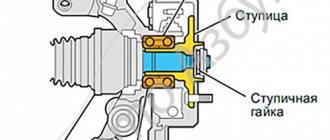

On Niva, wheel bearings are two tapered bearings (on each hub, i.e. there are four in total), the tension of which is ensured by a wheel nut, which is tightened with a certain torque. When tightening, it is necessary to control the runout of the brake disc using a micrometer... but this is wise! But in fact, almost all motorists, and even more so “servicemen,” tighten it like this: spin the wheel (brake disc), tighten the hub nut, tighten it... tighten it... and so on until a given moment (at best). As a result, quick bearing failure! In addition, this operation has to be carried out when replacing a CV joint or simply after a strong side impact on the wheel, for example on a high curb. It was decided to replace the package of Nivov bearings with a double-row front wheel bearing of the Moskvich 2141 (No. 2141-3103020), as I learned, this bearing is also installed on some foreign cars. The overall dimensions of the bearing (37*72*37) allow it to be installed in the Niva’s front hubs, subject to some “alterations”. It is necessary to slightly reduce the landing diameter of the hub itself to 37 mm. And bore the steering knuckle! This is the most difficult process because... requires coordinate grinding (to make an ideal seat for a new bearing). You can, of course, get by with a simple lathe and a good turner (it will be MUCH cheaper!), but I decided not to skimp on quality and turned to professionals in this matter, who, in turn, made all the parts I needed for a “tidy” sum. You also need special support washers with a thickness of 10.5 mm.

Now a little more about all this: We remove and completely disassemble the old hubs, clean everything from dirt. We go to the bearing store and buy the double-row bearing No. 2141-3103020 we need or its imported equivalent in the amount of 2 pieces. Personally, I bought American bearings from the “Craft” company, number: CR4172370, if I’m not mistaken. We will also need two retaining rings from the front wheel bearings of the Moskvich-2141 car (No. 366553-15), they can be of different thicknesses, so we be sure to buy them in advance. If you have chosen the cheap option, then we take the drawings and go to the turner and spend a long, long time persuading him to take on this task... Then we carefully monitor the quality of the work. After everything is ready, we try to press in the bearing and begin assembling. If you choose the expensive option, contact some organization related to high-precision machining, explain the situation, give them all the parts (bearings, retaining rings) and go home, wait for the result. Personally, I turned to a turner and for a certain amount of money they sharpened the hubs to fit new bearings, bored (or rather ground) the steering knuckles, made 4 pieces of support washers, at the same time corrected the “jamb” with the neck for the oil seal on one of the hubs, and ground the seats under the brake disc on the hubs, and also pressed new bearings into place and installed retaining rings. Next, having received a set of ready-made parts, we begin to assemble! Because The bearings have their own rubber seal, so there is no need for standard seals. But I still recommend installing them (you can use the cheapest ones), if only to limit the entry of water and dirt into the steering knuckle. We assemble the hub and brake disc. In this case, it is better to take a new brake disc (or an old one, if there is little wear on it!). The fact is that to replace the brake disc on a Niva, you need to remove the hub, and these new bearings can only be pressed out against the inner race - i.e. The bearing will then no longer be suitable for use! Next, we press the hub into the bearing (in the steering knuckle), not forgetting to install the support washers (one between the journal under the oil seal on the hub and the bearing, the second is installed later, on the other side of the bearing, between the bearing and the CV joint.)! We assemble the entire assembly and install it on the car. Now we tighten the hub nut with a large torque (about 200 Nm), as they say: “from the heart”! And from now on we go and enjoy...

Reinforced, non-adjustable hubs

For Niva 4x4 you can find on sale reinforced, non-adjustable hubs with double-row bearings from the Iveco Daily truck. According to the manufacturer, this modernized unit has the following advantages over Nivovsky:

Converting the hub to a double-row bearing

Do you want to modify your Niva, but have a small budget? Then we’ll show you how to remake the front hubs on a Niva with your own hands. Required:

We take the drawings and seek the services of a turner. The master must bore the hub to fit new bearings, grind the steering knuckles and make parts according to the diagram. By the way, some Niva 4x4 owners also use an AUDI 74x40x74 wheel bearing, in this case only the steering knuckles are ground.

After the parts are manufactured, all that remains is to press in the double-row bearing and reassemble the already non-adjustable hubs. At the end of the work, tighten the hub nut with a large torque “from the heart”. Their adjustment is no longer required, you can forget about the hum and howl while driving!

Have you ever encountered a similar modification to the Niva hub? Leave recommendations and reviews about your options for upgrading the VAZ 2121, 2131. Let us remind you that the domestic SUV has other shortcomings, which are also eliminated by modifications. You can also find information about the car you are interested in by its content.

Key words: 4x4 front suspension

Source

Symptoms of a problem

Bearing wear manifests itself as the following symptoms:

- Vibration of the front wheels, which can be reflected in the steering wheel or felt in the cabin.

