Technical features of the VAZ-2111 8 valve injector and its engine

All modifications of the VAZ-2110 have a number of standard features that distinguish these cars from other vehicles of this type. Let's look at them:

- Engine location is front.

- The drive also falls on the front wheels.

- The body of the supporting structure is all-metal.

- Body type – station wagon.

- Four-cylinder, four-stroke, 8- or 16-valve gasoline engine.

- The power system is carburetor or with distributed fuel injection.

Design features

After many years of modifications, the 2111 engine has the following design nuances:

- engine diagram - electronic control of distributed injection;

- engine block – has holes for fixing brackets for attachments;

- cylinders – bored to size 82 mm;

- crankshaft - with a long 71 mm piston stroke, reminiscent of the 2108 model, but the counterweights are more powerful to reduce vibrations;

- piston - oval recess on the bottom so as not to bend the valves, floating pin fit;

- connecting rod – length 121 mm, lower head is heavier;

- camshaft - the cam profile has been changed, the landing dimensions are the same as option 2108;

- Timing belt – copied from 21083, belt transmission;

- flywheel – the teeth are wider, the profile has been changed, the clutch seat diameter is larger (208 mm), the crown is wider than that of 2110 (27.5 mm);

- starter – gear with 11 teeth;

- belt – 742 mm in the basic version, 1115 mm with power steering, 1125 mm when the car is equipped with air conditioning;

- ECU - GM, Bosch or January;

- injectors – Siemens VAZ 6393 (nozzle with 4 holes, yellow color) with controller January 7.2 or M 7.9.7 or Siemens 6238 (nozzle with 2 holes, color gray) with controllers January 5 or MP 7.0.

Standard and major repair work: VAZ-2111 engine (8 valve injector)

Standard (typical) engine repair work on any vehicle is often needed not only when the car stops working. Depending on the indications, they may include the following operations:

- Replacement of components:

- valve lifters;

- oil deflector valve caps;

- timing belt;

- camshaft oil seal.

- Disassembly:

- cylinder heads;

- oil pump.

- Removal and subsequent replacement:

- lamp sensor that controls oil pressure;

- low oil level sensor;

- rear support of the power unit;

- manifolds – intake and exhaust;

- housings of auxiliary units;

- oil receiver;

- power unit supports;

- oil pan;

- camshaft;

- receiver and collectors.

- Adjustment:

- thermal clearances in the valve mechanism.

- Dismantling the ShPG (connecting rod and piston group).

Pros and cons

The above description of the parameters exceeds the characteristics of the entire line of internal combustion engines existing at that time, produced by AvtoVAZ. However, “inherited” from the 21083 and 2110 engines, the 2111 engine received disadvantages:

- breakage of studs in the muffler-exhaust manifold mounting;

- breakdown of the fuel submersible pump;

- leaking valve cover gasket;

- low resource of cooling system elements;

- periodic adjustment of valves.

Why do you need routine and major engine repairs?

As already mentioned, current repair work should be understood as the procedure for disassembling and assembling a vehicle engine with the subsequent replacement of some parts. Most often, replacements and upgrades require components such as:

- liners - main and connecting rod;

- piston rings;

- valve seals.

These replacements are a necessity, albeit periodic. They will not only increase engine resources, but also change the quality of its operation.

Engine tuning

By default, the engine uses the maximum cylinder diameter, so boring them out even more will not be possible or will be too expensive. The following types of tuning are used:

- FNS filter – zero resistance can “revive” the motor;

- throttle 54 – a valve with a larger diameter must be mounted in conjunction with the Federal Tax Service;

- direct-flow exhaust system - spider circuit 4/2/1 and resonator with banks;

- sports camshaft – gas distribution modes change.

Thus, the ICE 2111 is an order of magnitude superior to carburetor modifications, does not bend valves, is economical in operation, so it was produced for a long time and in large quantities to complete the entire line of front-wheel drive cars produced at that time. Thanks to several repair sizes of the piston and cylinder, you can make major repairs on your own.

