Marking features

All wheel rims are marked with a special marking that reflects all the parameters. Marking must be on any products, regardless of the material from which they are made. Let us show with one example what this or that number and letter in the marking means. For example, let’s take into account the marking 7.5Jx 15 H2 5×100 ET40 d54.1:

- the first digit 7.5 shows the width of the rim in inches from one inner edge to the other;

- the Latin letter J indicates the type of rim edge; the letters B, D, K, P, JJ, JK are also often found;

- the next “x” sign indicates that the disk is non-separable, otherwise a “-” sign is placed;

- the number 15 indicates the diameter of the disc, expressed in inches;

- the H2 symbol gives an idea of the shape of the protrusions for fixing tubeless rubber;

- the expression 5x100 indicates that this disk has 5 holes for mounting bolts, and the diameter of the circle on which their centers are located is 100 mm (PCD parameter);

- parameter ET40 is the size of the protrusion in millimeters;

- parameter d54.1 is the diameter of the central hole in millimeters.

What wheels were installed on different car bodies and configurations?

The factory equipment of the car is limited to the installation of stamped wheels. They have good performance in terms of strength, service life and wear resistance. However, as far as appearance is concerned, there is still room for work.

By the time the LADA 2110 was released, the automotive market was already filled with various alloy wheels of various sizes. The best option is to install alloy wheels, which are attractive and durable.

Before purchasing new disks, you must remember that not every disk may be suitable for a car. The product is selected based on the parameters determined by the vehicle manufacturer. The bolt pattern, the size of the central hole and the nuts that will secure the disk are taken into account.

And that's not all - the territorial conditions (climatic features) in which the car will be operated are also considered, as well as the external data of disks from various manufacturers.

The AvtoVAZ plant installed stamped wheels in black or white with the following standard parameters:

- bolt pattern 4x98, which indicates that the disk model is fastened with four studs, each 98 mm long

- departure ET35

The Ten is a universal model, the wheel arches of which allowed the installation of wheels with dimensions from R13 to R17. Car owners installed beautiful alloy wheels from well-known brands, which made the car even better.

VAZ 2110 2110x 2004 1.8i 16V

Generation: 2110xEngine: I4, Gasoline Power: 98 hp

(72 kW) Wheel bolt pattern parameters

| PCD (number of holes x circle diameter) | 4×98 mm |

| Center Hole Diameter (DIA) | 58.6 mm |

| Fasteners | M12 x 1.25 |

| Type of fastener | Bolt |

| Tires | Discs | PCD | Dia | Pressure |

| 175/65 R14 82H Factory kit | 5.5Jx14ET35 | 4×98 | 58.6 | 2 |

| 185/60 R14 82H Factory kit | 5.5Jx14ET35 | 4×98 | 58.6 | 2 |

| 185/60 R14 82H Tuning | 6Jx14 ET35 | 4×98 | 58.6 | 2 |

| 185/55 R15 82V Tuning | 6Jx15 ET35 | 4×98 | 58.6 | 2.1 |

| 195/50 R15 84V Tuning | 6.5Jx15 ET35 | 4×98 | 58.6 | 2.1 |

What wheel sizes does the manufacturer recommend to install?

The VAZ 2110 2110x 2004 1.8i 16V car is equipped with 5.5Jx14 ET35 rims assembled with 175/65 R14 82H tires as standard. Where:

- 5.5J - rim width in inches;

- 14″ — tire diameter in inches;

- ET35 - disc offset in millimeters.

The vehicle tire marking 175/65 R14 is deciphered as follows:

- 175 — profile width (cross section of the tire) in millimeters;

- 65 — profile height as a percentage of its width;

- R - radial cord winding;

- 14 is the tire diameter in inches.

In addition, information about its load capacity and speed parameters can be printed on the rubber - load index and speed index. The load index is a two- or three-digit number; the speed index is indicated in Latin letters, for example 82H:

- 82 - maximum permissible tire load 475 kg;

- H — maximum permissible vehicle speed is 210 km/h.

Using the recommended tire sizes will help you avoid problems with handling, safety and other difficulties. What non-standard sizes can be supplied? Refer to the table; it indicates possible acceptable alternative sizes for tuning. Although there are other options that we have not described in the table. For example, wider discs of the same diameter. Or install wheels of the same width, but with a larger diameter, which is quite popular among car owners. The choice of discs is huge; you can find copies with the same parameters, but with an overhang 1-2 millimeters more or less. It is not possible to list all the options.

At the same time, the bolt pattern for all types of wheels is the same - 4x98. Thus, all disks are mounted on four bolts and the distance between them is exactly ninety-eight millimeters. The diameter of the car's hub is 58.6 mm.

Standard tire pressure is 2 MPa.

Choice of alloy wheels

When choosing rims for a VAZ 2110 according to technical characteristics, you must take into account the following parameters:

- diameter (in inches), indicated by the letter R;

- width (in inches), indicated by the letter J;

- offset (in millimeters), indicated by the letters ET;

- size of installed tires;

- the diameter of the circle on which the centers of the fastening bolts are located, for VAZ 2110 cars it is 98 mm (denoted as PСD 4x98 for VAZ);

- the size of the central hole, it must be at least 58.5 mm in diameter.

We present the permissible indicators of diameter, width, offset and their correspondence to each other in the table:

| Disc diameter in inches | Width in inches | Reach (ET), mm | Tire size, mm/% |

| R 13 | J 5.0 | 35-38 | 155/75, 165/70 |

| J 5.5 | 35-38 | 175/70, 185/65 | |

| R 14 | J 4.0 | 45 | 135/80 |

| J 5.5 | 35-43 | 165/65, 175/65, 185/60 | |

| J 6.0 | 35-40 | 175/65, 185/60 | |

| R 15 | J 6.0 | 30 | 185/55 |

| J 6.5 | 30 | 195/55, 195/50 | |

| J 6.5 | 35 | 195/50, 205/50 | |

| J 7.0 | 35 | 195/50, 205/50 |

It is recommended to comply with the given parameters and correspondences. Otherwise, problems will arise either of a technical nature (for example, the inability to install wheels or accelerated tire wear), or the appearance will leave much to be desired (for example, low-profile tires on R 13 rims will look untidy).

You should also pay attention to the offset (ET) of the discs you purchase. It is possible that standard mounting bolts will be short and will only capture a few threads when screwed in. In this case, you should purchase extended bolts that will securely fix the wheels.

Some car enthusiasts install R 16 rims on low-profile tires on their VAZ 2110. This car looks really impressive, as can be seen in the photo. This is where all the advantages of such tuning end. Firstly, for such an installation you need to carefully select the wheels and seriously modify the design of your car. Secondly, low-profile tires when driving on our roads require caution to avoid strong impacts to the wheel, so as not to damage the rim.

