valves. Thanks to their proper operation, the required gas-air mixture ratio in the internal combustion engine is ensured. Such mechanisms began to be used in the 4th generation of HBO.

Some of the most popular are stock models from the companies Valtek (Valtek), Rail (Reil), Digitronic (Digitronic), OMVL (OMVL), Lovato (Lovato). Their undoubted advantage is that they are easy to repair, which consists of washing, replacing the repair kit and adjusting, unlike non-separable injectors such as BRC (BRS), Barracuda (Barracuda) and the like.

Second cleaning method

The unit must be cleaned every 6 months, but at least once a year. If there is an agreement on gas supplies, then the company’s specialists must carry out timely maintenance of gas boilers. If you want to clean the column yourself, then you must follow the following instructions:

- 1 Initially, you need to close the gas; the tap is usually located under the device. Then you need to loosen the bolts that secure the casing, then unscrew them and clean everything with a needle with 4 edges. Today it is possible to buy a special brush for cleaning boilers, which is more convenient to use than a needle. The next step is to wash the burner sections in a degreaser. If the wick is clogged, it also needs to be cleaned with a needle or metal scraper. At the last stage, you need to assemble all the parts of the column in the reverse order and fill the unit with water before starting the gas.

- 2 To clean the burners in the pipe through which the gas flows, you can use a stiff brush. The pipe must be cleaned with wire and rinsed with water and solvent. The upper area of the burner is cleaned with fine sandpaper.

- 3 Units that are cleaned in a timely manner will last much longer. The fire will be glare-free and uniform. If it is noticeable that the column is smoking, the fire is uneven, weak or, conversely, strong, then it needs to be cleaned. An uncleaned unit is dangerous.

A little theory

So, in general terms, what is a rod gas injector (injector).

The design of a gas injector is similar to that of a gasoline injector and consists of:

- housings,

- electromagnetic coil (low resistance of the order of 1-3 Ohms),

- rod (plunger) with seals,

- springs,

- fitting with a calibrated hole.

Often, for convenience, several injectors are collected into one common set - a ramp, mainly by the number of cylinders (if the engine is in-line) or by the number of cylinders in a row (opposite and V-shaped engines).

The rod coil operates on the principle of a simple solenoid valve: when power is supplied to the coil, the solenoid overcomes the force of the rod return spring, and by retracting the rod, it opens the supply of propane-butane gas through the calibration hole into the engine intake manifold. Since the injector electric coil has low resistance, the electrical signal is supplied to it not in one, but in several short pulses.

Rod injectors are among the cheapest and most repairable. However, due to the peculiarities of their design, they are also the “slowest”.

Types and device

The variety of injectors in terms of technical characteristics, as well as by manufacturer, is large. There are examples with a rare device (for example, “petal” injectors from Matrix), but there are two main types:

membrane (disc-shaped), popular representatives AEB (AEB) ECO/EVO, Landi Renzo (Landi Renzo) GIRS 12;

Barracuda injector design

rod ones - Valtak (Valtek) type 30 and many similar ones, for example Rail. In the same series are such samples as Barracuda.

The operating principle of gas injectors is essentially the same; signals (short-term electrical impulses) from the equipment's ECU are sent to the electromagnet coil. During this process, the rubberized core/piston in the rod or plate inside the nozzle moves, opening the seat hole for gas to escape. Closing occurs under the influence of a return spring.

Since the fuel at the outlet of the gearbox is already in an evaporated state, its atomization, as in the gasoline version, is not required. The volume of gas supplied is a multiple of the amount of gasoline (about 200 times). For this purpose, the cross-section of the dosing holes of gas injectors is made much larger, and also, unlike gasoline injectors, the coil resistance of the gas part is 1-3 Ohms, because the control process occurs as a result of pulse width modulation (PWM). The petrol one has 15-16 ohms.

Material

An important parameter is the material of the product. The operation of all equipment is carried out in various temperature fluctuations: from -200C with a cold engine to +1000C after warming up. The gas fuel itself contains impurities (for example, paraffin or oil), which lead to contamination of parts.

Under these conditions, the metal will deform, which is not acceptable. For example, one of the elements of an injector is a plunger that creates fuel pressure. It makes translational movements, with a stroke length of 0.5 mm. Any change in physical dimensions will affect the performance of the system. Therefore, it is desirable that the material has a minimum coefficient of thermal expansion.

In budget versions of injectors, it is possible to reduce the plunger stroke to 15-20%. This shortens the life of the injector, increasing its wear.

