To watch online, click on the video ⤵

Repair of the rear glass on a VAZ 2110. The boy's basin is pleasing to the eye. More details. Repair of the glass of the VAZ 2112. More details.

Repair of the glasses of the VAZ 2110 with your own hands. Read more.

repair welding of license plate VAZ 2110 traffic police requirements More details

VAZ 2112. Replacement of the rear glass. Body repair. More details

VAZ 2110. And again glass repair. Body repair. More details

VAZ 2112. Replacement of side member, mudguard, TV. Body repair. More details

NUMBER GLASS 2110 TORN OFF More details

glass repair glass welding, overcooking rotted license glass VAZ 2110 2112 2111 Read more

⚠ Rear support strut tore out - VAZ 2112 / Proper body repair in the service! More details

budget repair of rear windows of VAZ 2114 Read more

VAZ 2110. Rotten glass. Repair. More details

rotted and then the cup of the VAZ 2112 tore off. It’s not a problem, it can be fixed Read more

How to pull out a cup without a slipway. More details

Repair of glass (number) VAZ 2111 Read more

VAZ 2111 replacement, repair of the rear arch with glass, one of two! More details

Restoration of glass VAZ 2110 Read more

VAZ 2110. Extraction of side members, repair of the muzzle Read more

Disassembly, tens of hoods and a jamb with the hood. More details

Attached images

Replacing car body glasses

In what cases will glass replacement be required and what are the difficulties?

Based on the frequency of calls to service regarding the replacement of shock absorber cups, we will highlight three main reasons:

- Glasses torn out due to extensive corrosion damage. The main clients are owners of cars older than 7 years, who are inattentive to their cars or immediately after purchasing such a budget car.

- Glasses torn off due to jamming of shock absorbers or damage to other elements of the rear or front suspension. It vomits due to strong impacts, mainly when hitting holes at high speed.

- The glasses, most often together with the inner arch of the wing, are damaged or severely deformed as a result of serious accidents, and pulling out the metal on the slipway does not allow the geometry of the car to be restored.

The technology itself is quite standard - cut and clean, fit and weld, protect against rust. Possible problems are related to other factors:

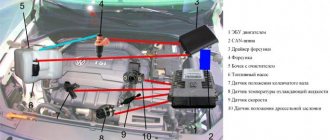

- There is a significant amount of disassembly, especially when working with the front glasses; in some cases it is necessary to remove the engine.

- When replacing the glass along with the inner wheel arch, a large amount of welding work has to be performed. At the same time, it is difficult even for an experienced craftsman to connect the arch with other body elements without errors.

- In almost half of the cases, replacing glasses is associated with the need to carefully check the geometry of the body at control points and restore it. It is difficult to do with improvised means (stands, stops); the required accuracy result can only be obtained on a slipway.

Please note that any error in adjusting the position of the glass leads to a misalignment of the shock absorber. This causes a reduction in the service life of all suspension elements, and you will have to forget about normal wheel alignment/camber adjustment. In general, the owner of a car on which glasses were welded with errors will become a frequent visitor to the services.

Therefore, be responsible when choosing a specialist for such repairs. By the way, we provide a guarantee on all body work performed.

Where and what replacement components do we buy?

First of all, about what spare parts we offer you. For almost all cars there are several options, and in different price categories, namely:

- Inexpensive glasses, mostly assembled with internal arches, from disassembly . Ideal for Russian-assembled cars, the most common budget or mid-priced foreign cars. With some luck, you can find components for more expensive cars.

- Contract glasses are mostly supplied exclusively assembled with an internal arch; companies do not want to deal with such small things, and the cost of delivery can sometimes reach the price of the product itself. The advantage of this option is that you receive the body element you need in “like new” condition, despite the fact that it has already been in use.

- New analogues of the original glasses can be found for almost any car model of Russian or Asian assembly. Based on our experience, we will say that in terms of quality they are not much inferior to the originals. Even if there are inconsistencies, they are eliminated during the adjustment process. Differences may be in the thickness of the metal and the quality of processing. But considering that we propose to carry out the entire range of anti-corrosion treatment work after installation, this drawback does not play a significant role.