Advantages and disadvantages of low profile tires

With low-profile tires installed, the vehicle's maneuverability and controllability are significantly improved - this is especially noticeable when cornering. The steering wheel becomes “sharper” and the car practically does not deviate from the trajectory due to the fact that the low sides of low-profile tires crumple less under lateral loads on the tire.

But when driving on a bad road, such wheels transfer much more shock loads to the body than standard-sized tires, and absorb various road defects less well.

It is worth noting that a tire with a low profile is quite easy to “punch” to the disk even on a small pothole and at low speeds, and the edge of the alloy wheel can become wrinkled and completely fail when using such tires.

Also, it would not be amiss to mention that according to traffic rules it is prohibited to operate vehicles with tires whose characteristics do not correspond to the vehicle model. However, experience shows that traffic police officers usually have a calm attitude towards tuned VAZs with alloy wheels “14”.

And this is not surprising, because R14 wheels are standard equipment on cars of the VAZ 2110 family, the chassis of which is similar to the VAZ 2108, 2109, 21093 and 21099 models. But with R15 alloy wheels, the likelihood of running into trouble when passing a technical inspection is much higher.

Source 5net.ru

Tire sizes according to the VAZ 2110 model. Table of standard, factory tire sizes for VAZ 2110

- What size tires can be installed on a VAZ 2110.

- Acceptable (standard) and recommended tire sizes for VAZ 2110

- Maximum and minimum tire sizes VAZ 2110

- Profile (width, height) and diameter of VAZ tires

Wheel selection rules

For the “ten”, the original wheels are 13- or 14-inch with a 4x98 bolt pattern, where 4 is the number of holes, 98 is the diameter of the circle on which they are located.

In fact, there is nothing complicated about it. It is not necessary to put your life in danger by installing discs with a drill even 1 mm more or less than permissible. Any wheels from Italian and some French cars are perfect for cars of the tenth family. Of course, with the same bolt pattern.

Here are just some of these cars:

- Ford Ka produced after 2009;

- Lancia Delta;

- Lancia Lybra;

- Lancia Musa;

- Lancia Ypsilon;

- Peugeot Bipper;

- Alfa Romeo 145, 146, MiTo;

- Citroen Nemo;

- a huge number of Fiat car models.

Table with bolt pattern 4x98.

It is worth noting that new VAZ cars have changed the Italian size to French. This happened with the arrival of the French B0 platform , on which Vesta, Largus, and Xray are built. Their disc drilling parameter is 4x100 mm. Select the right discs and do not forget about safety!

R13 or R14

Another important issue is the possibility of switching from standard R13 tires to R14. This issue is controversial; it comes down to tires rather than wheels. Since the disc size is larger, this affects the profile height. The lower the profile, the more the rubber will transmit road unevenness to the suspension, which will ultimately result in an increase in driving rigidity, but the car's handling will improve.

But if you take into account that the handling will improve slightly, but the possibility of damaging the disk itself or the slope on potholes will increase, then it is still better to use disks on the car assigned by the manufacturer. Many car enthusiasts in VAZs use R14 wheels in the summer, and in the winter they switch to R13, and stamped wheels.

Preparing for adjustment

Most often, the VAZ 2110 camber and alignment are installed at a service station, but you can do it yourself. First of all, check whether there is play in the bearings and whether the steering is loose. At the same time, check the diameter and absence of deformation of the disks, air pressure in the tires, and tread wear.

VAZ 2110 front suspension assembly diagram

Naturally, if a wheel is loose, action will need to be taken, and one with improper tread wear may need to be replaced. Wheels standing on the ground need to be pulled relative to the vertical. If you find any play, have a helper apply the brake and check the play again.

If it disappears, the bearing needs to be replaced. If after this the size of the play not only does not disappear, but only decreases slightly, the suspension needs to be checked, repaired, and sometimes replaced.

Front wheel hub diagram

After this, hang the wheel and check the play again. It is possible that the play has disappeared, but the wheel turns jerkily or is simply difficult, then you need to slightly expand the diameter of the bearing installation site.

If you hear a grinding noise, the bearing needs to be replaced.

Changing wheels

During operation, alloy wheels can be damaged, so they need to be restored or replaced with new ones.

Alas, the peculiarity of “casting” is that if the damage is severe enough, it is not possible to restore it. And it is not always advisable to try to restore the rollers, since this procedure can be even more expensive than buying a new set.

Please note that aggressive driving over potholes and potholes is dangerous not only for the wheels themselves, but also for the suspension. After all, during an impact, all its energy is transferred through the disk to the suspension

This is not typical for stamped steel analogues. They themselves are deformed, but do not harm the suspension.

Damage to stamping

It is recommended to replace a damaged disk at a service station that is equipped with special equipment. The wheel may get stuck, and it will be impossible to remove it manually in your garage.

Contact a workshop for restoring skating rinks. Ask how much this procedure will cost and estimate the cost of a new kit. This way you will understand what is best to do in your particular case. Self-recovery is impossible for the simple reason that it requires appropriate experience, tools and expensive equipment. There is no point in purchasing it for a one-time restoration.

Brief overview of manufacturers

We provide a list of producing countries and a brief description of the products of each of them.

- Products from China. The selection of Chinese alloy wheels is truly huge. Contrary to traditional opinion, it is worth noting that not all Chinese products are of low quality. Therefore, it would be appropriate to go shopping for wheels with a friend or acquaintance who has already purchased wheels from a certain Chinese manufacturer before and can confirm their quality.

- Alloy wheels of domestic production are known to everyone for their affordable price and corresponding quality for the money. Alloy wheels for a Russian-made VAZ are a completely acceptable and adapted option.

- The quality of alloy wheels from Turkey can be assessed as sufficient. However, the cost will be slightly higher than that of domestic analogues.

- Asian manufacturers (South Korea, Japan, Taiwan) produce alloy wheels of fairly high quality and are recommended for use on all brands of cars.

- Manufacturers from Western Europe and the USA offer the highest quality products, but also the most expensive. It’s worth thinking about whether it’s really necessary to purchase wheels for the “ten” at this price.

General background information

Ranges of possible values for tires and wheels VAZ 2110 2007.

Tires

| Diameter | 13″–15″ |

| Width (mm) | 175–195 |

| Profile (%) | 50–70 |

| The smallest size | 175/70 R13 |

| The biggest size | 195/50 R15 |

Wheel disks

| Diameter | 13″–15″ |

| Width (inches) | 5–6.5 |

| Reach (mm) | 35–35 |

| Drills | 4×98 |

Photo

Expert advice

When choosing tires for a car, you must first follow the manufacturer's instructions. Ask yourself a few questions.

- On what roads will the car be primarily used?

- Do you need increased cross-country ability?

- How much of the route will be city roads and how much will be highways?

- Will the vehicle carry heavy loads?

The answers to these and similar questions will help determine which tire parameters you need to pay special attention to.

How to choose the right wheels for a VAZ 2110 2007?

3 types of rims:

- Stamped (economical price category) - made from a sheet of iron by stamping on a press.

