Description of design

The bottom of the VAZ 2110 has the same design for all cars in the line and is made of rolled steel with additional stiffening ribs. The metal frame of the car is a type of frameless body; the entire load from the mounted units falls on the floor and side members, which act as a frame and ensure the massiveness of the entire structure.

Repairing the underbody of a VAZ 2110 in 90% of cases begins with checking the side members and involves the use of welding. The welding points that hold the body structures together are torn apart by vibrations, bolted connections become loose, and the solidity of the structure weakens.

Are there any differences between the bottom of 2110, 2111 and 2112

The wheelbase size for all cars in the generation is the same and is 2492 mm, while the cars have different lengths, heights and number of doors, depending on the model:

- Sedan (2110); dimensions 4265x1680x1420 mm.

- Coupe (21123); 4193x1680x1435 mm.

- Hatchback (2112); 4170x1680x1435 mm.

- Station wagon (2111); 4285x1680x1480 mm.

The body layout of each configuration has design differences, but these differences do not affect the central bottom. The bottom of the VAZ 2110 has average prices of 3,000 rubles. and is suitable for installation on the entire line. The part is made of ferrous or rolled metal, without protective galvanization, and therefore always needs to be treated with anti-corrosion agents.

Messages 12

1 Topic by vadim_sintsov 2015-05-15 09:50:57

- vadim_sintsov

- New member

- Inactive

- Registration: 2014-10-20

- Messages: 19 Thanks : 1

- Car: VAZ 2112

Topic: What is the cost of replacing thresholds and floors

Hello! Who changed the thresholds and part of the floor, something like this [video] How much will it cost?

2 Reply from iliaBkmz 2015-05-15 10:07:10

- iliaBkmz

- Forum legend

- Inactive

- Registration: 2012-11-12

- Posts: 2,042 Thanks : 584

- Car: outlander and 2104

Re: What is the cost of replacing thresholds and floors

Expensive! If you don’t know anyone, most likely it’s not rational. But everything, of course, depends on the region.

3 Reply from fade353 2015-05-15 12:09:03

- fade353

- Experienced

- Inactive

- Registration: 2014-07-16

- Messages: 404 Thanks : 70

Re: What is the cost of replacing thresholds and floors

I have a friend who changed it himself, and it only cost me a penny. and in terms of service, I think the prices are exorbitant, because... it's not fast in time.

4 Reply from Anton 2015-05-16 05:32:20

- Anton

- Local

- Inactive

- Registration: 2014-02-20

- Messages: 2,207 Thanks : 255

Re: What is the cost of replacing thresholds and floors

They told me 7 tyks for the doorsteps, but it’s without painting

5 Reply from kuler_78 2015-05-16 18:50:26

- cooler_78

- Experienced

- Inactive

- Registration: 2014-10-22

- Messages: 142 Thanks : 57

Re: What is the cost of replacing thresholds and floors

We will have about 20 thousand if we weld the entire floor and thresholds. You can find it cheaper if you look. There is another craftsman here, he does not do so well, but you can find a common language in money. In short, you can come to an agreement with him

Added: 2015-05-16 19:50:26

I have a friend who changed it himself, and it only cost me a penny. and in terms of service, I think the prices are exorbitant, because... it's not fast in time.

There definitely won’t be a penny right now. Especially if you buy a floor, and wire and gas cost money, plus cutting and cleaning wheels. Today I bought a bearing for hubs and then with. about 800 rubles

6 Reply from Michael400 2015-05-16 18:55:52

- Michael400

- New member

- Inactive

- Registration: 2015-01-14

- Messages: 98 Thanks : 9

- Car: VAZ 21120

Re: What is the cost of replacing thresholds and floors

Pure work 8000 rubles without spare parts. This is a replacement of the floor and thresholds. In Saratov. I'll be sending it in for repairs soon.

7 Reply from iliaBkmz 2015-05-17 08:47:42

- iliaBkmz

- Forum legend

- Inactive

- Registration: 2012-11-12

- Posts: 2,042 Thanks : 584

- Car: outlander and 2104

Re: What is the cost of replacing thresholds and floors

To be honest, there is nothing to talk about. What is shown in the video is not a replacement of the floor, but a replacement of the thresholds with welding of the bottom and ordinary metal and repair. basement parts. The price for such work in the garages of a good craftsman is 8 thousand thresholds + 2-4 thousand for welding, depending on the condition of the car.

And replacing the bottom means replacing the entire element so that the seams are only where there is a factory seam. And this entails dismantling the entire interior + re-welding the floor members - considering the cost of the floor - the price of such work is simply not rational for the 2110.

8 Reply from kuler_78 2015-05-17 14:07:46

- cooler_78

- Experienced

- Inactive

- Registration: 2014-10-22

- Messages: 142 Thanks : 57

Re: What is the cost of replacing thresholds and floors

To be honest, there is nothing to talk about. What is shown in the video is not a replacement of the floor, but a replacement of the thresholds with welding of the bottom and ordinary metal and repair. basement parts. The price for such work in the garages of a good craftsman is 8 thousand thresholds + 2-4 thousand for welding, depending on the condition of the car.

And replacing the bottom means replacing the entire element so that the seams are only where there is a factory seam. And this entails dismantling the entire interior + re-welding the floor members - considering the cost of the floor - the price of such work is simply not rational for the 2110.

