VAZ 1118 front wheel bearing size

__________________ ICQ No: 493227065

| ArTemKa user menu |

| View profile |

| Visit ArTemKa home page |

| Find more posts by ArTemKa |

| Read the diary |

| View downloads |

| User menu karakal |

| View profile |

| Find more posts by karakal |

| View downloads |

fiX

, about roller bearings:

They differ, in comparison with ball bearings of the same size, in having a greater load capacity. And they have the unpleasant property of “what if” - they jam right away, while the ball ones will play and buzz, but they will get you home.

The information comes from AZLK factory specialists, who at one time were forced to cross out the rollers from the list of acceptable ones for installation on 2141.

| Mikky user menu |

| View profile |

| Visit Mikky's home page |

| Find more posts by Mikky |

| SHOOM user menu |

| View profile |

| Find more posts by SHOOM |

| Jackson User Menu |

| View profile |

| Find more posts by Jackson |

| View downloads |

The feedback system of JSC AVTOVAZ received a question from you:

07/06/11

“Hello, I have the following question: what kind of lubricant is used in the VBF 256707A1KE12 wheel bearings installed in the front wheels of the Lada Kalina on the AvtoVAZ conveyor?

I ask the question because I could not find this information anywhere (including in the bearing markings), and mixing some lubricants is unacceptable. Waiting for an answer. Andrey" 07/06/11

"Good afternoon, Andrey Toropov!

The front wheel bearings use CHEVRON SRI GREASE NLGI 2 lubricant.” Department of inspection of service and sales network enterprises. Head Office. Anton Vladimirovich

You can add lubricant to the hubs without pressing them out. Carefully bend the edge of the seal and use a 2 ml medical syringe with a medium-thick needle. Don't forget about lubricant compatibility.

Currently, an unacceptable situation has arisen in terms of removing the bearings of the front and rear hubs of front-wheel drive vehicles. As a result of the commission work carried out in the city of Togliatti, it was noted that for 30 days there were no complaints from owners of front-wheel drive cars regarding defects in wheel bearings. I draw your attention to the fact that PSSS employees make a conclusion about the discrepancy between the wheel bearings based on the feeling of play when the wheel rocks in a plane perpendicular to the axis of rotation, WHICH IS NOT A FAILURE SIGN! The reason for replacing the bearing may be an increased axial clearance, measured using the technology set out in TI 3100.25100.20434, see the appendix for parameters. When owners of front-wheel drive cars make a complaint about the “noise” of the wheel bearings, I PRESCRIBE: 1. Check the compliance of the tires and wheels installed on the car with the requirements of the operating manual, as well as their condition. 2. If there are no deviations according to point 1, make a test drive. If studded tires or tires with an enlarged tread pattern are installed on a vehicle, a test drive must be carried out with the tires that are equipped with the vehicle at JSC AVTOVAZ. 3. If the presence of non-functional noise is confirmed, which can manifest itself from “rustle” to “hum” or “rumble”, it is necessary to conduct additional listening to the bearing when rotating the wheel on a suspended car using a phonendoscope (the rod touches the fist when checking the front bearing, the rod touches the axle when checking the rear), excluding contact between the elements of the hub units and brake mechanisms. 4. If non-functional bearing noise is detected, it must be removed from the vehicle. If unauthorized tampering with the hub assembly is detected (re-caulking of the nut or missing caulking), replacement will be carried out at the owner’s expense. 5. After dismantling, check that the date of manufacture and bearing markings match. If there are no deviations, it is necessary to conduct a micrometering of the mating surfaces (see appendix). Based on the measurement results, decide on a method for eliminating the discrepancy and coding the defect.

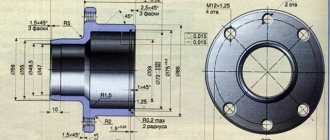

Steering knuckle 11180-3001014/15 Diameter for bearing Ø68 mm, (67.94…67.97) mm

Front hub 11180-3103012 Bearing diameter Ø35 mm, (35.002…35.018) mm

Hub bearing 11180-3103020 Outer diameter Ø68.015 – 0.011 mm, (68.004…68.015) mm Inner diameter Ø35 mm, (34.966…34.976) mm

