Cars of the Kalina-2 family are equipped with a steering rack similar in design to the Granta rack. This part transmits force from the steering wheel to the front suspension links. If you feel a knocking sound from the rack while driving, it needs to be adjusted (tightened) correctly. The effect described here can be observed after 10-15 thousand kilometers, and more often it makes itself felt on uneven roads. Next we consider how this problem is solved in practice. And the solution comes down to turning one nut.

A little theory: front suspension design

Before attempting to fix any problem, there is a tendency to look at the blueprints or repair manual. It is known that the VAZ-2192 parts catalog contains the following object:

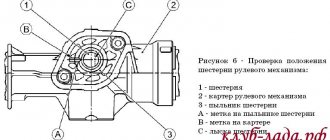

This is what the steering rack looks like in the drawing

Whether the knock will remain in the steering rack of Kalina-2 depends on the following: how accurately element “14” is adjusted. The adjusting nut, marked “14”, looks almost invisible here. But first impressions are deceiving. In the catalog, by the way, the element is called “Stop Nut”.

It is important to know that the thrust nut has external threads. And it spins clockwise. And the words “tighten the rack” mean screwing in the specified nut, and nothing more.

Now let's move on to practice and see what the node in question looks like in reality:

If you remove the rail, it looks like this

The nut has a non-standard notch, and it can only be rotated with a special tool. By the way, the recess will be closed with a cap. In the catalog it is designated by the number “15”, and now, let’s look at the appearance of the special key:

Rack adjustment key

The thrust nut is turned at small angles. We are talking about values of 10-15 degrees. What happens if you overdo it with tightening the rack? The knocking noise will disappear, but the steering wheel will turn with difficulty. Therefore, if necessary, the nut can be pulled back.

Repair, price

A lift is a fairly simple and quick way, but often it is only a partial, temporary solution to the problem. After all, the appearance of play can be caused by various reasons - the boot may be damaged, gaskets may leak and who knows what else, that is, there is a high probability that the steering rack is running dry. In this case, there is a risk that a short time after tightening it may simply jam. Therefore, troubleshooting the rack will be very useful, at least an external inspection, it will make sure that the anthers and corrugated casing are not damaged.

Lyrical digression

In Lada Kalina, the steering rack never makes a knock when we are talking about a new car. This is also true for the break-in period. Let's say in your case this is not done. Then, do not try to repair anything, but go straight to the dealer. According to reviews, the defect in question is covered under warranty, and most car dealers do this: the steering rack assembly is replaced with a new one.

This is what the replacement unit looks like, the rack assembly

There is a logic here. At the factory, adjustments are made correctly (this is true in 99.9% of cases). If a defect appears, the dealer replaces the assembly without expecting that adjustment will solve the problem. The owner does not need to hope for this either. The choice is yours.

Steering rack - simplicity and reliability

The steering mechanism of a car is designed to change the direction of its movement. It has been tested and tested for more than a hundred years, but meticulous designers still find new solutions to improve its performance.

The steering rack is no exception - a relatively simple and reliable mechanism, the operating principle of which is based on the interaction of the “rack-and-pinion steering shaft worm” pair, which converts the rotational movement of the steering shaft into the reciprocating movement of the steering rods.

Making adjustments yourself

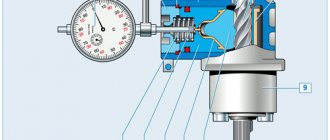

You can access the adjusting nut from the engine compartment, but to do this you will need to remove the battery, as well as the battery mounting pad. It is better to drive the car into a pit and then remove the crankcase protection (engine mudguard). If you look from under the bottom, the required element is immediately visible:

You need to turn this nut

And when you open the hood, you can feel the nut, but not see it. Its location is marked in the figure:

To make adjustments, place the key here

Before adjustment, remove the rubber cap from the recess. Its appearance is shown in the photo:

Remove the cap and install the key

If it is not entirely clear what exactly needs to be done, it is better to contact the service. The key is installed in the recess and then rotated 10-15 degrees.

When looking at the rack from above, turning the key clockwise corresponds to unscrewing it. The handle of the key comes from the center of the car - which means tightening is being done. By the way, the latter is true provided that the handle faces forward.