- Light alloy - manufactured by casting (more reliable than stamped ones).

- Forged (the highest quality and more expensive than the previous ones) - made from light alloys by stamping at high temperatures.

The choice depends on financial capabilities. However, it should be borne in mind that the quality of the road surface on which you have to drive every day must also be taken into account.

So, if it gets into a hole, a stamped disk will bend and will not cause harm to the tire, but a forged or cast one can cut it. There is a possibility that the cast disc may burst or crack.

It should also be noted that repairing “stamping” wheels is cheaper than repairing cast or forged wheels. But wheels with high-quality cast and forged disks kill the suspension less, because lighter and have more perfect geometry (better balanced).

The same wheels may or may not rub with tires on the same car - wheel alignment adjustment will help here.

What is the tire pressure?

It is the driver's responsibility to constantly monitor tire pressure. This will avoid standard problems associated with vehicle operation. An abnormal pressure value often causes:

- deterioration of management;

- uneven tread wear.

Often the car owner independently reduces the pressure in the wheels of his own vehicle. This reduces the load on the suspension, and the car “passes” various road irregularities an order of magnitude easier. But it is worth noting: a decrease in pressure even by 0.1 MPa leads to serious problems. The main ones include:

- increased fuel consumption;

- rapid wear of the outer tread segments;

- the car becomes less maneuverable.

An overinflated wheel causes no less problems. The central part of the cylinder begins to wear off quickly. In addition, at ambient temperatures of more than 60 degrees Celsius, the tire may simply explode. Which will lead to driving into the oncoming lane.

Features of disk sizes for “Ten”

The product dimensions listed above are ideal for the VAZ 2110, however, some climatic, operational and other external factors that may affect the operation of the car should be taken into account. All disc features for each radius offered by the manufacturer:

- Wheels on the VAZ 2110 are size 14 - a small wheel radius, typical for simple configurations or for economical drivers who install them to reduce costs. Most often found on the market in a stamped version, however, inexpensive and high-quality specimens can also be found in casting. Starting with a rim width of 6.0J, the wheels are ideal for installing winter tires, since the profile height of 60...65 mm guarantees reliable grip on the side surface of the tire even in deep snowdrifts.

- Wheels 15 by 2110 are the most universal size, at which the driver can safely install high-quality all-season tires and forget about changing wheels every six months for at least several years, depending on the driving style and the annual mileage of the car.

R16 wheels for VAZ 2110

- R16 - most often installed in a cast or forged version for comfortable driving around the city. The tire profile of 55 mm is sufficient for both dynamic driving on smooth asphalt and short trips outside the city on unpaved surfaces.

- R17 - for the VAZ 2110 are exclusive products that are installed exclusively for high-speed driving on high-quality roads. In the cold season, it is better to get another set of rims, since the cross-sectional height of a tire of 45 mm is not enough for safe driving on slippery surfaces.

When choosing wheels, it is important for the owners of the “Ten” to follow the factory parameters of the ET offset from 27 to 35 mm, since otherwise the wheels may touch the wheel arches, calipers or suspension elements, and also if the car owner purchases steel wheels for 2110 with zero or negative departure, then he needs to be prepared for rapid contamination of the side of the body of his “iron horse”.

By adhering to the geometric characteristics of the wheels specified by the manufacturer and choosing only trusted suppliers, any driver can be confident in the long and safe operation of his “Ten”. Also, when changing disks, the driver must remember that, while remaining in the same size and model, you should not buy only one wheel, and experts advise changing them in pairs or all at the same time, so that uneven wear does not affect the suspension imbalance.

As a standard, the plant installs stamped wheels on the VAZ 2110 car. Their quality is more or less normal, however, their appearance leaves much to be desired.

To stand out from the gray mass, experts recommend installing alloy wheels on the VAZ 2110. This will not only improve the appearance of the car, but will also have a positive effect on safety.

Photos of alloy wheels on the top ten

Choosing alloy wheels for the top ten is not very easy. The problem lies in approximately the same thing - each client is looking for the most interesting design from his point of view, which is combined with high quality and an affordable price.

The external parameter is a secondary issue in casting selection. First think about safety and product quality. And nothing else. Each set has the appropriate quality, composition and size. That's why the choice becomes more complicated.

Recommended tire pressure for VAZ 2107/2110 and 2112

The manufacturer recommends the optimal degree of tire inflation for its own vehicle models, taking into account all design features and the load on the wheelsets.

The complex formula affects maximum loads, wheel speeds and the “degree of roughness” of domestic roads. Violating the parameters is strictly not recommended, as this may impair the predictability of the car.

You can find an indicator of what the tire pressure should be in the Lada Priora and other modern modifications in two indicators.

- Typically the metal tag is located on the B-pillar near the driver's door. The nameplate contains the necessary numbers and recommendations. On other models of the manufacturer, the information element may be located under the hood, in the trunk or on one of the pillars.

- Factory instructions. The owner's manual usually contains comprehensive information about service intervals, correct tire inflation, and factory recommendations.

Tire inflation on Lada cars / Tire pressure table

It is most convenient to view the tire pressure of the Lada Granta in winter in the table. There is also a complete list of popular domestically produced cars.

| Model | Light pressure, BAR | Pressure under load, bar | ||

| Before | Back | Before | Back | |

| Priora 2170 | 2,0 | 2,0 | 2,0 | 2,2 |

| Kalina | 2,2 | 2,3 | ||

| Largus | 2,4 | 2,6 | 2,4 | 2,7 |

| 2101/2107 | 1,6 | 1,8 | 1,8 | 2,0 |

| Granta | 2,3 | 2,2 | 2,3 | 2,4 |

| 2121 | 2,2 | 1,9 | 2,1 | 2,0 |

| 2109/99 | 1,9 | 1,9 | ||

| 2114/2115 | ||||

| 2110/2112 |

Adjustment for tire inflation in winter depending on external factors

The tire pressure of the VAZ 2107 in winter and similar models (2101-06) is kept at 1.6/1.9 At for an empty vehicle and 1.8/2.1 for a loaded vehicle, respectively, on the front/rear axle. This is true on factory P13 wheels with a sidewall height of 70-75. At the same time, on station wagons (02 and 04), the rear axle will need to be pumped up by 0.2 BAR more during full load.

In cold weather, it is recommended to increase pumping by 0.3-0.5 kg, which is caused by compression of oxygen inside. The subsidence of the cylinders softens the sidewalls, and the tread shoulders can slip on loose snow or slippery ruts.

For the summer period, it is necessary, on the contrary, to bleed off the air volume, due to the expansion of oxygen when heated.

Alloy wheels for fourteen

The production of cast wheels, as their name implies, is based on the use of casting metal alloys into special prepared molds. Engineers use an alloy of aluminum and magnesium as the starting material. It does not rust, does not rot, and is lighter than steel. Let us briefly touch upon the issue of mass. Many are convinced that cast wheels are much lighter than stamped ones. This is partly true, but there are nuances.

