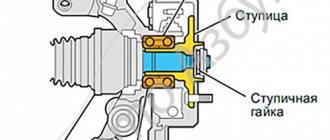

According to the vehicle maintenance card, it is necessary to replace the front wheel bearings of the VAZ-2108. Their dimensions are larger than those of similar ones installed on the VAZ 2101-2107 model. Moreover, there are features of the replacement. The “classic” uses tapered bearings; it is imperative to observe the permissible force when tightening the hub nut. Otherwise, the bearing will fall apart and you will have to buy a new one. Eights use cylindrical bearings; when tightening the hub nut, you need to apply as much force as you can - just don’t break the thread.

Front wheel bearing size VAZ 2108

Any spare part of a modern car must be perfectly matched to fit and technological dimensions.

Unfortunately, the manufacturer does not always take into account the specifics of using materials in spare parts, which affects their service life, reliability, and, ultimately, traffic safety. The chassis of a car is subject to enormous loads, so it is simply impossible not to pay attention to the correspondence of the factory dimensions with the ones being replaced. Content:

VAZ 2108 front wheel bearing size

If we take this issue more specifically, the chassis of cars of popular models and brands most often suffers from low-quality spare parts. First, let's look at this problem using the example of a VAZ 2108 front wheel bearing.

It would seem that there is nothing complicated - the hub has its own standard dimensions, which the roller bearing must correspond to:

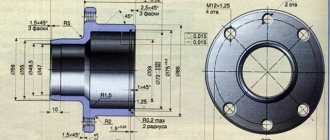

internal diameter - 34 mm; outer diameter - 64 mm; Bearing width - 37 mm.

Only by these parameters can you select a bearing, of which domestic factories produce thousands. Manufacturers from China actively help in this, providing products that are not of the best quality and do not stand up to any criticism. Neither the steel grade, nor the number of balls, nor the dynamic performance of such bearings meet the standards. There are bearings without any markings at all, and there are particularly zealous owners who buy them. Such bearings burn out within 1000 km and simply fall apart while driving.

Features of choosing a wheel bearing for a VAZ 2108

Naturally, we will not be able to check the dynamic load on the bearing races and on each of its balls. But you need to remember, like the Our Father, that:

- The VAZ 2108 wheel bearing is marked 25 69 07;

- according to the international marking system it is designated 53 20 66 DA;

- the bearing has a mass of 0.445 kg;

- ball diameter - 9.525 mm;

- number of balls - 28.

The difficulty in choosing bearings is that they are not consumable parts, and they are not changed as often as piston rings or silent blocks. That's why some manufacturers don't even bother making human packaging. In addition, the bearing used in the front wheel hub of the VAZ 2108 is maintenance-free, which means:

- the bearing does not require lubrication;

- does not require preload;

- does not require adjustments during installation and operation;

- must have a very high resource.

Design of wheel bearings for VAZ 2108

All VAZ cars are equipped with only three types of wheel bearings - wheel bearings for front-wheel drive VAZ cars, wheel hub bearings for rear wheels, and wheel bearings for Kalina and Grant cars, which are smaller in size.

All VAZ bearings are of the HUB-1 type, and this type is characterized by the design and installation features. The bearing has a double-row design, is a type of angular contact ball bearings with closed working surfaces and does not have flanges for attachment to the hub.

Manufacturers and prices of VAZ wheel bearings

These bearings belong to the middle price segment, so the demand for them is very high. Because of this, you can often find the fakes we mentioned. However, the transition of the VAZ plant to bearings of this type, instead of roller ones of the old type, made it possible to choose bearings not only of domestic production, but also of many other foreign factories.

The main percentage share of bearings used on VAZ cars lies with domestic manufacturers, among which several factories can be distinguished:

- Saratov Bearing Plant (SPZ) - 28%.

- "Volzhsky Standard" - 2%.

- Samara plant SPZ9 - 8%.

- "Lada Image" - 7%.

- Vologda Bearing Plant VBF - 4%.