Steering knuckle 21080-3001014/15 Diameter for bearing Ø64 mm, (63.94…63.97) mm

Front hub 21080-3103012 Bearing diameter Ø34 mm, (34.002…34.018) mm

Hub bearing 21080-3103020 Outer diameter Ø64 – 0.011 mm, (63.989…64.000) mm Inner diameter Ø34 mm, (33.99…34.00) mm

Wheel axle 21080-3104055 Bearing diameter Ø30 mm, (29.980. 29.998) mm

Rear hub 21100-3104015 Bearing diameter Ø60 mm, (59.94. 59.97) mm

Hub bearing 21080-3104020 Outer diameter Ø60 – 0.011 mm, (59.989…60.000) mm Inner diameter Ø30 mm, (29.992…30.000) mm

1. 11180-3103020-00 supplier of military-industrial complex (80280). On the seal: 256707А1КЭ12, VBF, RUSSIA, symbol of the year of manufacture. It is allowed to apply the symbol of the year of manufacture on the outer surface (Ø68) of the outer ring. 2. 11180-3103020-02 supplier EPK (78669). On the mud deflector washer: 6-256707АЭКЛ20, SPZ, symbol of the year of manufacture. It is allowed to mark on the outer surface (Ø68) of the outer ring the symbol of the year of manufacture and the symbol of the lubricant (L20 or L19). 3. 11180-3103020-03 supplier EPK (78669). On the mud deflector washer: 6-256707EK12, VPZ, year of manufacture (last two digits of the year of manufacture). On the outer surface (Ø68) of the outer ring there is a lubricant symbol (L20, L19, C28 or C35). 4. 2108-3103020-01 p

Military industrial complex provider (80280).

On the seal: 256907 AKE12, VBF, RUSSIA, symbol of the year of manufacture. It is allowed to mark on the end of the inner ring. 5. 2108-3103020-02

supplier EPK (78669)

.

On the mud deflector washer: 6-256907EK12, SPZ, symbol of the year of manufacture, symbol of lubrication (L20 or L19).

It is permissible to mark the symbol of the year of manufacture and the symbol of the lubricant on the outer surface (Æ 64) of the outer ring. 6. 21080-3104020-00

military industrial complex supplier (80280)

.

On the seal: - 256706E1, VBF, RUSSIA, symbol of the year of manufacture;

on cars with a production date from November 2009 - 256706 AKE12, VBF, RUSSIA, symbol of the year of manufacture. It is allowed to mark the symbol of the year of manufacture on the end of the inner ring. 7. 21080-3104020-02

supplier EPK (78669)

.

On the seal: 6U-537906E1 VPZ; at the end of the inner ring: symbol of the year of manufacture, symbol of the lubricant (L20, L19, C28 or C35). 8. 21080-3104020-04 supplier EPK (78669). On the seal: 6-256706E10; on the outer surface (Ø60) of the outer ring: SPZ, symbol of the year of manufacture, symbol of the lubricant brand (L20).

Permissible values of axial clearances of bearings in the assembled hub assembly

measured according to TI 3100.25100.20434

Front wheel bearing for Kalina, Priora, Granta

- Manufacturer: VPZ-23

- 0 reviews

- Description

- Characteristics

- Video

- Delivery

- Payment

- Reviews 0 ? '(' + product.reviewsCount +')' : »>>

Dear customers, in order to avoid errors when sending a front wheel bearing, please indicate your car model, year of manufacture, front or rear in the “Comment” line.

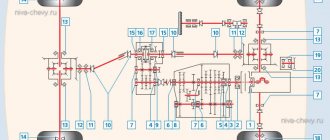

All VAZ cars are equipped with only three types of wheel bearings - wheel bearings for front-wheel drive VAZ cars, wheel hub bearings for rear wheels, and wheel bearings for Kalina and Grant cars, which are smaller in size.

Hubs play a very important role. Without them, the wheels will not rotate at the required speed, which will first lead to damage to the brake system, and then to failure of the entire car.

The front wheel hub is a rather complex forging. In the front wheel hub there is a double-row angular contact ball bearing, into which a driver with an internal splined cylindrical surface is inserted for the splined end of the drive shaft. To protect the hub, there is a cap covered with dirt-reflecting rings.

The bearing is of the HUB-1 type, has a double-row design, is a type of angular contact ball bearings with closed working surfaces and does not have flanges for attachment to the hub, which does not require lubrication and adjustment during vehicle operation.