Adjusting Valtek gas rod injectors

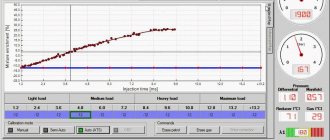

In the previous article, we discussed the issue of disassembling, cleaning and reassembling rod gas injectors using Valtek products as an example. To ensure proper operation of this system unit, after cleaning or replacing parts, as well as assembly into a ramp, it is necessary to carry out adjustment and subsequent calibration. We will look at how to adjust Valtek gas injectors with our own hands in this article and provide step-by-step instructions.

Required Tools

To adjust rod gas nozzles (using Valtek as an example), you must have the following tools:

- dial indicator with measurement accuracy of at least 0.01;

- extension rod;

- adapter sleeve for fixing the dial indicator;

- connector for supplying power to the gas injector;

- hexagon.

Adjustment

Adjusting Valtek gas injectors begins with unscrewing the adjusting jets from them. This can be done using a 12 key.

Next, install the extension rod and secure the dial indicator to the ramp using the adapter sleeve.

- Check that the extension rod is touching the gas injector rod. If the arrow of the device begins to move, it means that contact has been achieved.

- Set “0” on the indicator device. Apply power to the controlled part for up to 1 second.

- Write down the value obtained on the dial indicator as a result of the measurement.

- Do the above for all engine gas nozzles, recording the values.

- Next, using an internal hexagon screw located at the end of the electric coil, we set the required stroke of the rods. By rotating clockwise, we reduce the stroke of the rod, and vice versa, if we rotate counterclockwise, we increase the stroke. We set the same stroke of the rods, but not more than 0.7 mm, according to the recommendations of Valtek.

General principle of operation of Valtek nozzles

In order to figure out which nozzles are best suited for your LPG, you first need to understand their operating principle. In this case, we were lucky, since all the nozzles installed on the gas equipment operate on the same principle.

Its essence lies in the fact that, thanks to the solenoid valve installed in the injector, the gas mixture flows from the gearbox into the intake manifold. This algorithm is the same for all devices, and the only difference between them is the opening and closing time of the valve and the value of the coil resistance.

Advantages and disadvantages of Valtek injectors

The most popular among the nozzles produced by Valtek and having positive reviews are the following models:

- Valtek Type 30;

- Valtek Type 37.

Let's take a look at their technical characteristics and positive aspects.

Valtek Type 30

The main feature that distinguishes this product from others is its low price and the presence of jets that can be changed. If, during the installation process, you need to drill them to a different diameter, you can easily do this.

A big advantage is the ability to use them in most existing gas control units. In addition, these devices can be installed on engine types of different power and number of cylinders. This product has no obvious disadvantages.

Note! Gas installation specialists recommend using this type of injector in engines whose fuel injection time is equal to or exceeds three milliseconds.

Valtek Type 30 injectors have the following characteristics:

- recommended pressure is from 0.5 to 2 bar;

- the maximum possible pressure is 3 bar;

- operating temperature range – from 120°C to - 20°C;

- the minimum injection pulse is three milliseconds;

- the operating resistance of the coil is 2 ohms;

- case material – aluminum;

- has low sensitivity to pollution.

Valtek Type 37

Injectors that are inexpensive and have low noise activity during operation. The advantages of using this type of product include the fact that they are suitable for working with many gas equipment systems, and their installation is possible for single injection. Possesses efficient gas supply when operating at low temperatures.

These injectors have the following disadvantages:

- small working resource;

- during operation there may often be a need to adjust the stroke of the rod;

- The rods may wear unevenly during operation. This leads to the fact that over time the supply of the gas mixture to the cylinders will be uneven;

- high temperature dependence;

- high inertia.

Technical characteristics of Valtek Type 37:

- operating temperature range – from -40°C to 120°C;

- operating voltage – 16 V;

- resistance is 2.5 ohms;

- case material – plastic;

- The piston stroke can be adjusted.

Installation of Valtek injectors

One of the main parameters that determines the quality of a product is the choice of installation method and position in space. Below are general tips that will allow you to carry out the installation correctly:

- Select the correct position in space before installation. This is especially true for models that have a gas supply on the side of the rod. If such parts are installed on a car with the coils facing down, they will quickly begin to fail.

- The use of a vapor phase filter plays an important role when installing gas injectors. Its presence will improve the quality and increase the working life of the product.

- During fastening, it is necessary to ensure that the injector ramp will not be subject to excessive vibrations during vehicle operation. An advantage during installation will be the absence of contacts with wiring, numerous hoses and other car parts.