- Original glasses cannot be found for all cars. It is realistic to buy such components for a car no older than 5 years, but for expensive foreign cars it will be difficult. In principle, the problem can be solved, but searching and delivery will take time, so such orders must be made in advance. In terms of quality, this is, of course, the best option, but it also has a corresponding price.

The main problem of searching and purchasing body components is the need to make a remote purchase. When you do this yourself, it will be problematic to check the condition of the same glasses; you just have to trust the seller. This is what they take advantage of; more and more often you hear about cases of sending spare parts in unsatisfactory condition and refusals to send anything.

So that you do not have to deal with such fraud, we offer a service for searching, purchasing and delivering the necessary body elements and other spare parts. We work with a number of proven suppliers who solve almost any problem. Let us remind you that you receive all components exclusively at the purchase price, without risking anything at the search stage.

Possible replacement options

We change the right and left, front and rear shock absorber strut cups, there is not much difference in technology. The difference may be in the amount of preliminary disassembly of the machine (reinforcement work), but this has virtually no effect on the cost of replacement, except in cases where it is necessary to remove the engine.

Depending on the degree of damage to the glass, we offer the following replacement options:

- If only the upper part where the shock absorber is attached is damaged, and the condition of the inner arch is still satisfactory (there is living metal to which it can be welded), then we only change the glass itself.

- In cases where the damage also affected the arch, and to a significant extent, there is no point in restoring it. In such situations, it is advisable to change the entire element assembly, the inner arch and the glass itself.

Note that the second option is more preferable, since practice has shown that even an internal arch that is well protected from corrosion after replacing one glass lasts about 3 years. In addition, installing the torn part in such a way as to maintain the geometry of the body and ensure the correct position of the shock absorber strut will be problematic. By the way, it is the second replacement option that most sellers of body parts are pushing towards. This unit is mainly supplied assembled, since it is believed that the factory connection of the glass with the arch is more correct and reliable. Although this is not always true.

We will be able to say what technology we will use to replace the torn glasses only after diagnosing and determining the general list of damage in this area. Even a preliminary assessment from a photo will be purely indicative; inspection reveals a more complete picture.

General technology for replacing glasses

For the front and rear glasses, one standard replacement technology is used, which involves performing the following work:

- Disassembly and dismantling.

- Preparing and fitting a new part in place.

- Installation and welding.

- Anti-corrosion treatment and painting.

Only the locations of the welds differ. And when replacing the glasses themselves without an arch, there is no difference at all. In this case, we work according to the following scheme:

- We remove the shock absorber and provide access to the welds at the junction with the inner arch.

- We clean the paint and drill out the weld points.

- We remove the damaged part and align the metal on the base.

- We clean off the rust or remove it with a converter.

- We prime the arch and the glass itself with epoxy primer, and in the welding zone with a special conductive primer.

- We set and check distances at body control points.

- Boil and seal the seam with polyurethane sealant.

- We prime and paint again, and assemble the suspension.

Such a replacement takes up to 5-6 hours, it all depends on the condition of the suspension and the ability to quickly disassemble it. When completely replacing the wheel inner arch assembly, the situation is more complicated.

Reinforcement works and dismantling

Before starting disassembly during such a replacement, be sure to correct the geometry of the body as much as possible - stretch out the side members, wing reinforcements, rear or front panel. If you do not correct the shape immediately, then after removing the damaged glass it will be almost impossible to catch these millimeters. And any imperfections in the geometry lead to problems with the suspension and more.

When replacing the rear glasses, we disassemble the trunk trim, body pillars and threshold on the interior side, remove the rear seat and only after that dismantle the shock absorber.

There are more problems with the front cups, since you additionally have to remove separate equipment from the engine compartment, which makes it difficult to access the welds. You should not think that a locksmith is able to reach everywhere, although such a possibility exists in many cases. But in this case, installation and welding in hard-to-reach areas will take much more time. That is, in the end there is no saving. In case of serious damage, it is necessary to dismantle the engine, and when replacing both front glasses, it is better to do this in all cases.

