A timing belt is a rubber part with notches on the inside that connects the crankshaft and camshaft to ensure vehicle movement. The responsible owner of a Lada Vesta, who has driven more than 50 thousand km, had to replace the timing belt at least once - so as not to find out prematurely whether the valves are bending.

Unfortunately, on the VAZ this ailment is transmitted from engine to engine, they cannot work on it in any way and the valves are bent due to the assembly: belt, pump, rollers.

This unit is vulnerable and the valve will bend if one of these parts fails. The situation would have changed, or not, the problem would have gone away completely - install the AvtoVAZ pump separately, but alas, the pump is in one unit on all VAZ engines.

If the hr16de engine had entered the series, then this ailment would also be absent, you would only need to undergo maintenance on time, monitor the chain, and yes, valve adjustment, VAZ engines would again come into use.

After a significant mileage of the car or improper operation, the timing belt often breaks. Oil getting on the surface, untimely replacement of components, use of the car in severe frosts or, conversely, in sultry heat - this can damage the gas distribution mechanism drive.

Damage can be detected during maintenance of the Lada Vesta. Maintenance consists of inspecting the condition of the unit from time to time.

A rather significant problem for owners of Vestas with 16 valve engines in the event of a break is valve bending. This happens after the timing belt breaks or the links are stretched. When the links are stretched, the crankshaft continues to work, but the camshaft abruptly stops its movement. Next, the car engine stops completely. If you start it again, you can cause failure of the pistons, which will cause expensive repairs to the piston group of the cylinder block.

Read the article and your engine will be safe - you will replace the belt and rollers on time, preventing unexpected breakdowns.

Lada Vesta: When to change the timing belt, frequency and cost of repairs.

The vehicle's registration certificate provides for replacement of the unit after 180 thousand kilometers.

In practice, it is advisable to change the drive more often - after 80-100 thousand km, because the part does not always correspond to the original production.

The cost of replacement will be calculated taking into account the work of specialists and the cost of the part. Usually the cost of work is 3000-5000 rubles, and the price of the part depends on the manufacturer.

So, the average price:

- CT 1179 (CONTITECH) - from 1000 rubles;

- 5671 XS (Gates) — 3890 RUR;

- GATES K015631XS 16 class — 3890 RUR;

- Bosch 1987949686 (Bosch) - 1360 rub.

- Trialli GD770 - 2900;

- Lynxauto PK1300 - 2430 rubles per set.

How are timing belts replaced?

Before removing the belt, you should first remove other parts and assemblies that prevent access to the device. This also applies to a pair of V-belt pulleys, a servo pump that supports the steering, and an air filter. The next step is to release the device from the protection mechanism, as well as switch the crankshaft to the dead center position of the leading piston at the base of the first cylinder.

It is important to ensure that the markings on the cylinder head and the camshaft are fully consistent. To adjust, turn forward. When replacing the device, the belt is gradually loosened until completely removed. To install a new unit, perform similar steps in reverse order.

Standard belt from factory

The frequency of replacing the timing belt unit of a Lada Vesta car is about 90-100 thousand km.

A resource is the frequency through which a node needs to be changed. The service life of the Gates model is approximately 200,000 km. It is important to consider that the service life of the timing belt is also influenced by external factors, including proper operation.

For some car models, including Lada Vesta, belts are supplied by the well-known Belgian company Gates.

It is better to buy a kit, along with a tensioner and a regular pulley.

The car comes with Gates or Contitech parts from the factory.

Direct signs of a faulty timing belt

- Critical wear of the belt tensioner or its rollers (can be seen by removing the valve cover);

- Worn sprocket teeth (can be seen by removing the valve cover);

- Cracks and other signs of wear and damage.

If you notice the appearance of at least one of the described signs of malfunction, you must immediately check the condition of the timing belt. Experienced car owners can easily do this on their own, but it is better to carry out this procedure at a service station.

At a car service center, a specialist will be able to do a full inspection of the timing belt, check its tension and identify the degree of wear. If necessary, immediately adjust or replace it with the necessary components. Only an experienced specialist at a service station will be able to correctly tension the belt, because a weakly tensioned belt is more at risk of breaking.

