Any auto mechanic will explain to the motorist that the timing belt must be changed regularly, otherwise its rupture during operation will damage the vehicle. All motorists will be able to replace the part if they carry out the preparatory stage correctly, remove interfering components for a while, and set the timing marks on the Priora.

Experts advise checking the condition of this component of the mechanism every 105 thousand kilometers traveled. It will be useful for motorists to learn how to disassemble the mechanism and check for damage to the belt.

What is a timing belt

This is the connecting part that ensures the synchronization of two vehicle components - the camshaft and crankshaft. However, the belt not only combines these two mechanisms, it is also connected to other parts, as a result of which a huge load is placed on it.

Due to this load, it is subject to wear and therefore must be replaced after the expiration date. If you neglect the recommendations specified in the Priora instructions regarding regular replacement, the belt will break and all the mechanisms associated with it will fail.

Untimely replacement will cost the car owner too much; it is advisable to constantly check the mechanism for damage and the first signs of wear.

Experienced auto mechanics advise not to believe the statements of official dealers that the timing belt on a Priora is replaced every hundred thousand kilometers traveled. Sometimes a rupture is possible after fifty thousand kilometers, but there are cases when the mechanism has traveled more than one hundred thousand kilometers. Therefore, schedule several checks, for example every 10,000 km, to ensure that the mechanics are functioning at the proper level.

It is made of high-quality and durable rubber, smooth on top and serrated on the inside. The teeth provide the strongest grip on the gears. If, due to a long period of use, parts of the teeth fall off, the car may not even start due to the fact that the automobile oil is untimely or incorrectly supplied to the cylinders located in the engine.

A simple rubber component plays an important role in the entire mechanism of the machine. Try not to forget about checking it, because a problem detected in time will save money spent on repairs.

When to change: consequences of untimely change

It is recommended to replace the timing belt on a Priora after different periods of time. The manufacturer claims that it can withstand one hundred thousand mileage, but experience shows that a change may be needed much earlier.

The optimal period is every fifty thousand kilometers. Some argue that over such a short service life, rubber is simply not capable of failure. However, no one takes into account the conditions - roads, fuel quality, etc.

Also, during the operation of the mechanisms, it wears out, the rubber stretches, and therefore does not provide the correct tension of the timing belt, and slippage is possible. The teeth can wear off - because of this, traction with the gears is not ensured.

There is no exact time for a change that would suit all motorists. Some take good care of their vehicles, drive carefully, and use only high-quality fuel. Others use a more extreme type of driving, foreign liquids get on the rubber, etc.

In order not to lose your car during the repair period and not to spend a fortune on restoring the mechanics, write down or remember the date of the last timing belt change on the Priora. Next, regularly check the condition of the rubber; if worn, replace it with a new device.

Signs of possible failure

There are several characteristic signs that should alert the driver:

- When the engine is turned on, extraneous noise occurs. Sometimes drivers confuse a timing belt malfunction with a poorly functioning tension pulley.

- If the color of the exhaust gas has changed.

- The engine doesn't start well.

- An unusual vibration is felt.

Pay attention to these “symptoms”, even if the Priora’s mileage with a new timing belt has not yet reached 50 thousand km. It may fail earlier if foreign liquid gets onto the drive - oil, coolant, as well as dust or dirt.

It’s worse if it’s the coolant that gets onto the drive. Firstly, this means that the gasket that ensures the pump is sealed has failed, or there is a problem with the pump. Then the rubber is damaged and service life is reduced tenfold.

Even if the belt is new, but coolant or antifreeze gets on it, it will fail even after operating for 10 thousand miles. You will have to replace the Priora timing belt and figure out why foreign substances get on it.

How to check the serviceability of the belt yourself

If you suspect that it is time to replace the Priora timing belt, it would not hurt to check the serviceability of this rubber product. Visual diagnostics will allow you to check the serviceability and absence of scuffs on the Priora timing belt.

You should have a choice of one of the tools at hand, or two at once - a 5-point hex key, or a T-30 sprocket bit. If one doesn't work, try the second.

- Open and lift the hood.

- You will see the front panel covering the mechanism and timing belt.

- Take the key and unscrew the five bolts that hold the front panel, remove it.

- In front of you you will see a mechanism, including a tension roller.

- Place a jack on the passenger side and place the wheel in a suspended position. Engage fifth gear while it is working, look at the surface of the belt for damage, even small defects.

