VAZ-2114 cars, from the start of production, are equipped with eight-valve engines with a volume of 1.5 liters. Since 2007, they have been equipped with an eight-valve 1.6 liter engine with an environmental class of Euro-4. The operation of the car, sometimes incorrectly, brings “surprises” over time. The engine does not perform its functions at full power, and thrust decreases. Let's try to understand the causes and methods of elimination.

Why doesn't the VAZ 2114 engine pull? List of possible causes

In the absence of obvious breakdowns, why does the VAZ 2114 engine not run?

The question is very relevant, especially for the domestic automobile industry. Often this category of car surprises us at the most unexpected moment. The driver then has to play a guessing game about where and what. In fact, there can be many reasons for the “weakness” of the engine. Not many people are able to clearly identify the source of the breakdown the first time. Only experienced drivers can boast of this. In order to provide methodological advice to new car owners, as well as to replenish the memory of experienced ones, we will carefully consider each of them. Why doesn't the VAZ 2114 engine pull? A simple solution would be to get to the nearest service station at low speed. If this is not the case, then let's start with a list of reasons so that it is clear where to look.

Check the variable timing solenoid

Many European and Japanese cars, and now some American models, are equipped with variable valve timing (VVT) technology. Problems with VVT solenoids can sometimes cause loss of traction and shaking of the car coupled with jerking.

The computer uses VVT to adjust timing and valve control to improve engine efficiency.

The exact VVT configuration may vary from one model to another. If you suspect a valve timing problem, consult your repair manual or take the vehicle to a shop for inspection.

Clean or replace the MAF sensor if necessary.

List of reasons for power loss

The fuel filter is dirty:

Gasoline with various additives in the form of debris, rust, wool passing through the filter, settles in it and clogs the channels. As a result, poor throughput makes it more and more difficult for the engine to pump fuel. Only complete replacement of the filter elements is necessary. Contamination can only be determined by eye. Read more in the article: “List of reasons that the fuel filter is clogged.”

Malfunction of the mass air flow sensor:

Perhaps the most common problem that causes the mixture to become rich or lean. You can test it in the following way: disconnect the terminal on the sensor and start the engine, a red lamp will light up on the display, indicating a breakdown in the system, no big deal.

The speed will increase significantly to 1500-2000 rpm. try driving a few hundred meters, if the car is the same as before, then buy a sensor at the nearest store. The reason for this is untimely replacement of the air filter.

The fuel pump diaphragm is clogged:

As is the case with filters, the cause is dirty gasoline. To clean, simply unscrew the fuel pump cover bolt, remove the diaphragm and clean it. Read about the signs of a faulty fuel pump.

Air filter clogged with dust:

The element can be compared to a person’s lungs; accordingly, the dirtier it is, the more difficult it is to breathe. If you don’t have a new filter at hand, but you need to drive further, you can take the filter out of the casing, blow it a little, and tap it on a hard surface. This way, some of the dust and dirt will be removed, and you can proceed further. You should carefully inspect for the presence of dry leaves, insects, and moths. Since only large obstacles can block the air supply.

Candles are fiddling:

Due to poor quality or significant wear, sometimes the spark charge “slips”, the fuel does not ignite fully, and the combustion chamber is literally choked with gasoline. It can be eliminated by completely replacing it with a new set or unscrewing everything one by one and looking at the color.

Typically, black or wet asphalt indicates excess gasoline and insufficient combustion. It is necessary to wipe with a dry cloth, preferably with “0” sandpaper and screw it back in. Getting to the nearest auto shop is all it takes to fix it. See Signs of Bad Spark Plugs.

Low compression in cylinders:

Boiling due to systematic overheating and high wear can cause a sharp drop in compression pressure in the engine. Which leads to the consumption of motor oil in large volumes, incomplete combustion in the chamber, air leaks, and gasoline getting into the oil pan. Here, improvised means will not help. The engine must be overhauled. It can only be determined by the presence of a mixture of fuel and oil on the dipstick. The article “How to check compression in cylinders” can help.

System failure in the on-board computer:

Factory defect or random computer glitch. There is only one way out - to get to a service station by any means and carry out diagnostics. It is not recommended to repair the firmware yourself, as this should only be done by a qualified specialist.

Injectors clogged:

The situation is also common and has two solutions. The first is a trip to the service station, the second is to get to the nearest car store and purchase an injector cleaner. Typically, this is a liquid in a bottle designed to be poured into a tank. While driving, passing through the fuel channels, it cleans them of various dirt and rye. The engine acquires the same dynamics and throttle response. But the product may not always be effective, it all depends on the degree of contamination.