The welds at the rear wheel arch with the cup are located along the body pillar, trunk floor, side panel, side members, and outer arch. At the front there is a spar, a wing reinforcement, an engine compartment shield, and an outer arch.

Further work is standard:

- We clean the paint along all seams.

- We drill out the weld points, going through only one layer of metal until a characteristic click is heard.

- If it is impossible to drill in certain areas, we cut out the damaged segment, and cut out the rest of the metal using a pneumatic tool with a chisel.

- We remove the entire wheel arch and align the edges with the body.

In parallel with dismantling, we are preparing the wheel arch with the glass for installation.

Preparing the donor and body for installation of new glasses

We clean the donor element from the transport primer to the metal; it still cannot be painted on. Along all edges we drill holes for spot welding in increments of 2-3 cm. There is a basic rule - the number of points should not be less than the factory ones. All areas where welding will be carried out are covered with conductive primer with zinc. It will provide the required strength of the weld points. All other surfaces are covered with 1-2 layers of epoxy primer.

The main problem with the body is usually associated with the presence of significant areas damaged by corrosion. We pay special attention to the outer wheel arch, side members, and body pillars. If possible, remove red stains by simply stripping. For deeper damage, treat the surfaces with a rust converter.

In those areas where the welds were, we cut off the remaining beads of metal and align the edges. Further preparation is standard - degrease and cover with welding or epoxy primer. We start fitting the donor and welding only after the soil has dried. To speed up this process, we use infrared heaters.

Welding work

You should not think that problems with glasses being pulled out are due to insufficient strength of spot welding, and that it is enough to weld all the seams completely. This will only lead to more trouble, and here's why:

- When continuously welding thin metal, deformation caused by local overheating is inevitable. In addition, after such impacts, steel loses its individual strength characteristics, and how it will behave in the future is unknown. Note that straightening cannot remove such deformation.

- Increasing the strength of the welded joint leads to improper distribution of loads. And if, during factory welding, the glass itself tears, replacing which will not cost that much, then when strengthened, other body elements, including power ones, will tear and deform. And such repairs will cost much more.

- Spot welding gives body elements a certain freedom, the ability to move relative to each other. Thanks to this, minor deformations of one part are not transferred to another and do not lead to its damage. With continuous welding there is no such possibility.

You should not replace spot welding with other technologies; this production decision was not made in vain.

We weld the wheel arch according to the following scheme recommended by automakers:

- We try on the new element in place, give it the desired shape, and fix it at 3-4 points with pliers or clamps.

- We check the correctness of the geometry by measuring the distances between control points. We start welding only when these values correspond to the factory values.

- We weld 1-2 points at the joints with all adjacent body elements, after which we remove the temporary fasteners. We check the control distances again.

- We weld all the joints, moving in a circle through 3-4 points. It is not advisable to cook in a row to avoid local overheating of the metal. It’s easier to go through 3-4 passes than to constantly cool thin metal.

Note that last we weld the connection with the outer arch of the wing.

Corrosion protection

High-quality painting and anti-corrosion protection play a special role in the service life of the installed part. In this area we carry out the following activities:

- We clean the areas of soil damaged during welding, degrease them and re-cover them with epoxy primer.

- All welds must be protected from moisture penetration between the layers of metal. To do this, seal them with polyurethane sealant. We lay it in an even layer without gaps or breaks. We use only sealant intended for further painting.

- On the wheel side, we matte the surface, degrease it and apply 3-4 layers of anti-gravel or anti-corrosion. We offer a large selection of materials from this group based on bitumen or polymers. We work with Noxudol, Dinitrol, and a number of domestic products.

- We paint the side of the trunk, interior, and engine compartment in the color of the body; if you wish, we can leave only the primer, but this will not give much savings.

After all the coatings have completely dried, we assemble the suspension, put the shock absorbers and wheels in place. After such work, it is mandatory to adjust the wheel alignment, check the car in motion, and only after that we will return the car to you.