The drive shaft is secured in the driver with a self-locking nut and washer. The nut has an external hexagonal key, thread M 20 x 1.5, tightening 290 Nm ±10%.

If you hear a noise, a characteristic noise or a certain hum in the front part of your car, which only intensifies when entering a turn, this indicates the need to urgently replace the front wheel bearing on your VAZ 1118, 2170, 2190, 2192.

If the hum is heard on only one side, then only one bearing is damaged. But most likely the second one doesn’t have much time left either. Buying two bearings as a set will be cheaper than buying them separately.

When pressing out the wheel hubs, the bearings are destroyed. Therefore, pressing out the hubs should be carried out only in cases of increased bearing noise or a significant increase in the gap in them: more than 0.015 mm in the front and more than 0.030 in the rear.

Other articles of the product and its analogues in the catalogs: 11180310302000, T-02148, KT 100534, 11180310302004.

VAZ 1117-1119, VAZ 2170-2172, VAZ 2190, VAZ 2192-2194 (Kalina 2), VAZ 1117-1119, Largus, Datsun.

Any breakdown is not the end of the world, but a completely solvable problem!

How to independently replace the front wheel bearing on a VAZ family car.

AvtoAzbuka online store, repair costs will be minimal.

Just COMPARE and BE SURE.

Don't forget to share the information you find with your friends and acquaintances, because they may also need it - just click one of the social networking buttons located above.

Dear customers and visitors! Please note that we ship orders from the city of Tolyatti!

Before shipping, we will carefully check, carefully pack and quickly deliver to the Russian Post or to a transport company!

Happy shopping!

Dear visitors and customers, we would like to draw your attention to what methods can you pay for your orders?

Pay with any card on the website for ordering and delivery. There is also an option to pay only for the order - and pay for delivery upon receipt of the goods

If you want to pay for your order upon receipt of the goods, then we can only send you by Russian Post - Cash on Delivery. We only ask you to pay for shipping.

CV joint nut, how to unscrew, in which direction and why it does not unscrew, overview of types and types of nuts

The spline connection of the outer CV joint is a critical unit. It is this part that bears the torque load. It is no wonder that the grenade nut, which holds the floating axle shaft in the drive wheel hub, should not unscrew on its own.

Before unscrewing the hub nut, it is advisable to read the instructions for routine maintenance of your car. It indicates the method of fixation, the direction of the thread and other nuances.

- Changing the geometry of the nut (one side is oval). Anyone who has repeatedly unscrewed such a nut has seen that the threads gradually become unusable;

- Punching after tightening. This solution is not suitable for replaceable units, since this will damage the screw part. However, many car manufacturers fix the hub nut in this way so that it does not unscrew while driving;

- Hairpin. The most reliable method of fixation. The nut does not unscrew on its own, and the thread does not deteriorate. For some reason, not all car designers use this simple method;

- The retainer is a “shoulder-groove”. A common method, more reliable than core punching, but detrimental to carvings. Longitudinal grooves (one or two) are made on the threaded connection of the axle shaft. The CV joint nut has the same number of collars, which bend into grooves after tightening. It is almost impossible to unscrew the nut without damaging the thread;

- A variety of fixing paints and adhesives. Not used on hub connections.

Since the connection is in unfavorable conditions (especially if the boot cap is lost), the nut does not unscrew the first time. An inexperienced driver panics, starts turning the nut in the wrong direction, uses attachments on the wrench in the form of a meter-long pipe, and as a result breaks the thread. The consequences are a forced replacement of a still-living CV joint.

How to unscrew the hub nut without ruining the threaded connection

First of all, stock up on quality tools. An ordinary wrench is not suitable for plumbing work, although many car owners stubbornly use them to repair CV joints (the size is the same, but the cost of the tool is lower). An open-end wrench can only be used to unscrew an already “undermined” nut, this is really more convenient.

Important! Reuse of nuts is not permitted. Before unscrewing the old nut, make sure you have a new one.

- Thoroughly clean the surface from corrosion and dirt. If a spline-shoulder pair is used, you need to pick out everything that is in the holes;

- Treat the joint with a penetrating compound for soured threads. For example, WD-40 liquid, or regular kerosene. You may need to "soak" the thread for several hours;

- Remove all fixing devices;

- Place the socket on the nut and try to turn it using the lever. At this stage, it is better not to use handles with ratchets, as the mechanism may be damaged;

- After “undermining”, the nut can be unscrewed with any wrench that is more convenient.