- “How to check injectors”;

- “What should I use to clean the injectors?”

Of course, it is impossible to list all the reasons and answer why the VAZ 2114 engine does not pull. Because the most incredible and unusual situations happen in life. But every driver should know the main reasons so as not to get confused along the way and not find himself helpless.

Fuel pump strainer is clogged

Considering the quality of fuel supplied to our market, you can often encounter a similar problem. If you have checked everything listed above, but still have not figured out the problem, it is better to immediately go to the nearest auto parts store and purchase a new mesh there. The issue price is about 70 rubles.

Then, under the rear seats, we find the hatch and unscrew it, gaining access to the gas tank. We disconnect all the tubes and remove the fuel pump mount and remove the entire mechanism from the tank. A mesh will be attached to the supply to the fuel pump, remove it and install a new one. Afterwards we collect everything back into the gas tank.

Why does the VAZ 2114 engine pull poorly?

In short, the engine of the VAZ 2114 2008, the 8-valve engine, pulls poorly, now I clarify when starting the car, the engine seems to be trying to keep the correct speed, but suddenly and several times they drop, that is, as if trying to stall, then it returns to normal, and when accelerating, accelerating every gear, the engine tries to stall, but then it recovers sharply, and the traction is bad =( but you know, from time to time I admire when it starts to pull normally and accelerates quickly; the response to the gas pedal is instantaneous! I would really like it to always have good traction! But the consumption is very high. Please tell me how to get rid of this problem.

Given the symptoms you have, there can be quite a few reasons for this behavior of the car. If you say that sometimes the car drives well, then the problem is most likely not in the engine itself, but in the harness. First of all, you need to look at the sensors. You may have a stuck throttle position sensor or mass air flow sensor. Cleaning them sometimes helps in such cases.

You definitely need to look at the ignition coil and armored wires, maybe there is a break somewhere and there is a periodic spark leak, in the dark, start the engine, open the hood and look at the ignition system. If there is a breakdown, you will see it.

I know a case where a ceramic catalyst crumbled and periodically closed the passage in the exhaust pipe, the car behaved in a similar way. So, if you have a catalyst, this may be the reason.

And best of all, don’t rack your brains and go for computer diagnostics. There you will at least find out the reason, and then decide to repair it yourself or contact a service station.

Checking the transmission

Sometimes the power unit can develop serious power, but it does not reach the wheels. If while driving you hear that the engine is working hard, but you don’t feel speed, then perhaps the automatic transmission system is slipping or there are blockages on the brakes.

To check, you need to drive onto a straight section, set the automatic transmission selector to position D, and then see how the car behaves. If the speed decreases, then the brake system should be diagnosed. If everything is fine with the brakes, you need to go to a good service station and check the automatic transmission.

You can also check the parking brake. To do this, you need to go to free space. Warm up the car and then pull the handbrake. Next, press the brake pedal and set the gearbox selector to position D. Next, press the accelerator. If the engine keeps the rpm around 2000, then everything is fine with it. If it is less or more, you should go to a service station to test the automatic transmission.

The main reasons for the reduction in engine power

Crankshaft position sensor malfunction

There are situations when the DCPV untimely sends a control command to supply the air-fuel mixture. As a result, the power of the power unit drops before our eyes. The main cause of the failure is the shift of the toothed star relative to the pulley and the delamination of the damper. In such a situation, it is necessary to carefully inspect the damper and replace it.

Increasing (decreasing) the gap between the spark plug electrodes

During operation, due to strong temperature effects, the distance between the electrodes of the spark plug may decrease or increase. To exclude or confirm your suspicion, you need to check the size of the gaps using a round feeler gauge. If the distance is less or more than acceptable, you need to make an adjustment by bending the side of the electrode or replace the spark plug. As for the optimal spark gap distance, it can be different (depending on the type of spark plug) - 0.7-1.0 mm.

The appearance of carbon deposits on the spark plugs is another clear sign of a problem.

If the engine does not pull well, you need to unscrew all the spark plugs one by one and inspect them. If obvious carbon deposits appear on the electrodes, the device must be cleaned using a brush with metal bristles. It is important not only to clean the spark plugs or replace them, but also to find out the cause of this phenomenon.

