The topic of this article is the VAZ-2110 engine (8 valves) injector in the fuel injection system. The main task is to find all its advantages and disadvantages and compare it with a carburetor engine. But to do this, you will need to delve a little deeper into history, look at how this engine was developed, how good it is in operation and repair. And the story will begin in the late 70s of the last century, when VAZ engineers started thinking about designing front-wheel drive cars. And then we will look at the injection system, its differences from the carburetor, its advantages and disadvantages.

Engine history

And now the story about where the VAZ-2110 engine (8 valves) injector comes from. And it was put in place at the end of the 70s. During these years, designers begin to understand that the classics produced for many years have a high cost. In addition, the Fiat 124 was the best car in Europe in 1964. Almost two decades have passed, the model range needs to be updated. And the experiments began. First of all, we modernized the gas distribution drive and started using a belt. But it did not take root on the VAZ-2105 engine (production years: 1980-1988), although it reduced the noise level.

The reason is simple: the pistons need scrapings that prevent them from hitting the valves if they break. But when repairing engines, pistons with 1.3 liter engines were installed, as a rule, of suitable size, but without recesses. But in the early 80s the eighth generation was released. Newer, comparable to European counterparts. And most importantly, the cars have front-wheel drive, a motor with a belt drive to a timing mechanism. And this was the same engine that, with a lot of modifications, is installed on modern cars. On models 2109 and 2110, these power units were adapted for the first time to an injection system.

Which engine is better, 1.6 16- or 8-valve?

16 classes the engines were installed in a limited series at AvtoVAZ or at the SuperAvto subsidiary. They were also installed by tuning fans themselves.

In terms of manufacturability, they are superior to 8-cl. engines. Accordingly, if there is an option to take a 16-cl. motor, it would be nice to go with this option. But everything has its own nuances.

Advantages of 16-valve engines over 8-valve engines

- The best cylinder blowing is more power.

- More stable engine operation - less noise.

- Greater efficiency means lower fuel consumption.

However, 16th grade. the engine (1.6 l) from Priora (21126) bends the valves when the belt breaks. For some reason this scares many people. You just need to monitor the condition of the car, belts, rollers, pump, then everything will be fine! On all modern cars the valves bend.

Main engine components

No significant differences may be detected upon a cursory examination. Both carburetor and injection systems do not affect the basic design of the engine. But it's worth taking a closer look at the little things. For example, take a look at the VAZ-2110 injector thermostat (8 valves). What immediately catches your eye is that it can be taken apart! Exactly! Engineers in Europe sit and think about how to reduce the life of a car, while ours at the same time carry out real improvements that are for the benefit of the consumer. It is clear that it is not the housing that breaks in the thermostat, but the insides - the temperature-sensitive element or valve. Therefore, why produce millions of cases? It will be much more profitable to make one for the car, and if the thermostat breaks down, change only the insides.

But these are not all the advantages of domestic engines. Please note that in the USA and Europe all cars are the same, sometimes there is no point in repairing it, it’s easier to throw it away and buy a new one. The reason is partly in the engine. For example, AvtoVAZ is almost the only plant that continues to install internal combustion engine blocks made of cast iron on its products! In all developed countries, aluminum alloys have long been used for this purpose! The service life of the engines suffers, but most importantly, there is no way to repair it, since it cannot be bored or relined. And this is much cheaper than buying a new engine or car. Maybe a wealthy burgher can afford this, but in our country a car is still a luxury for many people.

Signs of a malfunctioning VAZ 2110 injector

Signs of a malfunction of the VAZ 2110 primarily manifest themselves in incorrect operation. But despite the fact that the LADA is a car. Unfortunately, there are problems that are quite difficult to determine without computer diagnostics. But we'll talk about this later. Below are examples of shortcomings in the operation of the car:

- check engine on the dashboard also came on

- The engine is not running stable;

- Power is noticeably reduced;

- Increased gasoline consumption;

- Difficult to launch or not possible at all.

Signs of a malfunction of the VAZ 2110 injector. The “check engine” indicator also lights up

The “ check engine ” indicator on the dashboard came on. The most common problem, but unfortunately it is not always associated with a breakdown. Because we must not forget that this is an AvtoVAZ and anything can be in it. Firstly, it may be a simple glitch in the program that does not affect operation. I have had moments when the indicator would light up and go out after a while. At first, I went to the service in a panic, but no errors were found. Because everything worked properly.

But if, in addition to the “ check engine ” indicator on the dashboard, you feel obvious deviations. You will have to do diagnostics to identify the cause of the breakdown, but even here there can be a catch. Since most experts do not recommend getting into the structure yourself, due to its complexity. But they cannot identify the problem themselves. For example, a situation where more than one service station could not find the cause. Referring to defective parts. Which I changed twice a day, buying a new one. And only one guy in the garages found a broken wiring. Which no one paid attention to.

What is an injector?

Now let’s see what the injector circuit looks like on a VAZ-2110 car, let’s look at the main components and operating principle. But first you need to answer the questions of what an injector is and what it is needed for. Everyone knows that until the end of the 90s carburetors were installed. In them, with the help of air flows, mixture formation took place, and then supply to the intake manifold of the fuel system. Moreover, such a cunning device can mix gasoline with air in an ideal proportion - 14 to 1. But there is a game of vacuum and atmospheric pressure.