- If you notice cracks of any size, mechanical cuts, or threads sticking out, be sure to replace it by contacting a specialist or yourself.

- Check the pump. If any traces of coolant leakage from the pump are noticeable, then the rubber will also have to be changed, even if there is no mechanical damage.

- Check the tension roller. Auto mechanics advise changing it less often than tires. The average lifespan is approximately one hundred thousand kilometers. Change it every other time you change the belt.

- Measure the belt tension. To do this, press on the stretched rubber in the area between the gears of the two camshafts. You need to press with a force of about ten kilograms. Correct tension of the timing belt should not bend more than seven millimeters.

- Check that the rubber is not too loose. Make sure that the Priora timing marks match the original condition. The first, similar to a recess, is located on the outer race of the tension roller. The next one is located at the base of the roller. The maximum deviation is four millimeters; if the tension does not meet the standards, the product will have to be changed.

Why is this so important?

I think it’s no secret to anyone what happens when the timing belt breaks, but perhaps there are those who are not in the know. In the event of a break, the synchronization of the operation of the cylinder-piston group and valves is disrupted. The pistons begin to move towards the valves, which are no longer controlled by the belt; as a result, the pistons “meet” the valves. After such a “meeting,” the pistons are destroyed, the valves are bent, and in general you end up with a major engine overhaul. Could this have been avoided? It is possible, of course, if the manufacturer of this engine thought about this at the design stage, completely eliminating such a phenomenon. By the way, there are quite a few “plug-in” engines in the world that, after a broken belt, do not need to be “overhauled”; you just need to get to a service station and replace the timing belt. In such engines, when the valve belt breaks, the valves do not meet the pistons.

The belt and rollers must be replaced immediately if, during inspection, you find:

- Roughness on the belt (on the teeth or sides);

- Mechanical damage;

- Engine malfunctions;

- Problems starting the engine;

- Extraneous sounds indicating friction of the belt against the casing, rollers or pulleys.

Separately, I would like to note the appearance of vibration and black exhaust; such symptoms, of course, can occur under other circumstances, but this option should also be considered.

Consider exclusively mileage in the question: “Is it time to change the timing belt or not?” - this is mistake. Firstly, even with low mileage, problems can arise with the belt or rollers. And secondly, there are many situations when you practically or completely do not move, while the motor is running, therefore, the belt wears out. For example, if the car is used mainly in the city, the mileage may be low, but the life of the belt itself will be at its limit, since in traffic jams the engine is running, but there is practically no movement.

There are other factors that can cause a belt to fail prematurely. For example, if oil, fuel, dirt or sand gets on it. Small particles of sand eat into the surface of the belt, destroying its surface; oil and other petroleum products soften it, reducing its strength and shortening its service life.

Finally.

To summarize the above, I would like to give some practical advice that will allow you to avoid timing belt rupture and, as a consequence, major repairs.

- Buy a quality replacement belt and rollers;

- Record the mileage and date of belt replacement;

- Every 10 thousand, perform a visual inspection of the rollers and belt;

- Change the belt earlier if you mainly drive the car in the city;

- If you buy a used car, it is better to replace the belt and rollers, since it is not known when it was changed.

That's all for me, write in the comments when you prefer to replace and how you monitor the condition of the above-mentioned elements.

Changing the belt yourself

Replacing the timing belt of a Lada Priora with 16 valves is not the most difficult procedure. Buy a kit that includes tension rollers, stock up on tools, and you’re good to go.

Instructions

- Lift the hood, use a hex wrench to unscrew the five bolts on the cover, and remove it. Unscrew the two bolts from the lower timing cover.

- Disconnect the crankshaft sensor.

- On the passenger side, place a jack under the wheel, lift the car with it, and place the wheel in a suspended position. This will make it easier to align the marks of the mechanism and camshafts - they should be parallel, opposite each other. Combine them with fifth gear engaged, turning the wheel to the correct position. Turn off gear transmission.

- Find the flywheel and remove the rubber plug with a regular screwdriver. Under the muffler you will see a flywheel with a mark, it should be located opposite the mark on the left side.

- You need to get to the crankshaft pulley; to do this, remove the wheel or turn it to the right, you need to turn it all the way. Unscrew the five bolts that secure the mudguard.

- Ask a friend to engage fifth gear and press the brake, at this time, using ratchet No. 17, unscrew the bolt that secures the crankshaft pulley. Rotate in the opposite direction clockwise.

