Taking into account the quality of Russian roads, coupled with the build quality of domestic cars, you need to be prepared for constantly occurring breakdowns in car parts. Even if you are lucky and your car is indeed equipped with high-quality parts combined with excellent assembly, natural shock absorption has not been canceled. Nowadays, a car's suspension includes a huge variety of different parts: shock absorbers, springs, bearings and much more. Each part is responsible for certain functions, but safety is guaranteed only through the quality of the installed mechanisms and their proper operation.

HOW TO CHECK THE OPERATION OF A SUPPORT BEARING

The main reason why owners decide to carry out such repairs is an extraneous knock when driving over even minor uneven road surfaces. When such discomfort occurs, replacing the support bearing is not always the best solution. First you need to check its performance, because the problem may lie in other parts of the shock absorber.

Checking the functionality of this suspension element is quite simple:

- open the hood;

- place your palm on the support;

- a partner rocks the car from side to side;

- If a characteristic cracking or knocking sound is heard under the palm, the bearing must be replaced.

It is important to know that failure or wear of the support bearing results in accelerated wear of the struts and a violation of the wheel alignment settings.

What is this?

It is not uncommon for owners of the domestic “fourteenth” VAZ model to notice that a knock . The reason for its appearance is failed support bearings.

Support rod brand SS20

But you don’t need to start replacing right away. The first priority is to check the condition of the support. And only then take appropriate actions.

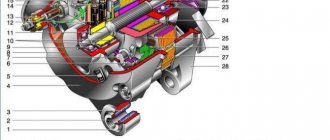

The support bearing is an element of the shock absorber strut located in the front suspension structure. Its job is to maintain the mobility of the connection between the body and the shock absorber of your car. If the bearing turns out to be faulty, mobility is impaired and a knocking noise occurs, which is difficult not to notice. Especially when it comes to bad roads.

ESSENTIAL TOOL

A high-quality replacement of support bearings on a VAZ 2114 with your own hands requires a minimum set of tools to perform these tasks:

- Standard set of open-end and ring wrenches size 12-24;

- Steering rod puller;

- Standard auto jack;

- Coupler for shock absorber springs;

- A “19” wrench is used to remove the strut rod nut.

Unscrewing the nut

Recommendations for checking and extending the service life of supports

If replacement is required

To easily and quickly dismantle a worn out faulty unit, you need to prepare a special rack wrench. It is assembled from 2 tubes of different diameters, obtaining a lever of the appropriate length.

Periodic inspection

Regular inspection and timely maintenance are a guarantee of increasing the service life of spare parts. Check the unit after 10-12 thousand kilometers, especially since this is not difficult to do.

Timely lubrication

Regardless of the car’s mileage, at least once a year (preferably twice, in spring and autumn), it is necessary to lubricate the support with silicone grease. Carry out the work with the protective cover removed.

Accurate vehicle control

Driving your car carefully, without sudden acceleration or jerking, as well as driving on good roads, is the best way to protect parts from premature wear.

Modernization and strengthening

To strengthen the supports, spacers are used to increase ground clearance and auto-buffers, which absorb the load. They also make a spacer between the posts.

The best manufacturers

OPs are produced by different companies. The optimal solution is to install original parts. Purchasing spare parts made in China is risky and there is a high risk of defects. Users of numerous forums note the best bearing manufacturers:

| Item No. | Brand name | Official company logo | A country |

| 1 | SNR | France | |

| 2 | SKF | Sweden | |

| 3 | F.A.G. | Germany | |

| 4 | INA | Germany | |

| 5 | Koyo | Japan |

HOW TO CHOOSE A SUPPORT BEARING FOR A VAZ 2114 CAR

The modern automotive industry offers a huge selection of this type of spare parts. Almost every car shop will provide any support bearings for the VAZ 2114, of various quality and price categories.

For this car model, the following types of bearings are most often used:

- support bearing with non-separable rings. Its advantage is the presence of installation holes that do not require clamping flanges;

- Design with removable inner ring. It is used for increased rotation accuracy of the outer ring;

- A completely dismountable system is used for increased rotational accuracy of the inner ring.

Based on the design and the availability of financial resources, the VAZ 2114 front strut support bearing is selected, which will be most suitable in your particular case. Do not save money, since low-quality products are unlikely to last more than 10 thousand kilometers and the procedure must be done all over again. The approximate price of journal bearings ranges from $10 to $80, depending on the manufacturer and design. By saving on the purchase, you risk damaging the shock absorber struts, and then repairs will cost several times more.