- Do-it-yourself repair of a VAZ 2110 radiator How to repair a VAZ 2110 engine cooling radiator with your own hands

- Repairing a Zhigulva classic heater using the example of a VAZ 2107 Do-it-yourself VAZ stove repair

- VAZ 2109: how to do a major overhaul with your own hands || We repair the VAZ-2109 engine

- Repair of wedging seat belt on VAZ 2107

DETAILS: Engine water hammer What is water hammer, how does it happen and what are the consequences

General structure of the 2111 engine

The serial number of the VAZ 2111 engine is 100026080. The operating and repair manual states the following technical characteristics of the unit.

| Aspects | Options |

| Number of cylinders | 4; |

| Number of valves | 8; |

| Working volume | 1490 cm3; |

| Compression ratio (how many times the cylinder capacity is greater than the volume of the combustion chamber when the piston is at top dead center) | 9,8; |

| Maximum engine power | 77 l. With; |

| Cylinder diameter | 82 mm |

| Vertical stroke of piston | 71 mm; |

| Maximum torque | 115.7 Nm; |

| Ignition order in cylinders | 1342 (reports from the crankshaft pulley); |

| Petrol | A-95; |

| Motor weight | 127.3 kg. |

The fuel supply system is fuel injection with distributed injection. The VAZ engine control system is electronic using sensors. The engine operates in four strokes (intake, compression, power stroke, exhaust). When intake occurs in cylinders 1 and 4, cylinders 2 and 3 stand still. When the piston in the first and fourth cylinders rises and compresses the fuel mixture, air and fuel are admitted into the remaining two cylinders. Gasoline is injected into the cylinders using injectors.

The engine, together with the gearbox and clutch, form a single power unit. This single unit is secured in the engine compartment using three rubber-metal supports. When viewed from the driver's seat, the crankshaft, camshaft and coolant pump drives are located to the right of the cylinder block. Connection - using a timing belt (111 teeth). The internal combustion engine is connected to the generator drive, which is also on the right, by a poly-V-belt.

On the left side there is a starter, antifreeze temperature sensor, and thermostat. At the front, spark plugs are screwed into the combustion chamber, with high-voltage wires attached to them. Also in the front part there is a knock sensor, a dipstick for checking the oil level, a crankcase ventilation hose and the main source of energy - the generator. A receiver, a fuel rail with injectors, intake and exhaust manifolds, an oil filter and an oil pressure maintenance sensor are attached to the rear.

The declared resource of the 2111 engine is 150,000 km. The 16-valve injector has the same wear period.

Specifications

The VAZ 2111 engine, the technical characteristics of which are presented below, was developed for the Lada 2110-2112 series of vehicles. As a result, it turned out that the power unit is installed even on modern production models, such as Largus and Vesta. Possessing high performance, ease of maintenance and repair, it has become the heart of many car enthusiasts.

So, let's look at the technical characteristics and features of the 2111 engine:

| Name | Index |

| Volume | 1.5 liter (1499 cm3) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 77 hp |

| Fuel consumption | 8.2 l/100 km |

| Cylinder diameter | 82 mm |

It is worth noting that with relatively modest characteristics, the service life of the VAZ 2111 engine is 250,000 km, and with proper maintenance, it can reach 280,000 km.

Why is the VAZ-2110 electrical circuit needed?

When replacing or repairing an injector with 8 valves, the electrical diagram serves as a kind of guide, with the help of which you can understand all the nuances in the process of connecting specific wiring parts. In addition, the VAZ-2110 electrical diagram when using an injector with 8 valves allows you to understand the functioning of all electrical wiring devices.

In the diagram, the injector valves are evenly spaced, while the system itself is presented in the form of two combined components:

- Fuel distributor;

- Electrical equipment for the ignition control system.

Also, the diagram with 8 and 16 valves indicates the location of the electronic unit, with the help of which the operation of the above two systems is coordinated. Backup equipment, in turn, protects electrical wiring from overloads and increases the operating efficiency of the entire injection system.

Advice: if you are going to repair the injector, be sure to look at the wiring diagram for the VAZ-2106. This will give you the opportunity to replace any faulty parts without affecting the overall functioning of the vehicle's wiring.

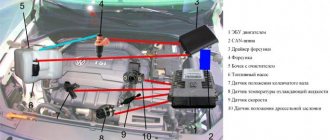

The elements indicated by numbers in the diagram are shown below:

The diagram of electrical wires and fuses gives an understanding of the entire operation of the injection system, and also shows the specific position of each of the elements. It contains the following elements:

- Central nozzle. Acts as a distributor of fuel supply to the system. There is also a special type of fuel regulator that works as a sensor and ensures that the fuel supply does not go beyond the normal limits.

- Diaphragm regulator. Monitors fuel pressure in the ignition system and removes excess fuel back into the tank body.

