Many Russian cars are widely known for their various “sores,” and problems with the steering mechanism are one of them. With frequent driving on broken city roads, as well as uneven dirt roads, unpleasant knocking noises may appear from the steering rack, and this malfunction can appear after the first 10,000 kilometers.

In the video, adjusting and “tightening” the steering rack on the Lada Kalina:

Therefore, it is very important to know how to tighten the steering rack with your own hands, using only a special tool, without going to a dealer or specialized workshops.

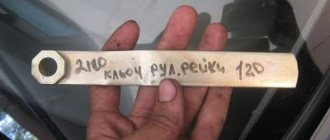

Wrench size for adjusting the Kalina steering rack

To adjust the steering rack clearance, hex and octagonal keys with a range from 10.0 (mm) to 55.0 (mm) are used.

A steering rack wrench is a special wrench that is inserted into the adjusting nut in the steering gear housing.

As a standard, wrenches with the following characteristics are used to tighten steering racks:

- Key for adjusting the gap (hexagon): from 10.0 (mm) to 55.0 (mm);

- Key for adjusting the gap (octahedron): from 17.0 (mm) to 24.0 (mm);

- Key for locking the locknut (open-end): from 24.0 (mm) to 54.0 (mm).

According to GOST 2838-80 ('Spanners') and GOST 11737-93 ('Wrenches for hexagon socket screws'), the tolerance dimensions for steering rack keys are:

- Key for adjusting the gap (hexagon): ±0.15;

- Key for adjusting the gap (octahedron): ±0.15;

- Key for locking the locknut (open-end): +0.72.

The strength of open-end wrenches is determined by the torque. Thus, according to GOST 2838-80, the test torque of keys 24.0-54.0 (mm) must be at least 143.5-858.0 N/m.

Important: before it needs to be tightened with a wrench, the new steering rack can move without knocking from 20,000 (km) to 40,000 (km).

| General view General parameters of keys for steering racks | Key for adjusting the gap (hexagon) Key for adjusting the gap in the gearing of the steering rack of a car |

Data are presented in millimeters.

| Parameter Description of parameter |

| Make and model of the car Name of the make and model of the car |

Caution: The above data are official figures from manufacturers, but please note that the information is for reference only and is not guaranteed to be completely accurate.

Comments. Have questions? We will answer everything.

Source

Lifting the Kalina steering rack with removal

You will need : a special key for the Kalina steering rack (suitable for VAZ 2110), remove the steering rack along with the rods (mustache).

We fix the steering rack in a vice, placing bars so that it does not move. We take the rods of the racks (whiskers) with our hands and shake them, determining the amount of play. Now, to remove play in the Kalina steering rack, you should use a special key. We insert it and turn it counterclockwise about 10-15 degrees, after which we shake the mustache with our hands again. If during the next check the rack play remains, then tighten the rack again by 10-15 degrees. We do this until the play in the rack disappears altogether.

The output is different in each case, so there is no specific tightening torque. Please note that you cannot overtighten the steering rack, otherwise the steering wheel will be difficult to rotate. After the steering rack is adjusted, you need to tighten the stop nut by hammering the crankcase threads.

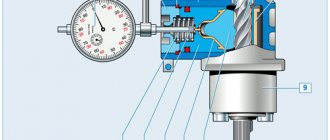

By the way, this is what the instructions for adjusting the rack from the service manual look like: Checking the gap between the rack stop and the stop nut

- Remove the steering gear from the car.

- Set the rack to the middle position, which is determined by the size (87±0.25) mm from the gear axis to the end of the rack. Using a special device, load the rack with a force P = (500±20) N, or (51±2) kgf, at a distance of 84 mm from the gear axis in the direction of the rack stop.

- The maximum permissible gap between the stop and the nut is 0.2 mm. The maximum permissible movement X of the rack, measured through the relative movement of the pressure punch 1, should not exceed 0.16 mm.

Tightening process, video

There are several ways to tighten. One of them is the method of removing the slats. The removed rail is clamped in a vice and then, using a special wrench, the nut is tightened 10-15 degrees by turning it counterclockwise.