Kinds

In analysis

There are several types of supports:

- A bearing with an integrated inner or outer ring. No clamping flanges are required for its installation. There are corresponding holes for installation;

- With detachable outer ring;

- With detachable inner ring;

- Finishing and cutting structure, the characteristic feature of which is its strong rigidity.

The name of the support bearing speaks for itself. This is something like a strut support on the front shock absorber, which is located in the area where it connects to the body. This arrangement indicates the axial loads that the support must withstand.

HOW THE REPLACEMENT IS MADE

It’s immediately worth noting that many modifications of these cars have the same suspension. For example, replacing the support bearing of a VAZ 2115, VAZ 2114 and VAZ 2109 is absolutely identical.

Let's proceed directly to the repair itself. There are several ways to carry out the work:

- removing the entire rack, with steering arms and other parts attached to it. In this case, the wheel tilt settings are saved, and you do not have to perform the wheel alignment again;

- you can disconnect the strut from the steering cam and then dismantle the remaining parts.

FIRST METHOD

- We dismantle the hub cap and unlock the CV joint

- We unscrew the CV joint until it is completely loose, while the brake pedal should be in a clamped state.

- Jack up the car and unscrew the wheel.

- Unscrew and unscrew the tip nut and press out the pin.

- Next, you need to dismantle the ball and free the brake hose from the shock absorber.

- Loosen the strut nut and unscrew the three support fixation nuts. Then the CV joint is removed and the strut is dismantled.

- Next, the spring is tightened, which is required before changing the support bearing on the VAZ 2114.

- After this, we put everything in place until the car is completely assembled.

SECOND METHOD

- We jack up the car and remove the wheel.

- Then loosen the hub mounting clamp and remove the steering tip.

- We dismantle the ball and remove the brake caliper.

- Next, loosen the strut nut and tighten the spring.

- We change the support bearing and put everything back together.

After completing the work, it is advisable to replace the strut mounting nut with a new one.

Diagnostics

To diagnose the current condition of the support element, you need to perform a couple of simple steps.

- Open the hood and place your palm on the element, that is, the bearing. In this case, your assistant should rock the car. If a knocking sound is heard, then it should be changed immediately.

- Disassemble the structure to clearly see that the element is faulty and needs to be replaced. It is important to note that the approximate service life of the support bearing on a VAZ 2114 is 40 thousand kilometers. This is the recommended mileage after which the element must be replaced, regardless of its current condition.

A faulty support can lead to quite tragic consequences, such as wheel alignment disorder, increased risk when driving at high speeds, and increased wear of shock absorber struts.

If you do not pay attention in time and do not take appropriate action to eliminate the breakdown, you risk completely destroying the suspension of your car. It is not uncommon for a hole to form in the hood from the pillar. As you understand, such problems entail significant financial losses.

WE CHECK THE QUALITY OF WORK PERFORMED

When doing the replacement yourself, some skill deficiencies may appear. Somewhere a nut was not tightened or any of the elements of the rack were installed much crookedly. In order to avoid getting into an unpleasant situation on the road in the future, it is necessary to check the functionality of all the mechanisms that you touched when replacing the support bearing.

First, let's rock the car and check it for extraneous knocks. Be sure to check the operation of the brakes, since the caliper was removed during replacement. If everything is normal, you can start operating, not forgetting to check the wheel alignment settings, since it is also very easy to knock them down.

The support bearing on VAZ 2108-2115 vehicles is replaced on average once every 40 thousand km. If you do not want to endanger the machine racks, replacement must be done for preventive purposes.

Basic faults

Wear of the VAZ-2114 bearing is the main reason for replacing it. A knock in the suspension, which is heard when driving on a bumpy road or when turning, should alert the driver. Checking the bearing is simple: you need to grab it with your hand and rock the car; a knock that may appear indicates the need for repairs.

The dirt that is abundant on the roads is one of the causes of defects in the mechanism. The support is practically not protected from it.

It is worth checking the condition of the supports at least after 20,000 km.

If the knocking does not go away, then think about this: a completely worn bearing can break completely, and this will lead to the strut breaking through the hood. Repair costs will be completely different.

Replacing a bearing is not that expensive - about 500 rubles per part, 1000 rubles for a replacement at a service station.

The most popular bearings are ss20. They perform best under relaxed driving conditions, although some drivers complain about their harshness.

For a more sporty driving style, with sharp stops and fast accelerations, Acomi bearings have proven themselves well.

Don’t skimp on spare parts; try to buy support bearings from a trusted manufacturer. When choosing, you need to rely on your own driving style and the characteristics of the road surface.