We have already complained more than once that today it is becoming more and more difficult for drivers to diagnose their own cars, especially while driving. The toolkit is constantly shrinking. Let's say that voltmeters have disappeared from dashboards like mammoths, and the driver learns about all problems with charging after the fact from a message from a laconic warning light. But even with the lamp, not everything is so rosy, they don’t talk about it in driving schools, in the instructions for the car there is only the phrase “contact the service center.” Most drivers roughly imagine that it is responsible for charging, but how exactly and what exactly it shows is something that not everyone understands.

Operating principle of the warning lamp

We have already written more than once about how the generator works; we would not like to repeat it. The operating principle of the control lamp is tied to the generator, although it is still a separate element. It's quite simple. Two electrical circuits are connected to the control lamp, which in a simplified form look like this:

1. The first circuit from the lamp runs through the fuse block to the ignition switch, from it to the generator and then to the battery.

2. The second circuit directly connects the generator and the test lamp.

The question arises - why are there two circuits and why are they both connected to the generator? That's the point. The control lamp depends on the current at both inputs; when the voltage is the same, the lamp goes out, when it differs, it lights up .

Imagine we turn on the ignition. In the first network, voltage came from the battery to the control lamp, but in the second it was empty, the engine did not work, the generator did not produce current, so the lamp lights up. And it will burn as long as the ignition is turned on.

But then we start the engine, the generator starts working and voltage appears in the second circuit; moreover, the first circuit also starts working from the generator. The same voltage is applied to the terminals of the control lamp, and it goes out. Some drivers believe that the warning light coming on before starting the engine is a diagnostic of the system, but in fact the car does not ring or check anything, it simply determines whether charging has started or not.

Now let’s imagine that the generator breaks down on the road. In the second circuit, the voltage has disappeared, but in the first circuit, power still continues to flow, but from the battery, so the warning light lights up again.

If the light is on

Some repair articles categorically state that a burning lamp is necessarily a problem with the generator. As is not difficult to see from the principle of operation, a lamp can burn for other reasons.

2. Open circuit between the ignition switch and the lamp.

3. Open circuit between the generator and the lamp.

It is easy to diagnose these problems using the elimination method; in the first two cases, the lamp will not light up when the ignition is turned on, and in the third it will light up, although the multimeter will show that the battery is charging. The repair is tedious, but simple - we check the contacts, nick the wires, replace the burnt out parts, and restore the integrity of the circuit.

To be fair, we note that such situations are still not very frequent, and in most cases, problems with the generator actually lead to a lamp fire , although on various forums we have come across stories of drivers who checked a working generator many times, although the problem was precisely in the circuits control lamp. It's always worth keeping this possibility in mind.

In all the situations listed above, charging is still going on and you can continue driving, but it still makes sense to do repairs. If the battery light is constantly on, it will not indicate anything if the generator actually breaks down, and no one is immune from this.

Fortune telling by lamp

Sometimes the warning light may not just light up, but glow at full intensity, flash, or light up only when the speed increases or decreases. Sometimes it is suggested to carry out diagnostics based on this behavior. It is believed that a burning lamp only at high speeds is a problem with the belt, slip rings or brushes, only at low speeds is a malfunction of the voltage regulator, flickering at full heat is a breakdown of one of the diodes of the diode bridge. But this diagnostic method must be called very unreliable. All of the above reasons can lead to this behavior of the lamp, but the problem may be completely different. In any case, you need to check everything.

When the ignition is turned on, the battery (generator) lamp does not light up.

The battery light does not light up when you turn on the ignition. If the battery light does not light up when you turn on the ignition, then this is a reason to conduct a full test of your car.

This type of problem is quite common; almost every experienced motorist encounters it. The danger of this malfunction is that a breakdown can occur somewhere far from crowded places, at night in winter. Then repairing or replacing a damaged part will not be so easy.