- Remove the thrust washer

- Unscrew the bolts securing the tension and thrust rollers. Use key 15. Remove the rollers, remove the belt.

- Now install new rollers, do not tighten the tensioner type, they will be used for adjustment. Reinstall the camshaft pulleys, then the crankshaft pulley.

- Put on a new belt - pull it onto the crankshaft, then around the pump, then onto the camshaft pulleys.

The new product is installed, all that remains is to adjust the tension:

- Pull the tensioner pulley in the opposite direction clockwise - when you installed the new kit, you did not tighten this pulley.

- All that remains is to align the marks on the tension roller, just tighten the bolts tightly.

- Turn the crankshaft pulley exactly two turns. Rotate the pulley in a clockwise direction. Be sure to make sure that the marks on the two shafts match.

To make sure the tension is correct, press the stretched rubber with a force of about ten kilograms. If the product bends by more than seven millimeters, you will have to carry out the rubber tensioning procedure again. In ideal condition, the rubber should not be pressed under a pressure force of 10 kg.

How long does it take to change the timing belt?

- According to the Lada Priora maintenance regulations, the condition of the timing belt should be checked after 105 thousand km, and replaced after 200 thousand km. However, sheared teeth or a broken timing belt can cause the valves to stick (valve bending) into the pistons, leading to costly engine repairs. Therefore, we recommend checking the condition of the timing belt more often - every 45 thousand km.

- On Lada Granta and Lada Kalina 2 cars, the timing belt is checked every maintenance (every 15,000 km), and replacement is carried out after 75 thousand km. mileage

What are the consequences of untimely replacement?

Questionable savings on the purchase of consumables for the timing mechanism can lead to significant costs for the restoration of the power unit. On the Lada Priora, the cylinder head has 16 valves, 4 for each working cylinder. If for some reason there is a mismatch in the operation of the timing belt and the crank mechanism, there will inevitably be a “meeting” of pistons and valves. In the best case, you will have to replace the damaged valve, but there can be more significant damage to the engine.

Check and replace worn timing drive parts in a timely manner; the machine will delight you for a long time with the flawless operation of the power unit.

Removing the timing belt

You will need : a 5-point hexagon, a 17-point, 15-point, 10-point socket and a large flat-head screwdriver.

Procedure:

- Remove the upper timing cover by removing 5 screws.

- Remove the lower timing cover by unscrewing the 2 screws. Remove the alternator belt.

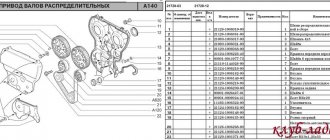

- Camshaft drive diagram.

In order not to disturb the valve timing, it is necessary to set the crankshaft and camshaft to the TDC (top dead center) position of the compression stroke of the 1st cylinder. For this:

- Turn the crankshaft clockwise using the generator drive bolt until the marks on the camshaft toothed pulleys align with the marks on the rear timing drive cover.

- check that the mark on the flywheel 1 is located opposite the slot 2 of the upper cover of the clutch housing.

We fix the flywheel by inserting a screwdriver between the flywheel teeth through the hole in the clutch housing. Then:

- Remove the pulley by unscrewing the bolt.

- Remove the support washer.

Visual inspection and work procedure

How to check a belt for rupture if the car “knocks” during a trip? To do this, some car enthusiasts just need to unscrew the timing cover and visually assess the condition of the part. And this is the easiest way for the Priora series, while some foreign cars are already equipped with detectors for such a breakdown, located right in the car’s interior. It is interesting to note that both domestic and foreign cars are susceptible to belt breaks on Russian roads, often regardless of their mileage.

How to install a new timing belt on a domestic Priora car? To do this, first of all you will need:

- Remove the fastening screws from the front top cover using a “5” hexagon;

- Remove the mudguard from the engine compartment;

- Using the socket at “17”, turn the crankshaft clockwise (by the bolt from the drive pulley leading to the generator). Inspect the timing belt for damage or contamination;

- Unscrew the pair of screws that secure the lower cover from the timing drive using a hexagon to “5”;

- Remove the cover and the generator drive belt;

- How to avoid violation of the gas distribution order? To do this, you need to put both the crankshaft and the gas distribution shaft in the top dead center position for the compression stroke of the first cylinder (turn the crankshaft by the pulley mounting bolt clockwise until the marks on the pulleys align with the marks on the rear cover from the timing drive);

- To check the position of the crankshaft, you need to remove the rubber plug located in the upper part of the clutch housing (at the same time, the coolant temperature sensors, the wiring harness from the sensors, and the cooling system hose must be disconnected). After this, it’s worth looking at how the mark is located on the “one” flywheel. It must be placed so that it is opposite the second slot on the top cover of the clutch housing on the Priora.