Throw away the old nut and stud. Clean the threaded connection from rust and traces of fixing compounds.

How to unscrew the CV joint nut if a fixing collar is used

For proper release, you need a special punch that exactly matches the size of the spline collar. You won’t find them during the day with a fire, so it’s wise to make a useful tool yourself. For example, from an old file. With its help, you can unscrew the nut while maintaining the threads on the axle shaft.

After disassembly, it is necessary to slightly grind the shoulder to remove burrs.

What to do if the nuts do not unscrew?

Have you removed the clamps, “soaked off” the rust, bought a wrench with a 1 meter lever, but it still doesn’t work? There are proven ways to unscrew a nut without a grinder.

- Reverse rotation. Sometimes it is enough to first move the nut in the direction of tightening, and the process will begin;

- Tap the nut. Use a small hammer (preferably brass or copper) to tap the edges;

- Heat. A gas torch or blowtorch is an almost 100% guarantee of success due to the expansion of the metal. In an electrified garage you can use a hair dryer. Heat for at least 5 minutes.

Don’t panic, hit the key with a sledgehammer, or cut the hub with a grinder. Rust on the threads is not welding. The connection is still removable, it just requires a little patience.

SwapMotor.ru

Lada Kalina - replacing the front wheel bearing

- ➡️ How to choose a front wheel bearing for the Lada Kalina ➡️ Table of bearing manufacturers

- ➡️ Price and dimensions of wheel bearing for Lada Kalina

On cars of the Lada family, the wheel bearing often fails. Reasons: bad roads, careless driving, and bearing failure after a run of 50,000 km.

The main sign that the wheel bearing needs to be replaced is that the Kalina begins to hum in the front of the car when driving even on a flat road, and a hum can be heard from the front chassis. Also reasons: vibration and grinding noise when turning. All these signs indicate that diagnosis and repair are needed.

Diagnostics of the Kalina wheel bearing:

- Lift the wheel with a jack and move it with your hands in the axial direction; if the play is more than 3 mm, then the part is not working properly.

- Also, if a wheel breaks down, the ease of rotation of the wheel is worse, much worse, and you may hear a characteristic grinding noise when rotating.

- You can professionally assess the condition of the bearing by measuring the axial play.

Replacement methods

First way

- In the first case, it is necessary to use a puller to remove the bearing;

- Simply carefully remove the bearing and replace it with a new one;

- After installation, all the steps above should be carried out in reverse order.

The main advantage of this method is the fact that the technician will not need to touch the camber adjustment bolt, which is very difficult to put in place later.

If we talk about the disadvantages, we can note the following: the master will have to take a very uncomfortable position to perform actions. That is why it is necessary to prepare a lift and climb into the inspection hole.

But it is still very inconvenient for a car enthusiast to knock out the hubs in this position and press in the bearing assembly.

Second way

Consists of the following steps:

- To remove the bearing using the second method, you must carefully dismantle the steering knuckle and completely remove the hub;

- After this, the master will need to go to the workbench;

- The VAZ 2110 wheel bearing is replaced directly on the workbench;

- After this, everything is installed back, just as it was removed before.

This method is undoubtedly much easier than the first, but since it affects the camber, problems with adjustment cannot be avoided. Before you begin to unscrew the knuckle mounting bolts from the strut, you need to mark their position with chalk or a marker.

The first mark in this case will indicate the location of the adjusting bolt on the rack. The second mark will indicate the previous position of the fists.

After the master begins assembly, he will focus precisely on these marks. Of course, it will be difficult to achieve great accuracy and it will not be possible to return the parts to their place. But with careful work, installation errors can be minimized.

There are some steps to follow:

- The master puts marks;

- Knocks out the knuckle bolts;

- Unscrews the mounting bolts from the lower ball joint;

- The bearing must be knocked out of the hub;

- The retaining rings are dismantled;

- Using a vice, the bearings are pressed out.

Before reassembly, the space in the fists must be thoroughly and thoroughly lubricated.

This method is often used when repairing not only one bearing component, but the entire chassis. As a result of this method, it will also be possible to safely replace ball joints, silent blocks of levers and steering tips.

Third way

It is carried out in the following order:

- In this case, you will need to remove the entire rack completely;

- After all the components have been removed, the technician will need a special vice;

- The wheel bearing will be replaced at the vise and all parts will be reinstalled.