It may, of course, not be rational. But it’s probably not because of a good life that people begin to sculpt old stuff. If there is no money, everyone looks for a way out for themselves. And the price greatly depends on the area. In Moscow there are some prices, in the regions there are different ones. And if a person there is no money for a new car, I don’t think you can explain to him that this repair is not rational

Added: 2015-05-17 15:07:46

Pure work 8000 rubles without spare parts. This is a replacement of the floor and thresholds. In Saratov. I'll be sending it in for repairs soon.

Your prices are normal compared to our region

9 Reply from Anton 2015-05-17 15:30:45 (2015-05-17 15:31:06 edited by Anton)

- Anton

- Local

- Inactive

- Registration: 2014-02-20

- Messages: 2,207 Thanks : 255

Re: What is the cost of replacing thresholds and floors

It may, of course, not be rational. But it’s probably not because of a good life that people begin to sculpt old stuff. If there is no money, everyone looks for a way out for themselves. And the price greatly depends on the area. In Moscow there are some prices, in the regions there are different ones. And if a person there is no money for a new car, I don’t think you can explain to him that this repair is not rational

10 Reply from Rusbuz 2015-06-03 09:20:45

- Rusbuz

- New member

- Inactive

- Registration: 2015-06-03

- Messages: 12 Thanks : 0

- Car: vaz 2112

Re: What is the cost of replacing thresholds and floors

Here in Perm I was charged 14,000 for replacing one threshold with painting. VAZ 2112

11 Reply from vadim_sintsov 2015-06-03 14:21:00

- vadim_sintsov

- New member

- Inactive

- Registration: 2014-10-20

- Messages: 19 Thanks : 1

- Car: VAZ 2112

Re: What is the cost of replacing thresholds and floors

Here in Perm I was charged 14,000 for replacing one threshold with painting. VAZ 2112

Wow. It's not really expensive!

12 Reply from kuler_78 2015-06-04 00:03:44 (2015-06-04 00:06:45 edited by kuler_78)

- cooler_78

- Experienced

- Inactive

- Registration: 2014-10-22

- Messages: 142 Thanks : 57

Re: What is the cost of replacing thresholds and floors

Here in Perm I was charged 14,000 for replacing one threshold with painting. VAZ 2112

Painting the surface is 5000 and the rest should be thought of replacing the threshold. The guys work hard. It’s better to avoid them. 5000 for the surface and that’s expensive. I’ll let it be painted this week, I agreed for 3000 for the surface, plus the hood for 2000 they agreed. Well, what if to paint the whole thing 25,000 for labor and 12,000 for material

When repairs are required

For all VAZ models, a mandatory condition is periodic inspection of the body for corrosion. Already from the factory, automotive hardware must be additionally protected from rust. The first VAZ 2110 began to become covered with corrosion from the area of the windshield frame. The paintwork peeled off quickly; after 6 months the first rusty plaques could be seen under the paint layer.

Cooking a rotten car body if the degree of metal destruction exceeds 70% is expensive and impractical. To protect the car from corrosion, once every 6 months it is necessary to carry out preventive maintenance and replace the old used metal.

The main reasons for rapid wear:

- The car is over 7 years old. The bottom is checked in the inspection hole: if there is minor corrosion, metal patches can be used.

- Accidents and driving on bad roads. Any deformation of the metal after an accident leads to the fact that the protective layer of anti-corrosion in places where it is broken is destroyed, and the metal begins to wear out faster. The same applies to frequent trips on bad roads.

- Car parking on the street. VAZ cars need a warm and dry garage. Considering that the car body is not treated with zinc, just one winter outside can cause corrosion of the sills and bottom. Moisture penetrates through the protective layer and destroys the metal of the seal, the outer part of the bottom.

- Water in the cabin. The liquid that has accumulated under the rubber mat quickly penetrates the bottom skin and contributes to the rapid rotting of the metal unprotected by anticorrosive.

A complete bottom repair will be required in the following cases:

- It is impossible to put the car on a jack; the jack falls through.

- It is clearly visible that the floor in the cabin has become uneven - the bottom is 60% rotten.

- It is impossible to adjust the driver's seat due to the skew of the bottom.

- Under the threshold, under a layer of putty, rust appeared. It is checked with an awl if the anticorrosive layer has peeled off.

- The appearance of rust on the inner surfaces of the sills in the interior and arches.