Failure of spark plugs

A decrease in engine power may be caused by product failure. In this case, it is necessary to check the performance of the spark plug on a special stand. If the suspicions are confirmed, then the only way out is to replace the set or one spark plug.

There is no gasoline in the tank

You can diagnose the problem using the fuel level indicator. If it is faulty or there is a suspicion that it is “inadequate,” then the presence of fuel can be determined by removing the fuel pump.

Fuel filter contamination, water freezing in the system, pinched fuel wire, fuel pump failure

All these malfunctions can be safely classified into one category, because they all have the same symptoms - the starter cranks the engine, but there is no smell of fuel from the exhaust pipe. If the car has a carburetor, then the reason must be sought in the float chamber. Most likely, fuel is not supplied to it. In the case of an injector, it is easier to check the presence of fuel in the ramp by pressing a special spool (installed at the end of the ramp).

To correct the problem, you need to warm up the engine thoroughly and bleed the power system with a tire pump. After this, all system pipes, hoses and the fuel pump itself are changed.

Fuel pump produces too little pressure

This problem can only be determined by special measurements (taken directly at the outlet of the fuel pump). After this, the quality of operation of the fuel pump filter is checked.

The solution is to clean the fuel pump filter, replace it (if repair is not possible) or install a new fuel pump.

Poor contact quality in the circuit

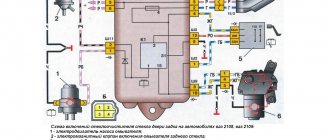

Poor contact quality in the circuit that powers the fuel pump or failure of its relay. The first thing you need to do to check is to make sure the quality of the “ground” on the car and measure the resistance using a multimeter. If the resistance level is really too high, then the only way out is to clean the contact groups, crimp the terminals well, or install a relay (if the old one is faulty).

Failure of injectors or malfunction in the supply system

If there is a suspicion of failure of these elements, it is necessary to check the resistance of the windings using a multimeter for a break or an interturn short circuit. If the cause of the problem is a malfunction of the computer, then such a check can only be carried out at a service station.

There are several ways to eliminate a decrease in engine power for this reason (depending on the depth of the problem) - install a new ECU, clean all injectors, ensure good contact in the electrical circuit, and so on.

DPKV failure

Failure of the crankshaft position sensor or damage to its circuit. In such a situation, the Check Engine light comes on. The first thing to do is to inspect the integrity of the DCP itself, make sure that the gap between the ring gear and the sensor is normal (it should be about one millimeter). The normal resistance of the sensor coil is about 600-700 Ohms.

To solve the problem, it is enough to restore normal contact in the electrical circuit and install a new sensor (if the old one turns out to be faulty).

DTOZH is out of order

The DTOZH - the sensor that controls the temperature of the coolant - has failed. Symptoms of the malfunction are as follows: the engine malfunction lamp comes on. If there is a break, the system’s electric fan begins to rotate continuously. In addition, it is necessary to check the serviceability of the sensor itself.

If engine power has dropped for this reason, then it is necessary to restore the quality of contact in the electrical circuit and install a new sensor.

TPS is out of order

The TPS sensor, which monitors the correct position of the throttle valve (or its chain), has failed. As in previous cases, the “Check engine” lamp comes on here. If there is a break in the TPS circuit, then the engine speed usually does not drop below one and a half thousand revolutions.

The solution to the problem is to clean the throttle assembly and restore the quality of the contact connection throughout the entire electrical circuit. If the sensor is faulty and cannot be repaired, it must be replaced.

DMRV has failed

The mass air flow sensor, the sensor responsible for monitoring mass fuel consumption, has failed. The optimal action here is to check the integrity of the mass air flow sensor or replace it with a working device. If the failure of the mass air flow sensor is confirmed, then it is necessary to make an attempt to clean it, and if repair is impossible, simply replace it.

Knock sensor failure

Damage to the knock sensor. In the event of such a malfunction, the engine malfunction lamp necessarily lights up on the instrument panel. In addition, if the motor fails, there is no detonation in any of the operating modes of the power unit and the engine power also drops. With such a problem, the best option is to restore the integrity of the contact group in the electrical circuit and install a new sensor.

Oxygen sensor failure

The oxygen sensor is broken or its circuit is broken. This malfunction is characterized by the “Check engine” lamp coming on. In this case, the first thing to do is check the heating coil for integrity. Firstly, the resistance is measured, and secondly, the voltage level at the output. The measurement can be made even without breaking the circuit - just pierce the insulation with needles.