Debugg

The main factor in the occurrence of knocking in the EUR is the presence of play that appears during the use of the Lada Kalina. So, if there is a drumming noise, the bearings are probably loose. Often, the smallest of the 3 electric drive rotor bearings, located at the top of the conical component of the power steering housing, rattles. You should literally tighten the adjusting nut, but do not overdo it. Otherwise, the bearing will fail.

Some modifications of the EUR do not provide an adjusting nut. If the amplifier is disassembled, then adjusting washers can be seen between the gear and bearing. In this situation, it will be possible to reduce the backlash by installing auxiliary washers, selecting them experimentally. Please note: the thicker the gasket, the harder the steering wheel will become. In turn, too small a thickness of the washer will provoke a knocking sound from the electric power steering.

Preparatory actions, dismantling unnecessary parts

To remove the crankcase protection, you need to unscrew 4 screws located in one row near the bumper. Also, unscrew two screws having a standard size of M6x16. In some configurations, the protection consists of two parts, but in this case they are attached only with self-tapping screws. These words are illustrated by the following photo:

This is how the crankcase protection works in different configurations

First, unscrew the “10” screws, and then the two “18” screws. In the second case, there will be more screws (eight).

Now let's look at how to remove the battery. First of all, disconnect its terminals. Then, you need to move the additional fuse box to the side. In general, actions are performed according to the photo:

Unscrew the terminal fastenings Dismantle the mounting bracket by unscrewing 2 nuts Remove the battery and plastic pad Continue dismantling by unscrewing 4 bolts

You also need to remove the mounting platform itself, for which you unscrew 4 screws. You will need a 13mm wrench, as well as a 10mm spanner. We will repeat the entire sequence again:

- Unscrew the nuts holding the battery terminals using a wrench 10;

- Remove both terminals;

- Move the fuse box to the side by unscrewing 2 fastening screws;

- Unscrew the nuts with a 10mm wrench and remove the battery;

- Unscrew the screws with a 13mm and remove the metal plate.

Just in case, here is a look at the fuse box mountings:

Mounting screws are located under the casing

Manuals usually recommend removing the negative terminal first. But when it comes to dismantling both terminals, the order in which they are disconnected is not important.

Tools for work

To make it easier to carry out all repair work, you need to ensure that you have the following tools:

- The key is "10".

- 13" socket and wrench.

- Special key for tightening the rack. (Marking for VAZ 2110 – approx.).

The cost of such a key in stores is about 100-150 rubles

Step-by-step order of preparatory work

If you are not the lucky owner of a garage with a pit or a lift, work on tightening the steering rack can be done on the ground, but before doing this you need to prepare the work area.

- First of all, remove the battery, unscrew the terminals and fasteners of the batteries one by one (if available - approx.).

Remove the battery clamps carefully

By unscrewing these 4 bolts around the perimeter, the pillow can be easily removed

Steering rack tightening

- In the very center of the steering rack, strictly on the opposite side, by touch we look for a rubber cap, which we remove from its place with our hands or with a screwdriver.

Any car enthusiast will enjoy this view from above.

It is on this seat (indicated by the yellow arrow) that the key should be fixed.

Should I repair it myself or at a car service?

Great! The steering rack is in your hands. Now you need to carefully cut off the plastic clamps from the anthers without damaging the rubber bands themselves if you plan to reuse them. The left clamp securing the rack to the body can be left untouched, but the right one must be removed along with the rubber band: this is necessary to replace the central corrugation.

You can also remove the gasket located at the point where the rack contacts the hole in the engine shield.

We remove the left and right anthers, and then the corrugation. Look at the picture I discovered when I removed the left steering rack boot. There was grease here, but mixed with dirt.

https://www.youtube.com/watch?v=13qasRZk8gA

On the right side, on the contrary, there was no trace of lubricant, but a whole mountain of rust spilled out from there.

The central boot is reluctantly, but still removed from the steering rack housing.

The right end of the rack was covered with a thick layer of rust without the slightest hint of lubrication. Not surprisingly, it dangled loudly in the broken bushing.

Soak the stop nut with kerosene or WD-40, and in the meantime you can try to remove the worm shaft.

Having unscrewed two hexagon bolts, I found a bearing and a disc spring, but I could not remove the worm shaft, no matter how much I knocked the rack body against a piece of wood.