Characteristics of the internal combustion engine VAZ 11183

| Characteristics of VAZ internal combustion engine | 11183 | 11183-50 |

| Serial production period, years | 2004-2017 | 2011-2017 |

| Type by cylinder arrangement | In-line (cylinders in 1st row) | |

| Cylinders | four | |

| Valves | eight | |

| Working volume, cm³ | 1596 | |

| Diam. cylinders, mm | 82 | |

| Piston stroke, mm | 75.6 | |

| Cylinder operating order | 1→3→4→2 | |

| Fuel supply | Injection, from four injectors in the intake manifold | |

| Intake manifold (receiver) | made of plastic, electronically controlled throttle body | |

| An exhaust manifold | together with the catalyst | |

| Max. power, hp | 80 | 82 |

| Max. torque, Nm | 120 | 132 |

| Compression ratio | 9.6 — 9.8 | 9.8 — 10 |

| Fuel type | AI 92-95 | |

| Amount of oil in the lubrication system, l | 3,5 | |

| Oil used in internal combustion engines | 5W-30, 5W-40 | |

| Gearbox oil filling volume, l | 3 | |

| Oil used in gearbox | 75W80, 75W90, 80W85, 80W90, 85W90 | |

| Environmental standards | EURO 2/3 | EURO 4 |

| Application on VAZ cars | Kalina, Granta, 21101, 21112, 21121, 2113, 2114, 2115. | |

| Resource, km | 150 000 | |

| Weight, kg | 112 | |

Injector features

But the VAZ-2110 engine (8 valves) injector is much simpler than the carburetor version. But this is from the point of view of an electrician. The fact is that the system consists of many electronic devices that are responsible for the operation of the entire engine. Instead of a carburetor, a ramp is installed on the intake manifold. Essentially, this is a piece of pipe that contains the air-fuel mixture. It is pumped from the tank using an electric pump under low pressure. By default, the ramp is completely sealed; it is separated from the intake manifold channels by electromagnetic valves - injectors. But here’s the peculiarity: a constant pressure is maintained in the ramp, which is regulated by a sensor, and the quality of the mixture and the amount of gasoline supplied depend directly on how open the throttle valve is.

Basic faults

The main malfunction characteristic of the VAZ 2110 is the appearance of the engine tripping effect. Malfunctions can occur for various reasons. Let's consider the factors that cause unstable engine operation, as well as methods of elimination.

Poor quality fuel

The first thing you need to check is how high-quality the fuel was poured into the vehicle. If the gasoline was of poor quality, then most likely one of the elements of the fuel system was forgotten. So, the motorist will have to find out what the fuel supply scheme is and find parts that could have failed.

So, the first element that comes under scrutiny is the spray nozzles. Malfunctions of the injectors can cause unstable operation of the engine, which will lead to tripping. A special stand is used to diagnose and clean the unit, but many motorists carry out the process themselves, using carburetor cleaning fluid.

Also, unstable engine operation may be caused by clogged fuel filters. One is located under the rear right wheel, and the second is in the fuel pump. There is a filter mesh on the fuel pump intake that needs to be replaced. The process is quite complicated, since you have to remove the rear seats and remove the fuel supply element. But the fuel filter under the wheel can be changed quickly and without any problems.

Ignition system

Damage to spark plugs or high-voltage wires can also cause tripping. So, it is necessary to check all the elements using a tester, as well as visually inspect them. If there is damage, it is recommended to replace the entire set.

Sensors and ECU

Another major reason for engine tripping is the failure of one of the engine sensors, as well as a malfunction in the electronic control unit. To carry out diagnostics you need to connect to the “brains”.

Next, based on the errors shown, find the faulty meter and replace it. If this does not help, and the error in the ECU remains, then it is recommended to reset, and in some cases, flash the control element.

Diagram of the injection system

So, now in more detail about the power supply systems of the VAZ-2110 injection engine. First on the list is the fuel pump. It is mounted directly in the tank, together with the filter, and the engine rotor is driven only when the ignition is turned on (provided that the pressure in the ramp is below the minimum level). Next, the fuel flows through the tubes into the ramp. This is where the mixture is formed. The air first passes through a filter for purification. The filter housing is connected to the throttle assembly by a flexible pipe.

VAZ 2111

| Name | Index |

| Volume | 1.5 liter (1499 cm3) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 77 hp |

| Fuel consumption | 8.2 l/100 km |

| Cylinder diameter | 82 mm |

Sensor system

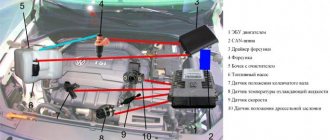

The VAZ-2110 engine (8 valves) is no less interesting. The injector, a control system device, to be more precise, includes many sensors. All control occurs using sensors. So, between the filter and the throttle there is a mass air flow sensor. A position sensor is mounted on the damper itself. In the ramp - pressure. In addition, between the second and third cylinders on the surface of the internal combustion engine block there is a knock sensor. And on the generator drive pulley - engine speed. The vehicle's speed is measured from the gearbox. All data that comes from reading devices is sent to the electronic control unit.

What cars was it used in?