- What action should be taken next so as not to disrupt the valve timing again when the bolt is unscrewed from the fastening on the pulley at the generator drive? In this case, you will need an assistant to fix the flywheel by placing a large-diameter slot-type screwdriver through the hole in the clutch housing and into the flywheel teeth.

- Next, you need to remove the generator drive pulley, having first loosened the fastening bolt and its support washer.

- Using a spanner or a 15mm socket, you need to loosen the fastening bolt from the tension roller of the belt itself (the roller turns - the tension weakens).

Return to contents

Installing the timing belt

Before installing the rollers, apply thread sealant to the threaded part. We do not completely tighten the tension roller bolt. Before installing the timing belt, check the alignment of the timing marks. It is convenient to control the position of the crankshaft by aligning mark 1 on the crankshaft toothed pulley with mark 2 (rib) on the oil pump cover.

We put the timing belt on the crankshaft pulley, tensioning both branches of the belt, we put the front branch behind the support roller, and the rear branch, putting it on the coolant pump pulley, behind the tension roller. Then we put the timing belt on the camshaft pulleys.

Manufacturer's terms

The vehicle operating instructions recommend replacing the timing belt, tension roller, and pump after 200 thousand kilometers.

How long it actually takes to replace it depends on many factors. If the car drives most of the time on country highways without traffic jams, sudden acceleration and braking, the belt can last 200 thousand kilometers. Aggressive driving style, traffic jams, poor-quality consumables and maintenance reduce the actual service life of the timing belt.

Experienced owners of this model and repairmen recommend replacing it after 50–60 thousand kilometers. You need to check the condition of the timing mechanism parts every 10–15 thousand km.

Particular attention should be paid not only to the tension of the timing belt in the timing drive, but also to the condition of its teeth. It is their cutting that causes breakdowns followed by expensive repairs.

Belt

This part in the timing mechanism drive transmits rotation from the crankshaft, two camshafts, and the coolant pump. The loads on the belt are large; high demands are placed on the quality of the material for its manufacture. It is quite difficult to break the body of the belt; most often its teeth are cut off.

Under ideal conditions, it runs for 150 thousand km. It is difficult to obtain such conditions on the roads of the CIS countries, especially in cities, so the service life of this part is reduced.

The optimal mileage when you need to replace the timing belt will be in the range from 50 to 60 thousand km.

There is confirmed data on earlier dates for performing such an operation, but in these cases, malfunctions in the valve drive mechanism, engine oil leaks, and the appearance of defects on the toothed belt were noted. The lubricant softens the composition of the belt material, which makes it easier to destroy, so engine oil leaks should not be allowed to occur, and if they occur, immediately repair the detected malfunction.

How to tension a timing belt

- Insert the tips of the locking ring pliers into the grooves of the outer race of the tension roller.

- Tension the belt by turning the tension roller counterclockwise.

- We combine cutout 1 of the outer race of the roller with the rectangular protrusion 2 of its inner sleeve. Tighten the roller mounting bolt with a wrench.

After installing the generator drive pulley, turn the crankshaft by the pulley mounting bolt two turns clockwise. We check the alignment of the installation marks on the crankshaft and camshaft, as well as the alignment of the cutout with the protrusion on the tension roller.

The process of replacing the timing belt is also shown in the video:

Checking the condition of the belt

Checking the timing mechanism

Any checks and adjustments of the drive belt are carried out only on a cold engine. Its maximum temperature should be no higher than 35 degrees.

If the car has an air conditioner, you should remove its drive belt, and only after that handle the timing belt. To remove the air conditioner belt, you need to unscrew the engine mount, and after removing the belt, install the motor on the mount, lightly tightening the screws that secure it.

Checking the timing belt is performed in the following order:

- Find and unscrew the five screws securing the plastic protective cover.

- Remove the cover from the engine.

- Jack up the front wheel on the right.

- We set the gearbox to fifth gear.

- Turn the wheel clockwise.

- The inner surface of the belt should not have cracks, abrasions, folds, or delamination of the rubber material.

- The outer surface should be free of marks, cracks, signs of heavy wear and protruding cord.

- If stains of operating materials (oil, coolant) are found on the belt, it must be replaced, but only after the causes of the leak have been eliminated.

