The VAZ 21214 engine was developed by VAZ for off-road vehicles of its own production, Niva. The design of the internal combustion engine is developed on the basis of the 21213 engine using parts and assembly units included in the 2112 specification. In modifications, individual components are taken from the 2123 engine. The internal combustion engine differs from the 21213 in the presence of: an injector (assembled); catalyst; hydraulic compensators for timing valves; power steering; engine assembly units modified for injector. The series was launched in 1994, later including modifications, and was used in the assembly of the VAZ Niva (2121, 21213, 21214, 2131) and Nadezhda 2120 SUVs.

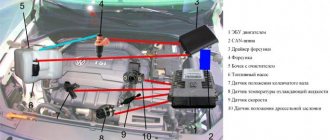

Initially, the unmodified engine model had centralized fuel injection from one injector (in the intake manifold) into 4 cylinders. The first modification of the 21214-10 engine received distributed injection from four individual injectors (1 per cylinder), with a Bosch MP7.0 controller and compliance with Euro 2. With the transition to Euro 3 and the installation of hydraulic compensators in the valve mechanism, it entailed further refinement of the internal combustion engine. Using certain innovations, the following subsequent modifications of the engine were produced.

Characteristics of motor 21214

It is believed that the basis of the ICE 21214 was the previous version 21213. In fact, ¾ of the parts in the engine

- the engine layout has changed - an injector instead of a carburetor;

- additional attachments appeared - DPKV, DXX sensor, Bosch MP 7.0 controller;

- crankshaft with a long crank radius of 40 mm, not used in previous AvtoVAZ engines;

- Cylinder head with holes for phase sensor and receiver studs, hydraulic supports for valve levers instead of adjusting bolts.

Hydraulic supports

Since the base model bends the valve, the 21214 engine did not escape this fate, so the manual includes not only a description of the engines, but also maintenance regulations in order to ensure at least the minimum declared service life of 80,000 km, which was promised by the manufacturer’s representatives.

Cylinder head 21214

The design of the power drive 21214 provides it with the following technical characteristics:

| Manufacturer | AvtoVAZ |

| Engine brand | 21214 |

| Years of production | 1994 – … |

| Volume | 1690 cm3 (1.7 l) |

| Power | 59.5 kW (81 hp) |

| Torque moment | 127.5 Nm (at 4000 rpm) |

| Weight | 122 kg |

| Compression ratio | 9,3 |

| Nutrition | injector |

| Motor type | in-line |

| Injection | distributed electronically controlled |

| Ignition | modular |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 2 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin |

| An exhaust manifold | cast iron or welded steel |

| Camshaft | original cam profile |

| Cylinder block material | cast iron |

| Cylinder diameter | 82 mm |

| Pistons | from 21213 |

| Crankshaft | from 21213 |

| Piston stroke | 80 mm |

| Fuel | AI-92 |

| Environmental standards | Euro-2/3 |

| Fuel consumption | highway – 8.3 l/100 km combined cycle 10.5 l/100 km city – 11.5 l/100 km |

| Oil consumption | maximum 0.7 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 5W40, 10W40, 15W40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Rosneft, Mannol, Mobil |

| Oil for 21214 according to composition | synthetics, semi-synthetics, mineral |

| Engine oil volume | 3.75 l |

| Operating temperature | 95° |

| ICE resource | declared 80,000 km actual 160,000 km |

| Adjustment of valves | hydraulic compensators |

| Cooling system | forced, antifreeze |

| Coolant volume | 7.8 l |

| water pump | with plastic impeller |

| Candles for 21214 | BCPR6ES from NGK or domestic AU17DVRM |

| Spark plug gap | 1.1 mm |

| Timing drive | single row chain |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | with check valve |

| Flywheel | from 21213 with clutch bore diameter 200 mm or 215 mm |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | manufacturer Goetze, light inlets, dark exhausts |

| Compression | from 12 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 800 – 850 min-1 |

| Tightening force of threaded connections | spark plug – 31 – 39 Nm flywheel – 62 – 87 Nm clutch bolt – 19 – 30 Nm bearing cap – 68 – 84 Nm (main) and 43 – 53 (rod) cylinder head – three stages 20 Nm, 69 – 85 Nm + 90° + 90° |

With the advent of hydraulic thermal valve lash compensators, it is recommended to use exclusively high-quality engine oil.