Protective polishing of the body

Protective body polishingfrom 3,000 2. Slipworks.installing a car on a slipwayfrom 3,000elimination of a simple misalignment of a car bodyfrom 3,000elimination of a misalignment of a medium-complex car bodyfrom 6,000elimination of a complex misalignment of a car body of a foreign car from 8,000removing the front bumper of a car assembly from 500installing a front bumper of a car as an assembly from 500removing the rear bumper of a car as an assembly from 500installation of a rear bumper of a car assy from 500 rear bumper dismantling from 500 car rear bumper - assemble from 500 front bumper disassembly from 500 car front bumper - assemble from 500 car front door - disassemble, assemble for painting from 1,000 rear car door - disassemble, assemble for painting from 1,000 foreign car door front, rear - replacement with reinforcement overhaul from 1,500 car front, rear door assembled - replacement with adjustment according to the opening from 1,500 side mirror of foreign cars without electric drive - replacement from 500 side mirror of foreign cars with electric drive - replacement from 500 replacement of front headlight from 500 replacement of tail light from 500 Replacement of car hood from 1,000 Replacement of car trunk lid from 1,000 Replacement of front removable fender from 1 000Replacing the roof of a car without a sunroof in assembly 6,000Replacement of a car roof with a sunroof assemblyfrom 7,000Replacement of a front side member with a mudguardfrom 3,500Replacement of a car's rear panel from 3,500Replacement of a car's front panel from 2,000Replacement of a car's side sill assembly from 3,000Replacement of the center pillar with a part of the sill from 6,000Repair No. 1 of the side of a car - sedan7,000Repair No.2 of the car side - sedan8,000Repair No.3 of the car side - sedan9,000Repair No.4 of the car side - sedannegotiableRepair of the car side - station wagon No.17,000Repair of the car side - station wagon No.28,000Repair the car side - station wagon No.39,000Repair the side of the car - station wagon No.4negotiablerepair of the mudguard front car No. 11 000repair of front car mudguard No. 22 000repair of front car mudguard No. 32 500repair of front car mudguard No. 4 negotiablerepair of front car door No. 19 00repair of rear car door No. 19 00repair of rear car door No. 21 5 00repair of front car door No. 21 5 00repair of front door car No. 32 500repair of the rear door of car No. 32 500repair of the front door of car No. 4 negotiablerepair of the rear door of car No. 4 negotiablerepair of the hood of car No. 19 00repair of the hood of car No. 21 5 00repair of the hood of car No. 32 500repair of the hood of car No. 4 negotiablerepair of the front fender of car No. 15 00repair of the front fender of car No. 21,000repair of the front fender of car No. 31,500repair of the front fender of car No. 4 negotiablerepair of the roof panel of the car No. 11 0 00repair of the roof panel of the car No. 22,000repair of the roof panel of the car No. 33,000repair of the roof panel of the car No. 4 negotiablerepair No. 1 of the trunk lid of the car, 5th door 9 00repair No. 2 car trunk lid, 5th door1 5,00repair No. 3 of a car trunk lid, 5th door2,500repair No. 4 of a car trunk lid, 5th door negotiablerepair of the rear panel of a car No.11,500repair of the rear panel of a car No.22,000repair of the rear panel of a car No.33,500repair of the rear car panels No. 4 negotiablerepair of sidewall threshold of foreign cars cost 1,000 Restoration of cloudy plastic headlights of foreign cars cost 1,000 Abrasive polishing of the car body from 4,000 Protective polishing of the car body 5,000 - 10,000Preparation for repair

When choosing to repair the bottom yourself, you need to prepare tools and materials. For experienced craftsmen, a complete replacement of a part takes at least 3-4 days; the cost of work at a service station averages 45–50 thousand rubles. To work you will need:

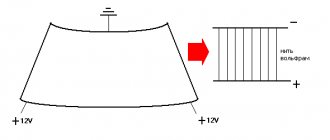

- Bulgarian. Using an angle grinder, the corrosion plaque is removed from the bottom, parts of the patches are adjusted, cut off, and welding seams are aligned.

- Welding machine. It is recommended to boil the iron body and bottom, in particular. Semi-automatic welding with wire and carbon dioxide is suitable. You can use gas welding and 3 mm electrodes, provided you are skilled in such work.

- Electric drill for drilling spot welds.

- It is not recommended to carry out underbody repairs in a pit - it is inconvenient; it is better to use stands, a lift or skids; in some cases, the car is turned over on its side.

- Sound insulation sheets.

- Anti-corrosion set: mastic, R-80 sandpaper, primer, auto enamel.

Preparatory work step by step:

- Disconnect the negative terminal from the battery or remove the battery.

- Drain the fuel from the tank.

- Disconnect the electrical wiring from the door power windows.

- Remove the doors, marking the fastener locations on the body.

Before dismantling the doors, it is necessary to insert iron spacers into the openings or weld a channel, this will ensure that the geometry of the body is preserved if the center pillar reinforcement is rotten and there is a possibility that the roof will fall or bend in half.

Dismantling the interior

Replacing the underbody involves work inside the cabin and under the car. Dismantling the interior is carried out in steps:

- Pull out the seats.

- Remove the interior trim by unscrewing the moldings.

- Pull out floor coverings and carpets.

- Remove air vents.

- Remove the sound insulation layer and additional anti-vibration pads.

- Disconnect all internal wiring, twist the cables into a bundle, and remove the fasteners.

- Remove the dashboard to open access to the engine compartment if you plan to completely replace the bottom.

If you are an inexperienced tinsmith and electrician, it is better to distribute all fasteners into separate packages and sign them. When installing the interior, this will help you avoid getting confused with the parts.

Approximate price

On average in Russia, it costs 8,500-29,000 rubles to digest the bottom of a VAZ-2112 car. Price of works included in this amount:

- Purchase of electrodes (about 3 kg per car) - from 550 rubles per 3 kg .

- Two cutting wheels for an angle grinder, two spare ones - about 270 .

- A pair of metal brushes for a drill - from 200 .

- Degreaser and Solvent – 150-160.

- Paint - from 700 rubles .

- Epoxy glue - about 200 rubles .

- Rubber-bitumen mastic – 150.

- Polymer-bitumen mastic – from 350 .

- Rust converter - about 85 .

- Large Movil cylinder – 345.

- Paint brushes – approx. 160.

- Two amplifiers under the seat - 400.

- A pair of corners - 300 rubles .

- Floor panel – 4500.

- Jacks - 160 rubles for two pieces .

- The work of a car mechanic costs about 20,000 rubles .

Welding work

Welding will be required both to replace the entire floor and during repairs, when the rotten part of the bottom is cut out and a patch is welded. The iron for the patch is cut out in advance; the size of the patch should be 2 cm larger than the hole around the perimeter. There is an option to use the original part of the bottom instead of a patch, which is sold separately.

