In general, I read a lot about the steering rack here and decided to check mine. He opened the hood and began to move the rod, a knock was clearly heard in his hand. I went to the store and bought a ten-size key for the steering rack.

Without removing anything, I easily stuck my hand into this nut and began to twist it.

The key turned 45° without much effort, I also tightened it 25-30° with some effort. I checked the traction rods again, there was no knocking, I immediately went to check, there were no knocking sounds, at the railway crossing too. But! The steering wheel began to turn tighter. Tell me, won’t this harm the EUR mechanism in any way? I just think this is a temporary solution, I will sort out the rack, but a little later. It was simply impossible to drive at all.

To tighten the steering rack you will need special wrenches

To perform the tightening you will need the following tools:

- Slotted screwdriver (in simple terms, a “flat” screwdriver);

- Wrench 13;

- A special 17mm wrench designed to adjust the steering rack.

To make the work more comfortable and faster, it is recommended to drive the car into a special inspection hole or overpass, and also use an assistant, whose role even a child can handle.

The lower rack fastening nut is not easy to unscrew

To get to the rail, you should perform a number of simple steps:

- Disconnect the battery terminals and dismantle it;

- Using a 13mm wrench, unscrew the bolt securing the battery stand, and then remove it;

- Directly under the steering rack, using a slotted screwdriver, you need to pull out the small plug of the adjustment system.

After this, you will have access to the nut responsible for adjusting the thermal gap in the rail.

Next, you need to put your hand under the steering rack and try to put the rack wrench on the nut. It is necessary to tighten the nut clockwise, but since the rack itself is located upside down, from the outside it may seem that the nut must be tightened counterclockwise. Experts recommend tightening the nut no more than 25–30 degrees at a time, after which you should try to rotate the steering wheel, which should turn without jerking or biting.

It is also necessary to listen to the sounds coming from the steering wheel - if there are no knocks when turning the steering wheel, and there are no other noises, then the rack is tightened correctly, and you can put the battery and rubber plug in their place.

The tightening process on video

How to tighten the steering rack on a Priora

VAZ 2170 Priora is a modern Russian-made car.

Like most modern cars, Priora is equipped with power steering. This, of course, makes driving a car much easier, making the steering smoother and lighter, and the car more maneuverable. It would seem that this mechanism has only advantages. Yes, that's practically true. But even here there was a small fly in the ointment. The Priora power steering has a key part that is vulnerable to the unevenness of our roads - the steering rack or, in automotive parlance, the “power steering gearbox”. It supplies force from the steering wheel to the drive wheels. This steering part is located between the steering propeller shaft and the steering rods.

The first sign that the steering rack needs to be tightened is the appearance of a knocking sound while driving over small uneven surfaces. You can hear it very well if you drive along a country road. Irregularities will hit the steering wheel and be transmitted into the driver’s hands, while being reflected throughout the car. In addition, when the steering rack adjustment nut is loosened on the highway, the car will have to be “caught” a little, that is, steered with the steering wheel. This will also become immediately noticeable.

How to avoid

To avoid the appearance of new knocks after repair, you must follow a few simple rules:

- Do not reach high speeds on uneven and gravel-covered roads, as well as when driving over potholes and potholes. And if you still can’t avoid this, be sure to ensure that the steering wheel is not in the extreme position at the moment the front wheels come into contact with the obstacle.

- Do not make sudden acceleration or braking when the steering wheel is in the extreme position.

- Do not drive onto curbs or high curbs.

Thanks to following these simple rules, knocks will not bother you for a long time, and the steering rack will last even longer.

How to tighten the steering rack

Of course you can. In fact, this process will not take you much time. And it does not require any special expertise, so there is no need to go to the service center for this.

In order to tighten the steering rack on a Priora, you will need:

- this article is a guide;

- special key for adjusting the rack to 17;

- inspection hole or overpass;

- flat blade screwdriver;

- key to 13.

It is recommended to perform this work with an assistant. Even a child or a girl can be used as it.

How to get to the adjusting nut

- Disconnect the battery terminals and remove it.

- Using a 13mm wrench, unscrew the bolt securing the battery stand and also remove it.

- From the inspection hole, look under the steering rack itself for the rubber plug of the adjustment mechanism. Pull it out with a flathead screwdriver.