This is followed by a check for backlash and, if necessary, the procedure is repeated, since the backlash can be more or less. It is not advisable to overtighten, it will be difficult to rotate the steering wheel. The advantage of this method is the ease of adjustment, but the disadvantage is that you have to remove and then put the steering rack back in place, and this requires time, certain knowledge and skills.

The second method is simpler, it does not require removing the steering rack, you just need to remove the battery and the platform under it with four bolts, but it is much easier and faster than removing and installing the steering rack. This way we gain access to the steering rack and steering rods.

We take hold of the rod with our hand and begin to shake it with force. A characteristic knock will immediately indicate the presence of play. The stop nut is located on the rack behind the left link from the bottom; you need to feel it with your finger. Now the task is to get the wrench into the nut and then turn it counterclockwise. We check for play and, if necessary, tighten it further.

But in the video there is another tightening option, even without removing the battery:

How to tighten the steering rack on Kalina without removing it

Despite the fact that the repair manual for VAZ 1117, 1118, 1119 says that to adjust the steering mechanism it should be dismantled, craftsmen tighten the rack directly on the car to save time and effort. The most convenient way to get to the adjusting bolt is from below, using the inspection hole.

The adjusting nut is on the bottom, so if you look at it from below, then tighten the rack clockwise; if you can get to it from above, then counterclockwise. To determine the rack play, we use the steering wheel rather than our hands. The rest of the process looks similar.

If, even after adjustment, the steering rack on Kalina rattles again, then it should be replaced with a new one, or try to repair it.

Do you know that in order for the steering rack to last longer, you should change the boots on time.

Source

Repair, price

A lift is a fairly simple and quick way, but often it is only a partial, temporary solution to the problem. After all, the appearance of play can be caused by various reasons - the boot may be damaged, gaskets may leak and who knows what else, that is, there is a high probability that the steering rack is running dry. In this case, there is a risk that a short time after tightening it may simply jam. Therefore, troubleshooting the rack will be very useful, at least an external inspection, it will make sure that the anthers and corrugated casing are not damaged.

If you suspect the need for repairs, consider whether you can handle it yourself. Get ready for the fact that you will have to spend the whole day in interesting positions, and you will also need an assistant to perform some operations. Do you know how to install the rack so that the steering wheel is level? If not, you risk having to do the installation again.

An alternative is a service station. They will charge you around 3,500 rubles for repairs, 200 rubles and another 200 will be spent on anthers and so on.

Wrench size for adjusting the Kalina steering rack

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

there is a key for the 08 model, and there is a key for the 10 model, and on the old tens they installed only the mustache from the tens from the 08 model

Well, it costs 80 rubles somewhere, so why strain your brains?

45 rubles in auto49, it’s nonsense to save in this way. crazy

I saw someone who likes to save money. himself - the housekeeper - that one, but such

yes do it, who is against it?)

I found that the key goes to 24, but I’m also interested in the diameter of the shaft at the steering rack, since the key comes with a hole for the shaft

What are you writing about, about the rack tightening nut or the steering shaft housing cover? On the 10th there is no threaded cap for a hexagon, there is a cap for 2 screws with an internal hexagon.

I found that the key goes to 24, but I’m also interested in the diameter of the shaft at the steering rack, since the key comes with a hole for the shaft

What are you writing about, about the rack tightening nut or the steering shaft housing cover? On the 10th there is no threaded cap for a hexagon, there is a cap for 2 screws with an internal hexagon.

All this can be found in the directory of designer ANURYEV

Source

Dismantling and disassembling the electric amplifier

Before removing the amplifier, you need to remove all the steering column switches. Remove the steering rack cover and dismantle the devices, remembering to disconnect the connectors from the power supply.

How to remove the EUR with your own hands:

- After removing the switches, you will need to dismantle the lower cross member of the dashboard. To do this, you need to press the fasteners that secure the connector with wires, and then disconnect the wiring from the control module. Once these steps are completed, you can disconnect the connector from the switches.

- The system bracket is secured with nuts; you will need to unscrew them with a wrench.