The 2111 engine was installed on the following models of front-wheel drive VAZ cars:

- 2108 – three-door hatchback;

- 21083 – three-door hatchback;

- 2109 – five-door hatchback;

- 21093 – five-door hatchback;

- 21099 – sedan;

- 2113 – three-door hatchback;

- 2114 – five-door hatchback;

- 2115 – sedan;

- 2110 – sedan;

- 2111 – five-door station wagon;

- 2112 – five-door hatchback.

The engine was installed on the “eights” and “nines” after 1987, respectively.

And in conclusion, I would like to say about tuning the VAZ 2110 engine.

In the VAZ 2110, engine tuning is very easy to do. To do this, you only need a tool and a room. This process can be done not only in a specialized workshop, but also in your garage.

Tuning a VAZ 2110 engine requires only a set of tools and patience:

- The first step is to simply replace the camshaft with a better one. Due to this, power will increase and engine performance will improve.

- You can also install a new crankshaft to increase the volume of the unit. If this is not done, then further tuning of the VAZ 2110 engine will be in vain.

- The installation of a compressor is quite simple. This unit allows you to increase power and get good torque.

- It is worth noting that tuning the VAZ 2110 engine can be done by anyone. This does not require special experience or skills. It is enough to know the structure of the car and have locksmith skills. Experts recommend installing a high-quality stock piston so that it can withstand about 0.5 bar.

Electronic control unit

This is, so to speak, the very heart of the system. On the VAZ-2110, the injector circuit comes down to precisely this device. A small case with many pins, and inside is the most interesting thing - a microcontroller. It is he who regulates the entire operation of the engine. The internal memory contains a so-called fuel map. Using it, the controller determines how much air and gasoline must be supplied to the ramp so that the engine operates in normal mode and detonation does not occur. But the most important thing is how long it is necessary to apply an impulse to the fuel injectors so that they open and inject the mixture into the combustion chamber.

Maintenance

Engine maintenance is carried out every 10-12 thousand kilometers. The schematic map is available from official representatives of the manufacturer. But, as practice shows, it all comes down to changing the oil and oil filter.

Many car enthusiasts ask the question - what is the best engine oil to pour into the VAZ 2110 8-valve power unit? The best option remains semi-synthetic motor oil of domestic or foreign production labeled 10W-30 or 10W-40.

Which is better: carburetor or injector?

And now a little about which VAZ-2110 engine will be more reliable: an injector or a carburetor? But you need to look at this issue from different angles. For example, beginners will like the injector. Constant speed, there is no need to shut off the air supply in cold weather, and starting off is much easier. But there is another advantage - the car is more responsive at high speeds. Even at a speed of 120 km/h, when you press the gas pedal, the car quickly picks up speed. With carburetor engines this happens much more slowly. Therefore, overtaking in a car with an injector is safer. But when starting from a traffic light, the carburetor will easily “break” the injector. And the reason is higher torque at the bottom. And the cost of maintenance, of course, is higher for injection “tens”, since sometimes it is not easy to make an accurate diagnosis in the event of a breakdown.

VAZ engine 16 valves or 8, what are the differences?

What's the difference between 8 and 16 valve engines? When there are 4 valves per cylinder instead of 2, then it is possible to more effectively use a larger area of the combustion chamber for gas exchange and make the 2112 engine “breathe” more intensely - especially at high speeds, when very little time is allocated for the processes of admitting a charge of fresh mixture and cleaning the cylinders from exhaust gases .

As a result, the 16-valve engine has become more powerful and makes the 10 a faster car. But the torque of the 2112 16-valve engine at low speeds will be acceptable only for calm drivers who prefer economical, leisurely movement without intense acceleration.

VAZ 2110 injector engine, diagram and principles of operation of the “tens” injection engine

The VAZ 2110 is an injector engine that is distinguished by its efficiency, increased power and stability of operation when compared with the VAZ 2110 carburetor engines. The widespread use of injection engines at AvtoVAZ began in the 2000s. Today we will tell you in detail how the “ten” injection engine works. It is worth recalling that the “ten” injection engines were installed with different volumes and number of valves. Today on the secondary market you can find injection VAZ 2110 with 8 and 16-valve power units with a displacement of both 1.5 and 1.6 liters.

VAZ 2110 engine injector, operation diagram

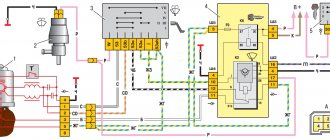

Power units with an injector differ from carburetor versions in the principle of supplying fuel to the combustion chamber of a gasoline engine. If a carburetor engine needs to “suck” fuel from the carburetor chambers, then in the injection version fuel is injected under pressure through nozzles. This is much more economical, since the solenoid valves of the injectors allow only the required amount of fuel to pass through and not a drop more. This is closely monitored by electronics, which gives commands using information from various sensors; after analyzing all the data, the necessary impulse is sent to the injector and it supplies fuel to the engine. Moreover, the entire process occurs almost instantly. Below is a detailed diagram of the operation of the VAZ 2110 engine injector.