Now you have access to a nut for adjusting the thermal clearance of the steering rack. Using a special key for adjusting the rack by 17, which can be purchased at any auto store, you need to tighten it so that the knocking noise disappears. In this case, you need to carefully monitor so that additional friction sounds do not appear and the steering does not become difficult to move.

The nut should be tightened no more than 25-30 o. Otherwise, when turning sharply, the steering wheel may “bite”. Therefore, ask an assistant to rotate the steering wheel, while you listen to the sounds from the steering rack. If the knocking noise disappears and no additional sounds appear, then the work is done correctly and you can install the rubber plug and battery in their places.

Source

Disassembling the steering mechanism

We disassemble the steering mechanism when repairing it. Remove the steering mechanism (see “Removing the steering mechanism”). Remove the steering gear boot (see “Replacing the steering gear boot”).

Remove the steering rod support. We insert the bit into the groove of the crankcase pipe mounting nut.

We unscrew the nut, striking the beard (right-hand thread)…

...and remove the crankcase pipe.

Use a screwdriver to press out the two clamps of the bushing located inside the pipe...

...and remove the bushing.

Remove the two rubber rings from the bushing (arrows indicate the bushing clamps).

If it is necessary to replace the nut, use pliers to remove the locking rings... ...and remove the locking ring... Remove the pipe securing nut.

Remove the rubber plug from the rack stop adjusting nut. Using a scraper, remove the jammed metal in the locking areas of the stop adjusting nut.

Using a special 24mm wrench with an external octagonal head, unscrew the stop nut.

We take out the stop spring. Using a screwdriver...

...remove the O-ring.

By hitting the crankcase against a wooden block, we knock out the rack stop. Using a screwdriver...

...remove the liner from the stop. A rubber ring is installed in the groove of the stop.

Remove the rubber ring from the crankcase that seals the hole for the steering mechanism on the front panel.

Remove the boot from the gear shaft. Use a 6mm hexagon to unscrew the two screws (shown by arrows)…

...and remove the crankcase cover.

Remove the separator with the thrust bearing rollers.

Remove the sealing ring of the cover.

We remove the rack from the crankcase.

We press out the gear shaft by holding the shaft in a vice with soft metal jaw linings and pressing the crankcase upward with the mounting blade.

We remove the gear shaft with bearing from the crankcase. We pry it off with a screwdriver...

...and remove the bushing retaining ring.

We take out the gear shaft bushing assembled with the support plate.

If it is necessary to replace the needle bearing, use a drill with a diameter of 4 mm to drill two diametrically located holes in the crankcase so that they extend to the end of the outer ring of the needle bearing. Through the drilled holes, using a rod of the appropriate diameter, we knock out the outer ring of the bearing from the crankcase.

Using a puller, we press the ball bearing of the gear shaft with the inner ring of the roller thrust bearing.

Use a puller to press the inner ring of the needle bearing off the shaft.

Using a screwdriver, pry and remove the gear shaft oil seal from the crankcase cover. If the outer race of the roller thrust bearing needs to be replaced...

... use a scraper to remove the extruded metal in four places and take out the ring. We generously lubricate the bearings, rack and gear teeth, and the plastic rack bushing with Fiol-1 lubricant. We assemble the steering mechanism in the reverse order. We press the outer ring of the needle bearing into the crankcase using a mandrel of suitable diameter. To seal holes in the crankcase, you can use “fast steel” or “cold welding”. We press the gear shaft with the ball bearing into the crankcase using a piece of pipe of a suitable diameter or a high head, applying force to the outer ring of the bearing. You can press the gear shaft into the crankcase, resting the outer ring of the bearing on the jaws of a vice. Then we put the crankcase on the bearing...

...and press the crankcase with light blows of a hammer through a wooden block.

We press the gear shaft seal into the cover through a mandrel or head flush with the end of the cover. We insert the rack into the steering gear housing. We install the pipe.

After tightening the pipe fastening nut, tighten the nut.

