Welcome! It's time to get into the clutch. Grant norm, engine 186, gearbox 2181, mileage 31t. with kopecks, 3 years like from the assembly line. Having read a lot on the Internet + rattling of the release lever (as I thought) + since the spring it began to twitch when starting off. Gradually, over the past five months, the jerking when starting off has increased. It was not comfortable to touch. I had to step on the gas. I waited until vacation to slowly start replacing the clutch. The plans were to change the basket (most likely) and the release lever. But first you need to take it apart, so to speak, perform an autopsy, and then make a diagnosis. This means that to replace the clutch we need a garage with a pit, a car with a manual transmission, two hands, a little gray matter in the head and the actual tool. Since the repair will take place in privacy, first (the day before) you need to purchase 3 bolts 150 mm long (quite enough), I estimated the diameter and thread by unscrewing one of the top bolts and... two hub nuts (in old ones, the thread will pull when unscrewing). 1 first of all, the very first thing is to pull off the hub nuts and unscrew them (I took a cut-off union nut, like a “30” one (it was rusty) and a 40cm pipe), pull off the wheel bolts, DO NOT UNLOCK IT! 2 You can start either from the top or from the bottom, but it is advisable to start from the top while your hands and gloves are clean. 3, remove the air intake and throttle pipe, take other wires and tubes to the side and tie them up so that they do not interfere with us. 4 unscrew the platform, pull off the power fuse block from it and two tubes (fuel and canister valve) are attached to it at the bottom. 5, unscrew the spark plugs to make it easier to turn the crankshaft by the flywheel in the future. 6 remove the starter (three bolts) + disconnect the harness block and the power wire “+” (but it’s more convenient to remove from below, unscrew one bolt at the top and two at the bottom). Under (behind) the starter there is a key bolt at “13” that secures the ignition coil (don’t forget about it).

6(a) we remove the gearshift cable, the principle of the hinge (the horizontal one was pulled off, on the third attempt after a couple of hours, the vertical one still couldn’t. I removed it together with the axle (having previously unpinned it) from (from) the gearshift mechanism. (There’s a little photo below). The nuance is that the fixation mechanism is located on the cable, behind the bracket (in the photo in the same color, gray L = 4-5 cm), it moves back accordingly, if it doesn’t work by hand, pry it with a screwdriver, otherwise you won’t have any luck. bracket (two bolts). Throw the cables over the steering rack rod, tie it a little. 7 fix the bar with the wires to the thermostat, otherwise it will interfere

8 unscrew the two upper bolts and one in front near the starter and tighten our long ones (bought bolts), one by one, not all at once. As they say, with feeling, with sense, with arrangement.

9 this nut is better (it’s more convenient to unscrew when the right drive is removed), but it’s possible without removing it, a knob + a long insert.

10 We unscrew the lower flywheel screen (three bolts with a key *10*) last, before removing the box, since this bolt (see below in the photo) is not convenient to unscrew and remove and install the screen itself. Accordingly, when assembling, we put it first and screw it on!

11 remove the wheels (both), put the car on supports. 12 we climb “into the grave” (under the car in a hole), remove the protection. We drain the oil from the box (a five-minute task). It is advisable to first remove the filler and drain plugs so that they “go by hand”. Then, substituting a clean canister (to use the oil in the future), unscrew the drain plug. If you unscrew the filler plug first, the pressure will be higher, we will cheat a little. 13, remove the screen of the right drive (at the CV joint, grenade, whatever). The right one is in the direction of travel, of course. We unscrew the ball (E12 sprocket head (who hasn’t changed it)). We move the rack to the side, pull out the CV joint (outer) from the hub. Most likely you will have to knock it (it sits on the splines) out of the hub a little. When dismantling the right-hand drive, it is advisable to turn the wheels to the right (the hub will interfere less). 14 on the left side you need to remove the lower lever along with the saber (stretch). Personally, it bothers me when you work alone. We remove the left drive in the same way. 15 place a jack (preferably a diamond jack, it is possible to lower the engine lower) under the engine sump). It is advisable to lift it later by moving the jack under the box. 16 unscrew the clutch cable bracket on the left support of the box, then you will have access to the support nuts and two pillow bolts (head on *15* both here and there) fa.d-cd.net/cc36678s-960.jpg (—//— ). 17 remove the rear support (three bolts on the box, two nuts on the body) 18 lower the box so that it goes under the wing. — after lowering, we remove the gear shift mechanism itself (three bolts), prying it a little (it sits on the sealant) and plug the resulting “hole” (no matter how rude it sounds) with a clean rag (rag) to prevent dirt from getting in during the work.

