When replacing the rear wheel bearings of a VAZ-2109, it is necessary to take into account many factors that affect the quality of the work. An important condition for repairs is the choice of quality products. While working, you may encounter many troubles, you need to overcome them properly.

If you do not understand anything about the design of the car, then it is better to entrust repairs to specialists at a service station. But, in any case, you should be able to determine the malfunction yourself. This is the only way unscrupulous mechanics will be able to scam you into costly repairs.

Why does a bearing break?

On the VAZ-2109, the rear wheels do not turn, so the hubs are rigidly fixed to the suspension elements. The bearing is pressed very tightly into the hub, which rotates on the shaft. The appearance of play in this design is unacceptable. The rotation of the wheel should be as smooth as possible. There should be no crunches or jamming.

The average service life of high-quality wheel bearings is about 100,000 km. But the service life depends on what roads the car is driven on. If operation is carried out on unpaved roads, through mud and holes, then the wear of the element occurs much faster. Strong impacts on the suspension also damage the bearing. In addition, natural causes of wear and tear affect.

Completing the operation

After this, the washer and nut are returned to their place, and the hub is driven in completely until it stops. After this is done, the brake disc is returned to its place, the wheel is put on, all the bolts are screwed in, and the car is removed from the jack. After completing all work, it is necessary to tighten the hub nut. It is worth noting that the tightening torque should be 19-23 kgf/m. In other words, you need to tighten it with the same force with which it was removed before.

After this, a cap is put on the hub. The bearing replacement is completed, and the VAZ-2109 is ready for further use.

Source: ladaautos.ru

How to determine the malfunction?

Before replacing the rear wheel bearing of a VAZ-2109, it is advisable to carry out diagnostics. Of course, you will notice the breakdown literally immediately. A very strong howling and humming noise coming from the rear of the car indicates a bearing failure. Moreover, this sound intensifies when cornering and increasing speed.

Therefore, if you suddenly notice that a growing sound appears when the car is moving, it is best to replace the faulty bearing. You can achieve maximum repair efficiency if you install new mechanisms on both rear wheels. If there is even the slightest sound, we immediately change the rear wheel bearings of the VAZ-2109 with our own hands. For a more accurate diagnosis, you need to hang up the rear wheel and quickly rotate it.

If there is extraneous noise or resistance to rotation is felt, then it’s time for replacement. Stop the wheel and move it laterally. If knocking noises are heard, this means that the bearing is completely worn out. It needs to be changed, and the sooner the better.

Checking the wheel bearing

The condition of the wheel bearings should be checked not only at intervals determined by the manufacturer, but also during each vehicle diagnosis. During inspection, it is necessary to determine the correct rotation of the wheel, which should not have free axial displacement (play). For this purpose, you need to act in the following sequence:

- We lift the rear wheel on a jack and give it torque by hand, while there should be no extraneous noise or “murmuring” of the rollers;

We spin the car wheel clockwise, checking it for extraneous noise.

- Alternately, in different planes, we loosen the wheel perpendicular to the hub axis. We act with both hands at the same time.

Checking for play is done by rocking the wheel in a vertical plane.

Be sure to test the rear hub for vertical and horizontal play.

In the horizontal plane, play is less common, but diagnosing this malfunction is mandatory

- In the first case, a check is made for the presence of corrosion “shells” and the cleanliness of the roller track, in the second, the wear of the treadmills is checked, where even a small play should not be noticed.

An example of wear on the running part of the outer race of the bearing

Video: how to check your car wheels for play yourself

Standard set of repair tools

To perform a step-by-step replacement of the VAZ-2109 rear wheel bearings as quickly as possible, you will need the following set of tools:

- Hammer.

- A small block of wood.

- Pliers.

- Puller for retaining rings. If you don’t have such a tool, you can use a flat-head screwdriver and an awl.

- Socket wrench or socket head “12”.

- A 30mm spanner or a socket with a reinforced wrench. Tightening is carried out with a very large torque, so you will need to use a small piece of pipe to facilitate the work.

This is a standard set of tools that you need to have to remove and install rear wheel bearings on nines and similar VAZ models.

Important points

- The wheel nut on the VAZ 2109 is tightened very tightly, and in addition, it is often covered with rust. It may take a huge amount of effort to move it. In such a situation, WD-40 liquid can help. If you don’t have this liquid on hand, you can generously pour oil on the nut and wait 10 minutes.

- Not every car owner has a wheel bearing puller at hand. In this case, to remove the bearing, you can use a hammer and a piece of steel pipe of suitable diameter (about 4.5 cm). The main thing is not to damage the inner surface of the hub with the pipe. If scratches and gouges remain there after pressing out, the new bearing will quickly fail.