Before starting diagnostics

An important point in deciding why the VAZ 2107 or 2106 battery charging light is on is the very fact that voltage is supplied to the battery from the generator. In other words, if it does not reach the battery at all, there is nothing to be surprised about. The lamp must light in such a situation. But if the battery charging light is on, but there is charging, it will be a little more difficult to solve this problem.

Our first priority is to determine whether voltage is supplied to the battery. This is not at all difficult to do, especially since this requires only one device - a voltmeter or multimeter turned on in its mode. We start the car engine, raise the hood and measure the voltage at the battery terminals with the generator running. If all elements of the system are working properly, the voltmeter should produce 13.6-14.2 V, and no less. This is a working indicator for normal battery charging. If the voltage is below these values, then there is some kind of malfunction.

How to determine that there is a malfunction?

Every time the ignition is turned on, all indicators on the instrument panel light up, this is how the systems self-diagnosis occurs. During this process, you need to pay attention that all indicator lamps are working properly. Most of the indicators go out after self-diagnosis and only a few lamps remain on.

Among them, the red battery icon must light up. This is as it should be, as long as there is no cause for concern. A lit icon indicates that the generator is not currently charging the battery.

A lit icon indicates that the alternator is not currently charging the battery.

Now let's start the engine. Immediately after this, the lit battery icon should go out, which indicates that the generator has started working and has begun to charge the battery. The situation is completely different if the indicator does not go out or it suddenly lights up while the engine is running.

The main thing to remember is that if the battery icon on the instrument panel is lit when the engine is running, then there is a serious malfunction in the electrical system.

Troubleshooting - Battery

Often, failures that result in a lack of charge occur when the battery is faulty or there are problems with the generator.

To detect deviations in battery performance, it is enough to compare the performance of the power source installed in the car and the new one. If the light goes out when replacing this part, you can confidently conclude that the cause of the failure was a failed battery. This can happen as a result of sulfation of the plates or their short circuit. And if in the first case it is possible to revive the device by repair, then in the second it will have to be replaced.

It is also worth remembering that problems associated with the battery do not always indicate a breakdown. Quite often the power supply simply runs out of charge. It's quite easy to check. If the battery charge level is below the usual norm, the power source must be charged and installed in the vehicle. If after this you were able to start the car and the indicator went out, the problem has been resolved and you can continue to use this battery without fear. But if the required charge level cannot be restored even after recharging, you will need to purchase a new battery.

Checking the generator.

To check the functionality of the generator and the charge of the battery, you need a multimeter. An inexpensive electronic device such as DT830C, M833, APPA iMeter 3 or similar is best suited for this. Pointer multimeters require precise polarity when connecting, and are very sensitive to shocks and falls. To check, just measure the voltage at the battery terminals. If the voltage is within 13.5 - 14.5 V, then the generator is working. If the voltage is less than 13.5 V, then the generator is faulty and the cause must be found and eliminated.

Troubleshooting - where to start

The first thing you should check is whether there is an overload in the on-board network. Of course, if your car has nothing installed other than a standard radio, then you don’t need to do this, but if you are a tuning enthusiast, then you should start checking with this option.

In order to check the load on the network, you will need to at least visually estimate the number of additionally installed light and sound devices, as well as compare their total power with the power of the generator.

If it ultimately turns out that these two values are approximately equal or the power consumption even exceeds the generated power, then you will need to remove some devices (what exactly to “sacrifice” is up to you).

After this procedure, you will need to start the car and check the operation of the generator. If the battery starts to charge, then the reason was precisely the overload.

The fact that the power generated by the generator is not unlimited should always be remembered when connecting new electronic devices to the vehicle’s on-board network.

The second thing you will need to check is the compliance of the generator and battery installed in the car. Thus, some motorists who install additional equipment on their cars also install batteries with increased power, thinking that they will be able to provide energy to all newly installed devices.

Diode bridge faults

The electrical circuit is designed to convert alternating voltage to direct voltage. If a breakdown of at least one of the diodes occurs, the functional unit ceases to perform its duties. The consequence of this is the supply of voltage that does not correspond to the required indicators.