As a result, I realized that I didn’t need this, because I could wash and lubricate the insides of the rail without even completely disassembling it. Having thoroughly lubricated the bearing, I returned the cover to its place and began to unscrew the stop nut. To do this, you will need a very good key, I came across this one.

Having unscrewed the nut, I saw the same picture as in the rail itself. Everything was covered in grease mixed with dirt, or maybe the grease had become unusable over time.

We take out the spring and rubber band, turn it upside down and hit it against a wooden block until the stop pops out.

When I took out the stop, I discovered that it was covered in dirt, like everything else inside the rack housing.

Compare the new stop with the old one: the plastic lining has worn off, the rack has become less pressed against the worm shaft, and now it is clear how the play in the steering arose.

But the rumble when driving over small irregularities comes from the steering rack bushing. To get out the old broken bushing, you need to use a thin long screwdriver to bend inward each of the two protrusions that hold onto the recesses inside the rack body, and pull the bushing out of the body using a steel wire hook.

So, we have disassembled the steering rack, and now it’s time to wash it properly. To do this, you can use gasoline, diesel fuel or kerosene, as well as dry rags and something long and thin to clean the insides of the steering rack housing. By moving the rack inside the case and cleaning out the remaining old grease and dust from it, I achieved almost perfect cleanliness of both the rack itself and the case, and also cleaned off the rust as much as possible.

If you want to bring the rack to a perfectly clean state, then right now you need to blow it with carburetor cleaner. Do not forget to rotate the worm shaft to blow out all the dirt from its reverse side. After such a wash, the rack looked almost like new, all internal surfaces shone with a dazzling shine and newness.

Now we wipe everything down, lubricate it generously and assemble it. We turn the worm shaft and lubricate it.

We do not spare grease on the toothed part of the rack - it is here, between the worm and the rack, that the main friction occurs.

We also coat the right end of the rack with lubricant, which will not only play the role of a preservative here, but should also extend the life of the new bushing.

Having thickly lubricated the right end of the rack, check whether the bushing fits onto it. It must be put on with some effort, only in this case the repair will bring silence when driving over small irregularities.

The bushing must then be removed from the rack and carefully inserted into the pre-lubricated housing. The locking protrusions on the bushing must fit into their seats on the inner surface of the rack body.

Now screw in one of the bolts that secures the tie rods to the rack, and with the rack housing with the bushing facing down, being careful not to damage the bushing, insert the rack into it. The rack should fit tightly, but with a certain force applied to the bolt, it should still move.

Attention! The following actions will determine whether you will be able to assemble everything so that the steering wheel faces straight. First of all, you need to find the middle of the window in the frame body, mark it, for example with a file or marker, and set the frame to the middle position. In this case, the central hole should be opposite your mark.

Since the stop is not yet inserted and does not press the rack against the worm shaft, by turning the rack body over with the stop hole up, we can put the worm shaft in any position we need. Install the shaft as it was when you removed the rack from the car. My groove on the shaft was on the right and was almost vertical.

New Lada: Lada Vesta Sport - why it will be a new step in the production of domestic cars

Having installed the shaft in the desired position, make sure once again that the rack is in the middle position and then, through the hole in the rack stop, press the rack to the worm shaft. In this case, neither the worm nor the rack should change their position.

Now lubricate everything generously and install the new stop, spring and rubber sealing ring in place, and screw it all on top with the stop nut.

Next, use a special wrench to tighten the nut by hand, and then unscrew it back 2 notches, which will correspond to 24°, as indicated in the instructions.

When you install the rack on the car, the steering wheel may seem a little heavy to you, but after a couple of hundred kilometers the stop and rack will break in, and you will get perfect steering.

Now we assemble everything in the reverse order, and do not forget to put all the removed parts back in their places. Secure the anthers with nylon ties.

When is it necessary to adjust the steering mechanism in Kalina of all years of manufacture?

How to repair the steering mechanism? All that is required is to adjust the steering rack. On a regular Lada Kalina you can adjust the rack yourself without any problems, but on the sports version of the car it’s not so simple, and you’ll probably have to turn to specialists.

Reasons that may prompt you to repair the steering mechanism:

- When the bushing is heavily worn in the place where it connects to the steering rods and the rack itself;

- The steering rack fastener is loose;

- The pair's engagements are poorly adjusted;

- Severe gear wear;

- The steering racks are heavily worn.