- When reassembling the hub, special attention should be paid to tightening the hub nut. If it is loosely tightened, play will occur, which will again lead to bearing wear. Therefore, with a 30 socket head, you should use the longest wrench so that the force when tightening the hub nut is maximum.

Replacing wheel bearings is a procedure that every owner of a “nine” will sooner or later encounter. The only question is whether he will be ready for this. If the driver prefers to repair his car himself, then it makes sense to purchase a puller for hubs and bearings in the store. This simple tool will greatly facilitate the work and also save the car owner a lot of time and nerves.

- Author: Alexey Stepanov

Copywriter with five years of experience. Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Special tool

In order to replace the VAZ-2109 rear wheel bearings with your own hands as quickly as possible, you will need several tools:

- Special three-jaw puller for the rear wheel hub.

- A two-arm puller for removing the inner bearing race from the axle.

- Puller for wheel bearings.

Be sure to have a good sharp chisel and a mounting blade on hand. These tools will be useful when disassembling the unit. You will also need a gas canister.

Design and purpose of the rear hub

Diagnosis and repair of the rear hub of the VAZ 2109 does not require any specific education; this operation is within the capabilities of many car enthusiasts. However, in order to carry out the necessary measures correctly, it is useful to familiarize yourself with the structure of this component of the car.

The rear hub is mounted on the beam using four bolts.

Location of the rear hub in a VAZ 2109 car

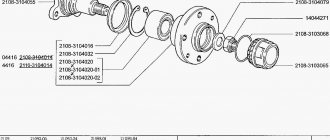

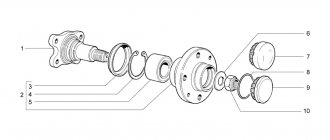

The hub itself includes several components. In the figure below you can see their list and relative positions.

Car rear hub device

From the presented infographics we can already conclude that the wheel bearing is the connecting link between the wheel hub and the vehicle axle. The wheel is attached to the hub flange using four bolts, and this entire structure rotates thanks to a rolling bearing.

The tasks assigned to the wheel bearing include:

- ensuring wheel rotation with minimal friction losses;

- quiet operation;

- comfortable and easy movement of the car;

- reliability and reliability;

- long service life.

In turn, the bearing is a system of interconnected parts: a cage, a boot, rollers and a separator.

Wheel bearing arrangement

Wheel bearings operate under conditions close to extreme:

- temperature changes;

- aggressive environment (road deicing agents);

- exposure to moisture;

- impacts due to uneven roads;

- dynamic loads (acceleration, braking, sudden maneuvers).

Which bearings should I buy?

On sale you can find many manufacturers of bearings for the rear hubs of VAZ cars. The most acceptable options are the following manufacturers:

- SPZ (Saratov).

- VBF (Vologda).

These elements have the best quality-to-cost ratio. It is not advisable to purchase bearings made in Samara. They have a rather bad reputation, their service life is very short, and the quality of the products is low.

There is also no point in purchasing bearings from foreign manufacturers, since their service life is slightly higher than those listed above. But the cost turns out to be significantly higher than that of domestic analogues.

TABLE OF RECOMMENDED MANUFACTURERS

| No. | Manufacturer | Catalog number | Price 2022, rub. | Equipment | |||

| Retaining ring | Dirt cap | Lock-nut | Instructions | ||||

| 1 | VBF Russia | 2108-3104020 | 500 | – | – | – | – |

| 2 | SPZ Russia | 2108-3104020 | 520 | – | – | – | – |

| 3 | SKF Sweden | VKBA1307 | 1900 | 2 | – | + | + |

| 4 | FAG Germany | 545312A | 600 | – | – | – | – |

Preparing for repairs

First you need to secure the car on a level surface. Be sure to install chocks under the front wheels to prevent the car from rolling away. Next, follow these steps:

- Remove the protective cap.

- Using a flathead screwdriver or chisel, align the locking collar that is on the nut.

- Using a wrench and a 30mm socket or a spanner, you need to remove the hub nut.

- Remove the wheel bolts.

- Raise the side to be repaired using a jack, place a reliable support under the car and remove the wheel.

At this point the preparation can be considered complete. Next you need to completely disassemble the entire assembly.

Selection of ZPS

When choosing a rear wheel bearing, you should focus on the required characteristics and manufacturers who today produce ZPS suitable for the VAZ 2109.

Let's start with the characteristics. The choice should be made in favor of bearings with the following parameters.

Characteristic

Index

Bearing ball diameter

Number of balls in the bearing

For the rear hub, a ball, angular contact, double-row closed type bearing is used.

Now let's talk about manufacturers. There are several of them, each of which has its own characteristics.

Bearing manufacturer

Peculiarities

VBF from the Volgograd plant

Motorists consider this bearing plant to be quite reliable and proven. An important advantage is that fakes from the Volgograd manufacturer are quite rare on the market.