The rectifier needs to be checked when the battery charging light is on, but there is charging.

You can determine the breakdown by using a multimeter. Take a tester and connect the red probe to the positive of the bridge, and the black one to one of the contacts marked AC.

The throughput voltage for diodes (silicon) ranges from 400 to 1000 mV. If the tester shows different values, then the bridge needs to be changed. Such a unit cannot be repaired.

Checking fuses of VAZ 2106 - 2107 with a multimeter

You also need to know how to check a fuse in a car with a multimeter because in some cases replacing it does not eliminate the malfunction; the circuit needs a more thorough check. Usually its failure is visible to the naked eye, but in some cases the break can be detected only after an instrumental check. To do this, use a car tester or even a simple voltmeter to measure direct current.

- We attach the probes to the fuse.

- Next, using simple manipulations, we melt the wiring inside the fuse. Therefore, we made a non-working fuse out of a working fuse. What won’t you do for a good article!? :-). Again we apply the probes to the fuse and look at the behavior of the multimeter.

- The resistance is infinitely large, we do not hear any sound signal like “peep”. The fuse is broken. It can be thrown into the trash bin.

A little theory: scheme of work

To solve the existing problem, you must understand the essence of the interaction between the vehicle generator and the power source (battery).

While driving, the battery is in constant charging mode with a voltage of 13.6-14.2 Volts. As engine speed increases, the voltage at the generator output increases. But this is unacceptable.

To limit the voltage, a small relay regulator is inserted into the rotor excitation circuit. Its task is to reduce the current to a normal level (even with a significant increase in the speed).

The result is maintaining the battery charge voltage at a stable level. If the battery light is on, this indicates a lack of charging from the generator.

How does the scheme work? After turning on the ignition, voltage through fuse No. 10 (for VAZ-2107) is supplied to the battery charge indicator lamp.

Next, the “+12V” voltage passes through the diode, the built-in relay-regulator (we mentioned it above), the brush, the slip ring and the winding.

As soon as the rotor speed increases, the phase voltage also increases. As a result, the voltage at the terminals of the battery warning light is equalized and it goes out. At the same time, the battery is charging.

Why do you need a battery charging warning light?

In order for the driver to monitor the charging status of the battery, there is a voltmeter with a scale on the instrument panel, as well as a small red window under which a warning light is installed. When we insert the ignition key and turn it in the lock one turn, this lamp turns on and lights up red. The voltmeter needle is in the zero position. This means that the generator is at rest and does not charge the battery. When the engine starts, the lamp should go out and the instrument needle should move to the right, indicating the amount of voltage supplied to the battery. This happens when the machine’s power supply system is fully operational. But if the VAZ 2107 or 2106 battery charging light is on even after the engine is started, most likely there is a failure somewhere. And our task is to find its cause and eliminate it.

Fuse failure

The electrical circuit for charging the battery is protected by a fuse. This element is located in the vehicle’s mounting block and is marked as F10. However, before checking for a malfunction in this place, it is better to first read the vehicle’s operating instructions, in which you will find out the exact designation of the required element.

If the fuse fails, the battery is not charged at all. However, there are times when the warning light comes on, but there is charging.

You can check the element using a tester (the part is removed from the mounting block). If the multimeter shows that the fuse is bad, all you have to do is replace it.

Poor contact at battery terminals

Check the condition of the battery terminals and battery contact wires.

It is not uncommon for oxidation to occur in these places and the contact to weaken significantly. When the lamp comes on and there is charging, this could be the cause. In this case, the generator operates normally, voltage is supplied to the battery, but weakens due to insufficient contact. As a result, the warning light on the dashboard comes on. As a rule, the indication lights up dimly.

To fix the problem, you need to clean the terminals and contact pins. Additionally, treat these elements with a water-repellent agent.