19 After everything that gets in the way has been removed, we extend the box to the full length of the bolts, adjusting with a jack.

I took it off and shortened the basket and disk, everything is fine there. The disk and basket are “Valeo” from the factory. On the basket, a couple of petals were almost out of plane (one of the reasons for the twitching). The disk was alive, the springs did not dangle (did not rattle), by the way, weak springs are the second reason for jerking and they are trying to replace such a disk.

How to replace the release bearing on a Lada Granta yourself?

The clutch is one of the most important components of a car, without which it is difficult to imagine a car with a manual transmission. The clutch acts as a connecting link between the gearbox and the engine (from the engine crankshaft flywheel to the gearbox input shaft), connecting or disconnecting torque when necessary.

The connection or disconnection of the manual transmission and the engine occurs when it is necessary to engage one or another gear (speed).

The clutch makes gear shifting smoother and also significantly extends the life of the engine and gearbox.

One of the main components of the clutch is the release bearing (clutch release clutch). Violations of the operating rules for a car with a manual transmission lead to the clutch release failing, resulting in the following problems:

- Extraneous noise and a slight knocking sound appear when the clutch is depressed;

- Gears are difficult to shift or do not engage at all;

- Clutch slipping, incomplete engagement or disengagement of the clutch.

If any of these symptoms occur, immediately diagnose the problem and, if necessary, replace the release bearing. If this is not done in time, over time the entire clutch assembly will have to be replaced. As you understand, a complete replacement of the clutch and release bearing will cost several times more.

Why did it happen so?

Perhaps the automatic requests do not belong to you, but to another user accessing the network from the same IP address as you. You need to enter the characters into the form once, after which we will remember you and be able to distinguish you from other users exiting from this IP. In this case, the page with the captcha will not bother you for quite a long time.

You may have add-ons installed in your browser that can make automatic search requests. In this case, we recommend that you disable them.

It is also possible that your computer is infected with a virus program that is using it to collect information. Maybe you should check your system for viruses.

If you have any problems or would like our support team, please use the feedback form.

Replacing the clutch on a Lada Granta takes from 3 to 8 hours. Replacing the Lada Granta clutch is done only with the removal/installation of the gearbox. On some models, to remove the box you need to remove the subframe. It is best to determine what exactly to change: the disk, basket or release bearing after the box is removed.

The decision to replace the clutch on a Lada Granta must be made after diagnostics at a car service center. Some symptoms may be similar to a faulty transmission or gearshift mechanism. On robotic gearboxes (robot, isitronic, etc.), after replacing the clutch, you will need to adapt the grip point. This can be done at our stations.

Cost of replacing a clutch on a Lada Granta:

| Replacement options | Price |

| Replacement of clutch Lada Granta, manual transmission, gasoline | from 4500 rub. |

| Replacement of clutch Lada Granta, manual transmission, diesel | from 5000 rub. |

| Lada Granta clutch replacement, DSG, robot | from 8000 rub. |

| Clutch adaptation of Lada Granta | from 2500 rub. |

| Removal/installation of Lada Granta subframe | from 3000 rub. |

If you notice that the clutch begins to behave differently than before, we recommend that you immediately contact a car service for diagnostics. If you start this moment, then subsequently, in addition to replacing the clutch on the Lada Granta, you will also have to replace the flywheel. And the cost of a flywheel is several times higher than the cost of a clutch kit.

When replacing the clutch, we also recommend replacing the crankshaft rear oil seal and replacing the axle shaft seals. When replacing a clutch, a good mechanic will always pay attention to the condition of the gear selector rod seal. The cost of seals is minimal and it is better to do everything at once without overpaying for the same work in the future.

How to replace a release bearing - step-by-step instructions

The entire bearing replacement process is outlined below, supported by photographs for greater clarity. To replace you will need: a new release valve (suitable from Priora, but you will have to trim the “ears”); pit or lift; set of tools.

1. Work is performed on an inspection pit or on a lift. We unscrew everything that may interfere with hanging the box (protection, hanging cables, etc.).

2. Unscrew the bolts securing the box and disconnect it from the motor.

3. We hang the box on ropes without removing it completely and without disconnecting the CV joints.

4. Remove the retaining spring, then remove the faulty bearing from the guide bushing.

Reassembly is performed in reverse order; during assembly, do not forget to lubricate the shaft on which the release bearing sits. If the replacement process is not described in sufficient detail for you, you can read the more detailed report “How to replace the clutch and release bearing on a VAZ 2109 with your own hands.”