Let us only note that Lada Image supplies products directly to the plant’s conveyor belt, and SPZ has the largest share in the spare parts market. It is impossible to say anything specific about the quality of workmanship, because there may be failures at every plant, but even if the bearing turns out to be of poor quality, the enterprise must replace it. Prices for VAZ 2108 front wheel bearings rarely exceed 250 rubles apiece, and imported models may cost a little more, but their quality is appropriate.

So, bearings from Kraft, SCT, Trialli, LGR can cost about 300-350 rubles, but these are world-famous manufacturers, and you can definitely count on the quality of the bearing. Choose the right bearings and let your figure eight roll forward with confidence!

Popular manufacturers

The best manufacturer of ball bearings 256706 by domestic standards is considered to be 23 GPZ (VBF), the products of Saratov SPZ are somewhat worse, but cheaper. Cheap, but also unreliable products with the SPZ-4 mark are Russian products assembled from Chinese parts.

When choosing an imported replacement for domestic bearings, you should pay attention to SKF or FAG products. These are products of the upper price segment, but of consistently high quality.

Do you have any questions about bearing 256706 or something to add? Then write to us about it in the comments, this will make the material more complete and accurate.

What is the diameter of the hub (exact factory data)

According to the regulatory documentation provided by the manufacturer, the hub diameter on the VAZ-2114 is 58.5 mm.

Thus, the bolt-to-bolt size is 4x98 , which allows you to install wheel rims with sizes R13, R14 and R15 . To secure the wheels to the hub, use bolts measuring M12x40 mm .

Standard stamping for factory hub

In order to choose non-standard stampings, but, for example, non-standard alloy wheels, it is necessary to change the size of the hub and the inter-bolt space. Of course, the manufacturer and car enthusiasts do not advise doing this unless absolutely necessary, so you should think several times before taking this action.

The most common size on European cars is 4*100 . Therefore, many people want to install just such disks. This is the hub size for Hyundai Accent and Renault Logan.

Catalog of VAZ-2114 hubs

Hub made by AvtoVAZ

2108-3103012 – original catalog number of the front wheel hub manufactured by AvtoVAZ. Using this article, you can determine a list of analogues that are suitable for installation on the Lada 2108-21099 and 2113-2115 family of cars.

Standard stamping on the rear wheel, hub diameter 4*98

So, using the catalog number, it is determined which hub becomes available for installation.

Preparation for repair

All work must be carried out on an inspection pit or overpass. But if you do not have such amenities, you will have to hang the rear of the car so that it is above the ground. The procedure for carrying out preparatory work:

- Place the car on a level surface.

- Place blocks under the front wheels.

- Turn on first speed.

- Loosen the nut that tightens the handbrake actuator (optional).

Main characteristics and varieties

The rear wheel bearing on the VAZ-2108 is produced under catalog number 256706. It has the following technical characteristics:

- weight, g – 400;

- number of balls, pcs. – 28;

- ball diameter, mm – 9.525;

- static load capacity, KN – 25.9;

- dynamic load capacity, KN – 30.1;

- rated rotation speed, rpm – 6500.

The VAZ-2108 rear wheel bearing number may be different. If a store offers you a product marked 537906, don’t be surprised. This is a high-load bearing. Some of its characteristics differ from the characteristics of the standard spare part:

- weight, g – 511;

- static load capacity, KN – 90.1;

- dynamic load capacity, KN – 64.8;

- rated rotation speed, rpm – 5000.

As you can see, the reinforced rear hub bearing on the VAZ-2108 has increased resistance to loads. But at the same time, its rotation frequency should not exceed 5 thousand rpm. Such products, when properly used, can “walk” freely up to two hundred thousand kilometers.

conclusions

In this article, the diameter of the VAZ-2114 wheel hub was determined, as well as the bolt-to-bolt distance and fasteners with which the wheels can be attached to this unit. Many motorists practice replacing the hub in order to change the size of the disks, but not everyone takes into account that it is also necessary to change the steering knuckles.