Reasons for the battery charging light to glow

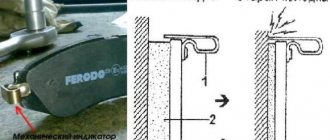

Such bulbs are available in VAZ 2107 injection and carburetor type cars. If, after starting the engine, the indicator in the form of a battery continues to light on the instrument panel of the VAZ 2107, then the owner’s first opinion is that the generator is faulty. This is a correct opinion, and in order to find the exact cause, you will need to carry out diagnostic measures. The reasons for the glow of the lamp on the instrument panel are:

- Weakening of the tension of the generator belt, as well as its wear and damage.

- The fuse link burns out.

- Malfunction of the relay regulator or rectifier (diode) bridge.

- A break occurs in the generator winding.

- Poor contact at the battery terminals.

- Abrasion of graphite brushes on the generator.

- Lack of ground contact.

You cannot operate a vehicle with a glowing battery indicator on the instrument panel. At any moment, the battery can be discharged, since it is not receiving charge from the generator, and the car will simply stall. How long a vehicle can drive with a faulty generator depends on the quality of the battery, its charge and the vehicle’s electricity consumption. Typically this period of time ranges from 10 minutes to 2 hours.

Vehicle electrical malfunctions

The list of faults in the electrical equipment of a car is quite wide. Conventionally, they can be divided into faults of current sources and faults of current consumers. This article discusses malfunctions of current sources.

As you know, the sources of current in a car are the battery and the generator. A malfunction of each current source can immobilize the vehicle at any time.

And if you don’t want to return home on a “tie” or a tow truck, attention must be paid to the technical condition of the battery and generator

In a vehicle's electrical system, the battery and alternator work in tandem. The failure of one leads to the failure of the other. For example, battery malfunctions lead to an increase in the charging current of the generator. Operating the generator in this mode can cause a malfunction of the rectifier unit (diode bridge). On the other hand, a malfunction of the generator voltage regulator is accompanied by an increase in the charging current, which, in turn, leads to systematic recharging of the battery and “boiling off” of the electrolyte.

Battery faults

Battery malfunctions include:

- short circuit between battery electrodes;

- damage to the battery plates;

- cracks in the battery case;

- oxidation of battery terminals.

The main causes of these malfunctions:

- violation of operating rules;

- service life limit;

- manufacturing defects.

Violations of the rules for operating batteries are:

- working with a faulty generator (leads to overcharging or discharging the battery);

- poor contact at the battery terminals (leads to oxidation and destruction of contacts);

- Frequent engine starts or prolonged operation of the starter (leads to deep battery discharge);

- weak fastening of the battery in the engine compartment (leads to mechanical damage to the battery and wires).

The battery can be used effectively for a certain period of time. The average battery life is 3-4 years. With intensive use, as well as operation in harsh climatic conditions, the service life is significantly reduced.

Modern batteries are low-maintenance and maintenance-free. The degree of battery maintenance is determined by the rate of evaporation of water from the electrolyte. For a maintenance-free battery, the critical electrolyte level is reached much later than the end of its service life.

When using rechargeable batteries, you have to deal with manufacturing defects. A faulty battery can be easily replaced under warranty by the seller or manufacturer.

All malfunctions have the same consequence - the battery stops performing its intended function - turning the starter when starting and providing consumers with current when parked. In this case, it is necessary to determine whether the battery needs to be replaced or whether the current source can still serve.

When operating a battery, you must remember that increased discharge at subzero ambient temperatures can lead to freezing of the electrolyte and destruction of the battery case.

Generator faults

The design of a generator is more complex than that of a battery. Therefore, this device has more malfunctions:

- wear of current collecting brushes;

- damage to the voltage regulator;

- damage to the rectifier (diode bridge);

- wear of the commutator (slip rings);

- wear or destruction of the bearing;

- pulley wear or damage;

- short circuit of the stator winding turns;

- damage to the charging circuit wires.

The main causes of these malfunctions:

- violation of operating rules (long-term operation under heavy load, incorrect polarity when connecting the battery, low tension of the generator belt);

- low quality of components;

- exposure to external factors (moisture, salt, high temperature, dirt);

- service life limit.