Cylinder block

The block is cast from high-strength cast iron. Cylinder numbering is carried out on the installation side of the crankshaft pulley. Each cylinder, based on the results of measuring its diameter, is assigned a size class.

| Parameter | Meaning |

| Material | ductile iron |

| Cylinder diameter, mm | 82 |

| Intercylinder distance (distance between the axes of adjacent cylinders of the block), mm | 95 |

| Block height (distance between the upper plane of the block and the axis of the crankshaft), mm | 214,58 |

| Diameter of boring of crankshaft supports (for main bearings), mm | 54,52 |

| Weight, kg | 40,000 |

The geometric parameters of the VAZ-21214 cylinder block coincide with the VAZ-21213 block. On the front engine cover there is now space for installing a crankshaft position sensor. Five classes are defined based on the deviation of the cylinder diameter. The size of each class differs from the previous one by 0.01mm. Classes are designated by letters (A, B, C, D). The cylinder block is marked on the bottom surface of the block.

Design Features

Initially, the 21214 engine was developed for distributed injection, that is, for an injector. It was planned to ensure an environmentally friendly standard, which was carried out successfully - during the finalization process, the internal combustion engines had Euro-2 - Euro-4, and for the export versions of Niva and Nadezhda, even Euro-5.

The main feature of 21214 was the factory boost:

- injector instead of carburetor;

- modified cylinder head (hydraulic pushers);

Hydraulic support ramp (bottom)

In turn, this required improvement of other designs:

- the volume of engine oil has increased, the pump sprocket now has 30 teeth to increase its performance;

- the double-row chain is replaced by a roller-type single-row modification to drive attachments and the timing camshaft;

- The camshaft cams have changed shape.

Design 21214

Upgraded chain tension system:

- the spring creates pre-tension when the engine is off;

- After starting, pressure is created in the system, the tension is regulated by hydraulics.

Hydromechanical chain tensioner

The manufacturer has provided additional do-it-yourself tuning due to the +50 hp potential built into the design. With. Overhauling the simplest internal combustion engine design does not cause any problems, including in a garage on your own.

Bosch 0280158110 injectors were first installed on the fuel rail, then yellow Siemens VAZ 20734. The ignition has a modular design with Bosch MP 7.9.7 and January 7.2 controllers. Pair-parallel injection provides Euro-2, phased injection – Euro-3.

Advantages and disadvantages

The specified engine characteristics and its design have disadvantages:

- high noise during operation;

- very low service life;

- significant vibrations on the machine body;

- overheating of the engine in the urban cycle;

- high engine oil consumption.

As a result, frequent major repairs and an increased operating budget. The main advantages were:

- automatic chain tensioner;

- valve lifters;

All the problems of the classic series remain, however, with timely maintenance, the engine does not cause any special problems for the owner.

Piston

The VAZ-21214 engine uses VAZ-21213 pistons of the original design; there are oval dimples on the bottom to reduce the compression ratio.

| Parameter | Meaning |

| Diameter, mm | 82 |

| Compression height, mm | 37,9 |

| Volume of internal recess, ss | 12 |

| Weight, g | 347 |

The hole for the piston pin is offset by 1.2 mm from the piston axis. The outer diameter of the piston pin is 21213–22 mm. Pin 21213 with a length of 67 mm has a mass of 103 g.

Characteristics of the VAZ engine

Main engine elements

VAZ engines.

Select VAZ engine model

What cars was it used in?