The wheel bearing ensures uniform rotation of the wheel around its own axis. Of all the elements of the car's chassis, it is the first to meet and distribute shock loads, so the main requirements for this part are strength and durability.

In this article we will talk about what a rear wheel bearing is on a VAZ-2108. We will look at the design of this device, its dimensions, and also understand the process of replacing it.

DIY rear wheel hub replacement

You can also replace the rear wheel hub yourself. You will need standard tools - wrenches, a small screwdriver, a jack, and so on. The installation algorithm is as follows:

- Take a wrench and loosen the nuts.

- Use a jack to raise the car.

- Take the wrench again, unscrew the nuts completely and remove the flywheel.

- Have someone hold down the brake pedal or place something heavy on the brake to hold the pedal in place.

- Carefully unscrew the nut and remove the brake cylinder and caliper.

- If the car has an ABS/VDC sensor, then take a 10mm socket and unscrew the bolt. Don't forget to clean the sensor from dirt.

- Remove the car from the brake, and then turn the flywheel so that the rubber cap is on the bottom. Put the car on the brakes again.

- Remove the cap, insert a small screwdriver into the hole and turn the gear wheel up until it stops.

- Remove the brake disc.

- If necessary, remove the parking brake pads.

- Find the 4 bolts on the back of the hub unit and unscrew them.

- Carefully remove the hub part (do not damage the rear wheel hub axle).

- Dismantling is complete. To install a new part, you need to perform the same steps, but in reverse order.

- In case of replacement, you can also use a hammer and a wheel nut to knock out 4 or 5 studs from the old part - the studs are quite expensive and they break relatively often, so it won't hurt to remove them.

Final assembly

To assemble, follow these steps:

- Install the hub onto the axle.

- Place the washer and tighten the nut by hand.

- Install the brake drum and tighten the studs.

- Place the wheel and lower the car.

- Tighten all threaded connections.

- Place the nut on the hub.

Reassembling the entire assembly occurs in the reverse order. The hub nut must be tightened to a torque of about 200 N*m.

Source

Welcome to the website Bearings in Russia

To quickly find the information you need, use the site search in the upper right corner.

Any spare part of a modern car must be perfectly matched to fit and technological dimensions. Unfortunately, the manufacturer does not always take into account the specifics of using materials in spare parts, which affects their service life, reliability, and, ultimately, traffic safety. The chassis of a car is subject to enormous loads, so it is simply impossible not to pay attention to the correspondence of the factory dimensions with the ones being replaced.

Content:

VAZ 2108 front wheel bearing size

If we take this issue more specifically, the chassis of cars of popular models and brands most often suffers from low-quality spare parts. First, let's look at this problem using the example of a VAZ 2108 front wheel bearing.

It would seem that there is nothing complicated - the hub has its own standard dimensions, which the roller bearing must correspond to:

internal diameter - 34 mm; outer diameter - 64 mm; Bearing width - 37 mm.

Only by these parameters can you select a bearing, of which domestic factories produce thousands. Manufacturers from China actively help in this, providing products that are not of the best quality and do not stand up to any criticism. Neither the steel grade, nor the number of balls, nor the dynamic performance of such bearings meet the standards. There are bearings without any markings at all, and there are particularly zealous owners who buy them. Such bearings burn out within 1000 km and simply fall apart while driving.

Features of choosing a wheel bearing for a VAZ 2108

Naturally, we will not be able to check the dynamic load on the bearing races and on each of its balls. But you need to remember, like the Our Father, that:

- The VAZ 2108 wheel bearing is marked 25 69 07;

- according to the international marking system it is designated 53 20 66 DA;

- the bearing has a mass of 0.445 kg;

- ball diameter - 9.525 mm;

- number of balls - 28.

The difficulty in choosing bearings is that they are not consumable parts, and they are not changed as often as piston rings or silent blocks. That's why some manufacturers don't even bother making human packaging. In addition, the bearing used in the front wheel hub of the VAZ 2108 is maintenance-free, which means:

- the bearing does not require lubrication;

- does not require preload;

- does not require adjustments during installation and operation;

- must have a very high resource.