Important! Compliance with these conditions, as well as periodic checking of all parts of the gas equipment will allow you to avoid a large number of problems and recognize a malfunction in time if one arises.

Setting up Valtek equipment

The best option to ensure safe and high-quality movement by car would be to set up the equipment using the services of a specialist. This will allow you to quickly and efficiently select the optimal parameters and not worry about possible errors made during setup.

However, if you are unable to follow this advice and want to perform this procedure yourself, then you need to follow the following steps to adjust the stroke:

- We unscrew the jet from the first cylinder of the ramp.

- Disconnect the power supply plug to the coil corresponding to the nozzle.

- We insert the adapter in place of the removed jet.

- We connect a micrometer to the adapter. Screwing is carried out until the arrow on it begins to move.

- We attach the plug to the coil of our injector.

- Reset the micrometer dial.

- We supply voltage at 12 v. The feeding time is 1 second, after which we record the resulting value.

- Next, the nozzle is adjusted. It is carried out by rotating a bolt with an internal hexagon located at the end of the coil. Reducing the stroke is done by rotating clockwise, increasing - rotating clockwise.

- Apply power again and check the result.

- The maximum recommended stroke is 0.7 mm.

Why do you need to flush the injectors?

During the combustion of the air-fuel mixture, a tar deposit is formed, which is deposited not only in the combustion chambers of the power unit, but also in the nozzles, gradually contaminating them. The diameter and shape of the hole in the nozzle through which fuel is supplied changes over time. This not only leads to insufficient supply, but also to changes in the spraying process. The mixture becomes heterogeneous - instead of fuel mist, streams of gasoline are supplied. There may be excess gasoline or oxygen in the mixture. This negatively affects engine performance, fuel consumption, etc. In winter, when fuel evaporates worse, pollution occurs more intensely.

To restore normal engine operation, you sometimes need to clean the injector, removing all deposits inside their channels.

The component is designed so that when using “ideal” gasoline, cleaning is not necessary. For example, high-quality European fuel saves EU car enthusiasts from cleaning car engine injectors.

Removing the ramp

At this point, the washing device is ready and you can begin to disassemble and remove the injectors. To remove them, you will have to remove the fuel rail.

We will consider all this using the example of a VAZ-2110 car with an 8-valve engine.

POPULAR WITH READERS: How to properly check the engine oil level in winter and summer

To do this you will need:

- Set of open-end wrenches;

- Screwdrivers, flat, Phillips;

- Set of hexagons.

The sequence of work is as follows:

- Relieve the pressure in the fuel rail. One of the simplest ways to do this is to disconnect the wiring from the fuel pump and start the engine. During operation, it will remove all the gasoline, completely relieving the pressure. You need to keep the engine running until it stalls, after which you should try to start it again; if it does not start, you can proceed to further work.

- Next, we disconnect the air filter pipe, the wiring of the ramp, the idle speed control, the TPS sensor, and the pipe from the fuel pressure regulator. Additionally, you can remove the accelerator cable.

- Using open-end wrenches, unscrew the fuel pipes going to the ramp. It is advisable to place a rag under the place where they connect, since there may still be some gasoline left in the ramp.

- Unscrew the bolt of the pressure plate of the fuel pipes.

- Using a hexagon, unscrew the two ramp mounting bolts.

- Carefully pull the ramp up (along the axis of the injectors). In this case, you will have to make an effort, since the nozzles sit quite tightly in their seats. After this, we move the ramp a little to the side.

- To remove the injectors, first disconnect the wiring from them. They are held in the ramp using clips that need to be removed. To do this, use a flat screwdriver to move these clamps along the ramp, after which it can be removed.

- We take out the nozzle. It sits tightly in the ramp, so we remove it with light rocking. In order not to mix up the elements, it is better to remove and wash them one by one.

On engines of other vehicles, removal of fuel cells for washing may be carried out slightly differently. But the essence remains the same - you need to remove the ramp to remove the elements.

Types of gas filters for cars

Depending on the location and functions performed, these mechanisms are divided into liquid and vapor phase devices. The propane-butane mixture passes through each gas equipment filter in different states, so they differ from each other, both in design and principle of operation.

- A coarse gas filter (also called liquid phase or high pressure) is located in front of the reducer, as part of the solenoid valve, or is part of the evaporator design. Its purpose is the primary cleaning of fuel from foreign mechanical inclusions. Applicable to all systems.