Depending on the specific LADA brand, our specialists perform a number of procedures that allow:

- check the degree of tension of the timing belt;

- carry out a visual inspection of the entire length of the belt;

- inspect the condition of its teeth;

- identify cracks and other signs of wear

- Identify and eliminate the causes of contamination of the timing system with coolant or oil.

It's time to change the timing belt or you notice signs of a faulty belt, do not delay your visit to a car service center, otherwise the consequences may be unpleasant.

Instructions for replacing the timing belt on Vesta

You can carry out the work of replacing the timing belt on your own, but this is labor-intensive work.

Replacement requires the necessary technical equipment and experience in carrying out repair work. At the beginning of installation and adjustment of the belt drive, you should remove its casing on the engine by removing the 5 fastening screws. Remove the casing and remove the belt. Using a 17mm wrench, turn the crankshaft using the roller bolts so that the marks on the camshafts coincide with the marks on the plastic casing. Turn until the crankshaft pulley with mark F coincides with mark E. Using the same key, remove the crankshaft pulley and the limiter washer. The remaining part of the casing is unscrewed with a 5-point hexagon: 2 bolts on the bottom and 3 on top. Using a “15” wrench, unscrew the tension roller mounting bolt, after which it is dismantled in the same way as the idler roller. New rollers are put on in their place. Then comes the installation of a new belt instead of the old one. First you should make sure that the marks are still set correctly, then the belt is installed on the camshaft and pulled to the crankshaft with tension. The timing belt tensioner pulley starts it last. Use a snap ring puller to rotate the tension roller until the marks are compatible. Next comes the assembly.

Replacing the timing belt without special tools

The method can be used if there is no need to change the rollers.

Procedure

:

- Cut off half of the old timing belt with a utility knife.

- Remove half of the old timing belt.

- We put a new timing belt on the crankshaft pulleys.

- We cut the second half of the old timing belt and remove it.

- Pull the new timing belt onto the crankshaft pulleys until the end.

Where can I buy

: Timing belt kits at low prices are available in our online store (Timing belt category).

Let us remind you that the characteristics and reviews of the VAZ-21179 engine can be found here.

Keywords: lada xray engine | Lada Vesta engine

0 0 0 0 0 0

Share on social networks:

Analogue belt brands

If we talk about the best brands, then Gates, Contitech, Dayco and Bosch are the most promising in the segment and enjoy decent popularity.

Drivers trust spare parts from the Belgian company Gates, whose manufacturers supply their products to car factories.

An analogue of Geitz is the German company Contitech; its parts are also used during vehicle assembly.

When choosing timing belts, you should choose the original, which may be more expensive in price, but will last a long time. We wish you that your timing belt never breaks and is serviced on time!

Engine options for Vesta

Here we consider options related to cars currently being produced or those that will begin to be produced in the near future. An 8-valve engine was also developed for Vesta - it definitely does not bend the valves and will definitely not be installed on top-end sedans in 2016.

Read more about the engines with which the Lada Vesta line is equipped in the material: What engines are installed on the Lada Vesta: technical characteristics and their service life!

ICE VAZ-21129, 106 “hp” (valve bending)

A little history. Motor 21129 is a modified version of another engine, namely 21127. The last of them, when the timing belt broke, successfully bent its valves, although grooves were made on the pistons (Fig. 1). The point is that the depth of the grooves was not sufficient: if certain conditions were met, the valve “met” the piston with all the ensuing consequences.

With the transition to a new generation of internal combustion engines, that is, 21129, the design of the pistons was modified. But the external shape has not changed much, and although the recesses remain, their depth is still insufficient.

Here we considered the question of whether the Lada Vesta valves with the “21129” engine are bent. And the answer was clear: yes, oppression.

In theory, the problem with valve bending is typical for all VAZ engines equipped with 4 valves per cylinder. Each new 16-valve engine “inherits” it. The exception is one rarity - the internal combustion engine of the VAZ-2112, the volume of which is 1.6 liters. There, the recesses are made conscientiously (Fig. 2).

122-horsepower engine “21179” (valve bending)

In terms of its design, the internal combustion engine of the VAZ-21179 is not very different from its predecessors. The working volume was increased to 1774 ml, which was achieved by changing the piston stroke length: it was 75.6 mm, it became 84.0 mm.

The piston itself is now better fitted to the cylinder than in engines 21127 and 21129. The distance from the piston pin to the piston bottom has increased by 1.3 mm - to 26.7 mm. But deeper grooves in the bottom never appeared. The timing mechanism still drives the belt, and if it breaks, the possibility of bending the valves has not been canceled.