Alloy wheels come in a variety of shapes

The fact is that the alloy of aluminum and magnesium is light, but fragile. Therefore, when in the 90s of the last century the first such samples began to appear in the vastness of our country, soon many car owners were faced with a situation where, when driving on domestic roads with a large number of holes, they simply cracked. Manufacturers drew the appropriate conclusions and simply increased the amount of alloy used to produce each disc, thus increasing their mechanical strength. However, this affected the mass, increasing it. Therefore, today the difference in weight between four stamped and alloy wheels is only 10…12 kg . Thus, one should not expect a significant increase in dynamic indicators.

Many car owners think that 14-radius alloy wheels on a VAZ will significantly increase the price of the car. In fact, the high cost of a car is often due to the presence, in addition to alloy wheels, of climate control, parking sensors, cruise control and other additional systems that create comfort for the driver and passengers.

Next, let's look at the advantages of 14-inch alloy wheels on a VAZ:

- Beauty and style. Nowadays you can buy alloy wheels in a variety of shapes.

- Reduced weight. As described above, the difference is small, but it is there. This factor ensures less load on the suspension, faster recovery of the trajectory at speed (less inertia, which has a positive effect on the car’s handling at speed), lower fuel consumption, and less wear on the brake pads.

- Easier balancing. Typically, alloy wheels themselves are stiffer, so they hold their shape better.

But if there are positive aspects, then there must be negative ones. These include:

- Because. Since alloy wheels do not bend, but crack, they cannot be driven at high speed on bad roads. Unfortunately, for our country this parameter is critical. Especially if you use budget drives.

- Unsuitable for repair. In some cases, alloy disks are soldered, but in any case, after such a procedure, their mechanical strength will be lower than the original one.

- When hitting a bump on the road, they transfer its energy to the suspension, which is harmful to its components and the system as a whole.

- Servicing alloy wheels is more expensive, since the procedure itself for removing and installing rubber costs more. In addition, balancing weights are also more expensive.

- Alloy wheels are used on light and medium-duty vehicles. So, they are never used on trucks. This is due to their fragility.

In accordance with traffic regulations, a car with wheels that differ significantly from the factory ones cannot pass inspection. However, as practice shows, traffic police officers are calm about 14-diameter alloy wheels. But the 15th may already cause disapproval on their part.

Next, as promised, we will draw conclusions whether it is worth using alloy wheels on a VAZ of 14 diameters or whether you can get by with standard stamped ones.

Review of the best summer and winter tires for the VAZ 2110

Every driver understands that the wheel plays a very important role not only in comfort and design, but also significantly affects driving safety. For this choice, the tire needs to be given enough attention. In addition to the basic or acceptable standard size, you should not forget about:

- speed limit in which the car will be operated (speed index);

- temperature regime (seasonality);

- climatic conditions (tread pattern and depth);

- weight load on wheels (load index).

If you choose tires by manufacturer, then from the many domestic ones you can choose several that have significantly increased the quality of their products compared to previous years. These can deservedly be called: Amtel, Matador-Omskshina, Kama.

- Amtel tires in Russia are undoubtedly the leaders (among domestic ones). Produced in Voronezh. In the process of testing this product, it was proven that it is no worse than foreign ones. The plant makes tires of all categories. The company has excellent specialists at its disposal who are constantly improving the production process.

- Matador-Omskshina is one of the youngest manufacturers, but sales volume is growing significantly every year. Drivers who prefer models from this manufacturer note reliability, stable performance and comparative cheapness.

- Kama (Nizhnekamsk) – produces tires for Russian buyers of all classes. But for cars of the 2110 model, the assortment is rather meager.

The main disk manufacturers whose products are set to ten

- Most VAZ 2110 representatives are equipped with products from the Russian manufacturer KiK. The brand is quite popular due to its huge assortment, as well as its design developments in the field of creating discs.

- The next popular manufacturer is Vicom, which produces sports products. The company was created on the basis of the Institute of Metals and Alloys, has its own production technology and produces interesting specimens with twisted colored knitting needles.

- The Krasnoyarsk SKAD plant produces wheels that are exported to other countries. The assortment is not very huge, but due to the mass production of disc models, the plant can set a minimum price for the product.

- Slik products have been supplied to the Russian automotive market for three decades now. The assortment is quite wide, here you can find exclusive items, wheels for high-speed travel and off-road driving.

- The very young brand IFree began its work in 2010 and has gained a certain respect among car owners.

These manufacturers produce products that provide the optimal solution for the driver: an affordable model price and its acceptable quality.

Suitable sizes

And yet, if a car owner decides to install alloy wheels on his VAZ 2109 or 2110, he must first understand the possible size options that are acceptable for installation without changing the design of the car. The size of VAZ 2109 and 2110 tires with a diameter of 14 inches (R14) is larger In general, wheels with a width of 6 inches and an offset of 35-40 cm are suitable, but wheels with a size of 265 65 r17 are not suitable. Similar models are marked J6.0 ET 35-40, respectively. You can install wheels with a difference of 1 inch to one side or the other from the standard, that is, R13 and R15 are also suitable options. With a strong difference, one can note such an unpleasant effect as friction of the wheel on the wheel arches and fender liners on sharp turns, as well as wear and tear on the car's running parts.

What you need to know about disks

Today castings are produced in a fairly wide range. The VAZ 2110 fits wheels with a radius of 13 inches, although it is quite possible to drive an R15.

When installing non-original wheels, think about the offset and width. Their parameters must comply with the standards laid down by the manufacturer of the “tens”.

| Disc diameter | Width | Departure | Size |

| R13 | J 5.0 | 35-38 | 155/75, 165/70 |

| J 5.5 | 35-38 | 175/70, 185/65 | |

| R14 | J 4.0 | 45 | 135/80 |

| J 5.5 | 35-43 | 165/65, 175/65, 185/60 | |

| J 6.0 | 35-40 | 175/65, 185/60 | |

| R15 | J 6.0 | 30 | 185/55 |

| J 6.5 | 30 | 195/55, 195/50 | |

| J 6.5 | 35 | 195/50, 205/50 | |

| J 7.0 | 35 | 195/50, 205/50 |

If you violate the recommendations, when turning and under maximum loads (full trunk, full passenger compartment), the wheels will begin to rub against the fender liners, touching the arches and suspension. Plus, the side parts of the body will always get splashed in dirty weather.

- When installing 15-inch alloy wheels, use only low-profile tires, otherwise nothing will work.

- If you want to install even larger wheels, you will need to make changes to the design of the car itself. And this is already a difficult task.

- When a VAZ 2110 car owner chooses cast rollers, he often comes across such a characteristic as PSD 4*98. He says that the disk is fastened with four bolts that fit into the circle R98 .

Which company to choose winter studded tires

There are not so many famous companies on the market that produce truly high-quality and sought-after tires. We are mainly talking about European manufacturers offering products with an optimal price-quality ratio. This ranking of the best winter studded tires features products from 5 of the most popular companies in the industry.