- A fine gas purification filter (vapor phase or low pressure) is located directly in front of the nozzles in the 4th generation LPG. As fuel passes through it, it is cleaned of oil particles and moisture.

When propane is supplied from a cylinder to the reducer, the gas passes through a special fine mesh installed on the multivalve intake.

Also, gas (propane) can undergo primary purification directly in front of the cylinder, through a filling filter built in after the VZU (remote filling device). Its filter element is made in the form of a fine mesh of sintered bronze, which is designed for repeated maintenance using the blowing/rinsing method. This device is installed optionally.

Material of manufacture

By analogy with a gasoline filter, an LPG gas filter consists of a housing and a special cleaning element. The material of the body parts is metal or plastic, resistant to high temperatures; it can be dismounted or non-dismountable.

Filter elements are made from:

- cardboard (filter paper);

- fiberglass;

- polyester;

- foamy substance called bulprene.

Filter paper is the most common raw material for the manufacture of gas filters. Cardboard blanks are impregnated with a special composition, due to which the material gains strength and is not afraid of moisture.

To prevent paper parts from losing their original shape and becoming deformed, the structures are reinforced with the help of reinforcing meshes.

Fiberglass elements have low resistance to gas flow and are less susceptible to destruction.

The design of the coarse filter (liquid phase propane) sometimes includes a magnet. It is necessary to attract and retain small metal inclusions contained in liquefied gas.

Products made from polyester are also resistant to damage and deformation. Synthetic raw materials are not subject to natural aging, external factors do not have a negative impact on them.

Thanks to the foam structure filling the entire body in a bulprene filter, the fuel is maximally cleaned of oil fractions and other debris. When passing through small pores, gas flows experience almost no resistance.

To purify gas in methane plants, felt or viscose wads are used.

How to choose a HBO filter?

When choosing a gas filter, it is best to rely on reviews from car owners and recommendations from installers. Not forgetting the important points:

- The selection must be made according to the characteristics recommended by the LPG manufacturer in the instruction manual;

- Price. A good consumable cannot be too cheap;

- It is advisable to consider original products from well-known manufacturers;

- The quality of packaging plays an important role;

- Availability of a set of replaceable seals (repair kit);

- It is better to buy from trusted stores.

The car market is full of fakes therefore:

It is worth paying attention to the presence of manufacturer logos (holograms) on the packaging and body of the device; The assembly quality of the liquid phase element can be assessed visually. Check the sizing of paper to plastic or metal parts, as well as the uniformity, density, number of layers of material

A filter of a non-separable type (fine cleaning), except for inspecting the housing assembly, cannot be checked. It is not uncommon for an element to be missing inside.

Useful tips for using a gas injector

Vehicles have different power and injection times, as well as other performance characteristics. Therefore, almost all pieces of equipment must be prepared for use on a given make and model of vehicle.

Most often it is necessary to adjust the capacity of the rod without relying on the factory settings.

In the accompanying documentation for the 4th generation HBO system, you should find a nozzle selection plate.

If it is noticed that the injection engine operates unstably on gas fuel, may stall when switching to gas, dynamic performance has deteriorated, fuel consumption has increased, or malfunctions have appeared during acceleration, it’s time to clean the injectors. Then they need to be calibrated.

- the ramp is removed;

- Next, you should unscrew the injectors from the ramp;

- the rods are removed from the body (usually removal shows that the nozzles are clogged with black soot);

- Using cotton swabs and alcohol (or solvent), the nozzles and everything inside the nozzle body are cleaned;

- then everything is assembled in reverse order.

Do-it-yourself adjustment of Valtek Type 30 gas injectors

Successful products Valtek Spa Unipersonale

The Italian company Valtek Spa Unipersonale, created in the 90s of the last century, produces high-quality gas equipment sets that have a long service life. Valtec injectors meet quality standards of the European Union and America.

Having its own research laboratory allows the company to produce safe, high-tech products, which are mainly exported.

The basis of Valtek gas injectors is a rod made of durable metal with a rubber tip. This design eliminates gas leakage. The electromagnetic coil is secured with a retaining ring. Special screws allow you to adjust the fuel supply; they have nothing to do with fixing.

Ramps are available that include 2, 3, 4 nozzles. You can choose products that match the number of engine cylinders.

The ramp includes a set of nozzles for the manifold, but calibration fittings, the diameter of which can be from 0.75 to 3.0, must be purchased separately. The diameter can be selected according to the table or drilled according to the power of the car’s power plant.