string(10) “error stat”

Every motorist is most likely aware that one of his most important responsibilities when driving on public roads is to notify other road users of his intention to perform a particular maneuver. For example, to indicate the desire to turn left or right, special indicators are used, controlled by a special lever.

However, progress does not stand still, and some warning signals are given automatically by the machine. A striking example of this is the reverse gear of the car, during which the moon-white rear lights light up automatically and in advance. This happens due to the presence of a special sensor in the design of the car. We will talk about the principles of its operation and repair in the article below.

Learning how to change the reverse sensor yourself

Modern cars use many different types of controllers and sensors. Such devices can be control and executive. If for some reason the controller fails, it can cause inconvenience in terms of driving. What is a reverse sensor and what functions does it perform? The answers to these and other questions are presented below.

Location

First you need to understand where exactly the device is located.

- Fly under the bottom and look up at the suspension. The desired object on the VAZ 2114 is located on the gearbox. There are only two sensors - speed and reverse.

- If you don’t want to crawl under the car or can’t, try getting to the device through the engine compartment by opening the lid. Although the first option is objectively more convenient.

The purpose of the reverse light switch on a car

Many people know that when you put the car in reverse gear, the white lights in the taillights are activated. However, few people know why this is necessary. To understand the responsibility of operating a vehicle with a faulty 3D sensor, you need to understand its purpose.

Turning on the rear lights is the main purpose of the product. This need arises for a number of the following reasons:

- Warning drivers of vehicles driving behind, or pedestrians, about performing the appropriate maneuver. In this case, the driver (behind the moving vehicle) can react in a timely manner by reducing speed or avoiding the obstacle.

- The 3X sensor on the car is also needed so that when reversing, the driver sees obstacles on the way and has time to react in a timely manner.

Typically, a malfunction of the car's auxiliary control gear is detected when the driver engages reverse gear at night and notices the lack of lighting. In this case, it is necessary to determine the cause of the malfunction and be sure to promptly eliminate it.

Replacement

Many people ask the question: where should you change the reverse sensor?

Of course, the easiest way is to take the car to a service station, where they will replace it at a price of 3-4 times its cost. But you can change it yourself, there’s nothing complicated about it. Let's look at the step-by-step instructions:

- It is necessary to remove the engine protection, if equipped.

- Turn off the electrical power and disconnect the wires connecting to the sensor.

- Prepare a container for oil, since all front-wheel drive cars leak oil when replacing reverse sensors.

- Using a 22mm wrench, preferably with a long ratchet type head, we try to remove the sensor. In this case, a problem may arise - the old thread does not allow it to be unscrewed. Then you need to arm yourself with a hammer and chisel.

- As soon as it is unscrewed, we substitute the oil container.

- We insert a new one very quickly.

- Using the same key, tighten it.

- We connect the wires and check the operation of the reversing lights.

- If everything works, add the leaked oil and install protection.

A malfunction of the reversing lights is not critical to the operation of the vehicle. But the key to safe driving is maintaining the entire vehicle in good condition.

Sensor failure

The faulty element is identified immediately: the reversing lights and other related devices stop turning on. This problem can also occur due to a broken wiring. How to check the sensor for serviceability?

- Remove the connector, connect the multimeter in dial mode, and engage reverse gear.

- The next step is to unscrew the sensor, connect the device, and press the rod (ball) manually.

Important! When dismantling the sensor, it is necessary to prepare a screw plug to quickly block the hole. Otherwise, oil may leak from the gearbox housing.

Repairing the reverse sensor is not practical. The case is sealed; after opening it and putting the contact group in order, it will be impossible to restore the structure to its factory condition. The unit is inexpensive, especially on domestically produced cars. Therefore, replacement will not be too expensive.

Important! There is no point in experimenting with selecting sensors from other car models. If the mechanical part is larger than standard, the gearbox may be damaged.

Replacement requires no special tools: just a wrench.

Functionality check

To diagnose the performance of the device, you will need to drive the car into a pit or overpass in order to gain access to the DZH. The verification procedure is carried out using a tester - an ohmmeter. Alternatively, you can use a multimeter, just set it to Ohm measurement mode.

Testing the device is carried out as follows:

- First you need to get to the DZH and disconnect the connector connected to it.

- Then you will need to connect the tester probes to the device plug, after which the device is set to resistance measurement mode.

- Turn on the ignition and shift the transmission lever into reverse gear.

- Start the power unit and look at the tester display. If the readings displayed on the screen are 0 ohms and the tester beeps, this indicates that the device is fully operational. If the reverse lights do not turn on, check the bulbs, fuse, connection circuit, and contacts.

- If the tester showed infinity as a result of the test, then this indicates that the controller has failed, and accordingly, it needs to be replaced (the author of the video about diagnostics and replacement is Igor K).

Summing up

A reverse light that doesn't come on is just as potentially dangerous a problem as a reverse light that stays on all the time, even when the car is moving forward.

Therefore, such a problem cannot be ignored under any circumstances. Just like installing a flashing brake light for the sake of beauty. It may look impressive, but it confuses drivers significantly.