Nokian Tires – our rating from this company includes 3 models of tires, each of which is made of high-quality materials and is safe to use in different weather conditions. It has options for cars, SUVs, and even vans and buses. On average, their width ranges from 165 to 315 mm. The products of this company regularly win specialized competitions. The price of the products is not very high and does not hit the budget too much.

Gislaved is a company specializing in the production of studless and studded tires, including those for harsh winters. They provide excellent grip on ice, excellent handling, excellent maneuverability and guarantee safe driving in different weather conditions. They are convenient to use both in the city and beyond. They have optimal traction characteristics, an acceptable noise level with a large number of studs and good stability when passing through uneven areas, without skidding.

Bridgestone – the year of birth of this legendary company is considered to be 1931, and tire products at the plant began to be produced from the first days of the company’s existence. The manufacturer quickly entered the international market and established itself there. The tires from this company make driving safer and more comfortable during the difficult winter months. It “feels” great even at low sub-zero temperatures. It’s convenient that Bridgestone’s assortment is divided into several categories - the premium line, as well as the “Comfort” and “Best Value for Money” series.

There is a discount on any product.

Goodyear is one of the leaders in the European market, attracting attention to its products with the optimal combination of cost and quality of products. His product shows exceptional performance even in difficult winter conditions and is not subject to rapid wear and tear.

Its spikes do not fly out immediately after purchase and there are no problems with traction on ice and snowy roads. The company's rubber is regularly successfully tested before going on sale, which eliminates defects and defects. It is often included in the ranking of the best winter studded tires according to various magazines.

Michelin is one of the largest manufacturers of tires, including winter studded ones, whose product range includes models for passenger cars, trucks, agricultural and motorcycle equipment. Its products are manufactured taking into account all requirements for environmental protection and the quality of such products. It deserves to be chosen due to its safety and ease of use. All designs are tested in real conditions, in particular in the northern regions.

There are no very cheap winter tires in this TOP, but the prices offered correspond to the quality of the products. They are made from proven materials and have excellent assembly.

What kind of disks can be installed?

Too huge a range of products can confuse the most experienced auto expert. Therefore, before purchasing a product, you need to familiarize yourself with the characteristics of popular discs, as well as know which countries produce them and are popular. What products are suitable for the LADA 2110 car?

- Domestic production. When creating models, the low quality of the road surface and the significant load on the wheel are taken into account. The product combines durability, reliable design and affordable cost compared to analogues from imported manufacturers.

- China. They became famous for their low cost and poor performance characteristics. At the same time, on the Chinese market for domestic use, there are product samples that are not inferior in their characteristics to well-known global brands. Many car enthusiasts order wheels online, which does not always pay off.

- Türkiye. Pretty good disk options. They have good quality, durability and stylish design. Quite suitable for our roads. As for the cost, they are much more expensive than Chinese and domestic manufacturers.

- Asian countries (South Korea, Taiwan, Japan). They have high technical characteristics and are reliable in operation. But the price of the product is very high.

- European brands and USA. Due to the high cost, wheels from these manufacturers are almost never found on our VAZs.

Review of the best summer and winter tires

It is better to acquire separate sets of summer and winter tires in advance. Pirelli Cinturato P1 Verde tires are ideal for the warm season. Their cost is relatively high (from 3,500 rubles per 1 tire). However, they perform excellently on wet asphalt and are highly resistant to wear.

- Continental Conti Premium Contact 5 is well balanced. There are a large number of special drainage channels - they make it easy to drain water from the contact patch. This kit will cost slightly less than the one discussed above.

- Goodyear EfficientGrip Performance provides good grip and low fuel consumption. However, the tread thins out quite quickly - especially during intense driving. The rubber is soft and handles well. Despite its softness, it is difficult to damage it redder.

- Dunlop Sport BluResponse is relatively cheap compared to all the options discussed above. However, it has its weaknesses. For example, on wet asphalt the wheels slip a lot and handling deteriorates.

- Semperit Comfort-Life 2 is a rare guest on Russian territory. However, on dry asphalt at positive temperatures it performs more than well. However, rubber is distinguished by its noise.

- GOODYEAR 175/70R14 UG ICE ARCTIC D-STUD - studded tires at a relatively low cost. Regardless of the ambient temperature, it retains its flexibility and softness. Cost – from 4,000 rubles.

- HANKOOK 175/70R14 W429 is a more budget option. Cost – from 2,800 rubles. Thanks to the deep tread and flexible design, the driver can feel completely safe on the road.

- KUMHO 175/70R14 WI31 84T usually costs several hundred rubles cheaper than the modification discussed above. The presence of studs makes this tire safe on almost any road.

- VIATTI TIRES 175/70R14 BRINA NORDICO is manufactured using rubber mixing technology. Reinforced lugs make this model indispensable not only in winter, but also on dirt roads in summer.

- SAVA 175/70R14 ESKIMO ICE MS is the most profitable option. It has a relatively low price (from 2,000 rubles). There are no thorns. However, the deep tread and its shape provide high-quality, reliable contact with any surface.

Choosing suitable tires for the VAZ 2110 is a relatively simple process

However, it is important to familiarize yourself with the intricacies of tire selection in advance. Wheels that are too large can easily damage the vehicle body

Tired of paying fines? There is an exit!

- Absolutely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter connector;

- Does not cause interference to radios and cell phones.

Winter is approaching, time to get new tires. However, due to the wide range of models, it is difficult to buy winter tires at VAZ. The experience of car enthusiasts in 80% of cases contradicts the ratings of glossy magazines and advertising brochures.

Stamped wheels 14th radius

Classic stamped wheels for VAZ

Any stamped wheel disk consists of two parts - the disk itself, which is made of sheet steel from a special reinforcing profile, and also the rim. These two parts are connected using spot welding. Next, the metal surface is rubbed, polished, paint and a protective coating (enamel and varnish) are applied.

Looking ahead, let's say that one of the main advantages of stamped rims is the ability to repair them. In particular, rolling. This procedure is performed at a service station using special equipment. In addition, the owner of a car with stamped wheels must remember that they require regular care and monitoring of their condition . In particular, it is necessary to constantly monitor the absence of chips on their surface, the absence of rust and other mechanical damage. If they are found, carry out repair work as soon as possible!

According to statistics, stamped wheels are the most common not only in the CIS countries, but throughout the world. The reason is that their price is 2…3 times cheaper than their cast counterparts, and also has a greater load capacity.

Manufacturers of steel rims

There are several trusted manufacturers of stamped wheel rims for VAZ cars. Among them:

- EuroDisk . Discs under this brand are produced by EurasiaTAPO-Disk CJSC (Fergana, Uzbekistan). This is an Uzbek-English enterprise, based on the former Tashkent Aviation Production Association named after. V. P. Chkalova (TAPO). The production volume of the enterprise is about 1 million wheels per year.