This method is the most complex and difficult because it requires the technician to dismantle the entire rack. In addition, it will be necessary to unpress the steering tip, and you also need to unscrew the fastening nuts, they secure the upper support to the body base.

Direct removal of this VAZ 2110 unit is carried out only after the entire rack has been removed from the car. And this process takes a lot of time.

Lada Kalina - front wheel bearing

The front wheel bearing marking is 6-256707 AKE12.

When choosing a manufacturer of spare parts for the front hub for the Lada Kalina, the question arises about the manufacturers. Let's list some of them.

Recommended Front Wheel Bearing Manufacturers

| No. | Manufacturer, country | Catalog number | Dimensions, mm | Price, rubles |

| 1 | VAZ (original) | 3103020-00 | 35*68*37 | 1040 |

| 2 | RK TOR Moscow | T-12103 | 700 | |

| 3 | AT | AT3020118B | 550 | |

| 4 | Pikenga, Italy | PW-P-1313 | 585 | |

| 5 | Finwhale | HB411 | 590 | |

| 6 | 23 PZ | VBF | 700 | |

| 7 | SPZ-4 | SPZ GROUP | 500 | |

| 8 | EPK | 3PZ, VPZ | 500 |

Kalina front wheel bearing price

Of the options presented above, the cheapest is EPK. The cost is on average 500 rubles. 23 PZ produces such products at a price of 700 rubles. The LSA brand, a Slovak factory, is also sold, expensive but at the same time high-quality products.

Front wheel bearing Kalina - dimensions

Parameters and dimensions of bearing 6-256707:

- Hole diameter: 35mm;

- External diameter: 68 mm;

- Height: 37 mm;

- Speed: 3500 rpm.

Which bearing manufacturers can you trust?

It doesn’t matter whether you need to buy a rear or front wheel bearing, you should pay attention to products only from trusted manufacturers. Therefore, we recommend products from reputable manufacturers such as SNR, NSK and Iljin. These manufacturers care about the quality of materials, assembly and lubrication of bearings. Several years may pass before the first signs of wear appear; the car will travel several hundred thousand kilometers. At the same time, the price of these bearings is not bad and is completely justified. * Please check the applicability of parts specifically for your car with our managers by phone (calls within Russia are free).

Replacing the front wheel bearing Kalina - preparation for repair

Replace on a flat surface, but it would be better to use an inspection hole. Put the car in first gear, secure it with wheel chocks, and remove the car from the handbrake. You will need a set of locksmith tools:

- hub puller with a set of discs of various diameters;

- hammer and chisel;

- socket wrench at “30”;

- impact screwdriver;

- round nose pliers.

- a set of open-end and ring wrenches, including a torque one (torque).

We lift the entire front of the car (both wheels) and begin replacement. Check out the design of the Kalina front hub:

Direct replacement of the front wheel bearing Lada Kalina

Now we will describe in detail the replacement process, with a description of all operations, how to remove and install all hub components.

- First, remove the decorative cap on the hub nut.

- Unlock and loosen the hub locknut itself.

- Unscrew the hub bearing locknut using a socket wrench.

- Remove the wheel and then unscrew the brake disc.

- Now we unscrew and remove the brake caliper, and secure it to the stand with wire.

- These bolts secure the repeater mechanism to the telescopic strut of the Lada Kalina.

- We unscrew these bolts with a key “17”, remove the Kalina rotary flywheel.

- Now we loosen the bolts that secure the ball joint to the knuckle.

- We disconnect the ball joint with the bearing from it and remove the Kalina CV joint from the hub.

- Now the Lada hub together with the turning mechanism can be easily removed by hand.

- We place the entire structure on the jaws of a vice, and using a mandrel of a suitable diameter and a hammer, carefully compress the hub, striking the end of the hub, NOT THE BEARING .

- The hub will fall out, leaving the inner part of the part on it, and the outer part in the knuckle body, as in the photo:

- Next, remove the retaining rings from the knuckle body using pliers.

- Now the rings will not interfere with pressing the outer part of the wheel bearing out of the housing with a puller.

- This is also done using a hammer and a mandrel, holding the body in a vice.

How to unscrew the hub nut - the main 5 ways

To solve the problem of how to unscrew the hub nut, it is necessary to determine the dismantling method. This can be done in one of two main ways:

- With the wheel removed.

- The car is on wheels.