How to check and adjust belt tension on a Priora

Timing belt in action

After inspecting the condition of the timing drive, be sure to check the belt tension and the condition of the tension and support rollers. This should be done in the following sequence:

- We turn the crankshaft by the hanging wheel until the marks on the toothed pulleys of both camshafts align with the bosses on the rear drive casing.

- Pay attention to the tension roller: the cutout in its cage must clearly coincide with the boss of the sleeve inside the roller.

- If the belt is tensioned satisfactorily, the boss will coincide with the cutout, otherwise it is necessary to loosen the roller mounting bolt with a 15mm wrench.

- To adjust the belt tension, turn the roller itself - counterclockwise to tighten, clockwise to loosen.

- This can be done either with a special wrench, or a bicycle wrench of a suitable size with a grip, or pliers for removing the locking rings.

- The roller is rotated until the cutout and boss coincide, after which the roller mounting bolt is tightened with a force of about 40 Nm using a 15 wrench.

When adjusting, it is important not to overtighten the belt or loosen it, since in the first case it will quickly wear out and lead to failure of the pump bearing, and in the second case, teeth may slip and the valve timing may be disrupted.

Timing belt with signs of wear

As a result, the valves can strike the piston crowns, causing serious and costly failure.

Replacing the timing belt without special tools

The method can be used if there is no need to change the rollers.

- Cut off half of the old timing belt with a utility knife.

- Remove half of the old timing belt.

- We put a new timing belt on the crankshaft pulleys.

- We cut the second half of the old timing belt and remove it.

- Pull the new timing belt onto the crankshaft pulleys until the end.

By the way, according to the survey results, replacing the timing belt on an 8-valve engine is easier than on a 16-valve engine.

Russian-made cars of the VAZ-2170 or Lada Priora brand have received recognition from many motorists. This is due not only to the modern design of this car, but also to the fact that the vehicle is equipped with a type 21126 engine. This is a 16-cylinder engine with a volume of 1.6 liters and a power of 106 hp. Along with the advantages, the Priora has a disadvantage, which manifests itself when the timing belt breaks. If the timing belt is not replaced in a timely manner, then when it breaks, the valves will bend. To prevent this from happening, the timing belt on a Priora 16 valve must be replaced in a timely manner, which can be done with your own hands. This procedure is not complicated, and each owner will be able to perform it independently, having understood some of the nuances.

Impact of mileage

The service life of drive parts depends on many factors, most often the following:

- The car's mileage before replacement.

- Operating conditions of the machine.

- Quality of material for manufacturing.

- Technical condition of timing drive mechanism parts.

Many experts and owners argue about how much mileage a car should have before replacement. No one gives a definite answer, since this can be done after 100 thousand km or more, sometimes much earlier than the recommended period. Usually, owners change the consumables of the timing mechanism after 50–60 thousand km, which many consider the best option. This figure can be changed in one direction or another. So, if the gears in the drive have wear, this will lead to accelerated failure of the belt. Its performance is greatly affected by the “age” of the product used.

When the car's mileage may be only a few thousand km, and the car has not been used for several years, in this case it is best to replace all the timing drive parts. The penetration of engine oil and other technical fluids into the drive operating area also reduces the service life of belts. The cost of timing drive consumables is significantly less than the cost of repairing the engine if the belt breaks, so you should not save on this.

Timing belt and its purpose

The timing belt is a rubber product that has a toothed surface on the inside. Durable types of rubber are used to make this belt. The product is put on the crankshaft and camshaft gears, which allows you to synchronize the operation of these mechanisms. With its help, fuel is supplied to the engine cylinders in a timely manner.

The teeth on the belt are designed to ensure reliable adhesion to the gears and prevent slipping. Priora is equipped with belts that have 137 teeth. If the belt breaks, the car will not be able to continue moving due to incorrect operation of the engine. That is why the regulations state that this element must be replaced every 30-45 thousand kilometers.

This is interesting! If it is noticed that the timing belt shows signs of wear or damage, but the mileage has not yet reached the specified value, then it is definitely necessary to replace it. This is especially important to do on a VAZ-2170 or Priora car, since in the event of a break, the valves fail.

The timing belt not only connects the crankshaft to the camshaft, but also drives the water pump. Despite the fact that the device is a “piece of rubber”, its importance in the design of the engine of any car is priceless.