Stuttering when accelerating? Dig! — logbook Lada Kalina Sedan 2006 on DRIVE2

As you know, every car requires attention. So mine demanded it. Sluggish acceleration, vibration, consumption, shocks when switching. List of suspects:1. MAF sensor. I recently measured www.drive2.ru/l/477094589040165062/. The multimeter reading is 1.04 V.

According to the diagnostics, it showed 1.016 V. There is a third way - remove the chip from the mass air flow sensor and drive it. I haven't tried it.

2. Candles. I forgot to take a photo. Yesterday I took it off, like new. Candles cost 17 dv. www.drive2.ru/l/473344429755728085/. I'm going to install DENSO.

3. Air filter. Yesterday I took it out dirty. I blew it out from the compressor. I was breathing better. It was easier to go.

photo from the Internet. It looks like it was for me.

4. I have long wanted to try running antifreeze past the throttle valve. The fitting was used from an old radiator.

That's how I sawed it off.

5. Corrugation. www.drive2.ru/l/478326591819088066/. I've seen some cars come out inside. I thought so too. It turned out not. It just rattled and siphoned. Although sound could also play a role. After replacement the vibration went away.

6. It remains to look at the injectors. There is no smell of gasoline. But the O-rings have already been purchased. I took washing for the injector and valves. I'll do it as soon as I fill the tank full. After this, you will need to replace the spark plugs as recommended.

Lost engine thrust: why does this happen and what should the driver do?

As a rule, during the long-term operation of a vehicle, almost every driver sooner or later notices that the engine does not pull well. In other words, the power unit has difficulty coping with the loads, there is a loss of power, the unit needs to be cranked up to high speeds to maintain the usual pace, the car accelerates worse from a standstill, picks up speed slowly, etc.

At the same time, in many cases the engine runs smoothly, does not tremble, there are no increased vibrations, extraneous sounds, knocking or noise during operation of the internal combustion engine. Let us note right away that there is a fairly wide list of possible reasons why a warm engine does not run, and there is a loss of engine power when cold and/or when hot.

In this article we will talk about why the engine does not pull, and also consider the most common malfunctions that manifest themselves in the form of loss of traction of the power unit.

Read in this article

conclusions

Maintenance, which should be carried out according to the manufacturer’s recommendations, will avoid many problems. The only question is where to go, at the “Kulibins”, or at specialized service stations equipped with the necessary equipment and equipment. The choice is up to the vehicle owner. The sooner the prerequisites for the failure of a particular part are identified, the less financial losses there will be in the future . It should be remembered that timely maintenance increases the safe operation of the vehicle.

The engine does not pull: the main reasons for the decrease in engine power

So, if no other symptoms other than loss of traction are detected, then you immediately need to pay attention to the quality of the fuel, the proper functioning of the ignition and power systems.

- As practice shows, more than half of the cases of reduced efficiency from internal combustion engines are associated with fuel. The engine does not turn on due to the fact that the tank may be filled with low-quality or unsuitable fuel for this type of engine (for example, 92-grade gasoline instead of 95-grade gasoline).

Typically, such manipulations are necessary when, parallel to the loss of traction, unstable operation of the internal combustion engine is noted, the speed jumps or floats at idle and under load, the engine does not start easily, the “check” light is on the panel, etc.

Also, owners of gasoline engines can independently determine the quality of gasoline by the spark plugs and their appearance. To check the spark plugs you need to unscrew them from the engine. A disruption in the combustion process of the fuel-air mixture in the cylinders, as well as the presence of impurities in the fuel, can be identified by soot on the spark plugs and its color.

For example, if the fuel contains a lot of third-party metal-containing additives and additives, then the skirt and electrodes may become covered with reddish soot (brick-colored). Black soot will indicate that the fuel is not burning properly, etc. In any case, malfunctions in the combustion process of the working mixture lead to the fact that the engine stops pulling.

- The next step in diagnosis is checking the spark plugs. A decrease in the efficiency of these elements is also accompanied by a decrease in the power of the power unit.

This is especially noticeable during sharp accelerations, and when the car is already moving at high speed. In other words, the motor has no “reserve” left for further acceleration.

The candles may be dirty, and it is also possible that their life has come to an end. To fix this problem, you can clean the spark plugs or immediately replace the entire set with a new one.

- If everything is in order with the spark plugs, then you need to check the condition of the fuel and air filters. In the first case, insufficient throughput can lead to the fact that the required amount of fuel is not supplied to the cylinders to prepare the so-called “power” mixture.