Advice: make sure that the pressure in the fuel supply system does not exceed 300 MPa. Otherwise, you will see the corresponding icon on the instrument panel and you will most likely have to replace the coolant on the VAZ-2110.

- Bypass valve design. It regulates the position of the cross diaphragm, which is subject to constant pressure from three sides: on one side, the pressure of the fuel itself, on the other side, the tangential load from the intake air volumes, and on the 3rd side, the tension from the spring attached to the valve.

Conclusion

The 8 valve engine of the VAZ 2111 has become very popular. Thus, due to high technical characteristics, ease of maintenance and repair, the automaker began to install the power unit not only on the “ten” series of cars, but also on others. So, the engine can be found on Kalina, Grant, Largus and even Vesta.

- The half rings should have their grooves facing the thrust surfaces of the crankshaft (an anti-friction layer is applied to the surface of the half ring on the side of the grooves).

- The hole for the pin on the piston is offset from the axis by 1 mm, so when installing the pistons into the cylinders, the arrow on the piston bottom should face the direction of the camshaft drive.

- When reassembling the engine, you should always install a new cylinder head gasket. Used gaskets are not permitted.

- The cylinder head bolts may only be reused if they have been extended to a length of no more than 135.5 mm. If the bolt is longer, replace it with a new one.

- It is prohibited to replace the flywheel mounting bolts with the camshaft pulley mounting bolt and vice versa due to their different coating. The flywheel mounting bolts are phosphated, and the camshaft pulley mounting bolt is oxidized.

- For a carburetor engine, fastening (or tightening the nuts) of a heated carburetor is not allowed.

Crank mechanism of engine 2111

The cylinder block is made of cast iron, similar to model 21083. The factory diameter of the cylinder is 82 mm; when boring, it can increase by 0.4 or 0.8 mm. Cylinders are divided into classes. Depending on the diameter, models A, 5, C, 2, E are distinguished. Wear is allowed - no more than 0.15 mm.

Five main bearings with caps are attached to the bottom of the block. The middle support has slots for support half-rings. They are designed to prevent the crankshaft from deflecting from its axis. The crankshaft play should not exceed 0.26 mm. If the indicator is exceeded, the half rings are replaced.

Bearing shells (main and connecting rod) are thin-walled from steel-aluminum alloy. The crankshaft is made of high-strength cast iron. There are 5 main and 4 connecting rod journals on the shaft. Eight counterweights are cast on the shaft.

At the front end of the crankshaft there is a camshaft drive pulley. The generator drive pulley is attached to it using a pin. In the space between the parts of the pulley there is an elastic element that softens the vibrations of the crankshaft. There are only 60 teeth on the pulley, 2 of which are missing to determine the top dead center (TDC) of the piston.

The other end of the shaft is attached to the flywheel. The flywheel is also cast iron. It is installed in such a way that the conical hole located next to it stands exactly opposite the connecting rod journal of the fourth cylinder. This is necessary to set TDC when assembling the VAZ 2111 engine.

Each connecting rod is made of steel and has an I-section. The upper head of the connecting rod is equipped with a steel-bronze bushing. There are different classes of 2111 connecting rods depending on the inner diameter of this bushing and the mass of the connecting rod. The diameter step is 0.004 mm. One engine must have connecting rods of the same marking.

This engine uses aluminum alloy pistons. The upper part is machined and has grooves for rings. In the groove of the oil scraper ring there is a hole for dumping the removed layer of oil into the finger. The hole for the pin in the piston itself is offset by 1 mm from the axis, so when replacing, look at the arrow that is stamped on the bottom. When looking for parts for repair, it is important to know that the piston bottom of the VAZ 2111 8-valve injector is equipped with an oval recess. It should not be confused with a piston for a 16-valve engine. Its bottom has a flat shape and 4 recesses for valves.

Pistons, depending on their diameter, are also divided into classes: A, B, C, D, E. When replacing, you must pay attention to the markings so that the piston matches the cylinder. The gap between new parts should not exceed 0.045 mm. A new piston can only be installed in a new or bored cylinder. The maximum difference in mass between the pistons is 5 g.

The compression of the VAZ 2111 engine should not fall below 10 atmospheres.

Short description

As can be seen from the technical characteristics, the 2111 engine has an 8-valve injector, which is quite typical for AvtoVAZ power units. The gas distribution mechanism has a belt drive protected by a casing. The cylinders are placed in-line transversely, which makes it clear that the vehicle is front-wheel drive. A 5-speed gearbox with mechanical shifting is attached to the engine.