Bearings of the Saratov plant - SPZ

A close option to the Volgograd plant, which is famous for its reliability and has impressive popularity among owners of domestic cars. There are a few more fakes

These are products of the same Saratov plant, only for budget consumers. Quite cheap bearings are characterized by less durability. Otherwise, there are no serious complaints about quality

20 GPZ. Kursk plant

Nowadays it is very rare to come across products from this plant, since the company produced bearings back in the days of the USSR and for some time after the cessation of its existence. Today there is no production, but occasionally the remains of bearings can be found. The quality is excellent (USSR, after all), but the shutdown of production will not allow you to easily find it. Maybe they are no longer anywhere at all.

Preparing to remove the hub

You need to know the design features of the mechanism before replacing the rear wheel bearing of the VAZ-2109. The hub layout on nines and similar models is almost the same.

Further steps for dismantling:

- Using a “12” wrench, you need to unscrew the guide pins.

- Very often the drum gets stuck, so you have to knock it down. This should only be done with a rubber hammer or a wooden block. But this is an extreme measure; first you need to try a simple method - screw the guides into adjacent holes. If the threads are intact, the brake drum will gradually move away from the hub.

- There is no need to disassemble the brake mechanism, just unscrew the hub nut and remove the washer located under it.

When to replace

The rear wheel bearing should be changed no later than every 100 thousand kilometers. But the realities of our roads and the quality of products are such that in fact the service life of the element is noticeably less than the specified period.

Practice shows that it is necessary to change the spare parts every 50-60 thousand kilometers, and in some cases even more often. It is best to focus not on mileage, but on signs of wear.

Symptoms of a problem

The car itself will tell you that it’s time to change the air conditioner by displaying the following signs:

Checking status

If one of the symptoms appears on your VAZ 2109, you must lift the rear wheels one by one and make sure whether the problem is really in the bearings. For this:

Removing the hub

Replacing the rear bearing of a VAZ-2109 and removing the hub is quite problematic, since you need to use a special tool. In order to dismantle the hub, you can use one of three methods:

- Sometimes it comes off easily; you can do it with your hands. To do this, you need to pull the hub towards you using a pry bar or wheel.

- If the first method does not help, then you can use two bolts about 15-20 cm long. They are screwed into the holes for fastening the wheel until the hub begins to move.

- The most convenient way is to use a special three-arm puller.

You can also screw the brake drum or wheel onto the hub with the reverse side. In this case, significantly greater force will be applied to the rear hub. You'll be lucky if the bearing is completely in the hub.

But very often the inner race remains on the shaft. If this happens, then it is necessary to remove the pads completely and use a chisel to knock the cage out of its seat. Then, when there is space to install the puller, you need to fix it and dismantle it.

How to remove a wheel: step-by-step instructions

To carry out repair work quickly, and most importantly, efficiently, adhere to the following algorithm:

- We park the car on a level surface.

- Opposite the wheel being repaired (diagonally) we install wheel chocks.

Diagram of installation of wheel chocks

- Jack up the wheel. To avoid unforeseen situations, it is best to leave the gearbox in first or reverse gear.

- Remove the protective cap, then use a 30mm head and use an amplifier to unscrew the hub nut.

An example of using an amplifier to unscrew a hub nut

- We soak the drum mounting studs with penetrating liquids, wait a few minutes and unscrew them (in our case, the edges of the studs came off; when removing them, we had to act according to the situation).

We unscrew the “stuck” studs using improvised means

- Check the handbrake; it should not be engaged.

- Holding opposite sides with both hands, pull the brake drum towards you. If it cannot be removed, tap it from the opposite side with a hammer through a wooden block. We process the part over the entire area, achieving its uniform displacement.

Tapping the brake drum with a block

During operation, it is necessary to act slowly and carefully to avoid distortions of the brake drum or damage to it, for example, chipping of the edges.

We take this opportunity to check the thickness of the brake linings and the condition of the working brake cylinder (leakage test)

- Using a “pincer” puller with rotating grips, we pull the hub flange from the seat. We put it in the puller.

By tightening the bolt, we dismantle the hub flange with a “pincer” puller

- If you don’t have a puller, you can use improvised means or, after screwing the wheel back on, you can try to pull the flange off with jerks.

We knock down the hub flange carefully, avoiding distortions

- As a result, we get the following picture: a “bare” hub axle rod.

We have freed the hub axle rod: the goal of the ongoing activities has been achieved

- Unfortunately, the bearing does not always remain inside the hub.

We dismantle the inner race of the bearing using a puller or carefully move it with a chisel (the main thing is not to damage the bearing seat)

- If the inner race of the bearing remains on the journal, remove the outer race with the separator from the hub. It is convenient to use tongs for this.