- After this, the steering rack will need to be carefully lowered down. To do this, you will need to find the bolt that secures the driveshaft to the booster shaft. This bolt must be unscrewed, but when unscrewing, you will need to fix the nut, this will prevent it from turning. When the bolt is removed, the fastening will need to be loosened, after which the intermediate shaft will be carefully removed. At this stage, we recommend marking the position of the shaft and gears; you can use a marker for this. This step is very important because doing it will prevent possible installation problems in the future. If the marks on the shafts do not match, this may cause problems with the amplifier. When dismantling, be careful not to damage the wiring, as this will also lead to the inoperability of the ESD.

- When the unit is dismantled, it will need to be disassembled and the failed elements replaced. Further editing is done in reverse order (the author of the video is Murzik Bely).

We adjust the Kalina-2 steering rack to eliminate knocking

Cars of the Kalina-2 family are equipped with a steering rack similar in design to the Granta rack. This part transmits force from the steering wheel to the front suspension links. If you feel a knocking sound from the rack while driving, it needs to be adjusted (tightened) correctly. The effect described here can be observed after 10-15 thousand kilometers, and more often it makes itself felt on uneven roads. Next we consider how this problem is solved in practice. And the solution comes down to turning one nut.

How the control system works in Kalina

In the model of the domestic automobile industry we are considering today, the steering rack, if disassembled from a technical point of view, is a mechanism that structurally looks like a gear, which in turn is installed on a shaft and is associated with special rods and a rack. Thanks to these elements, the car turns when moving the steering wheel in a certain direction allows the front wheels to move in the same direction.

Modern cars have 3 variations of the rack and pinion mechanism:

- Electric steering mechanism;

- Hydraulic modern mechanism;

- Mechanical mechanism.

So, the car control system is an electric drive. This is what helps reduce the load on the driver. In this case, the increase in turning force is carried out due to a special electric motor built into the column, so to speak. This device is used exclusively on premium and, accordingly, luxury cars. For example, in our Lada Kalina, the electric mechanism can be obtained as an additional option for an additional payment for the TOP configuration.

The next option is a hydraulic mechanism. Viburnums of the first and second generation are equipped with this mechanism. Owners of such cars receive sharpness and lightness of the steering wheel. And not only Russian cars, but also many modern foreign models are equipped with the popular and most convenient hydraulic drive.

The mechanical mechanism is the simplest in its design and is also found on many machines. In this case, as you understand, the rods will be turned only through the use of the driver’s physical force. It is clear that such a car is extremely difficult to drive.

In addition to the above mechanisms, there is also a mixed version - electrohydromechanical. It combines all the best qualities of an electric and hydraulic amplifier. You can find it on the Kalina Sport model.

Let us note that each of the systems we have listed has its own advantages, and to some extent disadvantages, but they all break down with the same frequency. If a breakdown of a mechanical control rack will lead to insignificant costs for repair work, then electrical and hydraulic breakdowns will force you to spend a fair amount of money on repairs. It follows that it would be nice to know how to tighten the steering rack on the car we are considering with your own hands.

A little theory: front suspension design

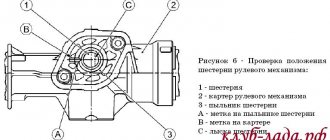

Before attempting to fix any problem, there is a tendency to look at the blueprints or repair manual. It is known that the VAZ-2192 parts catalog contains the following object:

This is what the steering rack looks like in the drawing

Whether the knock will remain in the steering rack of Kalina-2 depends on the following: how accurately element “14” is adjusted. The adjusting nut, marked “14”, looks almost invisible here. But first impressions are deceiving. In the catalog, by the way, the element is called “Stop Nut”.

It is important to know that the thrust nut has external threads. And it spins clockwise. And the words “tighten the rack” mean screwing in the specified nut, and nothing more.

Now let's move on to practice and see what the node in question looks like in reality:

If you remove the rail, it looks like this

The nut has a non-standard notch, and it can only be rotated with a special tool. By the way, the recess will be closed with a cap. In the catalog it is designated by the number “15”, and now, let’s look at the appearance of the special key:

Rack adjustment key

The thrust nut is turned at small angles. We are talking about values of 10-15 degrees. What happens if you overdo it with tightening the rack? The knocking noise will disappear, but the steering wheel will turn with difficulty. Therefore, if necessary, the nut can be pulled back.