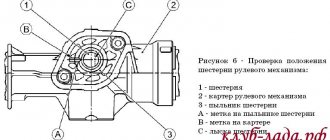

Scheme for monitoring the gap in the engagement of the rack and pinion shaft:

1 – dial indicator; 2 – indicator mounting bracket; 3 – nut; 4 – sealing ring; 5 – steering gear housing; 6 – needle bearing; 7 – gear shaft; 8 – bushing; 9 – crankcase cover; 10 – rack; 11 – liner; 12 – rack stop; 13 – indicator leg; 14 – spring

We rotate the gear shaft so that the flat on it is located on the right side. We move the rack so that the steering rod support mounted on the rack is located in the middle of the pipe groove. We insert the rack stop, the stop spring and tighten the stop nut. It is recommended to replace the stop nut with a new one. We adjust the gap in the engagement of the gear with the rack. To do this, set the rail in the middle position and block it from moving. Insert the leg of the dial indicator into the hole of the adjusting nut of the stop until the tip of the leg touches the stop of the rack. The diameter of the tip of the indicator leg must be at least 3.5 mm...

...so that the leg rests against the end surface 1 of the stop, and does not fall into its hole 2 (for clarity, shown on the dismantled stop). We apply a torque of 15 N m (1.5 kgf m) to the gear shaft, while the gear pushes the rack and stop. Based on the indicator readings, we determine the amount of movement of the stop, which corresponds to the actual value of the gap in the engagement. If it exceeds 0.05 mm, tighten the adjusting nut, achieving the specified amount of movement of the stop. After this, having unlocked the rack, we check the ease of rotation of the drive gear throughout the entire range of travel of the rack.

About the rake

The steering mechanism on Lada cars, starting with model 2108, has a steering rack. It is designed to move steering rods along a horizontal plane, which helps turn the car's wheels.

The design of the slats is quite simple and reliable, with the exception of one small drawback - a plastic bushing.

This bushing is made by the manufacturer from low-quality plastic, which soon leads to play in the rasp in it and the appearance of an unpleasant knock when moving on paving stones.

There is a rail between the engine and the passenger compartment, perpendicular to the exhaust manifold and attached with two brackets to the engine shield.

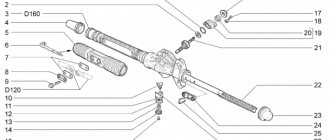

Design

Steering rack design: 1 – shaft boot, 2 – cover mounting bolts, 3 – Belleville washer, 4 – worm shaft oil seal, 5 – worm gear cover, 6 – sealing collar, 7 – thrust bearing, 8 – worm shaft with bearing, 9 – rasp, 10 – left boot, 11 – binoculars, 12 – binocular bracket, 13 – nut plug, 14 – thrust nut, 15 – thrust spring, 16 – locking collar, 17 – thrust piston collar, 18 – thrust rasp piston, 19 – piston liner, 20 – steering rod bolt, 21 – stopper, 22 – plate, 23 – plastic clamp, 24 – steering rack boot, 25 – left side boot, 26 – steering rack pipe.

Signs of play in slats

When driving over small irregularities such as a gravel road, shocks and knocks in the suspension are clearly audible and are transmitted to the steering wheel. These signs will not always refer to play in the rack. Similar impacts to the steering wheel can occur due to broken steering ends or a broken crosspiece of the steering mechanism. Before you begin repairing the rack, you must exclude the tips and steering cross from suspicion.

- Impacts to the steering wheel when driving over bumps

- Creaking sound when turning the steering wheel

- Biting the steering wheel in different positions

- The steering wheel does not return to zero position

Checking for play

Checking for play is done by rocking the swing arms up and down. To do this, we find the steering rods under the hood and pull each of them up and down; there should be no play or knocking. If any, then the rack should be maintained.

Steering of Lada Granta

It is designed to control the car while driving. Structurally, it consists of the following main elements:

The work of the mechanical part is that the driver acts on the steering wheel, the impulse through the steering mechanism and rack transmits force to the front wheels through the levers, and the car turns in the desired direction. A characteristic feature of a passenger car steering wheel is its smaller diameter (compared to a truck). The design of the mechanism also differs. The steering of the Lada Granta is complemented by an electric booster. The steering wheel can be adjusted in height. Unfortunately, there are no settings for departure.

The steering mechanism of the Lada Granta is rack-and-pinion type, the simplest and most inexpensive option.

The drive is mechanical, structurally consisting of levers, rods and hinges. For more efficient and convenient control, the Lada Granta is equipped with an electric amplifier. This is a complex mechanism that provides force through the use of electricity. An electric power steering, or simply EPS, is used to improve dynamic characteristics and controllability. And, according to some data, it allows you to save fuel by increasing the vehicle’s maneuverability.