Replacement of car underbody elements

After the car interior is cleared, a full inspection of the underbody is carried out. In some cases, you can limit yourself to a partial replacement—boil only the corroded areas. Rotting of the floor begins from the thresholds of the car; these elements are inspected first. Replacing the body also begins with reinstalling the thresholds.

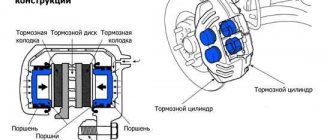

The bottom of the VAZ 2110 consists of the main elements:

- support platform;

- bottom panels;

- threshold extension;

- side member amplifier;

- crossbars;

- connectors.

It is necessary to check the condition of the panels under the driver's feet, side member reinforcements, jacks or support platforms. If the overall condition of the bottom is satisfactory, you can limit yourself to installing a patch on the damaged area or replacing the bottom element from the repair kit:

- A drill is used to drill the spot welding points with which the element is installed on the structure.

- The element is cut out with a grinder.

Under the bottom of the car on the driver's side there are tunnels for the fuel line and brake system. Removing the system on a VAZ 2110 is quite problematic; it is recommended to cut off the old lines and install new parts after repairing the bottom.

- A metal patch is cut out.

- The bottom is sanded and a patch is welded.

- Welding seams are cut off with a grinder and cleaned.

- The element is primed, sanded, and treated with anticorrosive.

Final processing

After welding work, it is necessary to clean the seams with a grinder, carry out anti-corrosion treatment, and install new sound insulation panels. The bottom of the VAZ 2110 must be treated with anti-corrosion agent both from the outside and from the inside. Bottom finishing:

- The welds are cleaned until they shine, a grinder is used, and at the final stage, sandpaper R-80 is used.

- The seams are covered with bitumen-based mastic.

- The bottom surface is primed outside and inside the cabin.

- An oil-based anti-corrosion agent is applied to the inner surface. The composition penetrates into all hidden grooves and pockets.

- The outer part of the body is treated with anti-gravel protection.

- Sound insulation panels are cut to the required size, heated with a hair dryer, and placed on the bottom inside the cabin.

- Doors are being installed.

The work on replacing the bottom is completed, all that remains is to mount the interior, install the trim elements, and connect the electrical wiring.

Preparatory work

Before installing new frames on the bottom or welding body parts, you need to make preparations and partially disassemble the car:

- remove the seats;

- remove carpet;

- dismantle the old sound insulation;

- put aside electrical wiring in those places where repairs will be carried out.

Before replacing individual elements or installing patches, the entire metal surface is freed from old sound insulation, thoroughly washed and wiped, and cleaned using a grinder, a sanding machine or sandpaper. Then the metal should be degreased and treated with a rust converter; only after this can you begin working directly with the iron.

How to extend the life of the bottom

The body on all VAZ models is not a high-strength unit. To maximize the life of the main part of the car, it is recommended to systematically carry out preventive maintenance. It is impossible to completely eliminate the aging process of metal, but every driver can increase the service life of a new underbody.

- Prevent water from entering the cabin through depressurized moldings on the windshield and side doors.

- Systematically remove the rubber mats under the driver's seat and check the floor for dryness. Systematically clean drains in thresholds and doors. Particular attention is paid to the area under the battery: under the influence of the electrolyte, the drainage holes on the platform become coked.

- If the first rust is found on the bottom of the interior, clean it, fill it with epoxy resin, and treat it with an anti-corrosive agent with the effect of preserving corrosion areas.

- Clean chips and renew the paintwork on the sills immediately after detection: the sills and fenders begin to rot first.

- It is necessary to lift the car with a jack only with the doors closed.

How to choose a part: average prices

To weld the bottom of a car at a car service center, the minimum price is 25,000 rubles. This applies to minor floor defects in all customer materials. A complete overhaul and update can cost up to half the cost of a car. Considering that the price of a VAZ is minimal, such repairs are not profitable for most drivers.

Many people prefer to carry out repairs and replacements on their own, buying a solid bottom. The repair kit is produced by AvtoVAZ, the element is suitable for models 2110, 2111, 2112, 2170, 2171, 2172. The cost does not exceed 4,000 rubles. Cold-rolled steel 0.8 mm thick is used in production.

There are options on the market to buy bottom elements: panels, amplifiers, connectors and cross members. The cost of each element is from 900 rubles. Parts of the bottom are chosen instead of metal patches if local repairs are necessary without welding out the entire bottom.

Types of service

Overcooking the bottom of a VAZ-2112 car can be:

- Using semi-automatic welding equipment:

- Using gas welding.

Depending on the location of the repair, the service is:

- In the garage of a private master.

- On the territory of the car service center.

- At the location of the client's car.

Depending on the time that the client allocates for work, overcooking occurs:

According to the performer, overcooking is classified into:

Self-repair of the underbody of a VAZ 2110

The current condition of the car can largely be assessed by analyzing the body.

If all kinds of consumables need to be replaced, you can even rebuild the suspension yourself and even install a new engine, then restoring a completely rusted body is expensive and pointless. No one will tune, modify, or invest a lot of money in a car if its body is already in its last years. This significantly reduces the cost of the car, even if the engine is in perfect condition.

Therefore, if you want to maintain the attractive appearance of your VAZ 2110, extend its service life, and, if necessary, sell it for good money, keep an eye on the body and periodically carry out repair or preventative body work aimed at combating corrosion.