Causes of bearing failure

The main cause of support bearing failure is dust and water, which inevitably penetrate inside. The lack of lubrication does not have the best effect. Sharp blows to the rack will not add to the service life

It is worth taking into account the quality of roads, because they have a direct impact on the natural wear of the support bearing. That is why with us, a part can wear out faster than its manufacturer claims

Dirt and sand are some of the hardest impacts on a bearing. We remember that a journal bearing is a type of rolling bearing, and it does not have any protection mechanisms against harmful factors. Driving at high speeds and harsh brakes, especially on bad roads, also do not add to the service life of the part in question. However, not only the bearing itself suffers from this, but also all other suspension elements as a whole will soon require repair.

Lyrical digression

In Lada Kalina, the steering rack never makes a knock when we are talking about a new car. This is also true for the break-in period. Let's say in your case this is not done. Then, do not try to repair anything, but go straight to the dealer. According to reviews, the defect in question is covered under warranty, and most car dealers do this: the steering rack assembly is replaced with a new one.

This is what the replacement unit looks like, the rack assembly

There is a logic here. At the factory, adjustments are made correctly (this is true in 99.9% of cases). If a defect appears, the dealer replaces the assembly without expecting that adjustment will solve the problem. The owner does not need to hope for this either. The choice is yours.

We change other details

We also pay attention to how the steering rack looks externally. “Kalina” can keep many secrets regarding maintenance, so if there is the slightest doubt about the serviceability of the rack elements, we replace them with new ones. Otherwise, you will have to remove this part again. The components themselves can be purchased in a repair kit. This will not pose much difficulty for the modern car enthusiast. Having replaced and adjusted all the necessary components, we assemble the rack in the reverse order. That's it, the repair has been successfully completed.

Making adjustments yourself

You can access the adjusting nut from the engine compartment, but to do this you will need to remove the battery, as well as the battery mounting pad. It is better to drive the car into a pit and then remove the crankcase protection (engine mudguard). If you look from under the bottom, the required element is immediately visible:

You need to turn this nut

And when you open the hood, you can feel the nut, but not see it. Its location is marked in the figure:

To make adjustments, place the key here

Before adjustment, remove the rubber cap from the recess. Its appearance is shown in the photo:

Remove the cap and install the key

If it is not entirely clear what exactly needs to be done, it is better to contact the service. The key is installed in the recess and then rotated 10-15 degrees.

When looking at the rack from above, turning the key clockwise corresponds to unscrewing it. The handle of the key comes from the center of the car - which means tightening is being done. By the way, the latter is true provided that the handle faces forward.

Malfunctions of RM Kalina and ways to eliminate them

Even the most reliable mechanisms wear out, especially if they are not protected from dust, dirt, water and aggressive environments. Although the steering rack of the Lada Kalina is located under the hood of the car and is protected from below by a pallet, during operation, especially in off-road conditions, it is exposed to all of the listed factors. The main malfunctions of the PM can be grouped into three groups:

- large free play of the steering wheel;

- knocking, noise and creaking in the mechanism;

- tight steering wheel.

Increased play, squeaks and knocking of the Kalina PM can be caused by:

- loosening the tie rod nuts,

- wear of their tips and silent blocks,

- loosening the PM fastening nuts,

- large gap between the rack and the adjusting nut.

These faults are easy to fix: you need to tighten the nuts and pin them where necessary, and replace the silent blocks with new ones.

Difficulty turning the Lada Kalina steering wheel can be caused by more serious reasons:

- wear of the bearings of the upper support of the steering column upper universal joint,

- damage to the rack support bushing,

- failure of the telescopic strut of the front suspension,

- faulty electric power steering or low tire pressure.

Many Lada Kalina owners are interested in whether it is possible to replace the standard rack with a mechanism of a different design. It's possible, but not necessary. The manufacturer does not structurally provide for the replacement of the rack and pinion steering mechanism with other types. Worm or screw PMs simply won't do. To facilitate steering wheel rotation, an electric power steering is installed on all Kalina models.