Lift

If knocking is detected in the steering wheel, it can be tightened, but tightening will be effective only if there is knocking from the worm gear. If the knocking noise comes from a broken plastic bushing, then tightening is useless.

As is known from practice, the worm mechanism is quite reliable and is very rarely the culprit of knocking. Most often the bushing is to blame.

You can determine the culprit of the knock by pulling the steering rods one by one.

- If there is a knocking sound when applying forces to the right link, then the bushing is to blame.

- If there is a knocking sound when you apply force to the left linkage, then the worm gear is to blame.

In the first case, a lift is not advisable. Since the tightening nut only tightens the worm mechanism. To eliminate the knocking noise, it is necessary to remove the steering rack from the car and have it repaired.

Removing the steering column

If adjusting the nut does not help and the play remains, you will have to completely disassemble the rack and repair it. True, first you still need to dismantle it, which is also not easy. There are two methods: with removing the steering rods and without removing them. Preferable and easier, of course, is the method without removing the steering rods, since it takes less time. Before starting dismantling, you need to jack up the front of the car. This is done in order to completely relieve the steering rods, otherwise you simply will not be able to dismantle the steering rack. So, let's start disassembling. Inside the car, where the pedal block is located, find and unscrew the steering shaft cardan bolt. Next, move to the engine compartment and there you will find the mounting bolts on the rods and unscrew them. Don't forget to bend the locking plate first. After this, unscrew the four fixing bolts that secure the steering column to the car body. All fasteners are unscrewed, carefully move the steering column and remove it through the opening under the left wheel arch.

Repair kit

In a Priora with an EUR, a rack from Kalina was installed with catalog number 11183-3400010 20. Therefore, the repair kit must be purchased specifically from Kalina.

Steering rack number

The repair kit includes a large number of parts necessary for repairs.

The price of a new rack starts from 5,000 rubles and higher, depending on the manufacturer, but new does not mean good, and the cost of a repair kit varies from 500 to 1,000 rubles, which is almost 10 times cheaper than a new rack.

How to tighten the steering rack on a Priora: tips and instructions, nuances with ESD and power steering, videos on the work

Lada Priora is a Russian-made car that is highly popular among our compatriots due to its low price and attractive appearance. However, even despite this, the Lada Priora has one vulnerability associated with the poor quality of the road surface - the steering rack or, in the language of specialists, the “power steering/power steering gearbox”. Fortunately, you can tighten it with your own hands.

When does the steering rack need to be tightened on a Priora?

The steering rack is a vulnerable point for Lada Priora

The first sign indicating the need to adjust the rack is the appearance of a knocking sound when driving over small uneven surfaces. The knocking will be felt especially clearly when driving on country roads. In this case, the driver will feel shocks and vibrations on the steering wheel, which will also be transmitted to the entire car body.

In addition, if the steering wheel adjustment nut is loosened when driving on the highway, the car will “float” a little, and additional steering will be required from the driver, which will also immediately become noticeable.

Experts also say that a tightening is necessary if the driver begins to notice the appearance of a clearly audible crunching sound in the area of the steering column, as well as an increase in the amplitude of the steering wheel rotation.

When tightening doesn’t help and the mechanism needs to be changed

It’s worth thinking about replacing the rack when tightening it does not in any way affect the car’s behavior on the road, and also does not help get rid of the unpleasant knocking noise. A failed steering rack will cause significant play in the steering wheel. Moreover, it may begin to jam (this happens extremely rarely, but similar cases are known). If the rack begins to jam, then it is better to stop using the car, as this can lead to the most dire consequences.

You cannot do without a replacement even if after tightening it you managed to get rid of knocks and vibrations, but they reappeared later.

What is needed for work and how to tighten the steering

To tighten the steering rack you will need special wrenches

To perform the tightening you will need the following tools:

- Slotted screwdriver (in simple terms, a “flat” screwdriver);

- Wrench 13;

- A special 17mm wrench designed to adjust the steering rack.

To make the work more comfortable and faster, it is recommended to drive the car into a special inspection hole or overpass, and also use an assistant, whose role even a child can handle.

The lower rack fastening nut is not easy to unscrew

To get to the rail, you should perform a number of simple steps:

- Disconnect the battery terminals and dismantle it;

- Using a 13mm wrench, unscrew the bolt securing the battery stand, and then remove it;

- Directly under the steering rack, using a slotted screwdriver, you need to pull out the small plug of the adjustment system.