Why install a belt or the advantages of the mechanism

This node has plenty of advantages, despite the “screams” of opponents, let’s list them:

- Silence of work. This is probably the biggest plus - with a belt drive, the engine runs quieter than an iron opponent. Maybe not by much, but the effect is, as they say, “noticeable”, or rather audible!

- Price. Belt drive is two to three times cheaper than a similar metal structure. This affects both initial production (in factories) and final consumption (the owner). Even if you change the belt every 70,000 kilometers, it will still be cheaper than changing the chain once every 250,000 kilometers.

- Space saving. It was a surprise to myself, but engines with a chain mechanism are about 10% larger than engines with a belt drive! Why? YES, everything is simple - the chain drive is inside in oil, and accordingly you need to make a valve cover, block, pan, etc. – more massive to close it inside. Here's to a larger engine! Of course, now they’ll say, “Didn’t you forget about the belt?” After all, it also has a casing in front? No, I didn’t forget, but the casing is usually smaller in size.

- Oil quality. Everyone knows that chain transmission is very demanding on the quality of engine oil; the service life due to poor quality lubrication can be reduced by 20 - 30%, which you know is significant! Therefore, it is advisable to change the oil every 10 - 12,000 kilometers. The timing belt in this regard is simpler; it doesn’t care about oil at all, it spins in the air and doesn’t come into contact with this lubricant in any way.

- Easy maintenance. Needless to say, the belt is much simpler and, let me emphasize again, cheaper to replace. There is no need to go into the engine and disassemble it, drain the oil, etc.

- Well, and probably the last thing - the belt is easier to tighten, you can at least tie it in a knot. You can’t do this to an opponent, that’s why the “tensioners” for the chain are unique.

Maybe I forgot something, but as you can see, there are quite a lot of advantages, despite the fact that many “dislike” it.

When does a belt need to be replaced on a Priora: possible consequences

It is recommended to replace the timing belt every 30 - 45 thousand kilometers. Of course, the probability of a belt breaking with such a mileage is very low, but the indicated mileage is the resource of the product. There are many cases where motorists clock twice the mileage indicated above on the tachometer, and have never changed the belt. The serviceability of the product in question is measured not only by its integrity. During operation, it stretches, therefore the quality of engagement decreases and the likelihood of slipping increases.

Timing belt with worn teeth: what can happen if the product is not replaced in a timely manner

This is interesting! The service life of the timing belt is influenced by various factors: the nature of the ride, the quality of the product, the ingress of foreign liquids and objects onto the belt drive, etc. It is impossible to indicate the exact mileage that a timing belt will last. To avoid having to go to a service station for major repairs, it is recommended to monitor the operating time of the product on a car such as the Priora.

Signs that the timing belt on a Priora needs to be replaced are the following factors:

- presence of extraneous noise when the engine is running;

- changing the color of exhaust gases;

- problems when starting the engine;

- extraneous vibration.

Photo of a worn and torn belt on a Priora: what you shouldn’t let your car do

Replacing the timing belt on a Priora 16 valve may be necessary much earlier than at 30-45 thousand km. This is due to oil, dirt and antifreeze getting on the belt drive. Antifreeze or coolant poses a particular danger to the integrity of a rubber product. If a coolant leak occurs, which is caused by a leak in the pump gasket or failure of the pump, then the service life of the rubber product is reduced tenfold. If a coolant leak is detected, the causes should be promptly identified and eliminated. If the cause is a violation of the integrity of the pump or gasket, then the timing belt will need to be replaced at the same time. If there are problems with the strength of the belt at high speeds, irreparable consequences may occur in the form of broken pistons and deformation of connecting rods.

Why is this so important?

I think it’s no secret to anyone what happens when the timing belt breaks, but perhaps there are those who are not in the know. In the event of a break, the synchronization of the operation of the cylinder-piston group and valves is disrupted. The pistons begin to move towards the valves, which are no longer controlled by the belt; as a result, the pistons “meet” the valves. After such a “meeting,” the pistons are destroyed, the valves are bent, and in general you end up with a major engine overhaul. Could this have been avoided? It is possible, of course, if the manufacturer of this engine thought about this at the design stage, completely eliminating such a phenomenon. By the way, there are quite a few “plug-in” engines in the world that, after a broken belt, do not need to be “overhauled”; you just need to get to a service station and replace the timing belt. In such engines, when the valve belt breaks, the valves do not meet the pistons.