As a result, the engine loses power, that is, it does not pull under load. In such a situation, it is enough to replace the specified filter element. As for the air filter, the problem is similar to the fuel filter, but in this case there is a lack of air in the fuel-air mixture.

This leads to the fact that fuel without a sufficient amount of oxygen burns incompletely. In such conditions, engine power naturally drops, carbon deposits form in the combustion chamber, spark plugs become increasingly dirty, etc. To solve the problem, the engine air filter also needs to be replaced.

Dirty throttle valve and pipes

From time to time the throttle valve becomes clogged, for example if the air filter is already in poor condition. Then it’s worth removing all the pipes from the throttle, checking them for permeability and blowing them out. It definitely won't be redundant.

Next, disconnect the throttle cable and wires and remove the throttle. The cleaner can be found at any auto store. In case of heavy contamination, take a clean container and soak the throttle valve in gasoline in it for some time. Don't be afraid to blow out absolutely everything, as the throttle has narrow channels that can also clog.

Malfunctions of the power supply system, ignition and impaired mixture formation

While problems with spark plugs and filters can be identified on the road, more serious problems associated with the power and ignition system are much more difficult to diagnose and fix on site. In cases where the engine does not pick up speed, and jerks and dips are noted when pressing the gas pedal, it is necessary to check and adjust the carburetor or injector.

Let's focus on the more common electronic injection. The list of main malfunctions of modern injection internal combustion engines includes:

- malfunctions, decreased performance or contamination of the fuel pump mesh filter;

- malfunction of injection nozzles;

- problems with ECM or ECU sensors;

- ignition system malfunctions;

- air leaks and leaking fuel lines;

Often, on many cars, problems are associated with the fuel pump, which is located in the gas tank, as well as with the specified regulator. To measure fuel pressure, a pressure gauge is connected to the rail; the obtained values are compared with those recommended for a particular engine. If the pressure is below normal, then the culprit may be either the fuel pump or the pressure regulator.

How to fix the problem?

The way to eliminate problems that arise is to replace damaged or worn parts.

It is better to correct such defects in a specialized service, where they will first clarify the cause of the problem.

Some causes of misfires in the VAZ 2114 can be found and eliminated yourself:

- If gaps and error 300 appear on the computer screen, you need to unscrew all the spark plugs, check the gap between the electrodes and see if there is a lot of carbon deposits on their surface. For errors like 0301, 0302, etc., you need to pay special attention to the condition of the spark plug in this cylinder.

- It is necessary to visually inspect the wires leading to the spark plugs; if cracks are found on the surface, they should be replaced with new ones.

- Check the condition of the camshaft drive belt and the alignment of the marks on it. If the phases are violated, it is necessary to adjust the gas distribution system.

- Check the compression, which should not be lower than 10 and not higher than 14 Bar and should not have a spread across the cylinders of more than 1 Bar. If the pressure is low, it is necessary to check the valve clearance adjustment.

- Check the clearances in the valve mechanism. Sometimes when adjusting, the clearances are set incorrectly and the exhaust valves do not close completely. Monitoring and adjustment of clearances must be carried out every 20 thousand km, and when using gas as fuel - after 10 thousand km.

- If there are misfires in different cylinders that occur under different operating conditions of the unit, the ignition module must be replaced.

Other reasons for reduced engine performance

The condition of the exhaust system also greatly influences engine power. The fact is that to protect the environment from harmful emissions during operation of the internal combustion engine, catalytic converters are installed in the exhaust.

As a rule, official services offer to replace a worn-out element, but the price of the spare part is very high. For this reason, on many cars in the CIS, the catalyst is simply knocked out, and the control unit is “deceived” by software or other available methods.

Also, when engine power decreases, it is necessary to separately check the installation of the timing belt or chain according to the marks in order to eliminate the possibility of valve timing failure. Sometimes there are situations when the belt can jump one tooth, the chain stretches, etc.

In this case, the synchronous operation of the valve mechanism in relation to the operating cycles of the internal combustion engine may be disrupted. This leads to various failures, unstable operation of the unit and reduced power.

Let us also add that engine wear and certain malfunctions also affect engine power. As a rule, worn-out internal combustion engines with mileage usually lose about 10% of their declared power.

One way or another, any leaks in the combustion chamber will lead to expanding gases breaking out of the cylinder during fuel combustion. This means that the pressure of these gases on the piston will decrease, and the internal combustion engine itself will draw poorly and operate unstably.