PRICE LIST AND PRICES FOR CAR BODY REPAIRS

Body repair prices are valid subject to the normal condition of threaded fastening connections (nuts, bolts, screws, etc.) that can be unscrewed normally without additional heating, and the use of special equipment. liquids and agents. For cars older than 7 years, a coefficient of 1.25 is introduced.

We have indicated prices for the main types of car body repairs. If you did not find the work you need in our price list, this does not mean that we do not do it. Our body shop performs the full range of body repair work.

The assessment of body work for each car is a purely individual matter. Please call and describe the breakdown or your question to our specialist in as much detail as possible. This will help us provide more detailed advice and understand the essence of the problem. Call - HERE IS YOUR PHONE NUMBER

Find out the cost of repairs from photos in 10 minutes!

Causes of rust and preventive measures

The first versions of the VAZ 2110 were characterized by the fact that their paintwork began to peel off in the area of the windshield frame. The problem began to develop from the seal and gradually spread to the entire body element.

Soon the manufacturer changed the painting and installation technology, but still the problem of a body that was not resistant to corrosion could not be completely overcome.

We will look at the main reasons for the probable appearance of rust on the sills, bottom, arches, and side members. We will also give some tips on how to deal with them.

| Causes | Prevention measures |

| Age | After 5-7 years, traces of corrosion may appear on the body and bottom. There are no remedies against age, so listen to the following protective measures |

| Accidents and accidents | It is easy to advise avoiding accidents. In this case this is the only recommendation |

| Poor quality repairs | Do not try to save money on body repairs, since an unqualified specialist will not really do anything, but will only waste your time and money. Choose experienced, proven craftsmen and service stations |

| Weather | The worst thing is snow and rain. Try to knock down and wash away the snow stuck under the bottom. Especially if you often drive on roads sprinkled with salt or snow and ice melters. |

| Humidity in the garage | Think about the issues of moisture protection of the room; in winter, periodically turn on the heater or heat fan in the garage in order to at least partially combat the high level of rust |

| Driving on gravel | Small stones destroy the anti-gravel coating within a year, after which corrosion begins to appear. Avoid such roads, carry out periodic preventive maintenance |

| Moisture in the cabin | It gets through wet shoes and snow brought into the cabin. As a result, the bottom begins to rot from the inside. Be sure to lay down rubber mats with sides in winter; be careful that water does not get inside the cabin during rain or car wash. |

To increase the service life of the underbody of your own car, periodically perform anti-corrosion treatment. Pay special attention to the hidden cavities of the side members and sills.

Rusted thresholds

Problem Definition

It is not difficult to determine the presence of rust on the bottom. Although if you bought the car second-hand, these problems can be carefully disguised.

- Be sure to inspect the body from below. Traces of corrosion may be hidden behind a layer of anti-gravel coating or putty. Use a hammer or awl to hit these areas lightly. If rust is present, you will see it.

- Check the condition of the body along the thresholds, in the cabin at the feet of the driver and front passenger. It is these places that are quite weak in the case of the VAZ 2110.

- If the bottom is rotten, you can notice this by the sagging of the floor under your feet under load.

- When the driver's seat comes off or cannot be moved, a rotten body may also be the cause.

- One of the most unpleasant situations is rotten thrust pads designed for lifting a car on a jack. But this way you will immediately determine that there are problems and they need to be solved.

Moscow, st. YOUR SERVICE ADDRESS, +7 YOUR PHONE NUMBER from 10:00 to 22:00 daily

Body repairs and dent removal are 37% more profitable than the market with a 3-year contract warranty

FIND OUT THE COST OF REPAIRS BY PHOTO IN 10 MINUTES!

Car brands we service

4 Cost calculation options

We will carry out a free troubleshooting for you in your presence

You yourself choose what suits you!

COST OF TURNKEY WORK

(ALL FOREIGN CARS) *including all consumables

You have the opportunity to control the quality of consumables, primers, paints and spare parts. parts!

THE EXACT PRICE IS KNOWN BEFORE THE REPAIR STARTS, SO YOU WILL NOT RECEIVE “SURPRISES” IN THE FORM OF ADDITIONAL MARKS OR UNAGREED WORK!

Paintless dent removal using PDR/DOL technology

with full preservation of the factory paintwork

| Size of damage (dent) | Repair cost | Repair time |

| 1-3 cm | 800-1200 RUR | 30 min |

| 3-5 cm | 1200-1800 RUR | 1 hour |

| 5-10 cm | 1500-3000 RUR | 1,5 hour |

| 10-20 cm | 3000-4800 RUR | 2 hours |

| 20-30 cm | 4800-5600 RUR | 3 hours |

| over 30 cm | 5600-8200 RUR | 4 hours |

- The price quoted by you over the phone remains unchanged

- We don't hide anything behind low prices.

- We keep a detailed service history in the service book.

- All work is certified according to GOST-P

- CASHBACK 10%

- 100% money back. If you don't like it, don't pay

- Together with you, standing on the lift, we will tell you what requires urgent repairs and what can still wait!

25% discount until the end of the month

Repair with delivery

We'll pick it up, repair it, and deliver it.

We receive an Application from you, fix the work and prices and agree on where to pick up the car.

A personal receptionist will always be in touch with you. He will advise you in detail on the price and timing of repairs and agree with you on all upcoming work.

We will send a business card to the driver who will come to you. During moving and repairs, your vehicle is insured.

Our drivers have over 8 years of accident-free driving experience. All of them are full-time employees and verified by our security service. All risks from the moment of transfer of the vehicle are insured for RUB 5,000,000.