Design of wheel bearings for VAZ 2108

All VAZ cars are equipped with only three types of wheel bearings - wheel bearings for front-wheel drive VAZ cars, wheel hub bearings for rear wheels, and wheel bearings for Kalina and Grant cars, which are smaller in size.

All VAZ bearings are of the HUB-1 type, and this type is characterized by the design and installation features. The bearing has a double-row design, is a type of angular contact ball bearings with closed working surfaces and does not have flanges for attachment to the hub.

Manufacturers and prices of VAZ wheel bearings

These bearings belong to the middle price segment, so the demand for them is very high. Because of this, you can often find the fakes we mentioned. However, the transition of the VAZ plant to bearings of this type, instead of roller ones of the old type, made it possible to choose bearings not only of domestic production, but also of many other foreign factories.

The main percentage share of bearings used on VAZ cars lies with domestic manufacturers, among which several factories can be distinguished:

- Saratov Bearing Plant (SPZ) - 28%.

- "Volzhsky Standard" - 2%.

- Samara plant SPZ9 - 8%.

- "Lada Image" - 7%.

- Vologda Bearing Plant VBF - 4%.

Let us only note that Lada Image supplies products directly to the plant’s conveyor belt, and SPZ has the largest share in the spare parts market. It is impossible to say anything specific about the quality of workmanship, because there may be failures at every plant, but even if the bearing turns out to be of poor quality, the enterprise must replace it. Prices for VAZ 2108 front wheel bearings rarely exceed 250 rubles apiece, and imported models may cost a little more, but their quality is appropriate.

So, bearings from Kraft, SCT, Trialli, LGR can cost about 300-350 rubles, but these are world-famous manufacturers, and you can definitely count on the quality of the bearing. Choose the right bearings and let your figure eight roll forward with confidence!

Also, using this method, you can replace the wheel bearing on the road with a simple tool. I have a wheel bearing puller, but I will deliberately change the wheel bearing using improvised means, close to travel and close situations. Explaining and appearing in photos the details of the replacement.

Loosen the wheel mounting bolts. We hang up the front part of the car (namely both front wheels, because otherwise the anti-roll bar interferes with dismantling, pressing the suspension elements upward). We remove the wheel, the brake pad guide together with the caliper and the brake disc (see Removing parts of the front wheel brake mechanism). We tie the guide of the brake pads with the caliper so that they do not hang on the brake hose.

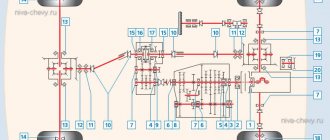

Description of design

The rear suspension is with 12 coil springs and 10 double-acting hydraulic telescopic shock absorbers.

The main load-bearing element of the suspension is a beam consisting of trailing arms 14 and a connector 13, welded together through reinforcements. At the rear, brackets 15 with eyes for attaching shock absorbers 10 and flanges for attaching the rear wheel axles and brake shields are welded to the suspension arms. At the front, the levers 14 are equipped with welded bushings with silent blocks 3 pressed into them. A bolt passes through the central bushing of the silent block, connecting the lever to the bracket 2. Three welded bolts are provided to secure the bracket to the body spar.

The suspension spring 12 rests with its lower end on a cup welded to the shock absorber reservoir, and with its upper end, through a rubber gasket 11, on a support welded from the inside to the body arch.

The lower eye of the shock absorber is bolted to bracket 15 of the suspension arm, and its rod is secured to the upper support of the suspension spring through two rubber pads 8 (one at the bottom of the support, the other at the top) and a support washer 7 (under the nut).