Finally, we note that the reason that the car has lost dynamics may not be the engine, but the transmission. In other words, the power unit develops enough power, but it is not fully transmitted to the wheels.

If, when coasting, it is noticeable that the car immediately begins to slow down, then the problem is obvious, the wheels are slightly blocked. If no problems with the brakes are identified, then automatic transmission diagnostics are necessary. It is better to entrust this procedure to experienced specialists by delivering the car to a service center.

Purpose, design features, installation location of the fuel pressure regulator of an injection engine. Signs of RTD malfunctions, checking the device.

As a result, jerks and dips appear when accelerating, and the car jerks in motion during transitional conditions. Causes and troubleshooting.

The most common reasons why an engine does not develop full power. Why do they occur? Common problems with gasoline and diesel engines.

Why the engine may not pick up speed: gasoline engine, diesel unit, car with LPG. Fault diagnosis, useful tips.

When you sharply press the gas pedal, the engine jerks, jerks and dips appear, the car does not pick up speed: the main causes of the malfunction and diagnostics.

Signs of a non-working cylinder (tribbing and vibration) of a diesel engine. Troubleshooting: compression, diesel injectors, glow plugs, injection pump and others.

Selecting and replacing the idle speed sensor

When choosing a new IAC, you need to consider some points:

- the distance from the protruding rod head to the flange should be no more than 23 millimeters;

- the last two digits of the catalog number of the new IAC must be similar, or with a subsequent number in relation to the old one being replaced (01-01 or 01-02, etc.).

Algorithm for replacing the XX sensor VAZ 2114:

- placing the car on a flat surface, tighten the handbrake and disconnect the negative terminal from the battery;

- Next you need to remove the protective casing from the power unit;

- loosen the clamp and remove it, holding the air filter pipe;

- Having slightly loosened the fastening screw of the cable from the gas pedal to the damper, use a rag to remove all dirt on and around the throttle assembly;

- Having treated the new rubber gasket that comes with the regulator with engine oil, secure the regulator with screws and make sure that it fits tightly to the throttle body;

- having returned the throttle assembly to its place, connect the connector, replace the cable, pipes and pipes, tightening all the clamps;

- put the engine protective cover back and calibrate the IAC by connecting the battery and turning on the ignition (within 10 seconds the ECU must perform the calibration on its own).

Why the VAZ-2114 engine pulls poorly: the main reasons and repairs

VAZ-2114 cars, from the start of production, are equipped with eight-valve engines with a volume of 1.5 liters. Since 2007, they have been equipped with an eight-valve 1.6 liter engine with an environmental class of Euro-4. The operation of the car, sometimes incorrectly, brings “surprises” over time. The engine does not perform its functions at full power, and thrust decreases. Let's try to understand the causes and methods of elimination.

Best driving instructors:

Automotive instructor Svetlana Automatic transmission: Hyundai AccentTeaches in Northern Administrative Okrug, North-Western Administrative Okrug, Khimki REVIEWS

Driving instructor Elena Automatic transmission: Chevrolet Lacetti Manual transmission: Chevrolet LanosTeaches in the Southern Administrative District, South-Eastern Administrative District, Vidnoye, Domodedovo REVIEWS

Driving instructor Marina Automatic transmission: Kia Cerato Manual transmission: Chevrolet LanosTeaches in the Northern Administrative Okrug, Dolgoprudny REVIEWS

Driving instructor Alexander Manual transmission: Chevrolet LanosTeaches in the Southern Administrative District, Vidnoye REVIEWS

Driving instructor Elena Automatic transmission: Kia Cerato Manual transmission: Chevrolet LanosTrains in the Northern Administrative Okrug, North-Western Administrative Okrug, Khimki REVIEWS

Driving instructor Natalya Automatic transmission: Kia Spectra Teaches in the Eastern Administrative District, Balashikha, Reutov REVIEWS

Driving instructor Oleg Automatic transmission: Chevrolet Lacetti Manual transmission: Chevrolet LanosTeaches in the Northern Administrative District, Dolgoprudny REVIEWS

Driving instructor Yana Automatic transmission: Kia Spectra Teaches in the Northern Administrative Okrug, Dolgoprudny REVIEWS

Driving instructor Yulia Automatic transmission: Chevrolet Lacetti Manual transmission: Chevrolet LanosTrains in the Eastern Administrative District, South-Eastern Administrative District, Lyubertsy, Reutov, Zheleznodorozhny REVIEWS