Motor 21214 was used to equip several cars manufactured by AvtoVAZ:

- Lada Niva 4x4 (VAZ-21214) – three-door SUV;

- Lada 4x4 M - modernized version with power steering and ABS;

- Lada 4x4 5D (VAZ-213100) – an extended modification of a five-door SUV;

- “Ambulance” (VAZ-213145) – Euro-2/3 in small series;

- Lada Nadezhda (VAZ-2120) is a seven-seater all-wheel drive minivan.

Niva Lynx 4x4

The management did not consider it necessary to install it on the seven-seater Largus minivan. But in all modifications of the Niva 3- and 5-door (Bronto, Kedr, Pickup, Reka, Bys and armored collection vehicle) it was present.

Let's sum it up

So, which is better - a Niva carburetor or an injector? For off-road use and for the city, the second option is definitely better. An injector is a more reliable and practical system. There are far fewer problems and headaches with it, as evidenced by numerous reviews from owners. The engine starts easier and responds better to the gas pedal.

Read news about the new Niva

- The modernized Lada Niva Legend (4x4) 2021 was shown on the Internet

- Lada 4×4 Bronto - sales stopped, new details » Lada.Online - all the most interesting and useful about LADA cars

- Description of the instrument panel Lada 4×4 (VAZ 2121, 2131) » Lada.Online - all the most interesting and useful about LADA cars

- LADA Niva – Operating manual – Official LADA website

- Chevrolet Niva gasoline consumption per 100 km

- Buy LADA (VAZ) 2131 (4×4) 2022 in Rostov-on-Don, low price for Lada 2131 (4×4) 2022 on the Avto.ru website

- Diagram and location of the fuse box Niva VAZ-21213 and 21214

- Fuses Niva 21214 injector «

Modifications

Since 1994, the manufacturer has adjusted the parameters of motor 21214 several times:

- 21214-10 (2002) – Euro-0, the first version had central gasoline injection;

- 21214-20 (2006) – Euro-2 controller Bosch MP 7.0, pairwise variable injection;

- 21214-30 (2008) – Euro-3, without power steering;

- 21214-41 (2011) – Euro-4 for the Russian Federation and Euro-5 for export, power steering, welded manifold;

- 21214-22 – Euro-2, hydraulic supports for valve levers appeared;

- 21214-31 – Euro-3, welded steel manifold, power steering pump;

- 21214-32 – Euro-3, power steering, cast iron manifold, flywheel for 215 mm clutch diameter;

- 21214-33 – Euro-3, cast iron manifold, hydraulic booster;

- 21214-34 – Euro-3, cast manifold without power steering.

All versions from the factory had INA hydraulic mounts, with the exception of version 21214-41, which was equipped with YAZTA hydraulic mounts.

Power steering 21214

Modification 21214-28 had a volume of 1.8 liters due to the larger piston stroke of 84 mm. The engine power reached 92 hp. s., and the torque is 159 Nm. In total, a little more than 69 engines of this type were produced.

Repair dimensions of cylinders and pistons of the VAZ 21213 engine during major repairs

| Repair cylinder size, mm | Piston and cylinder class | Piston diameter, mm | Cylinder diameter after boring, mm | Cylinder diameter after honing, mm |

| 1 repair | ||||

| 82,4 | A | 82,34-82,35 | 82,37-82,38 | 82,40-82,41 |

| B | 82,35-82,36 | 82,38-82,39 | 82,41-82,42 | |

| C | 82,36-82,37 | 82,39-82,40 | 82,42-82,43 | |

| D | 82,37-82,38 | 82,40-82,41 | 82,43-82,44 | |

| E | 82,38-82,39 | 82,41-82,42 | 82,44-82,45 | |

| 2 repairs | ||||

| 82,8 | A | 82,74-82,75 | 82,77-82,78 | 82,80-82,81 |

| B | 82,75-82,76 | 82,78-82,79 | 82,81-82,82 | |

| C | 82,76-82,77 | 82,79-82,80 | 82,82-82,83 | |

| D | 82,77-82,78 | 82,80-82,81 | 82,83-82,84 | |

| E | 82,78-82,79 | 82,81-82,82 | 82,84-82,85 | |

Also interesting: Chevrolet Niva air conditioning - design and repair

Maintenance

The manufacturer AvtoVAZ recommends servicing the 21214 engine on your own or at a service station according to the following schedule:

- the oil and filter are updated annually or after 7.5 - 10 thousand mileage;

- the chain has a high resource of 200 thousand, but is regularly monitored for stretching/tension;

- the fuel and air filters become unusable after 20 - 30 thousand mileage;

- spark plugs and batteries are usually enough for 60 - 70 thousand km;

- It is recommended to update the cabin filter annually, regardless of the car's mileage.

Initially, the internal combustion engine design was simpler, but it was necessary to periodically adjust the erroneous settings of the valve thermal clearances. Then the modernization added hydraulic pushers to the timing belt design, saving the user from this operation and monthly expenses.

Malfunctions, causes, elimination

Initially, engine 21214 has a characteristic failure - failure of 1 - 2 cylinders due to failure of the ignition module due to overheating. The coils and control switch burn out, and electrical equipment needs to be replaced. Other breakdowns are typical for most VAZ engines:

| At idle, the internal combustion engine is unstable and stalls. | 1) damage to the insulation of high-voltage wires 2) spark plug malfunction 3) valve timing failure 4) compression decreased | 1)replacement of high-voltage beams 2)adjusting the interelectrode gap, cleaning carbon deposits 3) installation according to shaft marks 4) valve grinding, cylinder repair |

| XX speed decreased spontaneously | 1) production of DXX | 1) replacing the idle speed sensor |

| The engine stalls while driving in the heat | 1) check valve stuck 2) the hose or tube is pinched 3) the drain line has failed 4) steam plug in the supply system | 1) valve replacement 2) inspection and correction of geometry 3) purging the line 4) purge and cleaning |

Hydraulic compensators eliminate the need for scheduled adjustment of valve clearances after 5–15 thousand kilometers.

Fuel and drain line

Problems

According to the established tradition for domestic engines, despite the fact that the engine has a fairly large number of advantages, it also suffers from common breakdowns. Power unit owners often encounter common problems:

- The power unit not only has high fuel consumption, but also consumes quite a lot of oil. As mileage increases, oil consumption only begins to increase. There is only one reason for this - the formation of carbon deposits on the cylinder walls and valves.

- The temperature of the VAZ 21214 engine during operation can be increased, even without constant loads. The culprit is the thermostat, which constantly jams. Less often, such difficulties arise due to a clogged radiator or the formation of air locks, since the cooling of the VAZ 21214 engine is not an imperfect system.

- Lots of noise during operation. The engine may start to run loudly, and clanging noises may appear from under the hood. There are quite a number of reasons for this, since hydraulic compensators may begin to make noise, or it appears due to wear on the camshaft. Less often, you may need to contact a car service, as the main or connecting rod bearings may make noise.

- The engine speed of the VAZ 21214 may begin to float. Most likely, the reason for this is the VAZ 21214 engine sensors, which are worth paying attention to. To ensure proper operation, you can try cleaning them, and if this does not help, then replace them.

Tuning

The manufacturer used only one technique to increase engine power - increasing the piston stroke. Self-tuning will help you modify the 21214 engine to use its full potential (about 90 hp):

- boring of cylinders in the block - scheme 84/84 or 84/88 to obtain 1.9 liters and 2.0 liters (cylinder diameter/piston stroke, respectively);

- modification of the cylinder head - boring of channels up to 31 mm (exhaust) and 33 mm (intake), installation of a lightweight SHPG flywheel, Nuzhdin camshaft.

Thus, the injection version 21214 is superior to the basic modification of the carburetor engine. It has increased torque and power, and bends the valves with pistons when the single-row chain wears out.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them