The rear suspension springs are divided into two stiffness classes according to their length in the free state and under load: A (more rigid, “high”) and B (less rigid, “low”). Springs of the same class must be installed on the front and rear suspensions. But in exceptional cases, if class A springs are installed in the front suspension, class B springs can be installed in the rear suspension (but not vice versa!). The quality of the springs can be fully assessed by the performance of the suspension on the car. If the suspension often “breaks through” to the bump stops on uneven roads or sags under load, stiffer springs should be installed. When replacing springs, do not forget to check the serviceability of the shock absorbers - after all, it is the shock absorber-spring pair that largely determines the characteristics of the suspension.

The hub has a double-row angular contact ball bearing, similar to the front wheel hub bearing, but smaller in size. The bearing fit on the axle is transitional (with slight interference or clearance). During operation, the bearing does not require adjustment or replenishment of lubricant. It is not allowed to eliminate the resulting play by tightening the nut; the bearing should be replaced. When dismantling the hub, the bearing is destroyed, so it is not recommended to disassemble the hub if the bearing is in good condition.

Design and purpose of hubs

The VAZ-2108 moves due to the fact that from the running engine, through mechanical transmissions, torque is transmitted to the drive wheels (in this case, the front wheels). But if the connection between the wheels, axles and the frame is rigid, then movement on an uneven surface will simply become impossible. In addition, all components will quickly fail as a result of colossal shock loads.

To prevent this, a system of intermediate links (levers), or suspension, is used. It should smooth out the effect of road surface irregularities on the ride. Its final unit, to which the wheel is attached, is the hub. This is a cylindrical housing part that is installed on the drive and driven shafts. Between the hub and the shaft there is a bearing, which allows the wheel to rotate.

The main functions of this node are:

Structurally, any hub consists of the following components:

- Outer rim. Made in the shape of a glass with holes for exiting and fixing the axle shaft, as well as the wheel disk.

- Bearing cup. In fact, this is not a separate unit, but just the inner part of the rim, which has the necessary dimensions for installing rotation supports.

- Slotted hole. Again, part of the rim is the central hole in it, which has a spline for installing and fixing the axle shaft.

The wheel hub is formed from a cast blank by machining the seating surfaces.

Lada 2106 Akkerman71 › Logbook › Front suspension 2. Fixed hubs

Hi all. Today there will be a little more letters) there is a little free time, you can press buttons). For the upcoming complete overhaul of the front suspension, I am collecting the necessary parts. One of the upgrades that the “patient” will undergo is non-adjustable hubs with one double-row bearing,

instead of two classic bearings, which from time to time need adjustment, without which wheel play appears and, as a result, control suffers, the wheels “walk” a little to the sides because of this, you have to steer the steering wheel, and they also absorb all these unnecessary beats ball joints and steering rods; excess loads damage them faster. There is a lot of information on the Internet about this and about installing non-adjustable bearings from a front-wheel drive family using adapter bushings on classic knuckles. The most common option is to install a 2108 rear hub with bearing dimensions of 60x30. Many people install and drive, but personally I don’t like this option. The bearing is not designed for heavy loads, since the main load comes from the engine and from the turning front wheels, so on the back of the 08 they made them smaller in size, so I didn’t consider this option at all. This whole thing is serious and I want to be completely calm and confident in the durability and, most importantly, the safety of all components and assemblies)). In second place is the installation of IZH Oda front hubs; a large front bearing 2108 with dimensions 64x37 is already installed in them. This option is already acceptable, in my opinion. The bearing is designed for installation “under the motor” and will run for a long time, which you won’t have to worry about. IzhOda hubs are installed either through adapter bushings, which is much simpler, or on modified classic knuckles, which is much more difficult to perform, since you still need to find a very good turner who will take on this and will not spoil anything the first time)) and with this they are just big problems)) I also refused this option, firstly, IzhOda is already a big rarity in our area, it takes a long time to look for hubs from them and used ones are used, this is not a new part, production will be present in any case. Therefore, I chose for myself the most reinforced third option with the largest possible size bearing and custom-made metal hubs. Bearing dimensions 72x37

installed on Moskvich 2141 and Renault Logan, compared to the front 2108 it is larger and looks preferable. The matter remained with the manufacture of hubs. From all the large factories with good machines, in our city (as elsewhere) only memories remain), everything was closed a long time ago, the equipment was cut into scrap metal, so I spent a long time looking for who and where to make it. As they say, “he who searches for a long time will always find”) I found someone who makes such hubs, even with adapter bushings,

source

Causes of malfunctions

And now about why the VAZ-2108 front wheel bearing breaks. Its dimensions (with a mass of 445 grams) are as follows:

- Width - 3.7 cm.

