A malfunction of the cylinder head will lead to incorrect operation of the car engine as a whole. This unit consists of many elements, but most often car owners are faced with the need to change the seal. In the article we will look at in what cases the cylinder head gasket of a VAZ 2114 is replaced and how to change this product yourself.

Where is the cylinder head gasket located on a VAZ 2114?

When should you change?

We change it with our own hands

Consequences of untimely replacement

Video “How the gasket replacement process occurs”

Comments and Reviews

Replacing the rear wheel hub bearing on a VAZ 2108, 2109, 21099 and their modifications

A failed rear wheel wheel bearing indicates a problem with a constant, often ear-piercing howl. It comes from the rear and does not go away when driving in neutral. As bearing wear increases, this sound may become increasingly louder. The rear wheel bearing needs to be replaced. This work can be done most quickly using special devices (pullers). If they are not there, then to achieve the goal, you should use available materials. Let's consider replacing the bearing with this particular slope.

Checking the rear wheel bearing

We hang the wheel on the bearing of which there are suspicions. We rotate it by hand. A wheel with a working bearing rotates almost silently. A faulty bearing reveals itself by noise and a sound “as if balls are rolling in the bearing.” The degree of noise and rolling depends on the degree of wear of the wheel bearing itself. For comparison, you can hang a wheel with a working bearing and listen to the sound it makes.

Required Tools

— An extended 30mm head with a long wrench, or a curved box wrench of a similar diameter (or a similar socket wrench, etc.)

To loosen the wheel hub nut.

— Thin chisel, center punch

To bend back the jammed edge of the hub nut.

— Three-legged puller (optional)

To remove the hub from the wheel axle.

— Two-legged puller, or a special semicircular one (optional)

To remove the inner bearing race from the wheel axle.

— Puller – pliers

To remove and install the retaining ring

— Puller for pressing the bearing out of the hub/pressing the bearing into the hub (optional)

— Open-end or any other key for 12 (11, 8, 7, depending on the type of pin)

For unscrewing the guide pins securing the brake drum.

— Key for 13 (14)

To loosen the parking brake adjusting nut.

Rear wheel bearing for VAZ 2108, 2109, 21099 cars with nut

Preparatory work

It is best to carry out work in a pit (inspection ditch), it is more convenient. But if there is no hole, you can do without it.

— We fix the car by placing it on a level surface, in first gear, placing wheel chocks under the wheels.

— Under the bottom of the car, loosen the handbrake tightening nut.

If the car is not installed in a pit (inspection ditch), then to perform this operation you will have to jack up one of the wheels, put a safety stop under the car and lie down to get to this very nut.

The procedure for replacing the rear wheel hub bearing on VAZ 2108, 2109, 21099 vehicles and their modifications

— Remove the protective cap on the wheel hub

— Removing the dent on the side of the hub nut

Using a thin chisel or core and hammer, straighten the jammed edge. For greater clarity, the wheel in the image has already been removed.

Wrinkled edge of wheel hub nut

- Loosen the hub nut

To do this, use a 30 mm socket with a long wrench (or a special wrench) to unscrew the nut. You may have to apply considerable force and extend the handle of the wrench with a metal pipe, as it may become stuck or rust over time. Also, to prevent the wheel from turning, an assistant inside the car can press the brake pedal.

Loosen the rear wheel hub nut

— Remove the wheel

Loosen the rear wheel mounting bolts, jack it up, place a safety stop, unscrew the bolts, and remove the wheel.

- Remove the brake drum

Using a 12 wrench (11, 10, 8, 7 - the pin size may be different), unscrew the two guide pins securing the brake drum. If they don’t want to turn away, lightly tap them with a hammer.

Unscrew the two wheel disc guide pins on the brake drum

Since we have already loosened the parking brake, the brake drum should come off without much difficulty. We rotate it left and right with our hands and at the same time pull it towards ourselves. If it goes badly, tap the drum in a circle from behind with a rubber mallet. This should help.

— Finally unscrew the hub nut

Remove it and the washer underneath it.

— Remove the rear wheel hub with bearing

We install a three-legged puller on the hub and rotate its nut to pull the hub off the wheel axle.

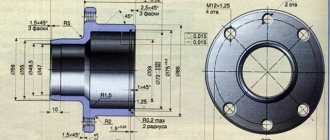

VAZ-2114 engine structure diagram

Cylinder head gasket close up (engine removed)

In order to understand the process and principle of replacing engine gaskets, you need to know the structure and sequence of parts in the main power unit.

So, let's look at the design of the VAZ-2114 engine:

Engine diagram and structure

| № | Detail number | Part name |

| 1 | 2108-1003298 | screw |

| 2 | 2108-1003278-01 | Washer |

| 3 | 2108-1003277-01 | Sleeve |

| 3 | 2108-1003277-02 | Sleeve |

| 4 | 2108-1003274 | Cover pin |

| 5 | 2111-1003260 | Cylinder head cover |

| 6 | 2108-1003271 | Bolt M12x1.25x135 |

| 7 | 2108-1003265 | Washer |

| 8 | 14328201 | Plug 10 cup |

| 9 | 14329101 | Plug 30 cup |

| 10 | 1118-1003011 | Cylinder head |

| 11 | 2101-1002042 | Sleeve |

| 12 | 14329201 | Plug 36 cup |

| 13 | 10158601 | Plug 16 spherical |

| 14 | 11183-1002011-10 | Cylinder block |

| 15 | 14234330 | Bolt M10x1.25x65 |

| 16 | 2108-1003284-10 | Ring sealing |

| 17 | 2111-1003284 | Ring sealing |

| 18 | 2111-1003286 | Bolt |

| 19 | 2111-1003288-10 | Stub |

| 20 | 10725911 | Nut M6 low |

| 21 | 11197773 | Conical spring washer 6 |

| 22 | 13541221 | Hairpin M6x22 |

| 23 | 2108-1003270-10 | Cover gasket |

| 23 | 2108-1003270-11 | Cylinder head cover gasket |

| 24 | 21083-1003020-10 | Head gasket |

| 24 | 21083-1003020-11 | Head gasket |

| 25 | 2112-3855020 | Knock sensor |

| 25 | 2112-3855020-01 | Knock sensor |

| 25 | 2112-3855020-02 | Knock sensor |

| 25 | 2112-3855020-03 | Knock sensor |

| 26 | 2101-1002040 | Sleeve |

Tightening torque for wheel bearings VAZ 2109

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Andri

I broke it once and changed the CV joint because of this.

I read somewhere: the lever is 40 cm and the weight is 70 kg. Optimal tightening type. Personally, I go by eye.

It's a gut feeling to say so!

Yeah. Well done! Now tell the guy where to buy a torque wrench with torque calibration up to 250 N/m

for a one-time puff to shell out a piece of rubles!?

can be easily pulled by a person weighing 70 kg on a 30 cm lever

Now tell the guy where to buy a torque wrench with torque calibration up to 250 N/m

with all the foolishness, don’t rip off the thread.

All these 40 cm levers and 90 degree turns do not provide any accuracy, and an overtightened or undertightened nut leads to the rapid death of the bearing.

Our bearings are not adjustable like on the classics, you can’t tighten them, you’ll most likely just break the thread. in my car, I immediately pulled out everything from the heart, already more than 100 thousand, everything is fine.

Don't compare. In Moscow and St. Petersburg you can buy a lot of things that you won’t find further in the volosts.

And so the key is of course not a question, just for it!