- KFZ _ Discs of this brand are produced at enterprises that are part of the ALCAR . The high quality of the discs is confirmed by the fact that they are supplied to the world's largest automakers. In particular, Alfa Romeo, Audi, BMW, Chevrolet, Chrysler, Jeep, Citroen, Daewoo, Dacia, Daihatsu, Dodge, Fiat, Ford, Honda, Hyundai, Iveco, Jaguar, Kia, Lancia, Landrover, Mazda, Mitsubishi, Mercedes- Benz, Nissan, Opel, Peugeot, Renault, Rover, Saab, Seat, Skoda, Subaru, Suzuki, Toyota, Volkswagen, Volvo.

- Mefro . The company's production facilities are located in Germany and South Korea. Discs released under this brand are of high quality. This is confirmed by statistics - the company produces more than 22 million discs per year. Their advantages are the absence of radial runout, the ability to withstand a side impact while maintaining pressure in a tubeless tire, and the presence of a protective layer of zinc and aluminum powder on the surface. The only indirect disadvantage is the fact that there are currently a large number of fakes on the market.

- VAZ . They also produce wheels for their cars directly at the plant itself. They belong to the middle and lower price category with mediocre quality of the products themselves.

- KrKZ (“Kremenchug Wheel Plant”, Ukraine, Kremenchug). It produces cold-formed steel wheels and wheels for cars and agricultural machinery. The products are of high quality and low price.

When choosing a particular manufacturer, you need to proceed from the ratio of quality and price. Naturally, European manufacturers sell their products at a slightly higher price, but their quality is also better. With domestic discs it's the other way around. But when buying imported goods, there is always a risk of purchasing a fake . This is especially true for discs in the high price category. Therefore, buy products only from trusted and certified stores.

Advantages and disadvantages of stamping

The manufacturing technology described above implies that 14-radius wheels on a VAZ have the following advantages:

- low price (about 20% cheaper than cast ones);

- ease of manufacture;

- possibility of repair;

- in the event of a significant impact, the disc is not destroyed, but only deformed, which significantly increases the safety of the car when driving at high speed;

- the stamped wheel absorbs most of the impact, thus protecting the suspension and steering system;

- use of standard mounting bolts (alloy wheels often use individual elements).

However, stamped wheels are not without their drawbacks. These include:

The appearance of the discs is hidden behind the caps

- unsightly appearance (stamped discs are often covered with various decorative caps);

- greater mass than alloy wheels, which affects the dynamic characteristics of the car and also places additional load on the car’s suspension;

- discs are susceptible to corrosion, which reduces their strength and service life;

- difficult balancing due to the fact that they “walk” along the axis;

- stamped wheels hold the road worse at speeds of 80-90 km/h and above, which is caused by their greater mass and, accordingly, inertia.

However, the balance of advantages and disadvantages of stamped discs is still shifted in a positive direction . They are very common in the domestic and foreign automotive industry. Especially among commercial and budget vehicles. We will move on to comparing stamped and cast wheels at the end of the next section, after we look at cast wheels.

Car wheels

Produced since 1995, the car replaced the legendary “nines” and other models. It has gained great popularity in the vastness of not only Russia, but also many neighboring countries. At the moment it is no longer produced; it has been replaced by more modern models “Lada Vesta”, “Largus” and “Granta”.

Today, a very wide range of products for cars is presented on the shelves of auto stores.

This applies to both any exterior parts and VAZ wheels, which are produced in various ways and have all sorts of characteristics, sizes and parameters.

Owners of this domestic car, like any other, are always faced with the need to replace tires before a certain time of year. In this case, you have to choose from many options for products presented in stores. These can be either very well-known and expensive brands or cheaper models. The price category is also different: it depends on the quality, size and reputation of the manufacturer.

Important! The choice of brand and characteristics of tires depends only on the personal preferences of the car owner.

It is important to remember that even products from very expensive manufacturers can be completely useless if used incorrectly. It is very important to select tires and wheels only with the correct sizes and constantly monitor their condition

This also applies to setting tire pressure, which is regulated by the manufacturer and must be indicated in the technical documentation.

It should also be noted that the safety of the driver and passengers will depend on the quality choice of tires.

In difficult weather conditions and on slippery surfaces, people’s lives often depend on the installed tires. In addition, tires have a huge impact on the level of wear of chassis parts, handling, dynamic characteristics and other qualities.

The tire size for the VAZ-2110, which is recommended by the factory, should also not be greatly exceeded, as this will affect comfort, increase wear on parts and increase fuel consumption.

Tire size for VAZ 2110 R15

Tuning

Many VAZ 2110 owners do not spare money on tuning their car. Tuned rims can become a real decoration for a domestically produced vehicle.

There are a lot of options for how to decorate the disks.

- Paint them in a variety of unique colors, make a combination of 2 or more colors.

- Apply patterns and interesting drawings to the discs.

- Equipping the wheels with LED lighting will make your trips around the city in the evening even more spectacular and will make others pay attention to your car.

- If finances allow, order wheels with an individual design developed by you. Many companies provide such services.

But still remember that in the case of wheels on a VAZ 2110, their quality should play a primary role. Appearance is a secondary selection criterion. In no case is it the other way around. The current assortment is wide enough to find a set that will meet your aesthetic requirements and meet the standards of quality and reliability.

Optimal car tire pressure

The main task of car tires is to provide effective traction between the car and the road. With normal air pressure in the tire, the load in the contact patch of the wheel with the road is distributed evenly, due to which tire wear occurs evenly, the car handles well and fuel consumption is within normal limits.

There are three possible scenarios in which the tire pressure will not be optimal:

- Increased pressure (tires overinflated);

- Low pressure (tires underinflated);

- Different pressure in all wheels.

Check the tire pressure with a special tire pressure gauge. This should only be done on cold tires, that is, before leaving the parking lot or garage.

If deviations from the normal pressure are detected in any of the tires (see the table below for what pressure should be in the tires of your passenger car), such a wheel must either be inflated or excess air released from it - that is, the pressure must be adjusted to norm. In one of our articles, we already talked about which car compressor is best for inflating tires.

It is worth noting that the tire pressure in winter should be exactly the same as in summer. But due to the sharp temperature change, in winter, monitoring the air pressure in the wheels needs to be approached more responsibly.

It is better to inflate your tires outside. Also, do not forget to check the tire pressure when there are significant changes in ambient temperature, and if necessary, adjust it:

- if it gets cold outside, the pressure in the tires will decrease,

- and when it gets warmer, it will rise.

It should also be remembered that while the car is moving, the tires heat up, the air in them expands, and the pressure increases, and the handling and braking properties change.

Increased tire pressure

With increased tire pressure, the load at the point of contact of the wheel with the road acts to a greater extent on the central part of the tire tread, thereby causing uneven wear of the tire.

On overinflated wheels, the car brakes worse! This happens because if the tires are overinflated, the contact patch with the road decreases, which means the friction force that keeps the car from sliding decreases. At the same time, the braking distance increases noticeably.