- 1 – ignition relay

- 2 – battery

- 3 – ignition switch

- 4 – neutralizer

- 5 – oxygen concentration sensor

- 6 – nozzle

- 7 – fuel rail

- 8 – fuel pressure regulator

- 9 – idle speed regulator

- 10 – air filter

- 11 – diagnostic block

- 12 – mass air flow sensor

- 13 – tachometer

- 14 – throttle position sensor

- 15 – indicator lamp “CHECK ENGINE”

- 16 – throttle assembly

- 17 – immobilizer control unit

- 18 – ignition module

- 19 – coolant temperature sensor

- 20 – controller

- 21 – spark plug

- 22 – knock sensor

- 23 – fuel filter

- 24 – fan switch relay

- 25 – electric fan of the cooling system

- 26 – relay for turning on the electric fuel pump

- 27 – fuel tank

- 28 – electric fuel pump with fuel level indicator sensor

- 29 – gasoline vapor separator

- 30 – gravity valve

- 31 – safety valve

- 32 – speed sensor

- 33 – crankshaft position sensor

- 34 – two-way valve

The most important element of the power system of the “ten” injection engine is the electric fuel pump, which is located in the tank; it is this that constantly provides the necessary pressure in the ramp with injectors through which fuel is supplied to the intake manifolds. The fuel pump in the VAZ 2110 injector is quite noisy. It is enough to insert the ignition key and turn it, and you will hear the characteristic “buzzing” of the electric fuel pump inside the car. If you do not hear a buzzing sound before starting the engine, but the engine still does not start, then the fuel pump is faulty. And therefore, it will not be possible to start an injection engine from the “pusher”, because there is still no pressure in the ramp and injectors, which means that fuel will not be supplied.

Repair and maintenance of injection engines requires special diagnostic equipment. The VAZ 2110 was equipped mainly with injection engines with a displacement of 1.5 and 1.6 liters, both 8 and 16 valve versions. Below are brief characteristics of these motors in the table below.

Engine model

| Working volume | Number of valves | Power hp(kW) | Torque Nm | |

| VAZ 2111 | 1499 cm3 | 8 | 76 (56) | 115.7 |

| VAZ 2112 | 1499 cm3 | 16 | 93.5 (69) | 128 |

| VAZ 21114 | 1596 cm3 | 8 | 82 (60) | 125 |

| VAZ 21124 | 1596 cm3 | 16 | 89 (65.5) | 131 |

The most powerful engine of all that was installed on the “ten” is the injection 16-valve VAZ-2112 with a volume of 1.5 liters. However, this power unit has one drawback: if the timing belt breaks, the pistons meet the valves, which leads to serious and expensive repairs of the power unit. And high-quality repair and maintenance of VAZ-2110 injection engines requires special diagnostic equipment. Often, a malfunction of just one sensor leads to unstable operation of the entire engine.

Thanks to Revenge for this valuable message from:

F9 - 20A - Recirculation valve. Diaphragm regulator.

It promotes the formation of a spark, which ensures the combustion of combustible masses. The car may jerk while driving.

A similar drive with 8 valves is simpler than a VAZ carburetor. This modification has been produced since the year, equipped with an 8-valve gasoline injection engine with a displacement of 1.6 liters.

Without them, it is difficult to identify problems that such an engine may suffer from. This system is required to create a high-quality spark, which is simply necessary to ensure combustion of the air-fuel mixture.

A modification with a body lengthened by millimeters in the rear door area, which provided more comfortable entry and exit for passengers. Full inspection of the integrity of connections and their reliability. Fuel consumption in the urban cycle is 9.5 liters per kilometer.

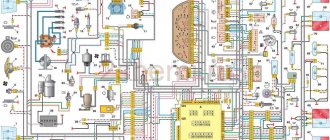

All equipment and devices powered by electricity in a VAZ car are based on a single-wire connection. With their help, you can get rid of switching with a high current button. Installation of Priora dashboard on ten 2110, 2112 Priorovedenie

principle of operation, device, how it differs from a carburetor

Every car enthusiast knows that a car can have either an injection engine or a carburetor. But not everyone knows what each of them is. Therefore, you should understand this issue as best as possible. First, let's note that the function is the same. A combustible mixture is formed and supplied to the engine. There is only a big difference between their work. Let's consider which one.

The principle of operation of an injection type engine

To be specific, a carburetor is a device that creates a mixture of air and fuel, and it is also able to regulate the flow of the resulting mixture. The principle of operation is to suck it into the motor. This is possible due to the fact that the intake manifold and the atmosphere have different pressures.

An injection engine involves the operation of electronics. In this system, the quality of the mixture is controlled without human intervention. It is injected in doses using nozzles. After injection, the mixture is sent to the engine for combustion. Currently, cars are equipped with an electronic rather than a mechanical system. Next, let's look at how one differs from the other.

Comparison of injector and carburetor

Let's look at the principle of operation of a carburetor. This device is capable of forming a mixture that consists of air and fuel. The mixture is rich in flammable and flammable substances. It is needed so that the motor can carry out the required work. No matter how many revolutions the propulsion system makes, it absorbs the same amount of mixture by volume.

In terms of costs, the carburetor consumes a lot of fuel. At the same time, the air becomes heavily polluted.

Now let's look at the operating principle of the injector system. The whole device works in such a way that a lean mixture of air and fuel is sent to the engine, which must be accurately dosed. In modern cars this occurs under the influence of the control unit. Since fuel is dosed in grams (portions), its consumption is significantly low. In addition, the toxicity of exhaust gases is practically zero when leaving the exhaust pipe. It turns out that the internal combustion engine practically does not pollute the air.