Tips for use

A complete replacement and repair is a series of actions, for the implementation of which you need to have not only special knowledge, but also a considerable amount of free time, so if the car owner does not have either the first or the second, it is preferable to go to the nearest service station.

It is better to entrust steering rack repair to service station specialists

At the same time, in order not to become their regular guest, you should know some secrets for operating the steering rack, which can significantly extend its service life.

- We strongly do not recommend “jumping” your car on curbs, or driving at high speed on rails, since each such trip causes cracks to appear on the rack itself, as well as deformation of the shaft that is part of the steering mechanism.

- It is not recommended to frequently turn the steering wheel all the way. Of course, in this case it will be very difficult to demonstrate your maneuvering capabilities, but this will significantly increase the life of one of the most important parts of the machine.

- Carefully monitor the condition of the protective anthers, which must maintain their tightness. Replacing anthers is several times cheaper than replacing the entire rack.

- It is also worth monitoring the level and condition of the hydraulic fluid, since its decrease or change in color is associated with problems in the vehicle’s hydraulic system, which can result in rack failure.

From time to time you need to undergo a full maintenance, which will allow you to eliminate faults in advance, which can cause irreversible consequences, injury to yourself, your loved ones and other road users. And also, if problems are detected in the operation of the car, it is better not to take risks and go to the nearest car service center as quickly as possible.

Key for tightening the Priora steering rack

In general, I read a lot about the steering rack here and decided to check mine. He opened the hood and began to move the rod, a knock was clearly heard in his hand. I went to the store and bought a ten-size key for the steering rack.

Without removing anything, I easily stuck my hand into this nut and began to twist it.

The key turned 45° without much effort, I also tightened it 25-30° with some effort. I checked the traction rods again, there was no knocking, I immediately went to check, there were no knocking sounds, at the railway crossing too. But! The steering wheel began to turn tighter. Tell me, won’t this harm the EUR mechanism in any way? I just think this is a temporary solution, I will sort out the rack, but a little later. It was simply impossible to drive at all.

To tighten the steering rack you will need special wrenches

To perform the tightening you will need the following tools:

- Slotted screwdriver (in simple terms, a “flat” screwdriver);

- Wrench 13;

- A special 17mm wrench designed to adjust the steering rack.

To make the work more comfortable and faster, it is recommended to drive the car into a special inspection hole or overpass, and also use an assistant, whose role even a child can handle.

The lower rack fastening nut is not easy to unscrew

To get to the rail, you should perform a number of simple steps:

- Disconnect the battery terminals and dismantle it;

- Using a 13mm wrench, unscrew the bolt securing the battery stand, and then remove it;

- Directly under the steering rack, using a slotted screwdriver, you need to pull out the small plug of the adjustment system.

After this, you will have access to the nut responsible for adjusting the thermal gap in the rail.

Next, you need to put your hand under the steering rack and try to put the rack wrench on the nut. It is necessary to tighten the nut clockwise, but since the rack itself is located upside down, from the outside it may seem that the nut must be tightened counterclockwise. Experts recommend tightening the nut no more than 25–30 degrees at a time, after which you should try to rotate the steering wheel, which should turn without jerking or biting.

It is also necessary to listen to the sounds coming from the steering wheel - if there are no knocks when turning the steering wheel, and there are no other noises, then the rack is tightened correctly, and you can put the battery and rubber plug in their place.

How to tighten the steering rack

Before we begin describing this repair, if it can be called such at all, let's look at the main reason why you have to tighten the steering rack on a Priora.

So, I think that many owners know that when a knock appears from the steering rack or its rod, it is necessary to make an adjustment, or rather, tighten the rack using a special nut, which is located on the inside of the case, which is clearly visible in the photo below.

To understand where this nut is located, look at the photo below, everything is shown from above - from the hood side, of course, in this case this nut is located on the reverse side:

To get to this adjusting nut, you will most likely have to remove the battery, since without it there is more free space under the hood. Although the good news is that even the battery in the Priora does not interfere with this repair (unlike cars such as Kalina or Granta).