The belt and rollers must be replaced immediately if, during inspection, you find:

- Roughness on the belt (on the teeth or sides);

- Mechanical damage;

- Engine malfunctions;

- Problems starting the engine;

- Extraneous sounds indicating friction of the belt against the casing, rollers or pulleys.

Separately, I would like to note the appearance of vibration and black exhaust; such symptoms, of course, can occur under other circumstances, but this option should also be considered.

Consider exclusively mileage in the question: “Is it time to change the timing belt or not?” - this is mistake. Firstly, even with low mileage, problems can arise with the belt or rollers. And secondly, there are many situations when you practically or completely do not move, while the motor is running, therefore, the belt wears out. For example, if the car is used mainly in the city, the mileage may be low, but the life of the belt itself will be at its limit, since in traffic jams the engine is running, but there is practically no movement.

There are other factors that can cause a belt to fail prematurely. For example, if oil, fuel, dirt or sand gets on it. Small particles of sand eat into the surface of the belt, destroying its surface; oil and other petroleum products soften it, reducing its strength and shortening its service life.

Features of self-checking the serviceability of the timing belt on Priora

If you are thinking about the need to replace a rubber product on a Priora, then it won’t hurt to initially check the belt drive. The inspection will reveal signs of wear and the presence of places where the product is deformed. To carry out the check, you will need to use a hex wrench set to “5” or a T-30 star-shaped bit (depending on the year of manufacture of the Priora).

The procedure for checking the belt drive is as follows:

- Use a hexagon to unscrew 5 mounting bolts, with which the front upper timing drive cover is secured.

Removing the timing cover

Marks on the tensioner pulley

This is interesting! The timing belt for the VAZ-2170 on the outer rim has the following information: engine type (21126 or 21127), number of teeth - 137, as well as marking with a product width of 22 mm.

Necessary tools for replacement

Having decided that you need to replace the timing belt on a Priora, you should prepare the necessary material and tools. The materials will require a new timing belt. Moreover, you can buy both the original belt and analogues. The original belt product is also equipped with two rollers: a tensioner and a thrust roller. The cost of such a kit is about 5 thousand rubles.

Original kit for timing system on VAZ-2170

If necessary, you should purchase a new pump if the car’s mileage exceeds more than 100 thousand km and the product has never been changed. If you are replacing the pump, you will also need to replace the coolant.

This is interesting! Antifreeze needs to be replaced every 2 years, and antifreeze every 4-5 years.

Of the tools to replace the timing belt on a Lada Priora, 16 valves will be needed:

- Head at "17".

- Set of open-end wrenches.

- Screwdrivers.

- Hex key or T-30 sprocket, depending on the year of manufacture of the car.

- Special key for adjusting the roller. Comes with a set of belt and 2 rollers.

It is not necessary to install the Priora in the inspection hole, since most of the actions will be performed in the engine compartment. Once all the tools and materials are ready, you can start working.

About the resource

Well, now we’ve come to the most interesting thing, namely the resource. You know, now I want to talk specifically about normal belts and tensioning equipment, about “PRIORS” will be a little lower.

Not all manufacturers strictly indicate how often to change the belt, but such information can still be found, even in the car’s operating books.

The average mileage recommended for replacement is 100,000 kilometers. On many foreign cars, this mileage can be much longer, about 150,000 kilometers.

Now the question may arise: what does it depend on? Guys, to be honest, the belt itself can run (as some manufacturers claim) about 200,000 km, but its service life is reduced due to tension and support rollers. They are often the culprits of the cliff!

The support roller is a kind of bearing on which the belt rests, often has a plastic housing.

The tension roller is almost the same plastic bearing, only it is located on a special mount that “tensions” the belt, that is, it keeps it in “tone” and prevents it from “sagging” and jumping onto a tooth.

Both videos must be of simply excellent quality, no, they simply must! With foreign cars this is almost always the case, these “support” and “tensioner” last a long time, and replacement is 100 - 150,000 km in advance.

If one of the rollers stands up, the belt wears out, within some 100–200 km of travel, or maybe even less.

As you may have guessed, not only the belt is changed, but also the tension and support rollers - THIS IS MANDATORY, REMEMBER THIS! As an indirect reason for a future replacement, there may be noise from the timing drive; when the rollers begin to “bend”, they begin to make noise.

Replacing rollers and timing belt: step-by-step steps

Initially, it should be noted that owners of a Lada Priora car with air conditioning will need to perform some steps to get to the timing mechanism. If you have a Priora with air conditioning, then initially you need:

- Using a wrench with a 15mm head, unscrew the generator tensioner pulley (not to be confused with the timing belt tensioner pulley). If the roller is humming, it is also recommended to replace it.