We pick up the car, record its condition, install a DVR, a seat cover and sign the document.

Transfer of the vehicle will take no more than 10 minutes. The driver will sign with you an act of acceptance and transfer of the vehicle and a power of attorney to drive the vehicle.

We carry out all the necessary work and record it in the work order with a 24-month guarantee.

All work with you is necessarily discussed and agreed upon. You know in advance the cost and time of repairs and decide for yourself what to repair and what not. We provide a 24 month guarantee on all work performed.

We return the car to you and receive payment from you.

You receive a repaired car, a full set of documents and make payment in a form convenient for you.

We will confirm your appointment within 10 minutes.

We will contact you within 10 minutes.

Preparatory activities

To repair the bottom with your own hands, you first need to prepare in a certain way. You will need a set of tools, premises, a lot of time, experience and desire to do such things.

Of the tools, it is especially important to prepare the following components:

- Welding machine. In the case of repairing the underbody of a car, it is better to use a semi-automatic machine with wire and carbon dioxide. It is better, more efficient and more reliable than gas and electrodes;

- Angle grinder. It will be useful, if necessary, to remove rust from the floor, to adjust elements and patches, to clean seams and surfaces;

- Car stands. Here you can use various items. So look for what you have;

- The rest of the kit is standard and includes such components as anti-corrosion solution, mastic for seams, welding wire, sandpaper, primer, soundproofing sheets, paint, etc.

Now you need to drive the car into the garage or other equipment room and put it on stands.

The machine should be positioned in such a way that it is comfortable and safe to work under it.

Disconnect the battery, then remove the doors. In this case, experts advise providing spacers for doorways in order to maintain body rigidity and the necessary geometry.

Dismantling the interior

Since you need to repair the underbody not only under the car, but also from the inside, you will have to completely disassemble the interior. This is a difficult task that will take a lot of time. Be psychologically prepared for this.

You will have to dismantle:

- Armchairs;

- Floor tunnel lining;

- Carpeting;

- Air ducts;

- Soundproofing layer.

Carefully collect all the wiring, combine it into bundles if they are not collected, so that later there will be no problems with assembly. Collect all fasteners, distribute them into boxes or bags, and label them. This is extremely important because you may face serious problems later.

If you plan to completely replace the bottom or weld a panel to the floor, then the dashboard and beard will have to be removed to create open access to the engine shield.

Lifting a car

Welding

So, you have disassembled your VAZ 2110, so now you can really assess the condition of the bottom, as well as analyze the required amount of work. The most optimal situation is one that does not require replacement of elements. The rust spots are cleaned until high-quality metal is obtained, after which they are strengthened by patches. But not everyone manages to face such a situation.

If the holes in the bottom turn out to be through, this will lead to a loss of body rigidity, therefore it is strongly recommended to replace the element completely.

In the case of the VAZ 2110, the following body elements are distinguished:

- Floor panels;

- Support platforms;

- Threshold extensions;

- Spar extensions;

- Crossbar;

- Connectors.

Now let's discuss a few basic nuances of welding.

- To replace a part that has “slipped” due to corrosion, it must be drilled out at the welded points or simply cut off using a grinder.

- Do not forget that the brake and fuel system pipelines pass under the bottom. It is extremely difficult to dismantle them, so the easiest way is to cut them off and install new pipeline elements during reassembly.

- If the floor panels are in critical condition, the entire bottom assembly should be replaced. But in this case, be sure to dismantle the exhaust system.

- If it is necessary to change the thresholds, they are dismantled and new ones are installed one by one. It is important to control the geometry.

- If the floor and thresholds are being replaced at the same time, the thresholds are replaced first, and only then the floor panels.

- Carefully mark the elements for welding. The old components must strictly correspond to the new ones being cut out.

- You cannot do without an assistant, so agree in advance with someone who can help you.

- Always start the bottom from the bottom, then grab it.

- Do not make the main weld using a continuous weld. Maintain a step of approximately 4-5 centimeters.

When welding work is completed, be sure to carry out anti-corrosion treatment.

Replacing the underbody of a car

- Disassembly and dismantling

- Installation and welding

Is it possible to replace it yourself in a garage?

To take on this amount of work in your garage, you either need to be too frugal or have a lot of faith in your experience as a bodybuilder. In a normal situation, no one will do the replacement of the bottom, even partially. It's just a waste of time and nerves due to sheer inconvenience. Absolutely everything gets in the way - from the seats to the fuel and brake system pipes.

But this is not the main problem; most often you have to deal with the following situations:

- The need to completely disassemble the interior and dismantle the wiring, since it is not always possible to install it conveniently.

- A large amount of preparatory work, since such damage usually spreads to side members, thresholds, and floor reinforcements. That is, it’s unlikely to get rid of it by replacing one trough.

- The need to perform work both inside and outside. Doing this without a pit, placing the car on jacks, would not be recommended to anyone. Whole arms, legs, and even the head are much more important and expensive.

- Often the work involves the manufacture of repair inserts; the problem cannot be solved using conventional methods. Such a replacement is mainly associated with the need to come up with non-standard solutions. It is impossible to do this without relevant experience.

- If you change the bottom completely, you will need to decide how to install it in the interior. The dimensions of the doorways do not allow this to be done; sometimes it was even necessary to cut off the windshield.

- If you miss the primer and high-quality anti-corrosion agent, then you shouldn’t hope for the durability of the new bottom; rust won’t take long to appear.