Features of replacing number glasses

Let's be honest, replacing number plates is a hemorrhoid. And not from the technical side, but purely from the legal side, related to the need to register such changes made to the design of the machine. So, we will do the technical part, and at the level of factory standards. But you will have to deal with obtaining permission for a replacement and subsequent re-issuance of documents yourself. We can only suggest a general algorithm for this process.

You will have to proceed according to the following scheme:

- Undergo a technical examination, which confirms that further operation of the machine is impossible due to a damaged glass.

- Contact the traffic police, get permission to replace it, and come to us.

- We carry out our part of the work in accordance with technological requirements.

- You re-issue the documents with the number of the new glass entered in the PTS.

Depending on your capabilities, this entire procedure will take from several days to several weeks. But this is the only way to solve the problem by acting according to the law.

If you have a need to change one or more shock absorber cups, you are simply looking for these components for your car, then call us or leave a request on the website. We will solve your problem to the required extent, with or without replacement. Call us and we will arrange a time that is convenient for both you and us to visit the service.

Why do they put spacers on the rear struts?

It so happens that a loaded “ten” touches the fender liners with the reverse wheels. To increase ground clearance and solve this problem, motorists install so-called. spacers for the rear struts of the VAZ 2110, which are placed between the lower plane of the shock absorbers and the brackets of the rear yoke (beam).

With an increase in rear clearance, the following vehicle characteristics change:

• position of the RD (pressure regulator) of the rear brake circuit; • vector of the direction of light of the front optics; • castor (angular distance of the axial inclination of the rotation of the front wheelset in the longitudinal section).

If the first two positions are subject to independent adjustment, then the angular distance must be installed at a specialized enterprise.

Repair of rear glasses of VAZ 2110

Similar articles

54 comments on “The glasses are rotten. The rear glass on a VAZ 2110 is rotten, how much will the work cost”

This is generally how it is.

what year is the car? 10 rubles, around this. I suppose your spar is still dead?

Dmitry, holy crap, did you buy it long ago?

Alexey, I’ve been driving for 3 years, today when I heard a knock I thought I was stoic at first and then I looked and I was surprised

Dmitry, this is fucked up, of course, you’ll have to spend a lot to get it welded... have you ever poured anti-corrosion agent on the bottom?

did you have fender liners?

they’ll digest it in 4-5 thousand

Alexey, no, I’m the second owner

Look at the other side too, it’s no ice there now either! Do both of them at once, but it’s better, of course, to change the car!

Anton, it didn’t happen, I think I drove like this for 10 years without fender liners

Dmitry, this is bad, because the body of the vases, even the new ones, is complete crap... I don’t know if anyone will take on this at all or not, and it seems to me that the frame is fucked up, and the side members too, look at the whole bottom with a screwdriver, even probably... or maybe It’s already easier to find a new body

Dmitry, then it’s clear why they rotted like that, right there the metal is 1mm and everything flies there from under the wheels, look at the side members and hope that they are intact then it won’t be very expensive

Anton, the spars looked normal and the other side was fresher

Dmitry, well, if the spars are normal, then not everything is as scary as they say in the comments, they will cut them off, they will lie where there is nothing to cook, they will make patches, they will not be expensive

Welding is not expensive, for 2000 they will do everything for you and paint it in color. But then it’s better to immediately insure the second side - if you need to boil it and tint it.

You don’t feel sorry for your lives riding on this! You can't call it a car

VAZ 2110 problem with glass

Gender: Registered: 05/21/2010 Messages: 76

Gender: Registered: 03.23.2005 Messages: 2605 From: Chelyabinsk

| Grease up and sell quickly _________________ In reality, everything is not as it really is. |

Gender: Registered: 05/21/2010 Messages: 76

Gender: Registered: 04/18/2006 Messages: 43678 From: Russia

what kind of glass is this? _________________ To be continued…

Gender: Registered: 08/25/2005 Messages: 7573 From: Shadrinsk

| Probably we are talking about the installation location of the shock absorber strut and support bearing, namely the right side, on which the body number is stamped. |

Gender: Registered: 08/11/2005 Messages: 41557 From: US State Department

| we need to find out why it started to tear off. Rotten? Have you cooked it yet? Does the stand not hold? _________________ Veni, vidi, vici Today our guest is an EXPERT fighter pilot-captain of a rank 8 submarine. Part-time KREMLEBOT 3 articles. |

Gender: Registered: 04/18/2006 Messages: 43678 From: Russia

yah! the wheel would have gone to the side, it's probably not about this glass _________________ To be continued...