It is important to know:

When unscrewing the hub locknut, it is important to ensure compliance with safety precautions. Under high load, the vehicle may move and injure the technician.

To prevent this from happening, we use stops. They are installed under the wheels on both sides. The parking brake must also be applied. This way we will ensure that the car body is held in a given position.

If the nut does not unscrew, we make a choice taking into account the following possible methods:

| Name | Description | What tools are needed? | When to use |

| "Barbarian" option | Provides for dismantling and subsequent replacement. | Drill with metal drills (of different diameters), chisel, hammer (small sledgehammer). | It is used if there is no chance to unscrew it in the usual way. |

| "Hot" method | Heating the metal at the joint. | Burner. | Bearings and hubs must be replaced. |

| "Delicate" work | Carefully unscrew the stuck part, gradually increasing the force with the lever while simultaneously tapping on the body. | Tubular socket wrench, heavy-duty screwdriver, hammer, extension pipe, deep penetration lubricant. | If necessary, perform the work as carefully as possible |

| Maximum force | A powerful wrench and a long pipe can significantly increase the force, thereby increasing the chances of stripping the thread. | Heavy duty socket wrench, long pipe. Heads for licked nuts. Key with hydraulic or electric drive. | A strongly stuck nut. |

| Using chemicals | A soaked rag will gradually relieve the problem. | Kerosene and (or) white spirit, hammer, rags. | If you have time. |

You can quickly unscrew a stuck element if you provide a lever. It is installed on the ratchet wrench using a small pry bar. You can use a piece of pipe of suitable diameter with a length of at least 1 meter.

Front wheel bearing SS20 for VAZ 1117, 1118, 1119 Kalina (repair kit)

Wheel bearings are subject to extreme loads, especially on Russian roads. To ensure rotation of the car wheel without play, with minimal noise and friction, it is necessary to carefully select wheel bearings. SS20 hub bearings have passed 100% quality control and guarantee car owners confidence in road safety.

Advantages of SS20 hub bearings

- high service life and reliability of the bearing;

- quiet operation;

- long service life;

- ensure easy and silent rotation of the wheels;

- high-quality high-temperature lubricant;

- sealed ball bearings are lubricated during assembly and do not require maintenance;

- low level of mechanical losses in the bearing due to low surface roughness and high dimensional accuracy;

- comprehensive protection against counterfeiting;

- complete installation kit.

In the hub units of front-wheel drive VAZ cars, double-row ball bearings are used. During assembly, the required amount of lubricant is placed in the bearing. The internal space of the bearing is reliably sealed with oil seals, which prevents contamination from getting inside. This ensures normal lubrication of the raceways, balls and cages throughout their service life. Wheel bearings SS20 for front-wheel drive VAZ cars are maintenance-free and do not require adjustment or lubrication during operation. This approach significantly reduces the labor intensity of vehicle maintenance and at the same time ensures high reliability.

The reliability of the bearing directly depends on the accuracy of manufacturing and compliance with all standards during the production of the bearing. Therefore, for SS20 double-row ball bearings we carry out a number of additional checks, for example, monitoring the amount of axial clearance and radial “runout” in the mounted state.

1 year warranty

| Packaging dimensions | |

| Height | 10 cm |

| Width | 10 cm |

| Length | 10 cm |

The wheel bearing is one of the most heavily loaded suspension elements. Wheel bearings allow wheels to rotate and the vehicle to move as a whole. In addition to the perception of loads directly from the wheel rolling on the road, shock and thermal loads are added. Through the hub bearing, all forces arising in the contact patch between the wheel and the road are transmitted to the suspension.

That is, of the suspension and the car depends on the correct choice of front and rear wheel bearings . The main problem when replacing wheel bearings is the large number of low-quality fakes on the market that last no more than 2-3 thousand km, as well as violation of installation technology and incorrect adjustment of clearances.

Malfunctions of wheel bearings manifest themselves in the form of hum, knocking and play when the car is moving, clicks when starting and stopping. As raceways, rolling elements and cages wear, rolling resistance increases and this is accompanied by increased noise and heating of the bearings.

You can determine the malfunction of the wheel bearings yourself. To do this you need:

- Check ease of rotation. Spin the suspended wheel with a sharp jerk and evaluate the noise level emitted by the bearing during rotation. The wheel run-out time is also estimated.