- After this, remove the alternator belt, which is also recommended to be replaced simultaneously with the timing belt drive.

- Now you will have access to the protective covers of the gas distribution mechanism.

Replacing the timing belt on a Priora 16 valves with your own hands is done by performing the following steps:

- Using a hexagon or T-30 bit in the shape of an asterisk, you need to unscrew 5 bolts securing the upper cover (plastic casing) and 2 bolts of the lower timing cover.

- The crankshaft sensor is disconnected by disconnecting the corresponding chip near the upper timing cover.

- Place a jack under the wheel on the passenger side, then lift the car and hang the wheel. This must be done in order to be able to align the marks of the camshaft pulleys. This procedure can also be performed by rotating the crankshaft pulley with a key to “17”. The photo below shows marks 1 on the mechanism body, as well as marks 2 on the camshaft pulleys. They must be combined by rotating the wheel with 5th gear engaged. If you do not plan to change the pump, then there is no need to loosen the camshaft pulleys after setting the marks.

Aligning the camshaft marks

Mark on the flywheel

Removing the crankshaft pulley

Removing the tensioner and thrust rollers

Removing the timing belt

Location of the inner timing cover bolts

We proceed to the procedure for adjusting the tension of the belt drive.

Weak link: pump, roller, belt

The reasons for repairing the timing unit are most often broken bearings of the tensioner roller and pump, as well as the timing belt. The pump also has to be changed if the seal of the structure is lost, causing loss of coolant. To replace it, you will have to remove the camshaft pulleys and the rear protective cover of the casing. Remove the generator roller tensioner fasteners (3 bolts), unscrew the 6 bolts (10mm) securing the casing, two of which are located under the camshaft pulleys. After removing the casing, unscrew the 3 bolts securing the pump.

How to check tension

At the end of the work, it is necessary to adjust the tension of the timing belt drive on the Priora. The adjustment is made as follows:

- Using a special wrench, you need to turn the tensioner pulley counterclockwise.

Tensioner adjustment key

You can check the tension by applying force to a rubber product weighing 10 kg. The deviation value should not exceed 5-7 mm.

When tightening the pulley and roller bolts, it is recommended to use a torque wrench. The tightening torque for each element is equal to the following values:

- for the tension roller – 35-41 Nm;

- thrust roller – 105-110 Nm;

- pump mounting bolts – 15-20 Nm.

After adjustment, you can put the protective cover back in place. Finally, the generator belt tensioner roller is installed, as well as the belt itself. It is also recommended to replace these elements with new ones. Finally, do not forget to fill the coolant before starting the engine.

Upon completion of the work done, you can start the engine and check its operation. If the marks are correctly set, the engine will start the first time the key is turned in the ignition switch. In this case, the engine should operate evenly and keep the speed in the region of 800-900 rpm. Listen to the timing belt drive. There should be no extraneous sounds or noises. The presence of a whistle or hum indicates that the tensioner is too tight and needs to be loosened.

Adjust the tension to ensure maximum mileage

Normal belt tension

What is the best way to adjust the timing belt tension? To do this, take pliers to remove the locking rings and insert the ends into the grooves from the outer race of the roller (tensioner). The belt is tensioned, while using pliers you need to turn the tension roller counterclockwise so as to align the cutout of the outer race with the protrusion of the bushing (rectangular). The roller mounting bolt is tightened with a wrench. It is worth noting that the spare timing kit does not include anything other than a belt and rollers, so all keys and sockets must be purchased separately.

How to complete the installation of this element? After installing the pulley from the generator drive, you need to rotate the crankshaft by the mounting bolt 2 turns (clockwise) and check the alignment of all marks. If there is a discrepancy, then all operations must be carried out again, because no matter how high-quality the timing belt itself is, it will not be able to perform its functions if it is poorly installed. After all the operations and reassembly of the parts, you need to start the machine and let it run for about a quarter of an hour.

Next, you need to re-check the belt tension: when a force of 100N is applied to the middle of its long part, the “sag” should be in the range of 5.5 to 6 millimeters. If you are not confident in your experience in carrying out such work, it is better to contact a car service center that specializes in Priora, so that later you do not have to pay for the repair of the entire engine. But it’s worth having basic knowledge of how to tension a belt, because this part often fails on the highway, far from service stations, even if the car has low mileage.