Source

Recommendations

Comments 20

I forgot to add that the rear bearings in the housing cannot just turn, they are clamped by a plate. There is no tight fit, only clamping with a plate, again, the factory tolerances are violated, everything must be measured during the assembly process, and the plate must be new, and tighten the screws with an impact screwdriver; do not tighten them to the required torque by hand.

Everything that is written here about the checkpoint is all at the level of speculation, and not knowledge of the technical part. Think theoretically, when the car is parked and the engine is at idle, then only the input shaft rotates in the gearbox, and only two bearings work with it. Roller front and ball rear. The ball knocks on very rare occasions, this is if he is really fucked up, mostly he howls. But the roller one makes a knock if it is of poor quality. It would take a long time to explain the nature of the knock; it has to do with the clutch disc and wear on the splines of the shaft and disc, and again the quality of the workmanship. Sometimes the gears on the secondary shaft jangle, they rotate, but the shaft stands still. At the factory they don't bother with quality. If all tolerances are met, the gearbox will work quietly, but for this you need to have several sets of gears and bearings, and select all this, which is impossible at home. The main couple howls as they walk, there’s nothing you can do about it. To reduce the howling, use additives, I poured VMP Auto.

Hi, what kind of thread locker is this? Do you have a number?

there are plates fixing the shafts, SKF bearings come from the factory to the 2181 gearbox

If the bearings start turning again on the outer race, everything will come back again. It's not even a matter of new bearings; the old ones turned out to be no worse than the new ones. The fit in the body of the box itself is simply loose. Therefore, the output was placed on a clamp.

Preparatory stage before replacing the clutch on the Lada Grant

Necessary tools, materials:

- set of car keys, sockets, ratchet;

- extension;

- calipers;

- additional lighting;

- screwdrivers with a set of bits;

- mounting blade;

- pliers;

- hammer;

- metal brush;

- hydraulic (mechanical) jack;

- cylinder and torque wrench;

- graphite-based lubricant “CV joint-4”;

- container for draining waste;

- 6 liters of gear oil;

- clutch assembly;

- wooden spacers;

- rags.

Car radio

Step-by-step instructions for installing a radio in a Lada Granta of the “standard” or “norm” modifications:

- Hook the central pocket-plug by the edges to remove the latches from engagement with the front frame.

- After removing the element from the socket, it is necessary to disconnect the plugs of the factory wiring harness, located in special sockets on the rear part. The car has 2 8-pin connectors for connecting power and speakers.

- Fold the glove box housing down; there are travel stops on the upper part of the rear wall that need to be disengaged from the dashboard frame.

- To expand the working area, it is recommended to remove the cover by pulling it towards you.

- Raise the decorative floor covering of the car along with the soundproofing mat near the passenger seat. Pull out the factory antenna cable equipped with a plug that needs to be extended to the installation location of the player.

- Place standard slides for attaching the radio using special bendable elements.

- Further installation of the radio in Grantu is carried out after switching the loudspeakers.

Installing the stock radio is slightly different from the procedure described above:

- Since the standard frame is designed for 1DIN size equipment, a replacement unit is required. To do this, you will need to carefully pry and remove the plastic climate control controls. The frame itself is fixed with latches, which are removed one by one from the mounting sockets using a plastic spatula.

- For final dismantling, it is necessary to disconnect the connectors connected to the control buttons for the air conditioning, hazard warning lights and heated rear window. It is necessary to make notes that will allow you to correctly connect the plugs on the new panel.

- Remove the keys, climate control parts and ventilation deflectors from the center console, which are transferred to the new unit.

- The “luxury” version of the cladding, designed for mounting a 2DIN radio, consists of 2 sections. The lower part is equipped with additional fastenings with screws, under which it is necessary to install counter elements. The parts are placed in standard places around the perimeter of the instrument panel in the upper and lower parts of the landing window.

- Place a separate adapter frame, which is supplied with the head unit, in the mounting socket of the radio.

- Place the cladding in place, securing the part with latches and screws. The switching cables for acoustic equipment and control buttons are routed through the corresponding holes into the car interior.

- Install a standard player into the guide slides, having previously connected it to the on-board network and antenna. The assembly is secured with side latches; if dismantling is required, the clamps are bent with a screwdriver.

- Install a horseshoe-shaped decorative cladding located around the perimeter of the central part of the decorative panel. Reinstall the plugs for the hazard warning, air conditioning and heated glass buttons, and then place the keys in the standard sockets.

When installing non-original equipment of 2DIN size, the owner is faced with the impossibility of placing the radio in depth. To ensure the fit, trimming of the plastic elements located in the instrument panel is required. The player is fixed in the mounting shaft located in the window of the central cladding; the display is framed from the outside by a transition frame.