Wear or destruction of the bearing is accompanied by increased noise when the generator operates. Other generator malfunctions are diagnosed by low charging current. This is indicated by a warning light on the instrument panel, which lights up periodically or constantly in the event of a malfunction.

The lamp works when the engine is on: how to identify the cause

Check how intensely the icon lights up and when it happens. Based on this, you will understand where the problem lies.

Constant light

Most likely, the problem is that the battery needs more charge while driving. The causes of this problem may also be:

- weakening;

- complete or partial wear of the alternator belt;

- regulator relay burnout;

- breakdown of generator brushes.

In any case, it is necessary to replace the failed element.

On turns

The problem lies in the diode bridge or in another system. For the most accurate diagnosis, it is recommended to seek help from specialists.

At high speeds

The slip rings are worn out. The problem may also be caused by a poorly tensioned alternator belt, faulty bearings or alternator brushes.

Idling

To find a defect, you need to examine the alternator belt, regulator and diode bridge. If the indicator is bright, start checking from the bridge; if it is bright, start checking from the relay.

Blinks, lights up periodically, dims

A flashing (dim) pictogram indicates abrasion of the copper armature rings or generator brushes. You need to stop using worn out parts and buy new ones.

If the charge lamp barely lights up, you need to check the generator brushes

When turning on the headlights and turn signals

It is necessary to check the contacts of the diode bridge, the condition of the generator or commutator brushes.

Burns barely noticeable

A lamp that burns at full intensity indicates a faulty diode bridge or insulation. To solve the problem, it is recommended to replace the bridge. Also, poor indicator performance may mean that the ignition key is not turned all the way - in this case, you just need to pour a little WD-40 into the ignition switch hole.

For better performance of the battery charge indicator, you should drop WD-40 into the ignition switch well

With the ignition off

The fault lies in the generator. Unfortunately, the car owner cannot do without replacing it, and this is fraught with significant financial expenses.

While charging

If charging is carried out, but the light continues to burn, then it is necessary to clean the oxidized contacts. Sometimes it may be necessary to transfer mass from the battery to the starter.

Troubleshooting

If you have identified the reason for the activation of this indicator, it’s time to start eliminating it. Below are the main problems and methods for solving them:

- You can eliminate the weakening of the belt or its rupture by adjusting the degree of tension or resort to replacing it;

- in order to clean oxidized terminals, it is enough to clean them using fine-grained sandpaper;

- in the event that the battery is discharged as a result of prolonged operation of electrical appliances with the engine turned off, it is enough to recharge it;

- If there are various internal damages, you should contact a specialist.

Faults such as failed “brushes” and generator wires, as well as broken windings or broken relays cannot be eliminated by repair. In this case, it is advisable to replace the spare part.

conclusions

By carefully monitoring the dashboard readings, you will be able to independently identify problems in the operation of your vehicle at first and avoid serious consequences. We also draw your attention to the fact that you can always order the parts you need from our company. We offer competitive prices and will help you save not only money, but also time, because you will not need to look for the necessary spare part in stores. We guarantee high quality and excellent performance. To place an order, call the contact phone number.

Reasons why the battery charge light is on

The battery begins to charge from the moment the engine starts running. To do this, the key is inserted into the ignition switch and turned to turn on the vehicle's on-board power supply. When turning further, the starter is turned on and the engine starts. If, when the car engine is running, the battery charging indicator continues to glow brightly or dimly, then the charging current from the generator does not reach the battery. In this case, the entire load of supplying consumers with current falls on the battery.

Video: reasons for the battery not charging

The reasons for the battery light not going off when the engine is running are always related to problems in the generator and on-board network.

Failure of the relay regulator

A malfunction of the relay regulator is another reason why the battery charging light comes on.

This node is responsible for turning on/off the signal indicator. The principle of operation of the device is as follows: when the ignition is turned on, current flows through its closed contacts, which comes from the battery and feeds the indicator signals. When the internal combustion engine starts, the generator starts working, which supplies the relay with already rectified voltage and the contacts of the unit open. At this time the light should go out.