- Determine the presence of play in the hub bearing. On a suspended wheel, applying a load with your hands in the vertical and horizontal planes, check for swing (play) in the bearing. By applying force along the axis of rotation of the wheel, you can estimate the axial clearance.

SS20 wheel bearings will help you avoid problems with low-quality spare parts. The reliability and durability of SS20 bearings is achieved through:

- accuracy of geometric dimensions in the design and production of a product;

- use of high quality steel;

- achieving the required level of surface roughness;

- use of high-tech equipment.

The manufacturing precision of wheel bearings, surface roughness and rolling elements are the key aspects that influence the level of mechanical losses in the bearing and, ultimately, determine the noise class.

During production, the service life of the hub bearings is checked selectively from the batch before failure on a stand that simulates real loads on the bearing. As part of a comprehensive quality assessment, bearing runout is checked with an assessment of the reduction in speed at two stages from 100% to 70%, and the drop in speed from the initial stage to a complete stop. At the same time, the vibroacoustic parameters of the freewheel bearing are checked.

A whole range of serious checks at all stages of the production process allows us to guarantee the buyer the high quality and reliability of SS20 wheel bearings.

SS20 hub bearings have the SS20 branding and additional protection against counterfeiting, which will provide car owners with confidence and safety on the road, and protect them from possible financial and time losses when using counterfeits.

The high quality of the lubricant ensures a service life of up to 300,000 km in the wheel bearing assembly. The amount of grease is calculated to ensure reliable lubrication of the bearings throughout their entire service life. The operating temperature range of the lubricant is from –40°С to +180°С.

Repair kits for front and rear hubs of front-wheel drive VAZ cars

In the hub units of front-wheel drive VAZ cars, double-row ball bearings are used. During assembly, the required amount of lubricant is placed in the bearing. The internal space of the bearing is reliably sealed with oil seals, which prevents contamination from getting inside. This ensures normal lubrication of the raceways, balls and cages throughout their service life. Wheel bearings SS20 for front-wheel drive VAZ cars are maintenance-free and do not require adjustment or lubrication during operation. This approach significantly reduces the labor intensity of vehicle maintenance and at the same time ensures high reliability.

The reliability of the bearing directly depends on the accuracy of manufacturing and compliance with all standards during the production of the bearing. Therefore, for SS20 double-row ball bearings we carry out a number of additional checks, for example, monitoring the amount of axial clearance and radial “runout” in the mounted state.

What are the signs of bad wheel bearings?

Signs of bad wheel bearings include the following:

- A rumble or hum that gets louder when accelerating or turning.

- Constant loud howling or squeaking sound when the car is moving

- Clunking sounds when driving on uneven surfaces

2. Excessive play or free movement of the steering wheel (uninformative steering wheel); 3. Vibration of the steering wheel, changing depending on the speed of the car or when turning; 4. ABS malfunction. Problems with the ABS system may be due to a faulty ABS sensor integrated into the wheel bearing.

What are the dangers of driving with a bad wheel bearing?

It is extremely rare for a wheel bearing to fail immediately and completely after you notice the first signs.

However, it is best to avoid long trips with a worn wheel bearing. As we already know, the wheel bearing is extremely important - it connects the wheel to the car. Any problem in this connection can have very serious consequences for the drive axle and steering system, as well as for your safety.

Replacing wheel bearings

Although today's wheel bearings are easier to install than in the past, correct installation, using the correct tools, and maintaining the specified torque values are still important for maximum performance, longevity and safety. Therefore, we recommend that wheel bearings be installed by a professional mechanic with the appropriate skills and tools.

High quality spare parts

When replacing wheel bearings, it is important to select high quality parts. MOOG offers a full line of premium, easy-to-install, durable wheel bearings that have been designed, manufactured, tested and approved to original equipment standards for maximum performance and durability. View MOOG's full range of products Find technical tips on wheel bearings.

The material contained in this article is for informational purposes only and should not be used as a substitute for professional advice from certified technicians or mechanics. For specific questions or concerns regarding any of the topics covered in this article, we recommend consulting with a certified technician or mechanic. We will not be liable for any loss or damage arising from your interpretation of the contents of this material.

Replacing the Grant rear wheel bearing

To find out what condition the Lada Granta rear wheel bearing is in, you need to hang the wheel in a free state and rotate it by hand. Ideally, the wheel should spin evenly and smoothly without knocking or sticking.