- Internal diameter – 3.4 cm; external – 6.4.

The most common reasons why a bearing lasts a long time is water ingress or impact. The bearing temperature increases if you drive for a very long time on the highway at high speed. If after this you get into a puddle, especially if you drive for a long time in swampy areas, the bearing will end up in the water. At this time, almost all the lubricant is washed away. After a short time you will hear extraneous sounds. It is worth noting that front-wheel drive VAZ cars, starting with model 2108, use a bearing consisting of two rows. It does not need to be lubricated during operation, so the risk of water washing away all the lubricant is extremely small. Very often, the cause of premature failure of the wheel bearing is driving on uneven roads. For example, when you are moving at speed, notice a hole, and begin to press the brake pedal sharply, then you are causing enormous damage to your car. Oddly enough, getting into a hole at speed without pressing the brake is much safer. The fact is that inertial forces arise, weight begins to move from the rear axle to the front. And when a direct impact occurs, the front wheel bearing is subjected to many times greater forces. For this reason, the front wheel bearing of the VAZ-2108 will need to be replaced.

How to understand that it is time to change the wheel bearing

A failed VAZ-2108 rear wheel bearing may indicate a malfunction:

- the appearance of a characteristic hum from the wheel;

- uneven rotation of the wheel;

- backlash formation.

If you notice that there is a hum coming from one or both rear wheels, rush to diagnose the wheel bearings. You can do this right in your garage. Simply jack up the rear wheel and turn it by hand. It should rotate easily and evenly without making any sounds. Next, grab it with both hands and try to shake it from side to side in a horizontal direction. If the wheel rotates unevenly and you feel play when it becomes loose, get ready for repairs.

What drives can be installed

When planning to replace old steel wheels with alloy wheels, you should choose either original products or products from well-known manufacturers who care about the quality and safety of their products.

Alloy wheels combine the following useful properties: they are lightweight, practical to use, endowed with sufficient strength and have an attractive appearance, which is aimed at transforming the entire appearance of the car.

The most common among alloy wheels are aluminum products. This is due to the fact that they are resistant to corrosion, meet strength requirements and, in comparison with other alloy wheels, remain relatively inexpensive.

Titanium alloy is the most expensive option. It also meets all the technical specifications, but at the same time has a more attractive appearance. In third place is the option using a magnesium alloy.

The latest models from AvtoVAZ use wheels with a 4x100 mounting pattern. When installing them on a 4x98 hub, you should use studs with an eccentric to compensate for the difference of 2 mm. To install disks with other mounting patterns, you will have to use the appropriate adapters (spacers).

You must understand that installing wheels larger than 15 inches is impossible without interfering with the car’s design.

Parameters of standard nuts

Fastening the cast disk to the hub involves the use of special bolts or nuts. It should be noted that nuts from stamped disks are unacceptable here. Firstly, because in cast specimens the conical or spherical part of the fastener is more pronounced than in stamped ones.

For example, the conical part of a bolt or nut has an angle of 60 degrees. This is done in order to increase the area of their contact with a material softer than steel. Secondly, the stamp is thinner than the casting, and when replacing the disk, the length of the bolt simply will not be enough.

It is better to immediately use the fasteners that correspond to the light-alloy wheel used, otherwise deformation of the holes, crumbling and scratches are possible.

By saving on the necessary nuts or bolts, you can irreversibly damage a more expensive element.

The softness of the metal also means regularly checking the tightness of the fasteners, especially at first and with new discs, when the material has not yet become compacted from work loads. Otherwise, under the influence of cyclic shock and vibration, the nuts may spontaneously unscrew.