- Knocking or crackling sounds in the front of the car when driving;

- Heating of the front wheels in the axle area.

If such manifestations occur, you need to check the condition of the wheel bearings. To do this, jack up the car and rock the wheel in different directions. Play and knocking in the bearing area indicates the need for replacement and adjustment. The malfunction may also manifest itself in the form of noise when the wheel rotates.

Separately, it is worth mentioning two problems that arise during the operation of the Chevrolet Niva:

1. The hubs get hot. It is important to understand that when braking, the kinetic energy of the car is converted into thermal energy. As a result, the brake discs and the hubs on which they are attached become very hot. Heating of the part during movement, and not during braking, indicates wear of the bearing or its incorrect adjustment.

The second option is typical for adjustable hubs. The adjusting nut must be tightened with a force of 2 kgf*m. If you tighten it further, the tapered bearings will be too tight.

Their rotation will be difficult. Prolonged operation of the machine in this condition leads to bearing failure and wheel jamming.

2. The adjusting nut is unscrewed while moving. Sometimes this happens literally after 20-50 kilometers. The phenomenon is observed in three cases: the master forgot to tighten the nut, there was a misalignment between the bearing races, or play appeared in the coupling of the CV joint with the hub.

Technologies for strengthening hubs on Niva

Niva is a domestic VAZ car, which differs from its predecessors in all-wheel drive and the ability to operate in off-road conditions. The technical characteristics of an SUV still attract extreme sports enthusiasts to this type of transport, since it has an affordable price, is well repaired, and is durable in use.

When using a car in serious off-road conditions, owners very often come to the need to modernize and improve some components and assemblies of the vehicle. The Niva’s hub unit, which was inherited from domestic classic models, is no exception. And if it has proven itself well on passenger cars, the need to adjust the thermal clearance of the hubs on the front wheels has become a real problem for SUV owners. Let's take a closer look at how to make a reinforced hub assembly for the Niva.

First changes and Lada 4x4

Since the mid-nineties, or more precisely since 1995, changes began to be made to the design of the car. Firstly, if previously the car had a 1.6-liter 4-cylinder 73-horsepower gasoline engine, now the volume has been increased to 1.7. The manual transmission now had five steps instead of the previous four. Secondly, they changed the dashboard, installed more comfortable seats in the cabin, and replaced the taillights with more modern ones in order to externally try to get closer to the Western automobile industry.

In 2006, “Niva” was officially renamed “Lada” 4x4, and models exported were called “Lada Taiga” 4x4 - this is what the car is now called in European countries. Externally and internally, the car has changed, if at all, only slightly: new mirrors have appeared - larger ones, the indicators and instruments on the panel have been changed. The new car model released in 2015 called “Lada 4x4 Urban”, which is considered “luxury”, did not receive any major changes - except for new bumpers, electric windows and air conditioning in the cabin.

Options for strengthening hubs on Niva

Incorrect adjustment of the hub clearance can cause a serious problem for the car owner. The consequences can be different, from frequent destruction of bearings, which requires constant replacement, to bearing jamming while moving, destruction of the hub assembly and the occurrence of an emergency. Theoretically, every owner knows that to solve the problem it is necessary to abandon tapered bearings in wheel hubs. There are two main options for solving the problem: installing non-adjustable hubs or converting parts for double-row bearings.

Installation of non-adjustable hubs on Niva

The first modernization option involves the purchase of a new reinforced Niva hub unit, which has significant advantages compared to standard products.

Benefits of using a reinforced hub assembly:

The kit consists of two knuckles with pressed bearings, two hubs and two boots. When purchasing, it is important to clarify how many splines your hub has, so that there are no problems with installation. There are kits for Niva that come with 22 and 24 splines.

Experts advise installing reinforced components in service centers, however, you can handle the replacement yourself, since installation does not require any additional modifications. It is important when installing new parts to also use new wheel studs and nuts. It is also necessary to lubricate all elements to prevent them from souring and before installing the caliper, clean it, which will have a positive effect on the progress of the vehicle’s pads.

The only drawback of this improvement of the machine is the high price of the hub unit. The second reinforcement option involves converting the hub to a double-row bearing and is characterized by minimal financial costs.

Converting a hub to a double-row bearing with your own hands

To remake the part, you will need to purchase two double-row bearings and retaining rings from Moskvich 2141. You can buy standard products or imported analogues of bearings. Imported products are characterized by higher quality.

This is interesting

And as a conclusion, here are some interesting facts about Niva:

- in 1998, this car climbed under its own power to the base camp at the foot of Everest - which is 5200 meters above sea level; in 1999 - on a plateau in the Himalayas, to an altitude of 5726. This is a record to this day.

- “Niva” even visited the North Pole, as part of the world “Day of Parachutists” - the car was dropped by parachute, and after a successful landing the car started up and drove off. This happened in April 1998.

At the Russian polar station "Bellingshausen" this brand of car worked without sparing its horsepower for twelve years.