Communities › VAZ: Repair and Modification › Blog › Front glasses are cracking

Good evening, fellow pelvis workers! I have a VAZ 2115 car. The problem is that the front glass where the VIN number is cracked. Tell me how to solve the problem? Please provide links or help with advice?! Thanks in advance)))

Comments 107

They won’t, you just need to take a photo like it was and is!

and the guys won’t wag their brains for welding when removing (or registering)?!

When everything is welded from the inside, you can install a spacer.

as already written below, install amplifiers. Both glasses also cracked at once, then the amplifiers were welded from the inside of the arch, now everything is fine.

Withdrawal procedure

1. Remove the telescopic stand.

2. Clamp the stand in a vice. We compress the spring with special ties. Unscrew the shock absorber rod nut, holding the rod from turning.

3. Remove the upper support of the rack.

4. Remove the upper spring bowl.

6. Remove the protective casing with the compression stroke buffer.

7. Inspect the rack. If deformation, cracks or damage are visible on the strut body, swing arm, bracket or lower spring cup, the strut must be replaced. Welding work on the rack can permanently damage it.

8. Place the strut vertically and swing the shock absorber rod several times. At the same time, make sure that the rod moves smoothly. If it moves with dips, jamming and knocking, then the rack needs to be replaced. The strut should also be replaced if it shows signs of fluid leakage or if the threads at the top of the stem are damaged.

9. Shock absorbers with a non-separable body (cartridge) can also be installed on the machine. To replace the cartridge, knock down the compression buffer support, unscrew the nut of the strut housing, remove the cartridge and put a new one in its place. When replacing a conventional hydraulic shock absorber with a cartridge, you need to remove the rod with the working cylinder from the housing and drain the liquid. Install the cartridge into the housing according to the manufacturer's instructions.

Replacement

If a problem is discovered and it becomes necessary to change the rear struts, then you need to carry out a number of operations. To begin, you will need to arm yourself with the following tools:

Dismantling

- we dismantle the luggage compartment in the area of the rear arches;

- Next, remove the rear belts, as well as the brackets that secure the rear seat;

- take a special wrench designed for struts and unscrew the rear strut rod nut;

Special key for disassembling the rack

- Now you will need to lift the car, or rather its rear part;

- Next, unscrew the nuts securing the lower part of the rack;

- remove the stand from its place.

Analogs of front shock absorbers Lada 2110-12

Very often, when replacing a shock absorber strut or liner, preference is given to foreign manufacturers, since their products are relatively cheap and have a high level of quality. The most popular are the racks presented in the table.

| Manufacturer | vendor code | price, rub. |

| Front shock absorber insert for 2110-12 | ||

| Hola | S431 | 1500 |

| KYB | 365507 - gas | 2300 |

| KYB | 665503 - oil | 2300 |

| Front shock absorbers for VAZ 2110-12 | ||

| QML | SA1038 - right SA1037 - left | 1500 |

| Kraft | KT073505 - right KT073504 - left | 2800 |

| Fenox | A61549C3 - right A61548C3 - left | 1900 |

| Hola | S436 - right S435 - left | 2200 |

| OAT | 21100290540203 - right 21100290540303 - left | 2000 |

| Fenox | A61549C1 - right A61548C1 - left | 1700 |

| Front shock absorbers for Lada 2110-12 from Priora | ||

| Pilenga | SHP2771O - right SHP2770O - left | 1600 |

| OAT | 21700290540303 - right 21700290540203 - left | 2800 |

| HOLA | S503 - right S504 - left | 1500 |

| Bort | G22252031R - right G22252031L - left | 1600 |

[thank you very much super. there is no rot. Damn, I didn’t think of that myself. I will do it and post a photo report.