Nuts must have conical or spherical washers. It is necessary to ensure that the profile of the washers exactly fits the corresponding recess in the hole of the disk being installed. Some disc models are designed to use cylindrical fasteners with flat washers.

VAZ 2108 hub and bearing - self-replacement

- Preparing to replace the hub or bearing

- Changing the wheel bearing "eight"

- Hub installation and assembly

Replacing the wheel bearing or the wheel itself is inevitable. The reason is simple - these are parts that wear out over time, no matter how carefully you operate the car. The VAZ 2108 hub is less subject to wear than the bearing, but it does not last forever. To replace one or another element, you can contact a service station, but the process is not so complicated, if you follow the technology described below, you can do everything yourself. In essence, changing the 2108 hub bearing is somewhat easier than replacing the complete hub itself, but the technology is practically the same.

Preparing to replace the hub or bearing

Replacing the front bearing on a VAZ 2108

Any technological process of car repair begins with diagnosing and identifying the fault, studying the manual, preparing spare parts and tools for repair. The first thing you need are the following tools:

- jack;

- pullers or pieces of metal pipe with a diameter of 3 and 6 cm;

- pliers;

- wrenches 12 and 30.

Please note that the bearing, the dimensions of which should be: outer and inner diameters of 60 and 30 mm, height - 37 mm, must be of high quality, since there is a lot of Asian consumer goods on the market. You need to approach the choice of the hub itself in the same way - it is better to purchase a high-quality part once, and subsequently permanently lay the car down.

Step-by-step procedure for removing the hub

- We get to the hub - fix the car with the handbrake (parking brake), put shoes under the wheels and loosen the wheel bolts.

- Then we jack up the side where we will do the work, completely unscrew and remove the wheel.

- If you change the bearing or hub of the rear wheel of a VAZ 2108, you will need to remove the drum.

- If the front one is a brake disc.

- To do this, unscrew the guides and try to remove them. If this doesn’t work, you’ll have to shoot it down.

- To remove the drum, you need a wooden spacer (any piece of block or board will do) with which you need to tap it from the inside.

- If the work is carried out on the front wheels, changing the bearing of the front hub 2108 or the front wheel hub itself of the VAZ 2108, first remove the caliper and hang it to the lever using ordinary wire.

- When there is access to the hub, remove it. If you have a puller, this is not difficult to do, but if you don’t have one, you will have to do it the old-fashioned way. We screw the wheel with its outer side to the hub (otherwise it will not fit into the wheel arch) and pull it towards ourselves several times.

- When it is removed, a new front or rear hub of the VAZ 2108 is installed, and if necessary, the bearing is changed.

Changing the wheel bearing "eight"

Replacing the VAZ CV joint and wheel bearing

After the hub is removed, you need to:

- press out or knock out the bearing. It doesn’t matter whether you are changing the rear wheel bearing of a VAZ 2108 or the front one - the process is the same. You need to remove the stopper and boot from it using pliers, and then carefully knock out or press out (which is preferable) the bearing.

- treat the seat on the hub with lubricant,

- then install a new bearing. If it is not possible to press it in, you will have to hammer it with a pipe with a diameter of 6 cm, along the diameter of the outer ring.

- then install the boot and stopper (preferably new ones).

When the bearing is tightly seated, we proceed to install the hub back.

Instructions for removing the hub assembly from the rear axle

- We turn off the engine, put the car in gear, and install stops under the front axle.

- We jack up the wheel we need.

- We tear off the mounting bolts and remove the removed wheel.

- Now we have access to the brake drum. Using a “12” wrench, unscrew the pin guides and remove it. The brake drum may be firmly in place. Then WD-40 universal lubricant will come to the rescue. And if the knot is stuck too tightly, you can remove it with a hammer or mallet, gently tapping it around the perimeter.

- Unscrew the hub nut.

- We remove the hub using a special two-jaw puller. If you don’t have one, you can simply screw the wheel to the axle and then quickly pull it off.