Direct tightening of the steering rack is most often required in order to remove or at least reduce the backlash present in the car's directional control system.

This manipulation will significantly help improve vehicle control in a variety of weather and even road conditions. In some cases, tightening the rack is required if it was initially adjusted incorrectly. In this case, you need to loosen the screw that makes the adjustment. After this manipulation, the steering wheel begins to move easier, and driving becomes normal.

In addition to adjustment, when difficulties in the operation of the mechanism are identified, it can be lubricated. The Russian Lada Kalina, like any other car, has an instruction manual, which indicates how to properly lubricate and how to tighten the steering rack. In this official manual you will find a description of the structure of the rack itself, as well as the type of lubricant used recommended by the factory.

Important! Adjustment is carried out in 2 ways:

• On the car itself;

• When the rack is removed.

When the rail is removed, the damage is significant. In this case, it is always necessary to replace worn parts of the LADA Kalina steering mechanism, therefore, not every car owner can do everything on their own without certain knowledge and experience and the proper tools.

But everyone can independently eliminate knocks and even play, and, if necessary, loosen or tighten the rack. In this case, you do not need to dismantle the steering mechanism. However, if you understand that you cannot cope, then it is better to consult a specialist. Or follow strictly the instructions we provide below.

Diagnostics

To check the amplifier in a car, you need to remove the plastic trim on the steering column; to do this, unscrew the bolts securing it from the bottom.

Then you will need to get to the 8-pin plug, its pinout is as follows:

- The blue contact is connected to the ignition switch, this is 12 volt power;

- the red-brown contact is the connection cable to the tachometer;

- the gray contact goes to the car speed controller;

- white and pink wire - amplifier control indicator;

- black-yellow contact is a diagnostic line;

- the next contact is empty, the wire is not connected to it;

- brown contact is ground;

- empty.

More accurate results will be obtained by checking the amplifier using a scanner. But since such equipment can usually only be found at service stations, you can try to check the operation of the system with a paper clip.

To check you need to do the following:

- First the ignition is turned off.

- Then, using a paper clip, you need to close contacts numbered 6 and 7 of this plug, while the plug itself does not need to be removed.

- Next, the ignition must be turned on.

- After completing these steps, the EUR failure indicator located in the dashboard will begin to blink; by the number of blinks, you can determine whether the system is broken (the author of the video is Gosha Vakhromeev).

How to understand where to look for the cause by the blinking indicator icons:

- one long signal and one short signal - the electric amplifier is working;

- one long and two short - no engine speed signal;

- one long and three short - the torque controller is out of order or there is no power supply;

- one long and four short blinks—problems in the operation of the electric power steering motor;

- one long and five short - the steering shaft position controller has failed;

- one long and six short - the motor rotor position controller has failed;

- one long and seven short - problems with the electrical network - the voltage is either too high or very low;

- one long and eight short - the control module of the electric amplifier has failed;

- one long and nine short - the speed controller is broken.

Changing the EUR on the Lada Kalina

The electric power steering is mounted on the steering column and is removed along with it. First you need to turn off the power to the car by removing the battery terminal and position the front wheels straight. To dismantle the Kalina steering wheel, remove the lower cross member of the instrument panel, disconnect the wires from the EUR control unit and the switches located on the column, and then lower the steering wheel to the floor.

Now it is convenient to unscrew the nut of the bolt securing the lower universal joint to the steering gear shaft. Then we open the joint connection, use a flat screwdriver to remove the intermediate cardan from the pinion shaft of the RM Kalina and dismantle the column along with the electric power steering. After replacing the EUR with a new one, installation is carried out in the reverse order to that described above.

New Lada: Immobilizer on Kalina is on - Auto magazine KarLazart

For safety reasons, replacement of various components and mechanisms should be carried out only with those approved by the Kalina manufacturer. If the vehicle requires repair, it must be carried out immediately, otherwise the risk of creating dangerous situations on the road increases. If damage is detected or there are irreparable faults, the mechanism must be replaced.

- Posts: 10185

- From: Angarsk

- Lada Niva 2131M Nissan Patrol

March 21, 2022, 08:57 #76 123 1

igorkmailru, March 20, 2022, 11:18 pm

I didn’t see any good advice on this site, only “. don't save money, buy a new one. “So I’ll look elsewhere.