In just twenty minutes of driving, taking turns as aggressively as possible, the pressure in the car’s tires can increase by 0.5 atmospheres. And on long trips at high speed, the pressure in the tires can increase to 4-5 atmospheres. And modern tires are designed for this.

But if the tire has a hernia or cut, it can heat up and explode while driving. But on the road it’s a disaster.

Low tire pressure

Wheels lowered to just half an atmosphere change the behavior of the car and become unusable much earlier than expected. When the pressure is low, the load on the tire surface is distributed unevenly. In this case, the sidewalls of the tire where the tire contacts the road are subject to increased wear.

The sidewalls of flat tires are softer and bend when you turn the steering wheel. The trajectory of the wheel and tire do not match, so the car responds to the steering wheel late.

Moreover, if the tire pressure is reduced, the wheel may even come off during a sharp turn.

Therefore, it is very important to regularly check tire pressure and maintain it within normal limits.

This is especially true in winter, since in cold weather the tire pressure can easily drop by 0.3 (or even 0.5) atmospheres.

It is also worth keeping in mind that low air pressure in the wheels leads to increased fuel consumption. Just in case, we remind you that our website has an excellent selection of tips on how to reduce fuel consumption in a car - be sure to read it, you will probably find something new for yourself.

Different pressure in car tires

The most common situation among drivers is when the pressure in all wheels is different. There can be many reasons, for example:

- Faulty spool valves;

- Uneven tire wear;

- Or perhaps you caught a nail with the wheel.

During emergency braking, in this case, the coefficient of road adhesion between inflated and lowered wheels will be different, which with a high degree of probability will lead to the car skidding or turning across the road.

If the car starts to pull even a little to the side, there is a reason to check how the tires are inflated. And remember that tires don’t last forever. Even very good tires need care.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

Index C means that the rubber belongs to the category of reinforced tires. The M+S index (Mud+Snow, i.e. mud and snow) means that the tires belong to the all-terrain category.

Tire speed index:

- Q - 160 km/h

- R — 170 km/h

- S — 180 km/h

- T — 190 km/h

- U - 200 km/h

- H - 210 km/h

- V - 240 km/h

- W — 270 km/h

- Y - 300 km/h

- ZR - over 240

Tire load index (IN - Load) : 60 - 250 kg 70 - 335 kg 80 - 450 kg 90 - 600 kg 100 - 800 kg 110 - 1060 kg 61 - 257 kg 71 - 345 kg 81 - 462 kg 91 - 615 kg 101 — 825 kg 111 — 1090 kg 62 — 265 kg 72 — 355 kg 82 — 475 kg 92 — 630 kg 102 — 850 kg 112 — 1120 kg 63 — 272 kg 73 — 365 kg 83 — 487 kg 93 — 650 kg 103 — 875 kg 113 - 1150 kg 64 - 280 kg 74 - 375 kg 84 - 500 kg 94 - 670 kg 104 - 900 kg 114 - 1180 kg 65 - 290 kg 75 - 387 kg 85 - 515 kg 95 - 690 kg 105 - 925 kg 115 — 1215 kg 66 — 300 kg 76 — 400 kg 86 — 530 kg 96 — 710 kg 106 — 950 kg 116 — 1250 kg 67 — 307 kg 77 — 412 kg 87 — 545 kg 97 — 730 kg 107 — 975 kg 117 — 1285 kg 68 - 315 kg 78 - 425 kg 88 - 560 kg 98 - 750 kg 108 - 1000 kg 118 - 1320 kg 69 - 325 kg 79 - 437 kg 89 - 580 kg 99 - 775 kg 109 - 1030 kg 119 - 1360 kg

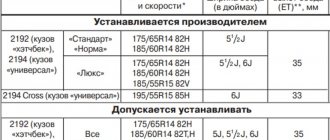

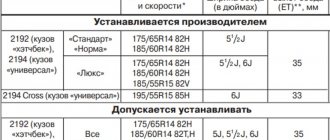

Tires, wheels for VAZ of the tenth family

Excerpt from the service book: on cars with a sixteen-valve engine, the manufacturer installs steel wheels (rims) for tubeless tires 5Jx14H2 ET35. The luxury ones are equipped with cast aluminum alloy wheels.

The VAZ 2110-12 is equipped with tubeless tires 175/65R14 82N. It is also possible to install 51/2Jx14 and 6Jx14 wheels on the car, as well as wider tires - 185/60 R14.

Tire pressure should be 2.0 bar (0.2 MPa), checked after the vehicle has been stationary for some time. This is because tire pressure can change while the car is moving at high speeds and frequent maneuvers (especially noticeable in the summer). This driving style can increase tire pressure by 0.2-0.3 bar.

In addition, tire pressure may vary depending on temperature. For example, when the ambient temperature rises, the pressure in the tire increases, and when it decreases, it drops. It is recommended to check tire pressure if the temperature difference reaches 10-15 °C.

FAQ

Are disk offset deviations acceptable?

- The offset of the disc must exactly comply with the requirements of the car manufacturer and no deviation in any direction can be considered acceptable. By changing the disc offset (not even a “minor” 5 mm), you also change the essential operating conditions of all suspension units, creating forces (and vectors of their application) for which your suspension is not designed. The simplest consequence is that the service life of the suspension elements is reduced, but under conditions of critical loads the consequences can be much worse, up to sudden destruction while driving.

Why do sellers say otherwise?

- The answer is simple - simply because there are a lot of disc offset options, and specifically for “your” offset it is quite difficult for them to select wheels that are suitable for your car in other respects. Those. neglecting the accuracy of offset matching significantly expands the range of wheels that can be offered to you, which significantly increases the chances of selling you something.

What happens when the calculated disc offset changes?

- The only thing that offset actually affects is the location of the central axis of the disk (wheel) relative to the hub. As the offset increases, the wheel will “sit” deeper on the hub, narrowing the wheelbase. Reducing the offset, accordingly, expands the wheelbase and “brings” the wheel outward.

What a car enthusiast needs to understand:

- this is that in both cases, the displacement of the central axis of the disk inevitably shifts the steering axis, while changing the steering parameters provided by the designer (this affects the handling of the car as a whole and the wear of rubber in corners), and changes the very moments of forces acting on the suspension , as well as vectors of their application. All this together forces the suspension to work in a mode not intended by the car manufacturer, and therefore its service life and driving safety (especially in extreme conditions) in this case are a lottery with little chance.

And now the main thing

- With good sound insulation, after a good pothole and at high speed, the probability of suddenly losing a wheel due to the destruction of the hub bearing due to an abnormal disc flight not only exists - it is several times greater than the probability of the same consequences, provided that all suspension elements meet the design requirements of the car designer. Do not agree? Well, that's your right.

What wheels and tires do you use on your car?