Automotive instructor Svetlana Automatic transmission: Chevrolet Lacetti Trains at Northwestern Administrative Okrug REVIEWS

Driving instructor Tatyana Manual transmission: Chevrolet Lanos Automatic transmission: Kia SpectrTeaches in Krasnogorsk REVIEWS

Driving instructor Peter Manual: Daewoo Nexia Trains at Northwestern Administrative Okrug REVIEWS

Automotive instructor Oksana Automatic transmission: Hyundai Accent Teaches in North-Eastern Administrative District, Mytishchi, Korolev, Pushkin REVIEWS

Driving instructor Dmitry Automatic transmission: Volkswagen Golf Manual transmission: Chevrolet Lanos Trains in North-East Administrative District, Northern Administrative District, North-Western Administrative District, Dolgoprudny REVIEWS

Driving instructor Oksana Automatic transmission: Kia Spectra Manual transmission: Chevrolet Lanos Trains in the Southern Administrative District, South-Western Administrative District, Vidnoye, Podolsk REVIEWS

Automotive instructor Dmitry Manual transmission: Lada Granta Teaches in the South-East Administrative District, Lyubertsy REVIEWS

Is the engine running poorly? Main reasons

The dynamics of a car, first of all, depend on the stable and stable operation of the engine. When this characteristic decreases, it indicates that there are problems with the engine.

Unstable engine operation is caused by the following:

- The fuel filter is dirty.

- The fuel pump diaphragm is clogged.

- The air filter is clogged.

- Spark plugs do not work or work poorly.

- Insufficient compression in the cylinders.

- The on-board computer is malfunctioning.

- The injectors are clogged (they need to be cleaned or replaced).

- The clutch disc is worn.

- Malfunctions in the operation of sensors that monitor: the position of the crankshaft, throttle valve; coolant temperature; air flow; detonation.

These are only some of the possible reasons why the engine may not pull well throughout the entire speed range.

It is worth mentioning the fuel pump, which fails. The real state of affairs is determined by detailed diagnostics.

INDEPENDENT DIAGNOSTICS IN THE GARAGE

If you have problems with the operation of the injection system, you should first diagnose the ECU. In this regard, the owners of the VAZ 2114 are more fortunate with the German VDO instrumentation - it has a self-diagnosis mode. On cars with a dashboard from Schetmash there is no such functionality.

VDO dashboard for VAZ 2114

Working with the self-diagnosis mode on the VDO panel is carried out according to the following algorithm:

- With the ignition off, hold the odometer button for several seconds;

- turn the ignition to position “1”, release the button;

- if the arrows start running on the display, everything is fine, press once (information message about the firmware version) and release, with a second press an error code will appear;

- You can reset the error by holding the button until “0” appears.

Injection problems that cause the car to stall can be indicated by the numbers 1 (ECU error), 14,15 (coolant sensor errors), 22, 23 (DPS errors), 33, 34 (MAF errors), 42 (ignition malfunction) , 44, 45 (lean or rich mixture). The disadvantage of self-diagnosis on the VAZ 2114 is that if there are several errors, the system sums up the codes. Thus, the number “22” may mean a TPS error or low on-board voltage and a coolant sensor error (8 + 14).

For more accurate diagnostics of the injector, you need to immediately contact a service center or purchase a diagnostic scanner (it costs about 1000 rubles).

If you have another car, you can find the problematic sensor by replacing the sensitive elements one by one with known good ones.

Cleaning a dirty carburetor

Another reason that can cause jerking during acceleration is a dirty carburetor. If you're dealing with a dirty carburetor and suspect parts may need replacing, then it's probably a good idea to rebuild the carburetor using a kit for your specific model.

Follow the procedure described in your vehicle's service manual if you are not familiar with the procedure. But keep these points in mind:

- Soak the carburetor and parts in carburetor cleaner.

- Blow everything out with compressed air. Compressed air will help clear small passages. Do not use wire or drills because you may scratch or enlarge the passages, interfering with the carburetor's function.

- Also check for play in the throttle valve.

- If necessary, adjust components during reassembly, such as float level and drop, idle mixture screw, throttle linkage and spring, anti-flat panel and accelerator pump.