I don’t know how it is in your city, but here they very strictly won’t deregister the car and won’t put it on alloy wheels; if a sports steering wheel is installed, they’ll also force you to change it to the original one; they’ll definitely pay attention to the muffler and toner. The slightest scratch on the cup and you’re out. expert.

How to digest a glass with a number on a VAZ 2110

Post by xxAndreyxx » 11 Sep 2012, 20:02

Good day. a problem has arisen. exchanged the UAZ 514 for a VAZ 2110, left the numbers, made 2 contracts and said goodbye. Today I was going to register, standing with the hood open, an inspector comes up like open the trunk and looks and there is a duplicate number. It seems like the bottom is different but the number is the same. They left all the documents. They ordered an examination and said to wait until October. The question is what to do. I can drive, I asked the traffic police, what should I do, would they take my car away and would it be possible to register it, since it seemed like the standard number on the glass was missing.

Messages: 2501 Registered: 08 Sep 2011, 00:00 Experience: 2008 Car: МВw639-Nivushka :

Awards: 1

| Rating: 7 020 |

| Reputation: +4 |

Thanked: 7 times Thanked: 62 times

Post by limi » 11 Sep 2012, 20:06

Source

Messages 7

1 Topic by alex3004 2015-04-22 18:55:45

- alex3004

- Participant

- Inactive

- From: Rostov region

- Registration: 2013-10-11

- Messages: 62 Thanks : 13

- Car: VAZ 2110103

Topic: How to replace a body part with a VIN number?

please tell me, has anyone encountered such a problem? it is necessary to cut off the front right side with the numbered glass and weld a new one without a number! but not a single master undertakes to do this without some kind of piece of paper authorizing dismantling and welding work in this place. If anyone knows who exactly I should contact, please tell me. Thank you very much in advance! p.s. They told me to contact the MREO, but they all point their fingers at each other and say that this is the first time they have encountered something like this.

2 Reply from Anton 2015-04-23 06:04:51

- Anton

- Local

- Inactive

- Registration: 2014-02-20

- Messages: 2,207 Thanks : 255

Re: How to replace a body part with a VIN number?

3 Reply from iliaBkmz 2015-04-24 08:00:15

- iliaBkmz

- Forum legend

- Inactive

- Registration: 2012-11-12

- Messages: 2,035 Thanks : 583

- Car: outlander and 2104

Re: How to replace a body part with a VIN number?

To be honest, all this overcooking of the numbered glass is a big headache. The one who will digest (only official service) must have permission to perform this type of work, with a copy of which then you need to go to the traffic police. But they will most likely still send you for examination. In general, there are a lot of headaches with such machines - I’m telling you from personal experience! Usually (in practice, such cars are used by those who have friends in the traffic police).

4 Reply from alex3004 2015-04-26 00:02:43

- alex3004

- Participant

- Inactive

- From: Rostov region

- Registration: 2013-10-11

- Messages: 62 Thanks : 13

- Car: VAZ 2110103

Re: How to replace a body part with a VIN number?

Thank you for your responses to this topic! I also found three generations of acquaintances in this field, but what is even more important - guys, it’s better to look for more than a dozen handicraftsmen, someone will take it! That's how I found the bodybuilder. He said, “Take a lot of money, but I’ll save the glass.” "The man answered for his words! so forum members, don’t despair, there are people who are afraid of this.

5 Reply from sergo9531 2015-04-26 13:04:29

- sergo9531

- Local

- Inactive

- From: Domodedovo

- Registration: 2014-01-12

- Messages: 578 Thanks : 208

- Auto: 21114

Need advice on repairing a number plate.

Comrades, this kind of trouble has slowly arisen.

While it's warm, I think I'll cook everything. Who was involved in such repairs, what is the best way to cook on both sides? What metal will the 1mm standard patch be made from? Or should I take it thicker? Is it necessary to remove the engine or can it be welded like this? There really isn’t enough space there!(((

Comments 40

Factory seams were not touched

Hello. How did you resolve the issue with the traffic police? I was also brewing a glass and decided to sell the car, so I’m wondering if the buyer will return the car back after it is sent for examination

They sent us for examination ourselves. DPS stop They did it for free and gave me a certificate that everything was fine))) The paint was only removed with a wash...

thanks for the info

The license plate on my car has already been tacked on by the previous owner. As if without certificates and other things. There isn't even a service order. The factory seams were not touched; no special marks were even made during registration.