It is worth noting that you may need the following tools for work:

- 10mm wrench or socket wrench

- key for 13

- the key for tightening the rack is exactly 2110 and not 2108

Now, using a special key from the inside, as shown in the photo below, insert it into the hole:

Tools

In general, repairing the steering rack on a VAZ-2114 car is not such a difficult task, but one set of keys is not enough. For successful dismantling, we will need a special control rod puller, a 17mm hexagon, a chisel, a set of open-end and ring wrenches, as well as Litol lubricant and WD-40. As a last resort, you need to treat the surface of the rail approximately a day before the proposed work - this will ensure quick and comfortable removal of all fastening parts. And you need to apply WD-40 to the following parts: 4 nuts securing the device, the stop tightening mechanism and the thread of the tips. After a couple of hours, you need to go through all these elements again.

Adjusting the VAZ-2112 steering rack: photos and videos, useful tips

There is an opinion among VAZ-2112 owners that the steering rack is very difficult to adjust, and sometimes only needs to be replaced. We absolutely tell you that this is not so!

The video shows the process of adjusting the steering rack on the front-wheel drive family of VAZ 2110-2112 cars.

Easily!

Thanks to the design of the car, any car enthusiast can easily remove and adjust or adjust the steering rack on the spot, because you just need to carefully read our instructions.

Causes of steering rack malfunction

If while driving, often on uneven roads, you find that all the vibrations are transmitted quite strongly to the steering wheel, then most likely the steering rack needs to be adjusted.

How to carry out this work in two different ways is written below.

Tighten the steering rack

Before you begin tightening the steering rack, you need to prepare a special wrench, which is made in the shape of an octagon with a diameter of “17”.

If you have such a key, tightening the rack can be done without difficulty.

And for the best access to the rail, it would not be amiss to have an inspection hole or a lift.

Step-by-step work order

- First of all, lift the hood and pay attention to the free space under the master cylinder.

- Next, take a flat-head screwdriver, as well as a flashlight or carrying lamp for the best visual access.

Everything is ready for work

We get to the steering rack nut from the rear of the subframe and follow the steering rack body to the part where it intersects with the steering shaft. This adjusting nut is located nearby.

The arrow indicates the location of the adjusting nut.

- Please note that most inexperienced car enthusiasts confuse a nut with a plug . A distinctive feature of the nut is the thick layer of dirt that is located on its body and its octagonal shape .

- Since the nut is closed from the factory with a special plug, it will be almost impossible to make adjustments without dismantling it. And in order to remove it from the seat, use a flat screwdriver, prying it off the edge of the base.

- Once it is removed, take the key you prepared earlier and insert it into the base of the nut.

Although visibility is minimal, it is possible to make a replacement. - Next, slowly move clockwise, turning the key 15-20 degrees, tighten it until the backlash disappears.

- Flat blade screwdriver.

- Hammer.

- Key or heads for “10”, “13”, “15”, “17”, “19”, “27”.

- Pliers.

- Special wrench for tightening the steering rack.

Please note that you should not tighten it all the way!

Diagnostics of rack tightening

You can diagnose the degree of tightening in the following way.

Turn the steering rack first in one direction, then in the other direction with sharp movements. And if during such manipulations no extraneous sounds arise, this will mean that the rail is tightened and in good condition.

After carrying out such work, you can reassemble everything in the reverse order, first of all this concerns the engine crankcase protection.

Tightening the steering rack on a removed mechanism

Before you start working, you need to prepare the tool:

When the tool is assembled, you can start working.

Removing the unscrewed rail

In order to remove the rack now, it is necessary to free it from the rotary arms to which the tie rod ends are attached.

- Having a “19” key on hand, loosen, but do not unscrew the nut that secures the ball pin.

By disconnecting the cotter pin, the bolt will easily come out of its place of fixation.

In this case, it is possible to apply light blows to its body. When it is removed, you can easily unscrew the tip completely.

This will allow us to maintain the approximate wheel alignment angle when assembling it.

- When the tips are dismantled, nothing will stop us from getting the entire rail from its place.

The process of adjusting the steering rack on a VAZ-2112

- Adjustment of the steering rack should be carried out with the device clamped in a vice . This is necessary so that it remains motionless in this state, and if necessary, bars are placed on its edges.

So, the nut will tighten easily.

Please note that there are two types of steering racks, with and without power steering.

Installation of the steering mechanism

- Before installing the rack, make sure that all connections are secure and that the adjusting nut is capped.

- Then inspect the condition of the steering tips; if their diagnostics reveals any play, they must be replaced with new ones.

- Otherwise, we install the steering rack in the same order as removal.

If you follow our instructions exactly, all work can be completed in the shortest possible time and without additional costs.