What to do if the battery light is on or the light is off but there is no charging: diagnostics

In a situation where the battery light is on while the engine is running, you need to check the voltage at the battery terminals with a multimeter. This can be done quickly, and the voltage itself should normally be 13.5-14.3V. When there is no charging, the voltage will be about 12V.

To check the charging status in more detail, you need to prepare a pair of screwdrivers (flat and Phillips), a 12V test lamp, a multimeter, a knife and pliers, as well as fine sandpaper. Now let's look at the main problems when the battery light comes on.

- First, the generator is charging, the tester at the battery terminals shows a voltage of 12V, and the battery itself is discharged. In such a situation, stripping of the terminals and wires will be required. After cleaning, the voltage on the battery is measured again.

- Secondly, the battery is discharged, and the voltage on the battery is 14V, but it drops under load. In this case, the cause may be poor tension of the generator belt, problems with the pulley, failure or wear of the generator bearings.

You also need to check the diode bridge and stator winding, since a breakdown of one diode can lead to insufficient charging. To believe this, you need to turn off the ignition, then check the generator, its diodes and other elements with a multimeter. At the same time, the generator brushes are also checked (if their length is less than 5 mm, the generator brushes need to be replaced).

Probable Causes

There can be quite a number of reasons why the battery on a VAZ 2114 is not charging.

The most likely ones look like this:

- the on-board network (and with it the generator - are overloaded);

- the generator does not match the used battery and vice versa;

- contacts have become loose or oxidized;

- the brushes are worn out;

- the drive belt is loose;

- there was a break in the generator windings;

- the rotor has closed;

- a stator short-circuit has occurred;

- bearings have failed;

- the control relay has failed.

As you can see, there are quite a few reasons why the VAZ 2114 generator does not charge, and the search should begin with the most probable and simple ones, moving on to more complex ones.

How to troubleshoot

To understand why this light is on, do not turn off the engine. You need to open the hood of the car and, with the engine running, measure the voltage that will be at the battery terminals with a load plug or multimeter. 13.5-14.5 Volts is considered normal. If charging is not occurring, the voltage will be 12 Volts or lower.

- A couple of screwdrivers - slotted and Phillips

- 12-volt lamp (control)

- Knife

- Pliers

- Sandpaper

- Multimeter

Different malfunctions are resolved in their own way, so I will list in turn all the possible options and methods of elimination.

Option one

The battery light is on and does not blink. When the multimeter shows approximately 12 Volts at the battery terminals, and the engine is started, but the battery itself is discharged. You need to clean the battery terminals with sandpaper, then the high voltage wires. Having cleaned the terminals and returned them to their place, we measure the voltage on them with the engine running.

When the situation does not change, check the voltage at pin “30” on the electric generator. To do this, we lean one multimeter probe against terminal “30”, the second probe against ground. If the voltage is higher than the voltage of the battery terminals, then the contact of terminal “30” must be cleaned. If necessary, replace the wire that goes from this terminal to the battery.

Option two

The battery light is on, but charging is in progress, but under load (headlights or signal) the lights blink. The battery has a reduced charge level. A possible reason is loose tension in the generator belt, pulley, or play in the generator bearing.

In addition, the cause may be a diode bridge and a broken stator winding. You need to turn off the ignition and use a multimeter to check all the diodes one by one; if a breakdown is detected, replace the diode or the entire bridge.

You also need to check the condition of the generator brushes. The remaining length of the brushes must be at least 5 millimeters, otherwise they must be replaced. Once you get into the brushes, check the condition of the holders, maybe they are worn out and causing problems for you.

Option three

In this option, the battery lamp does not light up or blink, the charge sensor does not work, but the battery does not receive charging. This means the fuse has blown. The fuse is marked “F10” and is ten-amp. It happens that after replacing it the result has not changed. Then look for a faulty ignition switch, or a problem with the ignition relay.