The injector can increase engine power by up to ten percent, and the valve block is designed in such a way that engine performance improves. The principle of operation that allows the internal combustion device is that the injector forms a mixture of air and fuel, and what is important for it is fuel that is of different quality, otherwise it is impossible to drive the car.

Also, I would also like to note that, unlike a carburetor, which freezes in winter and overheats in summer, the injector is not affected by the temperature of the external environment.

If we talk about how reliable a carburetor is, its operating principle is very simple. The device is made in such a way that after fuel combustion, heavily polluted air comes out through the exhaust pipe. But it does not require regular maintenance and repair work during operation. It is only important, in order not to damage the device, to use a fuel filter and only a high-quality brand.

Diagnostics of the VAZ 2110 injector

In this section I will tell you several diagnostic methods. Since there are cases when the “ check engine ” indicator on the dashboard does not light up. And there are no significant deviations in the car. But diagnostics can reveal the problem. So, let's begin.

Computer diagnostics

Computer diagnostics are carried out in two ways. First, contact a service station. Where specialists see the full characteristics and errors through a computer. They will point out the problematic part and usually send you to change it. But as I said earlier , this does not always help. Since the specialist sees only the electrical sensor from which there is no signal. But the problem may also be in the wiring, and you go to auto parts and spend money.

Secondly, using the phone. To do this, you need to purchase a wireless adapter for diagnostics and install applications on your phone. Then connect the adapter to the diagnostic connector. The one that is located in the cabin, near the driver’s feet. Next, turn on Bluetooth on the phone and connect to the device. Let's start scanning for errors. If there are problems in the brain, a code will be displayed on the phone. You can decipher it on kodobd.ru

Also, using the adapter , you can view measurements in real time. That is, revolutions, consumption and data from electrical sensors. In general, a very useful thing, you only pay for services once. When you purchase an adapter.

Self-diagnosis

Self-diagnosis is carried out using the on-board computer. One way is if there is a side panel on the center console, then you are very lucky. I had one of these on one of my cars. In general, there are no problems, it is very easy to check errors at any time. We go to the menu and use the “left” or “right” buttons to find the “diagnostics” section. Then use the “down” button to go in and look for “errors” in the same way. We are shown errors in the form of code . By holding down the down button, the error code will be cleared.

The second method of self-diagnosis, unlike the first, can be performed on every ten. This is done using a device. You do not need any special equipment to perform the procedure. Just with the ignition off, press and hold the “reset daily mileage” button on the dashboard. And at the same time turn the key to the first position, turning on the ignition. As a result, all the lights will light up. And also all the arrows will begin to move, from start to finish and back. Then we press the “reset daily mileage” button again, the brain firmware version appears on the display. Then press one more time and we see the error code . But in this case, the code will not be the usual “P0135”, but one or two digits.

Diagnostics of injection engines - how to come to the aid of your car?

Primary diagnostics of injection engines consists of monitoring the condition of all control sensors of the unit. To do this, a thorough inspection is carried out, during which it is necessary to ensure the integrity of the insulation and the reliability of the connection of the plug connectors.

Diagnostics and repair of injection engines - briefly about the device itself

But first, let's look at what an injection engine is. How is it different from a carburetor? The main difference is the air-fuel mixture supply system. In previous engines, the fuel mixture was sucked directly through the carburetor, where the components were dosed, and then the gasoline was mixed with air. At the same time, due to imperfect design, the engine lost up to 10% of power.

In a fuel injection (or injection) engine, fuel enters the combustion chamber by forced injection at high pressure through injectors. Dosing and control of the amount of incoming fuel is carried out by electronics. As a result, the level of harmful emissions into the environment is reduced, and engine power is significantly increased, its performance characteristics are improved, and fuel consumption is reduced.

Advantages of injection systems:

- precise dosage of fuel supply;

- by optimizing the composition of the air-fuel mixture, the level of toxicity of exhaust gases becomes significantly lower;

- the dynamic characteristics of the car are improved, the injection system adjusts the fuel supply depending on the load;

- the use of an injection system leads to an increase in engine power by more than 7%.

Disadvantages include expensive repairs to the injection engine power supply system, fairly high requirements for fuel quality, and the availability of special equipment for repairs and diagnostics.

Diagnostics of injection engines - how to detect a breakdown yourself?

What malfunctions most often plague injection systems? The most significant malfunction can be considered a breakdown of the sensor that controls the position of the crankshaft. In this case, engine repair is most often required, since the alarm failure is caused by serious problems with the power unit.

Preliminary diagnostics of an injection engine with your own hands is quite possible, but to accurately determine the cause of the malfunction you will need special equipment, which is only available at service stations. If the fuel pump fails along the way, the only thing that can be done is to replace the faulty unit. If it is not in stock, then you will have to rely only on a tow truck.

The simplest failure is considered to be the failure of the phase sensor. The injection system is designed in such a way that in the event of such a malfunction, it begins to supply twice as much fuel. It is unlikely that you will be able to determine the cause of excessive fuel consumption on your own; this will require special instruments for diagnosing injection engines.

Do-it-yourself injection engine diagnostics - a few more observations

What else can lead to a sudden increase in engine power consumption? Experts recommend paying attention to the mass air flow sensor. This malfunction can be identified by dark exhaust, decreased throttle response, the appearance of unpleasant jerks and unstable engine operation in idle mode. Naturally, you can drive such a car, but only to the nearest service station, where injection engines are diagnosed and repaired.