We can safely say that replacing the bottom and accompanying repairs of other body parts is still a pleasure. And if errors are also made with dimensions and geometry, then subsequent problems will begin to appear in geometric progression. Don't tempt fate, it usually deceives. The problem can be solved easier and faster only in a service center that has a lift and the necessary welding equipment.

Where to find a new or used bottom

For domestically assembled cars, finding new components to replace the bottom is not difficult. On sale you can find both the original and slightly different analogues. It will have to be cut and adjusted to size in any case. Let us pay attention to just one point - you should not buy obvious foil that bends with your fingers. With such a thickness of metal, the result will be short-lived even with normal anti-corrosion treatment. Even for homemade repair inserts, it is advisable to use iron with a thickness of at least 1.5–2 mm.

The situation with components for foreign cars is more complicated. For Europeans and Americans, it is difficult to find new body parts from the factory. Yes, the problem is being solved, but not as quickly as we would like. And in terms of cost, this option will be far from cheap. It is advisable to look for a new bottom only when repairing (restoring) an expensive car after an accident; finding one for any old woman is already problematic. The main option is to search for contract body parts. Such a solution is cheaper, and the quality is rarely inferior to new hardware; serious companies working in this area are monitoring this point.

Looking for the bottom in our showdowns is an equally thankless task. In most cases, they offer options with varying degrees of rust damage; you can only find something worthwhile with great luck. In this case, it is better to give preference to inexpensive analogues; they last longer with high-quality treatment with anti-corrosion compounds.

So that you don’t have to search for components yourself, we are ready to take on the solution to this problem ourselves. We work with trusted suppliers who ensure delivery of body parts for the most common car models in the capital in just 2–6 days. It will obviously be more convenient and calmer for you.

Features of partial replacement

The bottom of the car rots not only from the outside, but also from the interior. Therefore, anti-corrosion treatment performed immediately after purchase is not a reason to calm down. The risk group traditionally includes those who bring snow with them, forgetting to clean their shoes when landing. Even the presence of rubber mats or a full-fledged carpet does not guarantee that a puddle of melt water will not accumulate under them.

In most cases, the front quarter of the body on the driver's or passenger's side is damaged. The rear seat area rusts a little less often, however, this depends more on operating conditions and regular maintenance of the interior and body.

Replacing the bottom in separate troughs-baths (quarters) is more preferable. In this case, the amount of work is significantly reduced and the cost of the service is reduced. That is, if you want to save money, pay attention to the condition of the metal in the cabin, because sometimes it’s not difficult to remove the carpet and check for moisture under the carpet.

Required volume of reinforcement work

The amount of disassembly of the interior is also correspondingly reduced; if we are not talking about concomitant damage to the side members, sills, panels of the engine compartment or trunk, then it is quite possible to complete the replacement in 1-2 days. As an example, we will give the volume of reinforcement work when replacing one of the front quarters, since this is the request most often made to the service (in this area):

- We start with the rugs; they will definitely get in the way.

- We remove the front seats, and even when replacing one quarter it is better to dismantle both, they create additional inconvenience.

- We remove the internal lining of the sills, pillars, and disassemble the central tunnel.

- In some cases, it is necessary to remove the doors; in extreme cases, we unscrew the opening limiter.

- Pipes of the brake and fuel systems and exhaust elements are laid under the bottom, which are also subject to dismantling. Sometimes you even have to dismantle the gearbox.

The main condition is to provide access to all the welds along which the removed quarter of the bottom is joined to other body elements.

Dismantling damaged areas

The correct way is to drill out all weld points along all edges. It will take longer to cut out metal; we use this technology only when access to points is difficult due to cramped conditions. It is not advisable to cut with a plasma or an angle grinder; the danger of sparks and drops of molten metal should not be underestimated.

We drill with a special cutter or drills with a diameter of 5-6 mm, and we drill only the top layer of metal, otherwise welding a new element will be problematic. In addition, care is also needed in order not to damage the wiring and tubes running under the bottom. The main areas where this work is carried out:

- Connection to the panel (shield) of the engine compartment.

- Joining points with the threshold of the doorway, the central tunnel.

- Connection to floor reinforcement.

- Areas in which the removed quarter of the bottom is welded to the spar.

But before drilling, we remove the sound insulation layer, the internal anti-corrosion coating, and strip the paint down to the metal. Otherwise, it will not be possible to find all the weld points. When assembling cars, all such joints must be sealed with sealant, which will have to be cut or the bottom part must be pulled out by force.

Preparation of the body and repair inserts

New underbody parts do not require special preparation; they are usually supplied in a ready-to-paint condition. But there is one nuance that concerns inexpensive analogues. The manufacturer simply saves money and uses transport primer, which cannot be painted over; the coating will peel off in entire sections. Therefore, if dirty stains remain from a napkin (rag) with a solvent, we clean such soil down to the metal.

The main part of the work involves preparing the body itself; we have never had to change the bottom when there are no problems with the other elements. In the simplest case, there are traces of rust, not through or deep damage, but simple red spots. We fight this problem with the help of a rust converter or acid etching primer.

If more serious damage appears in other adjacent areas of the metal, we solve the problem radically - we cut out all the damaged iron without pity, and can only weld it to living metal. For such areas, we prepare repair inserts from steel 1.5–2 mm thick, trim them, and give them the required shape. We usually overlap welding using resistance welding.