The engine cooling system has two circles - large and small. After starting the engine, the coolant circulates in a small circle, and when the temperature reaches 103 degrees, the large circle opens with the help of a thermostat. When the coolant temperature reaches 105 degrees Celsius, the electric fan is forced to turn on, which helps cool the engine and prevent overheating.

How does the controller monitor the operation of the injector?

When determining the specific position and opening time of the injector design, the specific volume of fuel entering the valves of the VAZ-2110 cylinder is determined. At the same time, thanks to special sensors installed on the motor, the on-board computer records specific values and transmits them to the controller.

Subsequently, the controller, based on the information coming from the on-board computer, makes a decision on the position and duration of opening of the injector damper. If the controller malfunctions, the injectors will not be adjusted correctly, and the engine may stall while driving.

Tip: when starting the engine, the injector controller operates in asynchronous mode until the engine reaches a certain number of revolutions. That is why, after replacing the silent blocks of the front control arms on a VAZ-2110, you should warm up the car for 10-15 minutes.

Tags: repair, maintenance, VAZ tuning, faq

Comments 52

Good afternoon everyone! I ran into trouble that circumstances forced me to install an unloading relay on the starter, but I have a question about the correctness of the circuit that I used in this community: www.drive2.ru/c/48003/ why is it better or worse than this www.drive2.ru /c/595839/ There is no selenium in the electrics, I’m afraid of burning the car

Have a good time everyone. Need help, the dashboard lights are constantly on, when you turn on the ignition, not a single light comes on. Maybe someone had this.

hi all! Tell me what to do, I changed the sensor, drove 500m, and everything is new (the check light is on) ps there are no deviations in the car, everything is normal. NOT troit,

The other day I filmed a detailed video about replacing the cylinder head gasket www.drive2.ru/l/7753336/

maybe the hall sensor is working, if only the switch or coil?

VAZ 2110 carburetor at first troubled then everything, tried with A3-1, thought hall sensor, silence

here not long ago there was a 2112 that had a muzzle and rear arches made under the coupe, I can’t find it, help

I just have the first ten, I don’t really know anything about it, I just found the manual from you)

Yes, I have. If viburnum or Priora, or. you'll find it too

thank you, a lot of useful and necessary information) I wish there were more such wonderful people)))

that's exactly why) good luck

Add a topic! Replacing the foam lamp socket with a cigarette lighter. In my blog, here is the link www.drive2.ru/cars/lada/2…3/glebing/journal/202385/

There are no priors in the family yet. I’ll definitely take the advice. Thanks

Thanks for the info. I downloaded it on both Kalina and 10.

I saw an electronic version of Murzilka somewhere, but I can’t find it anymore, can anyone tell me? Not PDF, but in program form.

Whoa! Like this! In fact, I forgot that I needed it.))) I’ll go look for it on the tracker. Py-Sy. Here, I hope it will be useful to many! yadi.sk/d/JBFUaKkqdD5GW

What about removing and installing the internal combustion engine? Also a useful topic: How to do what, you can look in my blog

how to pull the power wire through the elastic band of the hydraulic corrector?

And also, I have a proposal to create a topic on consumables, what kind of oil, brake pads and timing belt, etc. I can even fill it out myself

Thank you, the manual has been added to the community FAQ. Everything is well written and the photos are on point! We need a topic regarding consumables; the same type of questions are asked every day. Will you do it?

I’ll do it, but the topic will need to be fixed in the same way as the faq.

And also, I have a proposal to create a topic on consumables, what kind of oil, brake pads and timing belt, etc. I can even fill it out myself

+1. suspension, pads, calipers, tips and all that from me

I would like to know something about the power steering and rack, otherwise the Murzilkas don’t have anything on the power steering, mine is leaking, I plan to sort it out when it gets warmer. I would like to know what to prepare for and where the difficulties are.

on the treatment of outgoing corners on the dashboard near the air intakes

How to distinguish original MAFs from fakes, a very useful link

Maybe someone will be interested in what an absorber is. The feedback injection system uses a fuel vapor recovery system. It consists of an adsorber installed in the engine compartment, a separator, valves and connecting hoses. Fuel vapor from the tank partially condenses in the separator, and the condensate is drained back into the tank. The remaining vapor passes through gravity and two-way valves. The gravity valve prevents fuel from leaking out of the tank when the vehicle rolls over, and the two-way valve prevents excessive increase or decrease in pressure in the fuel tank.