Pros and cons of “stampings”

The big advantage of stamped steel wheels is that they are stronger, withstand a more aggressive driving style, and are better suited to the quality of our roads.

Plus, they are manufactured by domestic manufacturers, which has a positive effect on pricing. Another advantage is the ease of repairing a damaged stamped roller.

But few car owners prefer them, since the design of such wheels is seriously outdated, they only spoil the appearance of the rather nice VAZ 2110 car.

A serious drawback is the heavy weight and susceptibility of stampings to corrosion. Therefore, over time, they will look even worse and will not allow those who love fast driving to enjoy speed.

Corrosion protection

For reliable operation of the chassis, everything is important: the bolt pattern, the dimensions of all components, the alignment/camber settings, and even the protection of the arches from corrosion. It is the arches that are more susceptible to adverse factors than other parts of the body - from ordinary moisture during rain to reagents on winter roads.

To ensure reliable protection of the arches, it is best to install lockers (fender liners) on the VAZ 2110. Such protection will cost much less than subsequent repairs of rusted arches. It is important to choose the correct size of the lockers and ensure their tight fit in the area of the arches.

We hope that by completing all the repair work yourself, you will provide your VAZ 2110 with many years of trouble-free service on the road.

Many owners of domestic cars make sure that their “iron horse” looks beautiful and somewhat unique. The widest range of light alloy wheels allows you to carry out minor tuning of your VAZ without relatively high costs and on your own. Let's look at how to correctly select and install alloy wheels on a VAZ 2110.

What tire sizes does the manufacturer recommend to install?

The standard size depends on the body type. Moreover, all cars without exception used discs with a hub diameter of 58.5 mm. The amount of overhang could fluctuate - within 37-40 mm. The rim width is also typical - 5-5.5J. The most common model is 2110. This digital combination is used to mark a car with a sedan body.

The manufacturer recommends the following sizes:

- 2110, 21101, 21102 – 175/70 R13;

- 21103, 21104 – 175/65 R14.

"Razboltovka" - 4x98 mm. A special modification is the VAZ 21108 Premier car. The car was produced for a relatively short time - from 1999 to 2001. The only difference from previous versions is that alloy wheels with a diameter of 13 inches were installed at the factory. There are no fundamental differences for station wagon cars.

The issue was carried out between 1997 and 2004. The wheels installed on ]wheels[/anchor] differed depending on the modification of the car and the marking of the specific model:

- 2111 – 175/70 R15;

- 2111i-2114 – 175/65 R14.

Hatchbacks were produced, like most other cars in this series, until 2004. The diameter of the wheels and their dimensions also differed slightly depending on various factors:

- 2112 – 175/65 R14;

- 21122 – 175/70 R13;

- 21124 – 175/65 R14.

Using tires of standard size and diameter will avoid damage to the body and other troubles. However, the automaker suggests the possibility of installing custom-sized wheels.

Maximum and minimum possible parameters of non-standard disks

The most acceptable option for mounting on a VAZ 2110 is considered to be alloy wheels. When choosing alloy wheels, you need to consider the following parameters:

- R – disk diameter;

- J – rim width;

- ET – indicates departure;

- Dimensions of tires mounted on the rim;

- the diameter of the central hole is 58.5 mm;

- the diameter of the circle on which the bolts are fixed is 98 mm.

All these indicators may vary depending on the selected model. For example, for 13-inch wheels the width ranges from 5 to 5.5 with an offset of 35 - 35. On 14-inch wheels the width increases from 4 to 6, respectively, and the offset decreases from 45 to 35. For 15-inch models the values are different .

Compliance with these values is very important. Otherwise, you can get into a lot of trouble driving your car on the road. A car with small wheels still doesn’t look as stylish or presentable.

Disadvantages of the VAZ 2110

The Achilles heel of the car is the stove. When driving down to -15° degrees it’s still okay, but when the thermometer creeps lower, there’s a real contrast in the cabin. The legs freeze from the cold, and the upper body suffers from the heat.

There is no need to talk about sound insulation, unless you bring it to mind on your own. Rattles in the interior of Russian cars are unlikely to surprise anyone, and the VAZ 2110 is no exception. The iron in the hood area is not thick, and pressing the hood frequently when closing it may cause dented spots.

It holds the road quite confidently, which is due to the streamlined shape of the car. Above 130 - 140 km/h, it really becomes scary, but overall not bad. The car's suspension is strong and designed for our country. Power steering is not included in the basic package, but it can be installed as a separate option upon request.

Wheel alignment

After replacing wheel rims, the dimensions and bolt patterns of which differ from those provided for by the design of the VAZ 2110, it is necessary to make all the necessary adjustments in order to ensure reliable protection of the entire chassis, as well as tires and arches.

Correct alignment angles are required for each front wheel. There are three parameters that require correct installation: wheel toe, caster angles of the steering axles, and camber angles of each wheel.

Wheel installation options

The rules by which the parameters of the front wheel are set are as follows:

- You won't go far if everything hangs out the way it wants, and the car is pulled to the side when it should be going straight. To ensure the stability of each front wheel, they are installed strictly at the required angles to the body and suspension elements. This is called the longitudinal inclination angles of the turning axis. Installation dimensions are indicated in the instruction manual;

- Camber is the angle between the plane in which the wheel rotates and the vertical. The camber bolt helps install it (it secures the telescopic strut and steering knuckle). If the camber is installed incorrectly, the car “steals” and the tire tread wears out more on one side;

VAZ wheel offset

Many drivers do not pay attention to this value. However, this is a very important geometric parameter. It determines the distance between the plane of contact of the disk to the surface of the hub and the symmetry of the wheel. Measured in millimeters.

The manufacturer must indicate the exact overhang size. During installation, even a minimal deviation of this value is strictly prohibited. When the disc offset dimensions change, the suspension operation changes.

Additional loads appear that quickly damage the suspension. As a result, it breaks quickly, and sometimes destruction can occur right at speed. There is no need to talk about the consequences.

Installing 4*100 disks

Let's consider several methods used by car craftsmen to install disks from foreign cars on a VAZ 2110:

- Sometimes holes are drilled into the disc hub on a lathe so that it will be possible to install the discs you currently have. Both 98 and 100 bolt patterns are suitable. And if you need to replace the disk, then this is also not difficult to do. The bolt sizes are standard;

- The simplest, but not the best way is to install the disk using extended bolts of regular diameter for wheels. But don’t be surprised later that this replacement led to the disc dangling, wheel play appearing, and it is impossible to establish the correct camber and toe, as well as the longitudinal inclination angles;

- A popular, relatively safe method is to install standard size bolts with an eccentric on a VAZ 2110 (an option is also possible if the bolt has an offset center). Today, online stores offer many sets of such bolts;

Wheel bolt with eccentric

If you replace the standard wheels of a VAZ 2110 with those with a 4x100 bolt pattern, then when you gain speed you will find that the wheel dangles, and during sharp braking it may even fall off, and how this “adventure” will end is unknown.