After all the surrounding areas are cleaned, digested, the surfaces are degreased, including the new quarter, and coated with epoxy primer, it has greater strength. Only for the edges along which welding seams will pass, we use conductive primer with zinc. It burns less and provides better quality of the weld point.

Welding work and anti-corrosion treatment

First of all, we try on the new quarter of the bottom in place; in rare cases, it is possible without additional adjustment or even trimming. We make sure to ensure a tight fit of the metal along all edges; sometimes we have to bend it. For all future welded joints, we drill holes with a diameter of 4-5 mm in increments of 3-4 cm. There is a rule - the number of connection points should not be less than for the factory assembly of the car, this is the only way to ensure the design strength and rigidity of the joint.

After this, we install the new element in place and fix it in 3-4 places with welding pliers to prevent spontaneous displacement. We start cooking at the points with the best fit of the metal. We do not weld in a row, but through 5–10 prepared holes, this allows us to avoid local overheating and deformation of the metal. If necessary, press the welded segment against the body to ensure maximum tight contact.

Upon completion of welding work, we carefully clean the metal from scale and cut off excess beads. A prerequisite for protection against corrosion is the treatment of all resulting joints with polyurethane sealant, which can then be painted. It prevents water from penetrating between layers of metal and reduces the risk of rust.

On the interior side, we degrease the new insert and all adjacent areas, restore the damaged primer and paint. Usually painting is done without careful color selection; it is enough to check compliance with the code. And some car owners, in order to reduce the cost of replacement, insist only on priming without further painting. We also carry out anti-corrosion treatment of the bottom from the outside only by prior arrangement. But we do not recommend abandoning this method of protecting metal, especially since we have a fairly good selection of various materials for this purpose.

Features of a complete replacement of the bottom of the car

This replacement is practiced mainly in the most unfortunate situations, when both the side members and the sills are damaged. And this entails a violation of the geometry of the body. Therefore, you should not experiment on your own; without a slipway, precise control of dimensions at the main points will not be possible.

There is a rule - a new bottom should be adjusted and welded only after the damage to the sills and side members, floor reinforcements and jacks has been completely eliminated. Yes, in some cases you have to cook it this way, but only when it comes to a partial replacement, and then only as a temporary solution. For a complete replacement, this method is categorically unacceptable.

All such defects are already visible during preliminary diagnostics, so we discuss the issue of purchasing all components immediately. Otherwise, there is no point in taking on work. It is for this reason that the replacement time can be increased to 3-4 days without taking into account the search and delivery of components.

The main difficulty is associated with the increased size of the trough-bath. And you will have to cook more, process the seams, and it’s not easy to just turn around in the car with such a large part. In some cases, you even have to install them in separate segments.

Disassembly and dismantling

The interior, and not only it, will have to be completely disassembled. We especially have to work on rear-wheel drive cars, in which we also need to remove transmission elements. Filming:

- Seats and doors.

- The lower part of the interior trim.

- Lining of the central tunnel.

- Interfering tubes and wiring sections.

- Cardan and, if necessary, other transmission elements.

- In some cases, we also cut out the windshield.

The bottom itself is dismantled using proven technology - we drill out all the welded points in places adjacent to other body elements. To do this, we first remove all the coatings in the interior, clean the paint, and remove the noise. In order not to waste time, we cut the entire bottom into several separate segments, so it will be much easier to remove it. When the interior is completely disassembled, there is no longer any danger from cutting.

Installation and welding

Further actions are also standard. We carry out work to prepare the body for installation of a new bottom:

- We thoroughly clean or treat corroded areas with a rust converter.

- If necessary, we install repair inserts or change elements that cannot be used in the future.

- Before we start replacing the bottom itself, we change or restore the sills and other power parts with a mandatory check of the body geometry.

- We prime all the junction points along which the welds will pass.

- We clean the bottom itself down to the metal, drill holes for welding, and prime it.

- If replacement is planned in separate segments, we arrange them so that the joints fall on the floor reinforcements. Be sure to overcook.

- After cleaning the deposits of metal and removing scale, thoroughly blow with compressed air, degrease and seal all welding seams.

We recommend not to refuse additional painting of the bottom from the interior side. This will not take much time, since we use infrared drying equipment. This coating will provide additional protection and will delay the reappearance of rust for another couple of years.

What additional things do we recommend doing when replacing the underbody of a car?

Before you begin reassembling the interior, we recommend taking advantage of some of the car's upgrade options. Thus, upon approval, we are ready to perform the following work:

- We will replace the electrical wiring, the condition of which is unlikely to be normal. Additionally, we will lay lines for connecting parking sensors, heated glass, amplifiers, subwoofers and other acoustic devices.

- Improve noise and vibration insulation by gluing several layers of STP or Shumoff materials. We will select options with different soundproofing capabilities that will minimally weigh down the body. This complete treatment will make the car interior more comfortable.

- And most importantly, do not give up anti-corrosion treatment on the outside of the bottom. We use only proven compositions of bitumen and polymer mastics. Coatings of this class extend the service life of the metal by 3-4 years. It would also be a good idea to check the condition of the anti-corrosion protection on the wheel arches, trunk floor, and rear side members. These areas are just as susceptible to rust as the bottom itself.

Upon completion of all agreed upon work, we begin reassembling the machine. All equipment that has been dismantled will be connected with a mandatory performance check. By the way, if you have a desire, we are ready to make changes to the interior of the cabin; styling provides ample opportunities for this.

To buy and replace the bottom of the car completely or partially, leave a request on the website or call us. If it is impossible to get to the service center on your own, we will provide a tow truck.