Squeeze and pull out the retaining ring with pliers

- We turn the hub over and install it on a vice.

Knock out the bearing with sharp blows of a hammer.

- We take a spacer of suitable diameter and place it under the flange.

To achieve the desired result of “pressing out”, do not forget to place spacers under the flange

- We carefully inspect the bearing seats both on the axle and on the inside of the hub for the presence of radial burrs, indicating that the bearing has rotated. Otherwise, the defective unit should be replaced.

We clean the seat from dirt with fine sandpaper, then lubricate it and the outer part of the outer race with grease.

- The wheel bearing of the VAZ 2109 car is a closed type, that is, it is lubricated at the manufacturer and does not require additional preparation before installation.

- Further installation of the bearing into the seat can be done using pressing tools.

We set the plane of the cage strictly parallel to the hub, carefully press it in, tightening the pin

- It is allowed to install the bearing in the “old-fashioned” way, using a hammer. First, carefully, with light blows, “wind” the bearing into the hub.

When the bearing is in the hub, we intensify the blows, aiming strictly at its center

- For the final “seating all the way”, we use the old outer race as an insert and strike it until a characteristic dull sound is produced.

- Reinstall the retaining ring. To do this, we squeeze it with special forceps.

After the retaining ring is in place, carefully use a screwdriver and a hammer to knock it tighter into the groove

- We place the hub assembly with the bearing on the axle. We hold the part with both hands: evenly, pre-install the hub.

Carefully install the hub, aligning it with the inner race

- We apply a mandrel of a suitable diameter to the inner race.

Using sharp blows of a hammer, press the hub onto the axle

- Then tighten the nut until it stops.

Tighten the nut, not forgetting to securely tighten its edges

- The hub nut is tightened with a tightening torque of approximately 19–23 kg * meter (this is quite a large force), and if you do not have a torque wrench, then you need to use an amplifier about a meter long and tighten the nut with a force twice that force tightening wheel nuts.

- Reassemble the rear wheel in reverse order.

Video: replacing the rear wheel bearing of a VAZ 2109 with your own hands

In conclusion, I would like to recommend that car owners pay more attention to the condition of their wheel bearings. Even a small extraneous noise is already a signal to the driver about unscheduled diagnostics and repair of the hub unit. Please note: by postponing repairs, you provoke the creation of a traffic accident, which will inevitably occur when the faulty bearing is destroyed and the subsequent wheel jams.

Malfunctions and procedure for self-replacement of the heater radiator of a Daewoo Nexia car

Design features and procedure for self-replacement of the water pump on various modifications of Gazelle cars

Installing a new bearing

The old bearing simply needs to be knocked out using a hammer and a mandrel. But be sure to remove the retaining rings. An old bearing cannot be reused, so you can subject it to any loads, including impacts. But the pressing needs to be done correctly. To do this, use one of the following methods:

- It is recommended to install the bearing using a special puller. In this case, it will enter the inner hole of the hub very smoothly and due to this, its resource will increase. Instead of a puller, you can use a good vice.

- You can warm up the hub a little using a gas can. It is advisable to simultaneously put the bearing itself in the freezer for several hours. But you can’t warm up the hub too much; two minutes is enough. Otherwise, when installing a new bearing, the rubber seals will melt.

- If none of these options helps, then you can simply hammer the bearing using a hammer and a suitable attachment. It is advisable to strike only the outer ring, as it is stronger. Misalignment must not be allowed, otherwise it will be very difficult to get the bearing during the next repair.

After installing the new bearing, the entire assembly can be assembled. The last thing to tighten is the nut on the hub using a “30” wrench. Don't forget about the washer that is underneath it. This completes the replacement of the VAZ-2109 rear wheel bearing. Be sure to check that the wheel rotates without jamming or effort.

Necessary tool for working on VAZ 2109

The complexity and speed of the repair directly depend on the availability of special tools. There is a minimum required set:

To speed up, additionally use:

For alternative methods without using pullers, see further in the instructions.

When choosing a bearing, pay attention to Saratov bearings marked SPZ and Vologda bearings (VBF). Bearings from Samara have a bad reputation, and imported ones are not worth the extra money. Therefore, the first two options are the optimal combination of price and quality.

Bearing replacement instructions

To quickly and accurately complete the job, follow these recommendations:

First, remove the protective cap and unlock the rear wheel hub (this can be done with a hammer and chisel).

Loosen the bolts on the hub and wheel. Please note that the tightening torque of the hub nut is very serious, so it would be useful to increase the “shoulder” of the wrench with an additional pipe.

Put the car in first gear and secure the car (this can be done by installing special “shoes” under the front wheels). Do not use the handbrake.