In some cases, you can find and eliminate the cause yourself. And without any problems. But there are also situations when the best solution is to visit an experienced auto electrician.

Operating principle

The reverse sensor is exactly that device that is designed to activate and turn off maneuver indicators in the form of lamps or LEDs. Its task is to respond instantly when reverse gear is engaged and just as quickly to disengage when moving forward. Moreover, this operating scheme does not depend on the type of transmission, be it manual, automatic or CVT.

Where is the reverse sensor located? Obviously, if the lamp should turn on when the gear shift lever is moved to a certain position, then the sensor itself must be located in the area of the transmission.

Thus, this device consists of an electrical circuit that connects the battery to the lamp.

Obviously, between the battery and the lamp there must be some kind of system that is capable of responding to movements of the gear lever and being activated only when the lever is in reverse or reverse.

This function is performed by a limit switch, which is located along the direction of movement of the automatic transmission selector or on the manual transmission rocker, next to the reverse position point. What is a limit switch? At its core, this is a button that anyone often has to see in real life. Only, unlike most household appliances, this button is activated not directly with a finger, but with the help of a lever that presses it while in a certain position.

When the gearbox is switched to reverse mode, a limit switch powered by the battery is activated. The switch completes the circuit, voltage is applied to the lamp, and it lights up. When you turn off the transmission, in the same way, the button is released and the lamp stops lighting.

Performance diagnostics

After you have found out where the VAZ 2114 reverse sensor is located, you can begin diagnostics. To do this, you may need light bulbs with wires or a tester. However, there are ways to do without their participation.

The verification procedure itself should proceed as follows:

- The hood must be opened and the cover removed from the fuse console.

- Then check 15A, who is directly responsible for its operation. If the white light does not come on after replacing the fuse, the diagnosis continues.

- The ignition must be turned on to record electrical voltage on the console. If it is not there (and its indicator should be 12 V), then it is likely that the contacts have oxidized. If there is, the check is carried out further.

- And then you need to crawl under the car. The protection is removed from the electric motor, the ignition and the corresponding gear are turned on. Now you can see whether voltage has appeared at the sensor connector or not.

- As mentioned above, if there is no tester with an arrow, you can use a test light. Its glow should make it clear about the existing voltage.

- Then comes the key point: it is necessary to short-circuit the conductors of the sensor in question. When the light appears, all that remains is to state the fact that the VAZ 2114 reverse sensor needs to be replaced.

After completing the diagnostics, you can begin the replacement procedure.

Design and principles of operation of the sensor

Reversing is one of the most important capabilities of any car. It is the inclusion of reverse gear that allows the car to move back without using a 180-degree turn. Thanks to this feature, the driver can not only be conveniently located in parking zones while driving, but also significantly save his time when performing a number of maneuvers.

When reversing, it is important for a motorist not only to carefully monitor compliance with traffic rules and control the location of objects standing behind, but also to be sure that every third-party participant in the movement is aware of his desire to reverse. Fortunately for all car enthusiasts, the notification process in this regard is fully automated and occurs through the use of a reverse sensor installed directly in the vehicle structure. Considering such an important function of this component of the car, every car owner must monitor its good condition and, if necessary, repair it.

The reverse sensor works according to a simple principle, the essence of which is as follows:

- The driver, wanting to move in the opposite direction, engages reverse gear;

- The gearshift lever, reaching a certain place, moves the on/off switch (sensor) of the reverse lights to the “ON” position and they, accordingly, light up;

- After the maneuver is completed, the driver changes the reverse speed to first or neutral, which turns off the previously turned on headlights.

The electrical circuit of the reverse sensor is quite simple, if not primitive. Its operation, as a rule, is based on the use of a limit switch, which is a button located on the path of movement of the gearshift lever along the path of the reverse speed and is pressed/released when it is turned on/off. That is, when wondering how to change the reverse sensor, you should be prepared to partially disassemble the gearbox, since this unit is installed specifically in it or within its functioning.

Purpose

Obviously, the car's reverse mode is designed to accelerate the car in the opposite direction without resorting to a 180-degree turn. This allows you to park more comfortably, maneuver faster and, finally, save time for yourself and other drivers.

A reverse signal is needed to warn surrounding drivers of an upcoming maneuver, similar to the way turn signals or brake lights do, embedded in the taillights.

Thus, when reverse gear is activated, a white lamp lights up. All drivers and pedestrians behind are instantly informed that the driver plans to reverse and make decisions about their further maneuvers.

The reverse alarm is also intended for maneuvering in the dark and in fog. The lamp, which has a fairly powerful light beam, allows the driver to better see what is happening behind the car and avoid annoying accidents and incidents when maneuvering. In any case, it is worth paying attention to the condition and operation of the lights. This will eliminate most problems and protect the car from accidental damage.

Place of the switch in the light switching circuit

On cars with manual transmission, voltage to the lamps when reversing is supplied through a limit switch (the so-called frog), which is screwed directly into the gearbox housing. When reverse gear is engaged, the switch button is pressed inside the gearbox. The contacts inside the “frog” bridge, and current begins to flow to the lamps.

