Step-by-step replacement of the rear wheel bearing of a VAZ 2109

The rear wheel bearing of the VAZ 2109 can be changed in several ways. The quality of the repair depends on the “correctness” of the choice. Below you will find detailed instructions describing each method. You can decide for yourself which one is closer to you. At the service station they won’t ask you what’s best, and they’ll do it their own way. This is a good reason to delve into the “topic” and make a replacement yourself, especially since such repairs can be done by anyone.

Step-by-step instructions for replacing it yourself

Place the car on a flat surface. “Tear off” the bolts and nut of the hub with the wheel standing on the ground.

Raise the car with a jack. Don’t forget to install wheel chocks on both sides before doing this. For safety reasons, we fix the car on stands or adjust the spare wheel under the side member.

We remove the wheel. Using a screwdriver, disconnect the caliper. We take it to the side and secure it with wire.

Next, unscrew the brake disc fasteners. If necessary, remove the trunnion.

For easier removal of parts, use lubricating fluid VD40 (Vedashka). It is necessary to spray the dismantled parts. Wait 30 minutes and then continue working. They will be much easier to remove.

Let's consider several options for replacing the bearing:

Option #1

In this case, I use a puller and do not need to remove the steering knuckle and also remove the strut. In this case, the camber does not need to be weakened. Using a puller, we remove the bearing and install it.

Option No. 2

It is significantly more difficult. We use it if we want to carry out a complete repair of the car's chassis. We carry out the work in the following sequence: — it is necessary to remove the tip from the steering rod; — insert the stand into the yew; — Replace the front wheel hub bearing;

Option #3

You don't need a puller for this option. The downside is the wheel alignment adjustment. In this case, it is necessary to remove the fist and dismantle the hub.

Remove the retaining ring.

We clamp the hub in a vice and use a metal mandrel to knock out the bearing.

Clean the inside with sandpaper.

Wash with diesel fuel and wipe with a rag.

Lubricate with lithol.

Again, using a mandrel with a hammer, carefully drive the part in 10mm. We make sure that there is no distortion. And then with stronger blows we put the bearing in place. You can use a puller for this purpose.

We carry out installation in the same way as dismantling, but in the reverse order. We adhere to the marks previously placed on the parts when dismantling them.

Causes and symptoms of the need for replacement

The rear wheel does not need to be turned, so the mounting system is quite simple. The bearing, pressed tightly into the hub, rotates on the shaft. No backlash is allowed in the design, and rotation must be smooth.

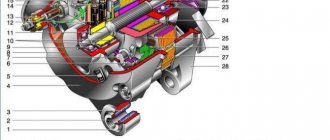

We are interested in the 4th position

Such a breakdown is difficult not to notice. While driving, you will hear a distinct howl or hum from the rear of the car (increases in turns). For a more “targeted” check, you need to jack up the rear wheel and spin it strongly (if possible). If you hear noise while rotating, it’s time to change it. Knocks when moving transversely indicate an extreme degree of wear. In the latter case, do not delay repairs.

Check both wheels. It is not always possible to correctly determine the side by ear. The breakdown has been discovered, now we move on to preparation.

Installing a new bearing

To simplify installation, you can do a little trick - warm up the hub a little and cool the bearing in the freezer. In the first case, the metal will expand, in the second, it will contract. Pressing will be much easier and faster. The main thing is not to overheat the hub, otherwise the seal on the bearing will melt and the lubricant will leak out. As a result, you will have to buy new spare parts and do the repairs again.

Lubricate the inner surface of the hub and install the retaining ring on one side. Carefully now you can begin to press in the wheel bearing of the VAZ-2108. If the dimensions are correct and there are no deviations in the geometry of the nodes, assembly will not take much time. When finished, install the second snap ring. Assemble the entire assembly and install it on the CV joint, tightening the bolts at the top and bottom. If necessary, replace the ball joint.

The hub nut is tightened with a “30” wrench with very high force after assembling the entire suspension and installing the car on the wheels. The entire assembly is carried out in reverse order, do not forget about the marks on the surface of the shock absorber strut. After all the work, make sure that there is no significant wear on the rubber - otherwise, do a wheel alignment.