It happens that the engine starts to stall. Experienced drivers know that the reason may not only be a malfunction in the fuel supply, but most often this occurs due to breakdowns of electrical equipment (faulty ignition coil, spark plugs, etc.). Even a novice car enthusiast can determine this. But if you need to repair injection engines, the malfunctions of which have already been described in this article, then it is best to contact professional service centers.

An injection engine is a rather complex mechanism, the operation of which must be well tuned in order to get maximum performance from it. The article discusses in detail the operating principle of an injection engine.

Before we start talking about this miracle of technology, let's dispel some myths. An injection engine works on the same principle as a diesel engine, with the exception of the ignition system, however, this does not give it much more power than a carburetor engine. The increase will be a maximum of 10%.

The center of the entire system is the ECU (electronic control unit). It goes by many names, "brains", "computer" and so on. Essentially, yes, it’s a computer that contains a huge number of tables on mixture composition, fuel injection time, and so on. For example, if the engine speed is 1500, the throttle is open 10 degrees, and the air flow is 23 kg, then one amount of fuel will enter the cylinder. If the input parameters change, then the result will be different. If any problems arise with the control unit, for example, the firmware crashes, then everything goes to waste, the engine either starts to work haphazardly or stops altogether.

Testing for spark

If there is an ignition coil on each of the engine cylinders, then testing for the presence of a spark occurs somewhat differently. In this case you will also need a Hall Sensor. If there is no spark on only one coil, then it should be replaced. But if it doesn't appear at all, then the problem is much more complicated. In this case, the problem may be due to a faulty controller or broken wiring.

To more easily test the presence of a spark discharge, it is advisable to use a Hall Sensor.

It must be brought to the faulty coil and turned on. If the arrow starts to rise, it means there is current in the wires.

Injection engine sensors

All elements can be divided into actuators and sensors. First, we'll look at sensors.

Mass air flow sensor (MAF)

This element is installed in front of the air filter, right at the inlet. Its operation is based on the principle of difference in readings. So, electricity passes through two platinum filaments. Their resistance changes depending on the temperature. One of the threads is reliably hidden from the air flow, which makes its resistance unchanged. The second one is cooled by the flow, and based on the difference in values, according to the same tables mentioned above, the ECU calculates the amount of air.

Engine absolute pressure and temperature sensor (DBP)

It is used either as an alternative or in conjunction with the above for higher reading accuracy. In short, it has two chambers, one of which is sealed and has an absolute vacuum inside. The second chamber is connected to the intake manifold, where a vacuum is created during the intake stroke. Between these cameras there is a diaphragm, as well as piezoelectric elements. They generate tension when the diaphragm moves. The signal then goes to the ECU.

VAZ 2110 engine design and operating features

Engine VAZ 2110 16-valve

Today, every motorist knows that the internal combustion engine is the heart of every car. Knowing the structure of the VAZ 2110 engine is not a whim for the owner of the corresponding car, but a practical necessity. The life of an engine is partly determined by its quality, and partly depends on the intensity of daily use of the car. Of course, the higher the mileage, the higher the likelihood that the engine will fail. The design of the VAZ 2110 16 valve engine is given in detail in the article below.

Actuators

The actuators got their name because they make adjustments to the operation of the engine. That is, the control unit receives a signal from the sensor, analyzes it, and then sends the signal to the actuator.

Fuel pump

Let's start with the power system. It is installed in the tank and supplies fuel to the fuel rail at a pressure of 3.2 - 3.5 MPa. This ensures high-quality fuel spray into the cylinders. As soon as the engine speed increases, the appetite also increases, which means more fuel must be supplied to the ramp to maintain pressure. The pump begins to rotate faster at the command of the control unit. Most modern cars, starting around 2013, are equipped with a fuel module, which includes a pump and a built-in filter. This significantly affects the cost of filter replacement, because the entire module must be replaced. Some manufacturers write in the instructions that the module is installed for the entire service life of the car, but you should not believe that any filter can last more than 2 seasons.

Nozzle

After the fuel has passed the entire circuit of the wire, it enters the nozzle, which meters its supply into the cylinder. The injector is a very small diameter solenoid valve that sprays gasoline into the combustion chamber. The ECU modifies the amount of fuel supplied by time intervals while the injector is open. As a rule, this is tenths of a second.

Throttle valve

We have all once seen a carburetor and looked into it from above. So it had dampers that blocked the air. The principle is the same here. Perhaps there is nothing more to tell.

Idle air control (IAC)

This is also an electromagnetic valve, the rod of which closes the air duct that bypasses the throttle valve. Depending on the voltage that the control unit supplies to it, it opens this very channel.

Ignition module

Transmission and suspension VAZ 2110 8 valves injector

Lada 21102 has a built-in five-speed manual transmission (MT). This box is used on all versions of the 2110 line. It has good noise insulation, the lever stroke is comfortable, and the smoothness of switching is much better than that of Zhiguli and Samara.

The body (casing) of the box is made of aluminum alloy. Inside the casing there is a primary (drive) and secondary (driven) shaft. The shafts are combined with the differential and final drive. The five forward gears are equipped with synchronizers, which improve smooth shifting.