Let's sum it up

The standard Niva hub unit is a headache for owners of a domestic SUV. For the safe use of a vehicle in conditions of increased impassability, it is important to strengthen the Niva’s hub assembly. If you know how to work with tools and have previously done car repairs, then this kind of modernization is definitely up to you.

Which way to choose to strengthen the hub assembly of an SUV is up to you to decide. It all depends on what financial costs you are willing to incur. Any of the proposed options will please you with an impeccable result.

Source

Non-adjustable hub NIVA

The content of the article :

“Reinforced” hub unit for Niva with reinforced hub 2123 (24 splines) from VolgaAvtoprom

I purchased this product:

An initial inspection showed the presence of strange holes through which water freely gets to the bearing bypassing the seal...

Holes past the seal

VolgaAvtoProm has a conditionally dismountable unit (not dismountable) - each time an expensive bearing must be replaced. Because it comes apart and the clip remains on the hub.

In addition to everything, the hub has no traces of heat treatment and when measured for hardness, it turned out that the hub is completely raw.

Raw hub VolgaAvtoProm

As soon as I drag the 100% original Conveyor hub to the stand, I will make a note about it.

Now I’ll take measurements of the geometry of the VolgaAvtoProm hub. Then I will add the results to this post.

Its only advantage is that it is a little thicker - in the place under the oil seal, there is no press-on ring, and the hub is solid, which slightly strengthens the hub.

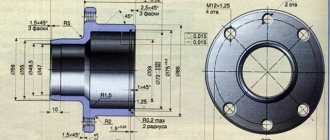

Continuation: I measured the hub, see the picture:

VolgaAvtoprom hub drawing

Replacement

To replace the front wheel bearing in the field, it is necessary to remove the front axle brake calipers. Why you should:

- Hang up and unscrew the wheel; Using a chisel, knock the cap off the hub;

• Using pliers, remove the cotter pin located on the lower axis of the clamping lever;

• Carefully remove the axis of the clamping lever using a metalworker's drift and then remove it using pliers;

• Using a flat-head screwdriver, having previously removed the clamping lever and springs, remove the brake caliper from its seat and place it behind the steering knuckle in such a way as not to interfere with the further process (hang it).

Installation of double-row roller bearings from the IVEKO Daily truck into the front hubs of Niva 21213

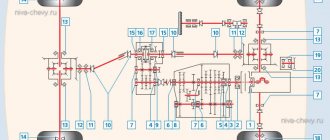

Wheel unit VAZ 21(21,213,214,218,30…)

one of, I’m not afraid of this word, the most colorful, in terms of purely Russian (obscene) words addressed to him by Nivavodov, an engineering sophistication, and today the managerial stupidity of AvtoTAZ is completely archaic.

When assembling, to adjust the clearance in the bearing according to the book, you need to: “...Install a new adjusting nut. We tighten it to a torque of 19.6 N.m (2.0 kgf.m), simultaneously turning the hub in both directions. Loosen the adjusting nut and tighten it again to a torque of 6.86 N.m (0.7 kgf.m). Then loosen the nut 20–25o. We check the clearance in the bearings: it should be in the range of 0.02–0.08 mm. We lock the nut by pressing its collar into the grooves of the shank of the outer drive joint...” It would be fine if I did it once and forgot, but the need for adjustment often arises, especially if you drive on bad roads. And if you miss the moment a little, the hub will begin to rotate in the inner race of the bearing, and that’s it - the play can no longer be eliminated by simply tightening the nut and I ran to the shops to buy bearings (2 pieces for 250 rubles each), a new hub (750-1000 rubles), and the sellers Thanks to AvtoTAZ engineers, meanwhile, they are happily rubbing their hands.

But okay, if I just went and bought the part I needed in the store, installed it and drove off, but no! After TAZ began installing hubs and grenades with 24 splines in Niva, the production of hubs with 22 splines for spare parts was stopped, like if you need it, then buy external grenades with 24 splines along with the hubs, because rich people drive around in Niva, they There is no problem at all in providing charitable assistance to starving Ketai people. So people are toiling around, buying the devil in stores: Either the diameter of the hub is +/- a kilometer, or the metal is raw meat, or the bearings are like crazy, you’ll understand what kind of fit. In general, again everyone knows parsley with the quality of spare parts for a Russian miracle of engineering.

Algorithm of actions

Since the advent of double-row bearing designs, everything has fallen off the chain. Let's straighten everything out. I know 5 different designs and maybe only one does not cause serious complaints in its operation. Now a specific algorithm of actions. If you are lucky and your standard unit has driven more than 20-30 thousand km, the car has a roll and only needed tension adjustment, then your knuckles are bored out coaxially. If necessary, provide good Russian or German bearings and good hubs, and continue to live happily ever after. The most important and important thing is that the Niva wheel bearing must have a steel cage. If you are unlucky and the wheel bearings are “consumable”, or the car does not roll without replacement, your knuckles are misaligned and therefore it is better to think about other projects, since you have nothing to lose. There is an article on the website about the hub version of the IVEKO truck.