Now we know whether the valves bend on a Lada Vesta with a 1.8-liter engine. The answer will be the same as for all 16-valve VAZ internal combustion engines (with the exception of 2112). The problem with the transition to a new generation remains the same. But VAZ does not intend to return to “heavy” pistons.

The timing drive on 21179 engines is equipped with not one, but two tension rollers. What was done to make the design less susceptible to timing belt stretching.

One of the automatic tensioners may jam, but then its function will be taken over by the second automatic roller.

Pistons that do not bend valves

Piston kits for some “old” 16-valve engines are produced by third-party companies. These parts are equipped with deep recesses. The point is that the piston does not reach the plates and cannot bend the valves.

ShPG elements of different engines (21127, 21129, 21179) are compatible. But there is no need to install pistons from “old engines” into the Vesta engine:

- In ICE 21129, after such “tuning”, friction losses will increase;

- If pistons from the 26th or 27th engine are installed in the ICE 21179, the working volume will immediately change.

The “29th”, as well as the “79th” Lada Vesta engine bends valves only with “VAZ” pistons. But after installing a “tuning” part, do not expect an increase in power. Also, by using non-standard elements, you can greatly reduce the resource (lose the warranty, get unforeseen consequences).

Nissan HR16DE engine (does not bend, there is a chain)

In most trim levels with a manual transmission, the Vesta sedan is equipped with a Nissan engine. This engine is planned for installation on bodies: station wagon, crossover and coupe! Its name is HR16DE, and its displacement is 1.6 liters. Let's look at what the piston crown looks like.

There are no “deep recesses” here.

Now let's pay attention to how the timing drive mechanism works. There is no belt with teeth here - it is replaced by a chain

It is difficult to imagine the following two situations:

There is no toothed belt here - it is replaced by a chain. It is difficult to imagine the following two situations:

- The chain could have jumped over the teeth of one or more gears;

- One of the elements was damaged so badly that the presence of damage led to rupture.

As long as the chain remains intact, the valves and pistons cannot meet each other, no matter what happens to the engine. The only bad thing is that the chain may jam.

Do the valves of a Lada Vesta with a Nissan internal combustion engine bend? The answer “no” would be wrong - a circuit break is not excluded. But in reality it will be almost impossible to face such a situation. Let's look at why.

Can a broken timing belt bend the valves?

Many owners of a car from the Russian Federation Lada Vesta, and other models, are worried that due to the fact that the timing belt was not replaced in a timely manner, this can lead to bending of the valves, and in order to repair them they will have to pay a tidy sum. This is true. Experts say that in car power units that come with a timing belt from the factory, in most new car models, unpleasant valve failures often occur.

The design of the Lada Vesta engine with a power rating of 122 hp will in most cases bend the valves when the belt breaks. Even the fact that at one time, to eliminate this unpleasant situation, grooves were introduced into the piston itself will not help. The depth of these very grooves is not sufficient, and a torn belt easily bends the valves. Avtovaz's creators of the popular domestic car changed the piston system, but did not succeed in this matter. All the same, the valve mechanism came out of order due to the timing belt falling off. And there is only one panacea: timely replacement of the timing belt. And we told you when to change it at the very beginning.

Step-by-step instructions for replacing the timing belt in Vesta (necessary tools)

- We install the Russian Lada Vesta on a lift.

- We remove only one negative terminal on the battery.

- We dismantle the starter and, accordingly, the belt drive of the automobile generator.

- Now lower the lift completely.

- A traverse is carefully installed on the right side of the engine.

- Lift the motor using a hook.

- Using Torx 12 sockets, remove all bolts. A hexagon wrench will be required to unscrew the 8 fasteners, which are located on the protective special casing of the drive (3 on the bottom, 5 on top).

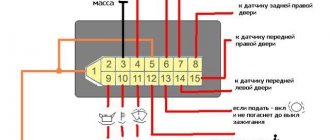

- The following steps when replacing the timing belt entirely depend on what type of unit is in the car. To do this you will need a matching diagram.

- The video material will clearly tell you about all the subtleties that will prevent valve failures.

- After installing a new belt, it is necessary to adjust the tension, and then check the functionality of the entire system.