And on the other side, what kind of help will they give you? Like, come, we’ll fix it?

- Posts: 3613

- From: Tolyatti

- VAZ 2109

March 26, 2022, 12:29 #77 123

igorkmailru, March 20, 2022, 11:18 pm

I didn’t see any good advice on this site, only “. don't save money, buy a new one. “, so I’ll look on others. What kind of Russian ferrous metal is that began to crumble after 2000 km of run. Maybe I should immediately buy new raspberries for spare parts? I’ve had classics, 9s, 12s, but this is the first time I’ve encountered such a viburnum firewood. If I hadn’t serviced it myself, I would have gone broke on services long ago. Once upon a time I started with Tavria. Kalina and Tavriya are twins.

I love doing everything myself and it really saves money. Machines have weak points that need to be monitored. There are also “rotten” places that cannot be corrected, and you have to live with them. It happens that they collected it in such a way that there were only refusals. Nevertheless. All the flaws appear over time, and you get a car that you enjoy driving.

If you have the opportunity to change the unit yourself, find a simple steering unit. The cheapest option.

- Posts: 6954

- From: Ekaterinburg

- Renault Megane Extreme

March 26, 2022, 18:40 #78 123

igorkmailru, March 20, 2022, 11:18 pm

I didn’t see any good advice on this site, only “. don't save money, buy a new one. “, so I’ll look on others. What kind of Russian ferrous metal is that began to crumble after 2000 km of run. Maybe I should immediately buy new raspberries for spare parts? I’ve had classics, 9s, 12s, but this is the first time I’ve encountered such a viburnum firewood. If I hadn’t serviced it myself, I would have gone broke on services long ago. Once upon a time I started with Tavria. Kalina and Tavriya are twins.

Why a new one straight away for spare parts? Maybe drive it first, maybe you'll be lucky and the steering wheel won't knock. And even without an amplifier, the rack of all vases knocks, so it’s better with an amplifier.

- Posts: 3613

- From: Tolyatti

- VAZ 2109

March 26, 2022, 19:30 #79 123

I have a nine. There are no knocks, although they showed how it happens. The car was under warranty, the knocking noise was removed at the service center, but I don’t know how. Lost contact with the person.

- Posts: 6954

- From: Ekaterinburg

- Renault Megane Extreme

March 26, 2022, 20:24 #80 123

The rail was pulled up in about three seconds. Only the knocking always remains, some people feel it, but others are happy with it anyway, so they say that there is no knocking. Both my nines and tens behaved the same in this regard. The knocking started to be noticeable at 15 thousand, then I constantly tightened the rack stop at least once a year, I also changed the ball joints, but I still felt gaps in the steering wheel on uneven surfaces.

- Posts: 1

- From: Bakal

Tightening process, video

There are several ways to tighten. One of them is the method of removing the slats. The removed rail is clamped in a vice and then, using a special wrench, the nut is tightened 10-15 degrees by turning it counterclockwise.

This is followed by a check for backlash and, if necessary, the procedure is repeated, since the backlash can be more or less. It is not advisable to overtighten, it will be difficult to rotate the steering wheel. The advantage of this method is the ease of adjustment, but the disadvantage is that you have to remove and then put the steering rack back in place, and this requires time, certain knowledge and skills.

The second method is simpler, it does not require removing the steering rack, you just need to remove the battery and the platform under it with four bolts, but it is much easier and faster than removing and installing the steering rack. This way we gain access to the steering rack and steering rods.

We take hold of the rod with our hand and begin to shake it with force. A characteristic knock will immediately indicate the presence of play. The stop nut is located on the rack behind the left link from the bottom; you need to feel it with your finger. Now the task is to get the wrench into the nut and then turn it counterclockwise. We check for play and, if necessary, tighten it further.

But in the video there is another tightening option, even without removing the battery:

Product delivery options

Note! Below are the shipping methods available specifically for this product. Payment options may vary depending on the shipping method. Detailed information can be found on the “Delivery and Payment” page.

Parcel by Russian Post

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 5 to 12 days.

Parcel by Russian Post 1st class

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 2 to 5 days. More expensive than regular delivery by Russian Post, approximately 50%. Parcel weight up to 2.5 kg

Express Parcel EMS

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 3 to 7 days. More expensive than regular delivery by Russian Post, approximately 100%.