Option four

When the battery lamp does not light up after turning on the ignition, there is no charge, and the lights work normally. You need to remove the wire from terminal “61” on the electric generator, after which you connect the wire to the body. If this causes the battery light to light up, then its excitation winding has burned out.

An oxidized connector contact on an electric generator gives a similar effect, clean the connector. We don’t rule out the possibility that the light bulb simply burned out; it doesn’t last forever. When only one battery light blinks or glows dimly, the problem is also in it itself. If this is not the problem, then other devices and light bulbs will behave in the same way, that is, they will all blink in the same way, or glow at the same level.

Option five

The battery light is on or blinking, charging is missing or intermittent. Check the connector in the instrument panel to see if the contacts are corroded. Clean if necessary. Check the operation of the relay regulator. To check it, you need to power it up and measure the voltage on the generator brushes. When the voltage on the brushes is 12 Volts, then the relay is working properly. If not, the relay regulator will have to be replaced.

Self-diagnosis of systems responsible for battery charging

Minimum required set of tools:

- 12 V indicator light;

- a pair of screwdrivers (both flat and Phillips);

- knife and pliers;

- sandpaper for possible cleaning of contacts;

- multimeter

Basic functions and capabilities of the multimeter

Below is a plan for self-diagnosis and identification of possible defects in the operation of the battery charging system. Along the way, attention will be focused on points indicating wear and failure of a particular component/part.

- First of all, we look at the generator fuse.

- The next step is to check the generator rotor windings for short circuits or breaks. To do this, we attach the clamps of a multimeter switched to measuring resistance to the slip rings. Acceptable numbers can be considered a range from 1.8 to 5 ohms. It shows less - you have a short circuit in the turns, a clear increase is visible - which means there is a direct break in the winding.

- Checking the belt for integrity and tension. Low output of the generator may well be due to weakened tension of the drive belt. A clear indication of this will be a clearly audible whistle when you sharply press the gas pedal or accelerate.

- Visual inspection of the wiring to identify insulation damage and burnout.

- You need to run your eyes over the body of the generator itself - suddenly there are cracks, damage and whatnot.

- Checking the slip rings and brushes of the generator. As you already know, brushes can wear out and even warp during use. Along with this, the grooves of the slip rings can become clogged with graphite dust over time. The evidence here would be excessive sparking.

- The bearings will also need to be checked. You will need to pay attention to them if your generator begins to whistle and hum noticeably loudly.

- Determining possible stator failure. To properly check the winding of the latter, it is necessary to disconnect it from the voltage stabilizer. If a multimeter switched to measuring resistance produces a value that goes to infinity, then we can say that the stator windings do not have proper contact with the body (ground).

- Checking the diodes in the voltage stabilizer. This operation also requires a multimeter. First, for example, the positive clamp clings to the “+” or “–” of the stabilizer, and the negative clamp to the phase output. Then you just need to swap the clamps. And if during these operations the readings on the multimeter differ noticeably, then the diode is not problematic, but if not, then it is faulty. Also, oxidized contacts indicate the imminent failure of the diode bridge.

Checking the operation of the generator with a multimeter (video)

Some useful tips

To avoid problems associated with a faulty battery charging circuit, use the following tips.

- Pay more attention to your car's dashboard. This way you will know not only about the charging status of the battery, but also about the operation of other systems and mechanisms.

- Check the alternator belt regularly. The correct operation of the entire on-board network when the engine is running depends on its condition and tension. If you find the slightest defect in the belt, do not delay replacing it.

- Don’t be lazy at least once a month to check the voltage supplied by the generator to the battery terminals. If any discrepancies with the recommended values are detected, perform a full diagnostic of the on-board network.

- Periodically conduct a visual inspection of the condition of the battery terminals and generator terminals. Having discovered their oxidation, clean them with fine sandpaper and treat them with a liquid like VD-40.

- Do not allow water to get on the generator, battery and relay regulator. It can cause a short circuit in the electrical circuit. It is better to entrust engine washing to specialists.

- When repairing the battery charging circuit, avoid using spare parts that raise doubts about their quality.