Sequence of actions when removing and replacing the Lada Granta clutch with cable drive

- After removing the manual transmission (the process is described above), we mark the location of the basket and flywheel with marks. In the event that we do not plan to replace the basket or pressure plate. The decision is made by the repairman based on the diagnostic results.

Removed manual transmission

- Unscrew the bolts and remove the basket with the pressure driven disk.

Cart with disc

Note to the driver. We loosen the tightening of the bolts evenly, according to the diagonal principle, one turn of the key.

- Remove the discs from the clutch basket.

Removing a disc from the bin

- We carry out troubleshooting of parts, adjacent mechanisms and elements.

What to pay attention to when troubleshooting:

- cracks, breaks in parts;

- depressions of more than 0.2 mm;

- check for cracks on the diaphragm spring;

- We inspect the support rings; there should be no signs of wear, visible or obvious defects on them;

We replace worn elements with new ones as necessary.

Do-it-yourself clutch installation on a Lada Granta

- Using a mandrel, we install the driven disk, basket, and centering pins.

- We fix the basket to the flywheel with three bolts. We tighten the bolts evenly according to the diagonal principle with a force of 37 N.m. We use a torque wrench.

- We remove the frame and install the manual transmission.

- We fix the clutch drive on the manual transmission.

- We adjust the distance from the plastic bushing to the drive fork. It should be equal to 27 mm. We adjust the key value to “10”.

general information

Like the vast majority of modern cars, the Lada Granta is equipped with a fairly simple clutch, which contains only a few elements.

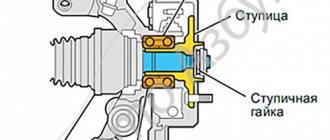

The clutch (also called the clutch basket) includes a housing, a driven disc, and a throwout bearing. The casing, in addition to itself, also includes a pressure disk; in addition, a complex part is the driven disk, consisting of a damper, friction linings and a ring.

Each Granta is equipped with a closed-type single-plate clutch, which has a special element designed to dampen vibrations generated during rotational moments during shifts. The coupling is ensured by dry friction between the driven disc and the friction linings, which is why this type of clutch is called dry.

In addition, clutches on Grants are devoid of gaps between the release bearings and the legs of the pressure springs located in the casing, which is their main distinguishing feature compared to all previous modifications.

Signs of clutch wear

| Sign | Cause and remedy |

| Incomplete engagement of the clutch (slips) | Replacing discs, cleaning clutches |

| Incomplete shutdown (leading) | Prevention of the clutch mechanism |

| Periodic jerks | Clutch cable wear, clutch replacement |

| Vibration, beating when shifting to higher gears | The flywheel is bent, the gripper teeth are worn out. Replacing the flywheel and related consumables |

| Noise, creaking, grinding noise when activated | Damper spring wear, replacement with a new one, drive lubrication |

| Pedal free play is increased, exceeding 2 -3 mm | Tensioning the cable, replacing with a new one |

| You can hear the smell of burnt friction linings | Dismantling the clutch block, replacing worn elements |

| Increased fuel consumption | Flywheel worn, teeth damaged |

| Reduced acceleration dynamics | Replacing clutches |

Interesting Facts

Let's look at the interesting facts that we managed to learn about the new Lada Granta gearbox:

- The VAZ-2181 gearbox will not be installed on the Priora, since the designers considered that it would not be cost-effective to redo the entire design of the power units.

- The cost of Lada Grant and Kalina 2 increased by 5000-7000 rubles. with the introduction of a new gearbox into the car.

- According to reviews from car owners, the first copies of cable-driven gearboxes were not entirely successful and had quite a lot of flaws: vibration became audible after 70-80 thousand mileage, howling of the gearbox, increased wear of parts, etc. Based on this, the manufacturer made adjustments to the design and improved the characteristics, but many car owners had a negative impression of the VAZ-2181 cable-driven gearbox.

- The AVTOVAZ plant continues to develop and modernize a new gearbox, which will become the second generation of cable gearboxes. It is planned to install it on the 2nd generation Lada Granta, which is currently under development. The designers promise to take into account the experience gained during the development of the first generation and not allow such an oversight a second time.