Source

Necessary tool for working on VAZ 2109

The complexity and speed of the repair directly depend on the availability of special tools. There is a minimum required set:

- a hammer (where would we be without it) and a wooden block or small board;

- pliers for removing retaining rings (an alternative is an awl or a thin screwdriver);

- key or socket for 12;

- 30mm head with a knob (to make it easier to unscrew, lengthen the knob using a pipe).

To speed up, additionally use:

- three-legged hub puller;

- two-legged puller for the inner race of the bearing;

- universal puller for pressing/extruding;

- chisel.

For alternative methods without using pullers, see further in the instructions.

When choosing a bearing, pay attention to Saratov bearings marked SPZ and Vologda bearings (VBF). Bearings from Samara have a bad reputation, and imported ones are not worth the extra money. Therefore, the first two options are the optimal combination of price and quality.

Repair tool

To replace the front wheel bearing of a VAZ-2108, you will need a tool. All work must be carried out on a well secured vehicle. You will need the following tool:

- Set of keys and sockets.

- Mounting blade.

- Bearing puller.

- Gas-burner.

- Jack, wheel chocks and secure supports.

- A small piece of pipe with a diameter of 10 cm.

- Hammer and chisel.

- Pliers for removing retaining rings.

The procedure for carrying out work on the left and right wheels is the same. It is advisable to replace bearings on both sides at once. It is required to install elements from the same manufacturer, which are recommended by the factory.

How to replace the rear wheel bearing: instructions

- We will not describe the removal of the wheel. The main thing is, do not neglect your safety - place an additional support under the threshold of the car (an unscrewed wheel, a stump, a special stand). Before removal, you need to remove the central plug and align the locking “shoulder” on the fastening nut (a flat-head screwdriver or chisel will help). Now “tear off” the nut with a 30mm socket wrench (turn counterclockwise). At this moment, the wheel must be on the ground or an assistant is needed to press the brake pedal firmly.

Preparing for repairs

Now it's time to remove the old VAZ-2108 front wheel bearing. Its dimensions are indicated in the article below; when pressing out, you can use a clip from an old roller. Before starting work, do the following:

- Loosen the front hub nut.

- Using a 30mm wrench with a large lever, remove the nut.

- Install wheel chocks under the rear wheels.

- Remove the wheel bolts.

- Raise the side to be repaired with a jack.

- Place supports under the car.

- Remove the wheel and place it under the car engine.

That's all, now you can start dismantling the front wheel bearing of the VAZ-2108. The dimensions of the old and new must match. If the diameter is slightly larger or smaller, the bearing may not work properly.

Which wheel bearing puller to choose or how to make it yourself

A wheel bearing puller is a specialized tool designed for pressing and pressing parts into vehicle hub units.

Since the bearings are installed on the seating surfaces with interference, pressing or pressing them requires a lot of force to be applied to a limited area of the unit. Conclusion - for this operation you need a reliable and also universal tool.

A wide range of size ranges for hub units correspond to various types of wheel bearing pullers (HBP). Choosing the right puller for replacing bearings is not easy. You will learn what parameters to follow by reading the article. We will also touch on the topic of making the device yourself and how to operate the tool.

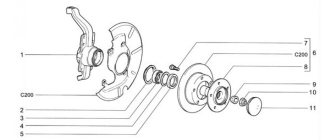

Bearing sizes

The article contains a photo of the VAZ-2108 front wheel bearings, as well as a drawing of a puller indicating all dimensions. Therefore, if you are in doubt whether you purchased the right roller, check the dimensions of the hub. The part number is 256907.

- The outer diameter of the holder is 64 mm.

- Inner diameter – 34 mm.

- Weight – 445 g.

- Balls with a diameter of 9.525 mm are installed inside.

- The total number of balls is 28.

- The unit is designed to operate at rotation speeds above 6000 rpm.

In any car store, salespeople will be able to advise you on the best quality product.

Types of wheel bearing pullers

Study the summary table, which presents several main types of BSC, as well as specific recommended models.

| Type and model | Application | Average price, rub. |

| With 3 legs | Removing parts from axles and shafts, including rear hub ball bearing races. | 2000-3000 |

| With 2 legs | Removing parts from axles and shafts, including rear wheel hub bearings. | 1000-2000 |

| Cup with a set of mandrels | Removing and pressing parts into holes, including steering knuckles and front wheel hub bearings. | 6000-8000 |

What pullers are needed to remove and press in wheel bearings?