Gear ratios: 1st gear - 3.636, 2nd - 1.95, 3rd - 1.357, 4th - 0.941, 5th - 0.784. For reverse gear - 3.5. The final drive ratio is 3.7. The operating instructions state that you need to change the transmission oil every 75 thousand km.

Mitigating the impact of the chassis on the body, as well as ensuring stability and smoothness, is carried out by the front and rear suspension of the Lada 2110. An independent design is used on the front axle. Each wheel has an independent coil spring, inside of which a MacPherson strut is placed. Each strut has its own hydraulic shock absorber. The lower control arms are attached directly to the steering knuckles, and the anti-roll bar is attached to them.

Levers help reduce wheel roll (rotate it around the longitudinal axis). When the car makes a turn, the wheel, which is turned “inside the body,” can move away from the axis of rotation. The stabilizer prevents this from happening by twisting. Thus, the front suspension of the Lada 2110 allows you to maintain the stability of the car when cornering.

The rear suspension is a rigid structure, the main element of which is the transverse beam. Since the rear wheels do not rotate, there is no need to provide maneuverability, but rear stability must be at a high level. Therefore, this design was used. The beam consists of trailing arms attached to each wheel and a connector that welds the arms together. The wheels on the rear axle are also equipped with hydraulic shock absorbers to soften impacts.

The Lada 2110 is equipped with 175/70 radial tires. Ventilated disc brakes are used on the front wheels, and drum brakes on the rear wheels.

The principle of operation of an injection engine

So, after we have figured out the main components of an injection engine, let's see how it works. After the starter cranks the crankshaft, the DPKV tells the control unit which cylinder is in which position. In turn, the phase sensor reported the clock cycles. The control unit took this information into account and opened the injector in the cylinder in which the intake stroke begins. But he opened it for a reason, but for a strictly defined period of time, which, according to the tables, corresponds to the readings of the mass air flow sensor or DBP. This is how the working mixture was formed.

Video: how a gasoline injection internal combustion engine works

After the intake stroke has ended here, compression begins, at which time intake occurs in the other cylinder. Here the piston reaches top dead center, as indicated by the DPKV and DF, respectively, it is time to apply voltage to the ignition module, to the desired cylinder. To do this, the control unit contains two transistors, which take over two cylinders each.

Then, when the explosion occurs, the ECU looks at the readings of the knock sensor and adjusts the ignition timing for the next cylinder along the stroke. But that is not all. After this, when the gases reach the oxygen sensor, the control unit adjusts the composition of the mixture, namely, the opening time of the injector, which allows for the most efficient use of fuel and its combustion. If the ECU detects a lack of oxygen, but the throttle valve remains open, the idle air control valve opens slightly.

Engine warm-up and engine temperature sensor

This point is worth considering separately; let’s just say this is a small clarification. So, the engine warm-up mode is in no way connected with the readings of some sensors, that is, nothing depends on them. In particular, these are mass air flow sensor and air pressure sensor, as well as a knock sensor. The block, as already mentioned, contains certain tables, there are a lot of them, millions. So, during the warm-up mode, the ECU works strictly according to these tables and nothing else. This means that if the air to fuel ratio is written into it as 14.1:1, then it will be so. This figure is the generally accepted standard for operating temperature. So, until the engine temperature reaches the one specified in the firmware of the control unit, the warm-up mode will not turn off. Afterwards the ECU starts working based on the sensors.

Engine chip tuning circuit

Not many car enthusiasts can boast of a powerful 2110 engine. Thus, to improve the power characteristics of the engine, it is necessary to carry out chip tuning of the VAZ 2110. To do this, they usually turn to specialists, but more and more vehicle owners are doing the process themselves.

The chip tuning scheme is quite simple. To perform the operation yourself, you will need an OBD II cable (USB-Auto), a laptop computer and software. It is worth remembering that there are three options for modifying the power unit: for power (but this will increase consumption), for reducing consumption (leading to a loss of power) and balanced (balance between the optimal indicators of consumption and power).

Typically, chip tuning of a VAZ 2110 is done with the aim of reducing fuel consumption, therefore, if the owner of the car decides to do it himself, then it is necessary to select the appropriate software. But, it is recommended not to take risks and turn to professionals for help.

Which is better, an injection or carburetor engine?

This issue is quite controversial; each point of view has many opponents and supporters, both among ordinary drivers and among specialists who fully understand the principle of operation of an injection engine. So, the carburetor engine is distinguished by simplicity and transparency of operation. That is, if the mechanic adjusted the idle speed, then it remained that way.

As for the injection engine, it all comes down to timely maintenance, as well as the quality of the parts used.

>

A practical look at the structure and functioning of the VAZ 2110 engine

Note. Today, the majority of “ten” car owners have an eight-valve injection engine under the hood, so considering this model is the most popular option of all those currently existing.

Engine design VAZ 2110 8 valve

Today, most “ten” are equipped with a 1.5 liter injection engine. The main features of the injection engine for the VAZ 2110 are:

- four cylinders with the same number of strokes;

- operating exclusively on gasoline;

- the distribution shaft is located at the top;

- the engine itself is naturally aspirated and has eight valves;

- has a transverse arrangement;

- The engine is equipped with some electronic control systems such as: Bosch and January.