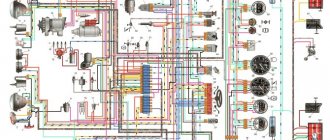

On the circuit diagram for turning on the reversing lights, we can see that on the VAZ 1118 Kalina, the current from the battery through the ignition switch (No. 2) is supplied to fuse F1. Passing through the fuse that protects the switching circuit, “+” goes to the limit switch (No. 10). The contacts are in a normally open state and close only when reverse gear is engaged. Thus, current begins to flow to the light bulbs. The second contact of the lamps is connected to the “–” battery through the common ground contact of the lamps.

On cars with automatic transmission, the role of the limit switch lies with the selector position sensor. Information about changing the location of the gearshift knob is transmitted to the engine ECU, the light control unit.

How to check the "frog"

- Remove the headlight switch chip.

- Turn on the ignition.

- Using a small piece of wire, connect the contacts of the reverse gear sensor connector to each other.

If the reverse lights are on, then the problem is in the “frog”. Some drivers disassemble the switches, clean the contacts, after which the device continues to work properly. It is up to you to judge the appropriateness of such measures. But keep in mind that on many cars (including VAZ models) the limit switch is located below the oil level in the gearbox. We recommend simply replacing the power sensor. To minimize oil loss, jack up the car on the side where the end switch is installed.

On some cars, the reversing lights do not light up due to incomplete activation of the limit switch. The problem can be solved by installing a thinner washer under the “frog”. To make sure that the switch is working, check with a multimeter in ohmmeter mode whether the contacts close when you press the button.

Checking the circuit

The essence of diagnosing the reason why the reverse lights do not work comes down to identifying the section of the circuit where the voltage is lost. To do this, you can use a regular control light. Continuity testing is done with an ohmmeter, so you need to know how to use a multimeter.

You can start checking directly from the limit switch connector. Turn on the ignition. Connect one contact of the control light to an unpainted metal part in contact with the body, and the second to the “+” connector.

- If power comes in, check the reverse sensor.

- If after installing the “jumper” in the connector the lights do not light up, then the problem is in the section of the wire circuit going from the connector to the lights. Ring the wire to the point where it divides into light bulbs on the left and right sides. Most likely, the reason is the break.

To find the pinout of connectors, light contacts, and wire colors, be sure to study the electrical diagram of your model and vehicle configuration.

The lamps are constantly on

If the lights on your car are constantly on or come on regardless of whether reverse gear is engaged, the cause will be among the following breakdowns:

- short-circuiting the “+” going to the reverse gear sensor and the light bulb wires from the switch;

- the wire going from the connector to the lights has a short to “+” (this happens if the wires in the harness fray);

- The sensor is stuck in a closed state.

Description of DZH

Purpose

Let's start with the purpose. DZH is a device designed to activate white lamps, indicating that the car is in reverse gear. The device is used to turn on the reversing lights, which allows other road users to know the driver's intentions and the maneuvers he is about to perform.

When it's dark outside, white headlights will also help warn drivers behind you that your car is in their path. This, in turn, helps prevent possible incidents and emergency situations on the road. Where this device is located - the location may vary slightly, but as a rule, the controller is located on the gearbox.

Design and principle of operation

The DZH itself consists of a housing, contacts for connection, a rod, a moving ball, and a return spring.

As for the operating principle, it is as follows:

- The driver shifts the transmission lever to the reverse gear position.

- In this case, the gear shift fork is pressed against the controller.

- Next, the device shorts the cable to ground.

- After this, the light source installed in the rear lights is activated, which warns other drivers that the car has started to reverse.

Symptoms of a problem

What signs of malfunction may indicate a breakdown of the DZH:

- One of the problems that happens most often is oxidation of contacts on the terminals or wiring. This problem is relevant for many car owners. To solve this problem, it is necessary to thoroughly clean the contacts and then install them in place. When performing this work, the battery should be disconnected. If the contacts are inoperative due to the fact that they are burned out, then they will have to be changed in any case. But before making a replacement, it is necessary to find out why the burnout occurred; most likely, the essence of the problem lies in voltage surges in the on-board network.

- The device became loose in its seat. During vehicle operation, the controller may slightly move out of its installation location; this problem is usually caused by high vibrations. In this case, you will simply need to more securely fix the device at the installation site.

- Another reason for inoperability is the lack of contact with the on-board network in the gearbox. In this case, it is necessary to diagnose the condition of the contacts, as well as electrical circuits. If necessary, failed components must either be cleaned or replaced.

- The next problem is that there is no contact between the connection connector and the safety mounting block. In this case, you also need to diagnose the condition of the contacts, as well as clean and change the wires, if necessary.

- Failure of the safety device. In this case, the problem can only be solved by replacing the fuse. If this part often fails, then the reason may lie in the same voltage surges. It is necessary to check the electrical circuit more carefully.

- The reverse light may not turn on because the light source itself, that is, the lamp, has burned out. In this case, you will have to dismantle the optics cover in the trunk and replace the failed device.

- And finally, the last reason for inoperability is the breakdown of the DZH. In this case, you will not be able to repair it, since such devices, as a rule, cannot be repaired. The controller will need to be changed (the author of the video is the Do-It-Yourself Auto Repair channel).