For the front and rear wheels, it is recommended to use two types of tools: with three or two legs and a cup puller - this is the minimum set of removable tools for the correct and safe removal and pressing of parts of hub units.

Manufacturers

Many motorists do not know which VAZ-2108 front wheel bearing to choose for their car. Now you can find several manufacturers on the market:

- GPZ-23, Vologda, has the abbreviation VBF. The plant has earned the trust of motorists and is one of the best manufacturers of wheel bearings for domestic cars. Due to the relatively low cost, these parts are practically not counterfeited.

- SPZ, Saratov - according to many experts, the bearings of this manufacturer are the most reliable, durable and high quality. And most importantly - the very low cost of parts.

- GPZ-20, Kursk is no longer engaged in the production of wheel bearings, but you can find products in stores and warehouses.

- Experts do not speak very well of the Samara SPZ-3. The cost of the bearings is very low, but the quality is not great, the service life is very short.

Some auto stores try not to deal with little-known companies that produce low-quality products. Therefore, on the shelves you can only find bearings from Saratov and Vologda.

A quick overview of wheel ball bearing pullers

It is impossible to choose a universal kit for all types of car repairs, since the range of actions is limited:

- a variety of shapes, sizes for charging to the starting position;

- limited work space.

Cup - “Force 9T0311”

- Internal mandrels 34-80 mm.

- External mandrels 44-90 mm.

- The dimensions of the outer diameter of the cups are 44-90 mm.

- Rod (stud) with nuts.

- The plates fit a wide range of sizes.

- The steering knuckle remains in place.

- The set is included in the workshop press kit.

- Pressing-pressing takes place in one step.

Three-jaw – “KS TOOLS 630.3002”

Garage tool. Suitable for use in restricted access work areas.

- Long life if you follow the manual.

- The articulated design of the paws engages securely.

- Removing stuck parts from shafts and machine axles.

- Wide grip range - 20-230 mm.

- Maximum force - 4.5 tons.

- Screw rod dimensions: M18 x1.5 x 240.

- The dimensions of the bolts for the hinges are 19 mm.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

- Remove the washer by unscrewing the wheel bearing nut all the way.

- Insert bolts (about 130mm long with M12x1.25mm thread) into the two holes of the brake disc. Screw the bolts into the hub holes to a depth equal to its thickness.

- We press out the hub by sharply hitting the bolt heads with the brake disc.

- Unscrew the fastening of the ball joint to the steering knuckle and remove the CV joint from the bearing hole.

Wheel and bearing puller for VAZ and LADA cars

To replace the front and rear hub units on VAZs, according to the manufacturer’s recommendations, two types of removable devices are needed.

- Gripping tools are used to remove the ball bearing from the rear wheel.

- For pressing and pressing the bearing at the front wheel, cup types are used.

You can select models of these tools from the overview presented above. To select a cup puller, focus on the outer and inner diameters of your bearings, but as a rule, it is enough to read reviews and get advice from the seller.

vazoved

I drive a LADA VESTA CROSS, Moscow

Then there will simply be no one to pay the fines! This is a Korean tablet video recorder 15 in 1 for Android..

I forgot about fines and Yandex Navigator.

There is FULL HD shooting, radar detector and GPS with 32 satellites. I got it at a reasonable price for such great functionality: HERE

Nuances

In the process of reassembling the entire node, you must proceed as follows:

- Press in the bearings;

- Install retaining rings;

- Collect your fists;

- Mount new bearing components on them;

- Mount the assembly on the hub;

- Using a mandrel, you need to drive the hubs until they stop.

You can use a puller or press to press in bearing parts. But in no case should you use a hammer, since in this case cracking of the component will inevitably occur. The forces should be directed to the outer rings.

It should also be noted that double-row ball bearings are installed in the hubs, which do not require lubrication and adjustment measures.

Due to the lack of such care, the VAZ 2110 bearings will certainly be destroyed when removed from the hub, so this measure should only be resorted to for a complete replacement.