The structure and principle of operation of the crank mechanism

VAZ 2110 16 valve engine device

The cylinder block is made of strong and reliable metal - cast iron. The total diameter of all cylinders will be approximately 82 mm, which in turn allows you to directly increase its diameter if there is a need to replace the piston group. In particular:

- the first repair increases the base diameter by 0.4 mm;

- the second repair allows for another additional increase by a similar amount.

Functions and structure of the crankshaft

The crankshaft is located at the bottom of the block, while simultaneously rotating on five main bearings, which in turn have removable roofs. The roofs themselves are attached to the block using special fastening bolts.

Note. Axial displacement of the crankshaft is impossible, since the central (middle) support of the main bearing is equipped with a special socket that contains half rings. It is these half rings that prevent axial displacement of the crankshaft.

Aluminum and steel are the base material for the manufacture of the front half-rings, while cermet is the base material for the manufacture of the rear half-rings:

Note. If play appears on the crankshaft, it must be replaced immediately. Structure of bearing shells

- In total, there are exactly two types of bearings: connecting rod and support, and both of these types are thin-walled;

- The bearing shell is made from a specialized alloy of steel and aluminum;

- The groove is contained on almost all bearing shells, with the exception of the third main bearing.

The crankshaft itself has the following structure:

- the crankshaft is made of extremely strong metal - cast iron;

- the crankshaft contains 5 main journals and 4 corresponding connecting rods;

- 8 specially cast counterweights are also included in the crankshaft.

There are drilled channels on the inner surface of the shaft, which, in turn, are covered with plugs. These channels simultaneously perform two functions:

- the oil supply to the main journals is supplied from the connecting rod journals, thanks to the existence of these channels;

- At the same time, the channels act as a filter, purifying the oil from all possible mechanical impurities that the main oil filter could not retain.

Note. You should always remember that during operation the channels become clogged and require immediate cleaning, which must be carried out during major engine overhauls and during removal and replacement of the crankshaft. You should also always remember that after cleaning, the old plug must be replaced. Structure of the function of the front part of the crankshaft

- The alternator pulley is attached to the camshaft pulley, which is held by the front of the crankshaft;

- the generator drive pulley acts as a damping device;

- between the inner and outer parts of the pulley there is an elastic device, thanks to which the generator drive pulley acts as a damping device;

- the rear end of the pulley is attached to the cast iron flywheel using six specialized bolts;

- The cast iron flywheel contains a special gear-shaped crown, which is needed to activate the engine using a starter

Ignition system sensors and marks

For the ignition system to operate correctly, the computer needs to read the correct information from the sensors. Subsequently, this information will be processed in accordance with the fuel maps hardwired into the injector.

The main signal comes from the crankshaft sensor. This sensor shows what position the crankshaft is in at a given time and, based on it, calculates at what moment it is necessary to inject fuel, and at what moment this same fuel should be ignited, depending on the engine speed, which is also determined by this sensor.

1 – crankshaft drive disc; 2 – crankshaft position sensor; 3 – angle of rotation of the crankshaft; 4 – output signal of the crankshaft position sensor

And this is what a typical signal received by a computer from the crankshaft sensor looks like. Pay attention to 270° - this is like the zero point, showing the computer that the engine has completed a revolution and a new cycle begins. This is achieved due to the absence of a tooth on the crankshaft drive sprocket.

Injector types

The injector controls fuel injection and can also control the ignition. On all new injection machines, the ignition is set by a computer and regulated by filling in different firmware. But this was not always the case, and on older cars, the same Japanese from the 90s, the computer regulates only fuel injection, and the ignition timing is set using a distributor and is set in the same way as on old Lada models, and depending on the speed The ignition timing is adjusted using a more complex vacuum system than on carburetor Zhigulis. Sometimes, one tube breaks, and during operating mode the traction may disappear; you will have to look for and correct this defect.

Setting the ignition timing

Required only for carburetor models. For the work you will need one tool - a strobe light. It is sold in almost any auto store and has a reasonable price. It is also advisable to have a wrench so that you can unscrew the nut that secures the distributor.

When the ignition timing is correctly set, mark 1 on the flywheel should be between the middle division (notch) 2 and the previous division 3 of the scale. Otherwise, adjust the ignition timing.

To adjust the ignition timing on a VAZ 2110 you need to:

- Carry out work at idle speed. The crankshaft should rotate at a speed of up to 820 - 900 rpm. The hose coming from the carburetor and connecting to the vacuum corrector must be disconnected.

- Take a strobe, connect the leads to the battery terminals “-” and “+”. The tip of the high-voltage wire must be removed from the socket and the wire coming from the strobe must be inserted.

- Remove the rubber plug from the slot in the crankcase and point the strobe light into the vacant space. After this you need to start the car. During its operation, you need to monitor the mark on the flywheel. As soon as the engine starts, the strobe light will start working. It will blink to indicate the mark. The flashing will be fast and the mark will remain stationary. However, if you move the distributor, the mark will also move.

- To move the mark and the distributor, you need to loosen the upper nut securing the distributor, as well as the 2 lower ones. After this, the distributor can be turned slightly. At this moment, the mark on the strobe light will also move.

To understand the ignition adjustment process in more detail and clearly, it is recommended to watch the corresponding videos. To resolve the issue of how to set the ignition on a VAZ 2110 injector 8, you can additionally consult with experienced car owners.

Source