Review of Manufacturer Prices

| Manufacturer article number | Price, rub.) | Resource (Thousand km) |

| Set of wheels LADA 2190-316010001 | From 3100 | 85 — 105 |

| —/— 2190-31601000 | —/— | —/— |

| —/— 302050901 | —/— | —/— |

| —/— 302052223 | —/— | —/— |

| —/— 302052307 | —/— | —/— |

| LADA 21810160118001 clutch | From 650 | 80 |

| LADA 21090160119000 input shaft guide | From 750 | 75 — 80 |

| LADA 21010160121500 fork support | From 150 | 75 – 95 |

| LADA 21810160120001 plug | From 800 | 85 – 95 |

| Connecting spring fork and clutch 21010160118800 | From 350 | 85 — 95 |

Types and design features

In the design of a car clutch, two types of release bearings are used:

The main elements of release bearings are closed ball or roller bearings. They are used on both mechanical and hydraulic types of products. Their design also includes a housing.

In mechanical elements, this housing is designed to interact with the clutch drive fork. Such units can have a very different design (the housing is presented in the form of a bushing inserted into the inner race, or it is installed on the outer ring), but all housings have special protrusions on which the fork acts. In general, in mechanical bearings, housings are designed for just this.

Clutch diagram of a VAZ car - 2107 1 - flywheel; 2 — clutch driven disc; 3 — clutch basket; 4 — release bearing with clutch; 5 — hydraulic clutch reservoir; 6 - hose; 7 — master cylinder of the hydraulic clutch release; 8 — servo spring of the clutch pedal; 9 — clutch pedal return spring; 10 — clutch pedal travel limit screw; 11 — clutch pedal; 12 — hydraulic clutch release pipeline; 13 — ball joint fork; 14 — clutch release fork; 15 — release spring for clutch release fork; 16 - hose; 17 — working cylinder of the hydraulic clutch release; 18 — clutch bleeder fitting

Reviews

| № | Positive |

| 1. | Vladimir: I have been successfully using the machine for two years now, there are no comments on the work. Investments are minimal, consumables, filters, oils. |

| 2. | Gennady: I attend every scheduled maintenance according to the schedule. The car is in good condition, the technician is carrying out computer diagnostics. Soon the mileage will be 90,000 km, I hope that repairs will occur after 105,000 km. |

| 3. | Vasily: at 60,000 km I replaced the cable, it started to creak, I didn’t lubricate it, I bought a new one. There are no more comments, everything works properly. |

| 4. | Ignat: I have no special complaints about the car. Of course, Lada is not ideal, but for the budget segment it is the best solution. |

| 5. | Dmitry: at 80,000 km I replaced the repair kit for the bushings on the clutch pedal, it started to creak. Additionally, I lubricated the cable. My recommendations to motorists. All work was carried out independently, without the help of service station workers. |

| 6. | Kirill: I replaced the clutch at 95,000 km, I think that this is a very good mileage for a domestic car. The installation process is not complicated, I did the work myself. Special thanks to the store manager for recommending quality spare parts. |

| 7. | Georgy: replaced the release bearing at 105,000 km, mileage as in the instructions. There are no problems with the engine, the car runs like a watch. |

| Negative | |

| 1. | Victor: my bearing fell apart at 50,000 km, it was replaced at a service station. After 10,000 km the cable creaked and was also replaced with a new one. The Granta model is crude, has many flaws, I do not recommend purchasing it. |

| 2. | Vyacheslav: over the past six months it has undergone unscheduled repairs twice. Initially, the basket flew off after a problem with the starter. |

| 3. | Kirill: despite the manufacturer’s warranty, the clutch basket has already flown for 60,000 km. Contacted the service for diagnostics and repairs. The manufacturing quality is low, the actual service life of the parts is lower than stated. |

Conclusion

The clutch installed on the Lada Grant is copied from the Lada Kalina. The mechanism has proven itself well, the warranty period is “nursing” (100,000 km).

A number of negative reviews about the Lada Granta are unfounded. Many unit failures are associated with violation of operating conditions, aggressive driving style, and failure to comply with technical inspection deadlines.

Often the reason for premature clutch wear is that drivers save money on monthly maintenance and purchase cheap spare parts. After all, a low-quality part cannot work for a long time without breaking.

Source

Selection of components

The clutch life on Grants depends on the operating conditions in which the car is located, and therefore can have significant differences. When using the car sparingly, the clutch is changed after 100,000 km. One of the most common types of clutch installed by the Volzhsky Automobile Plant is LUK clutches.

As a rule, clutches are sold in the form of kits, which include a clutch disc and basket, as well as a release bearing. The approximate cost of clutches for Granta starts at 2,000 rubles and can vary significantly in a particular region.

To purchase an original kit and not a counterfeit, buy parts only in specialized retail outlets, based on real customer reviews, or order the kit directly from the manufacturer (for example, using the Internet). Sometimes clutches are assembled from components made by different manufacturers.