As a last resort, the number is duplicated in the back of the matryakh.

And so, regarding the welding, there is a patch of 2 mm metal, welded on both sides. When working, you will have to remove the stand. There is no need to remove the motor, you can crawl up, but the motor should be covered.

A familiar picture. On my Ten, the glass is also rotten (the one on which the body number is stamped and the engine number is stamped). In a good way, it’s better to overcook the glass. But then you need to formalize this matter somehow - because of the stamped number. Therefore we will make a patch. But we find out from a friend whether we need to report to the cops that the glass has been patched.

As I was told at the MREO, any technical work, in principle, should be registered as a change in the design of the car. I’ve already changed my mind about going to them, I’ll do it carefully, I don’t need to cook a glass, but a splash pad. I won’t touch all the factory seams on the glass, everything is fine there. Well, if they screw it up later during re-registration, I’ll do an examination

Source

Faceted Glass Day in Russia

The history of a product is stored not only in historical facts, but also in the memories of people whose everyday life is integrally connected with it. They drank sparkling water from it right on the street, tea on trains, for which they put a cup holder, and drank alcoholic beverages. The Soviet cut glass has become a housewife's assistant in the kitchen. It helped to accurately measure the number of grams of a bulk product or milliliters of liquid.

Therefore, it is not surprising that later a date was set when the holiday of the cut glass could be officially celebrated. This is one day a year - September 11, on which the first glass came out of the Gus-Khrustalny glass factory assembly line. Although there is no documentary evidence of this fact. Russia timed this day to coincide with the All-Russian Day of Sobriety. Which can become the countdown date for giving up a bad habit for everyone.

Is the numbered glass brewing?

Comments 38

My mother-in-law faced this problem. from the beginning you go to an expert, he records the fact of corrosion or cracks, then you cook, digest and again go to the expert, like this, and if you do it yourself, then before the first traffic police check and then prove that it is not stolen

Yes, I understand. I’ll contact the experts tomorrow, let’s see what they tell me...

The photo shows that it was not the glass itself that was cracked, but the upper reinforcement of the front right mudguard. All this can be cured after removing the wing, you can also boil it from below, then putty, apply seam sealant at the joint with the glass, then paint.

Okay, thank you all so much for your answers! We will decide what and how.

I came across this situation. I had a similar situation on the 99th. The glass had rotted and there was simply no need to cook it. I set it as numberless. For this operation, I chose the official service, which has been in our city since Soviet times. Only they have all the permits, licenses, and documents. And still, when I went to fill out the documents, everything dragged on for 4 months. They told me that I first had to get permission from the head of the MREO (that's nonsense), then they were checked three times by experts and checked against all sorts of databases. At the same time, there were ALL the documents and photographs, plus an old glass in stock... In this country... I won’t tell you, you know everything yourself.

Damn, what passions are written here about examination, theft, etc. The seam is short, many cars are sick, the main thing is to leave the number itself, it’s covered up even if you can’t see it, the examination is a scam of money (1000 rubles). a friend with a completely digested glass spent 1000 rubles (but under no circumstances should you beat him, this is already a crime)

any traffic cop, when you first open the hood, seeing your boiled glass, will confiscate the car, and then try to prove that you are not a gladiolus! your car must undergo an examination, where they will write a paper for you, saying that the license plate part of the body was damaged anyway, and then they will tell you what to do: cook this one, or take a repair one and get a new number! the process is long and unpleasant, that’s why people just cook it themselves and drive until the first accident, where the car is sent for examination and a weld is found there, and after that, of course, the car is bye-bye! or they may write it off as a thief, but God forbid you are a thief!

This is what I was waiting for. And I was even a little surprised by the previous answers. And as far as I know, the examination even happens several times ((for each money and a lot of time. I got it in general