Preparatory actions, dismantling unnecessary parts

To remove the crankcase protection, you need to unscrew 4 screws located in one row near the bumper. Also, unscrew two screws having a standard size of M6x16. In some configurations, the protection consists of two parts, but in this case they are attached only with self-tapping screws. These words are illustrated by the following photo:

This is how the crankcase protection works in different configurations

First, unscrew the “10” screws, and then the two “18” screws. In the second case, there will be more screws (eight).

Now let's look at how to remove the battery. First of all, disconnect its terminals. Then, you need to move the additional fuse box to the side. In general, actions are performed according to the photo:

You also need to remove the mounting platform itself, for which you unscrew 4 screws. You will need a 13mm wrench, as well as a 10mm spanner. We will repeat the entire sequence again:

- Unscrew the nuts holding the battery terminals using a wrench 10;

- Remove both terminals;

- Move the fuse box to the side by unscrewing 2 fastening screws;

- Unscrew the nuts with a 10mm wrench and remove the battery;

- Unscrew the screws with a 13mm and remove the metal plate.

Just in case, here is a look at the fuse box mountings:

Mounting screws are located under the casing

Manuals usually recommend removing the negative terminal first. But when it comes to dismantling both terminals, the order in which they are disconnected is not important.

Diagnostics of the condition of components and troubleshooting

After carrying out a visual inspection of the suspension of the Lada Kalina, which will allow you to find out the cause of the knocking, you can proceed to dismantling the faulty elements. For example, car shock absorbers. Diagnostics are carried out by placing the car over an inspection hole or using a jack

Particular attention is paid to elements adjacent to the body or car frame

Diagnostics involves a thorough examination of the suspension elements, the presence of various damages, cracks and breaks on them. If a breakthrough is detected in the rubber protection of the steering tip, it must be repaired. Rubber seals are inspected for mechanical damage and those areas where there are breaks and cracks are identified.

As a result of a muffler breakage, a knock will be heard in the suspension. To identify the cause of such sounds, which may lie in the exhaust pipe, the muffler should be rocked in different directions. This is a quick way to diagnose the front suspension. After this is completed, you can proceed to suspension repair.

The front suspension consists of: 1 — nut for securing the upper strut support; 2 - bolt; 3 — upper support of the front suspension strut; 4 — bearing of the upper support of the strut; 5 — upper insulating gasket of the spring; 6 — front suspension spring; 7 — protective casing; 8 — telescopic stand assembly; 9, 10 — nuts securing the strut to the steering knuckle; 11 — bolt with eccentric; 12 - bolt; 13 — steering knuckle; 14 — front wheel drive shaft; 15 — stabilizer bar; 16 - stretching; 17 — lever; 18 — ball joint; 19 — hub; 20 — hub fastening nut; 21 — brake disc; 22 — front suspension compression buffer; 23 — upper spring cup; 24 — compression stroke limiter of the upper strut support; 25 — travel limiter of the upper strut support; 26 — stabilizer strut mounting nut; N - reference size

It is possible to eliminate various malfunctions that occur in the front suspension of the Lada Kalina car if their cause is known. If there are faulty front suspension struts that can knock, they should be replaced. In some cases, they can be repaired.

If during the diagnosis it was revealed that the bolts that secure the stabilizer bar that provides lateral stability to the car body are loose, then they need to be tightened. Worn rubber or rod pads are replaced.

If the fastening of the upper support of the Lada Kalina suspension strut is loose, then it is necessary to tighten the nuts securing this unit. If the front suspension exhibits destruction of the rubber support of the strut, then it must be replaced. If the rubber-metal hinges (silent blocks) are worn out, new ones should be installed.

The presence of a malfunction in the stabilizer bar struts requires replacement. If the front suspension spring settles and the front suspension spring breaks, it should be replaced. If the compression stroke buffer is destroyed, it is dismantled and a new one is installed. If there is increased wheel imbalance, you should contact a tire repair shop so that specialists can eliminate the identified malfunction.