Accelerator pump, carburetor channels and jets

Continuing the topic of loss of power in a carburetor engine, we cannot fail to mention the accelerator pump. The response of the power unit to pressing the accelerator pedal depends on its serviceability. Most often, the problem lies in the fuel supply, and the “nozzles” of the sprayer, through which gasoline is supplied in a thin stream, are to blame. To check the functionality of the carburetor accelerator pump, you will need to remove the air filter to expose the first chamber. Next, you need to open the throttle and hold it for a few seconds. In this case, a thin (about 1 mm) stream of fuel should escape from the “spout” of the accelerator, directed precisely into the second chamber. If the jet is low-power or crooked, this is a sign of clogging of the sprayer, jets, and accelerator pump valves. This problem can be solved by cleaning them.

Toyota gas pedal

Toyota Motor Europe has confirmed that it has carried out a comprehensive repair of the gas pedals on 8 Toyota models scheduled for recall in Europe. Toyota engineers have developed and extensively tested a solution that involves strengthening the pedal assembly to eliminate the potential risk of excess friction that can, in rare cases, lead to a stuck pedal. The first shipments of parts needed for this repair will begin arriving in Europe next week.

At the same time, plans are being implemented to communicate with the owners of damaged cars. In addition, Toyota has already implemented an efficient production solution for vehicles sold in Europe. “Toyota is committed to putting the customer first under all circumstances,” said Tadashi Arashima, president and chairman of Toyota Motor Europe. “We understand that the current situation creates problems and we deeply regret this.” We also want to reassure our customers that a potential problem with the gas pedal is very rare. The announced action is a preventive measure to ensure that the highest safety standards are maintained for all customers.”

“We at Toyota are fully committed to safety standards, we know what the problem is and how to solve it, so now we are focused on solving it as quickly as possible. We carry out the necessary checks to ensure that customers do not purchase problematic vehicles in the future,” added Mr. Arashima.

In case the driver feels that the gas pedal is stuck in the partially open throttle position or slowly returns to the idle state, the car can be driven by pressing the brake pedal firmly with constant force. Do not press the brake pedal more than once in a row as this may weaken the brake booster, requiring you to press the brake pedal harder. You must stop the vehicle in a safe place, turn off the engine and contact an authorized Toyota dealer or Toyota Assistance Service for assistance.

has no information about any traffic accidents in Europe caused by this defect in the design of the gas pedal. In addition, this problem is in no way related to the defect in the driver's floor mat, which was previously identified in the United States.

On January 28, Toyota Motor Europe announced a recall of 8 Toyota models in Europe to address a potential problem with the gas pedal. Below is a list of models and their production periods:

AYGO (Feb 2005 - Aug 2009) iQ (Nov 2008 - Nov 2009) Yaris (Nov 2005 - Sep 2009) Auris (Oct 2006 - 5 Jan 2010) Corolla (Oct 2006 - Dec 2009) Verso (Feb 2009 - 5 Jan 2010) Avensis (Nov 2008 – Dec 2009) RAV4 (Nov 2005 – Nov 2009) The exact number of cars is still being determined, but could reach about 1.8 million units. Other Lexus and Toyota models are not included in this group.

How Toyota will repair recalled vehicles

Experts have identified a problem that, in rare cases, can cause the gas pedal to stick when pressed on the recalled vehicles. The problem arises due to the friction mechanism of the gas pedal, which is necessary to ensure its “information content”. This mechanism increases the pressing resistance and makes it smooth and stable. The design of the mechanism includes a slider that rubs against the surrounding surface during normal operation of the pedal. Due to the nature of the materials used, the degree of wear and weather conditions over time, rubbing parts may stick briefly and not work effectively. In some cases, friction may increase so much that the pedal will be slower than normal to return to its original position, or, in rare cases, the pedal may become stuck, leaving the throttle valve partially open.

The solution found by experts is simple and effective. The unit will have a steel reinforcing bar inserted into it, machined with a particularly high precision cutting tool, which will reduce the surface tension between the ram and the surrounding surface. This redesign eliminates excess friction that can cause pedal sticking. Our company's specialists have confirmed the effectiveness of the modified gas pedals by conducting thorough tests of gas pedal assemblies, which previously showed some tendency to stick.

Source

Insufficient compression

And finally, the most unpleasant malfunction, which leads to a decrease in engine speed and loss of power, is insufficient compression. It is a consequence of wear of the piston group parts or the occurrence (coking) of the piston rings. As a result, the pressure in the combustion chambers decreases, and part of the energy from the combustion of the combustible mixture is simply lost.

Compression is measured using a compression meter. Its normal values, depending on the type of engine, can vary from 10 to 14 kg/cm2. Having discovered such a problem, you should think about a major overhaul of the engine.