Classic "nine"

With the advent of electronic sensors in the design of a modern engine that control the operation of its systems and mechanisms, it has become possible to achieve fuel efficiency of the engine and reduce the concentration of harmful gases in the exhaust. At the same time, malfunctions occurred in the operation of special sensors and control units.

One of the most common malfunctions of Lada gasoline models is when the VAZ 21099 injector floats at idle speed. Moreover, such a problem can arise both when the engine is cold or when the engine is warm, when the car is stopped at a traffic light.

Device

At the initial stage of development of injection engines, rotor and solenoid devices were used as idle speed regulators. They could have two operating positions - here we can draw an analogy with a shut-off valve. The sensor operated in the fully open or fully closed position. This did not allow the idle speed to be effectively stabilized.

Subsequently, AvtoVAZ engineers created an idle speed sensor for the VAZ-2109 injector in the form of a stepper valve. It is distinguished by the presence of stepwise adjustment of the air supply through a bypass channel in the throttle valve.

The IAC is designed as follows: it is based on a small stepper motor, and the device also contains a rod, a spring and a needle.

Other reasons why the engine stalls when hot

In addition to the above material, I would like to note a number of malfunctions that lead to a sudden stop of a hot engine while driving. The unit may stall while driving if the timing belt or chain is broken. This situation means that in most cases the power unit will require expensive repairs, since as a result of a break the valves are bent, piston defects and other damage to engine elements occur.

Another reason for a sudden stop may be overheating of the engine, which causes it to jam. In this case, a common culprit is the internal combustion engine cooling system, which has malfunctioned. Water hammer should also not be ruled out.

Operating principle

When the car is moving and the throttle valve is open, the IAC is not involved in the process, its valve is closed and the rod is motionless. When the damper closes and the engine goes into idle mode, voltage is applied to the electric motor and the rod moves towards the opening - the valve comes into operation. It opens slightly, and air enters the engine bypassing through a special hole.

When the driver turns on the ignition, the IAC rod fully extends to its extreme position and closes the calibration hole in the throttle pipe. The sensor then counts the steps and the valve returns to its home position. As for this basic position, it can be different and depends on the firmware installed in the ECU. For January 5.1 firmware the position is 120 steps, for Bosch firmware it is 50 steps.

Carburetor car engine starts and stalls

Symptoms of a problem

— The engine starts, runs for a few seconds and stalls, repeated starts are unsuccessful.

— The engine starts with difficulty, after running for a short time it stalls, after restarting it starts and runs.

— The engine starts and immediately stalls, starts again and stalls again, and so on several times, but then it still starts working.

Causes of malfunction

There is no fuel in the float chamber

Pump it up using the manual pump lever on the fuel pump.

The fuel pump or power system may be faulty. Remove the hose from the carburetor fuel supply fitting and press the manual primer lever on the fuel pump several times. A strong pulsating stream of gasoline should come out of the hose hole. If it is missing or weak, check the fuel pump or power system.

VAZ fuel pump check

The strainer at the carburetor inlet is clogged

Remove it by unscrewing the cap, clean it (you can use a toothbrush), rinse with acetone or gasoline and blow with compressed air. At the same time, clean the filter seat in the carburetor cover.

The solenoid valve is faulty or the fuel jet of the idle system is clogged

Check whether the solenoid valve or the idle air system fuel nozzle holder has become loose due to any circumstances. Tighten it. Remove the wire from the valve, and then put it back on. You should hear the click of the valve being activated. If it is not there, we connect a piece of wire plus the battery and the valve outlet. There is no click - we change the valve. There is a click - we check the EPH system.

Check the serviceability of the valve itself by unscrewing it from the carburetor and removing the fuel jet from it. The jet should be carefully inspected for contamination and deformation. We also check the ease of movement of the valve shut-off needle, the presence and integrity of the rubber O-ring on the valve body.

carburetor solenoid valve device

Unscrew the idle air system fuel nozzle holder (on carburetors with a holder instead of a solenoid valve), rinse, clean the fuel nozzle and blow with compressed air.

“Suction” of foreign air into the carburetor

In this case, the fuel mixture is lean. If the engine starts and immediately stalls, it is most likely very lean. The image shows probable places where foreign air is “sucked in” on the 2108 Solex carburetor.

Read more about the “suction” of foreign air in the article “Suction of foreign air into the carburetor.”

Trigger diaphragm damaged or out of adjustment

Disassemble the starter housing and replace the diaphragm with a new one. Adjust the starting device.

Fuel and air jets, emulsion wells and tubes of the main dosing system are clogged

It is necessary to remove the carburetor cover, unscrew the jets, remove the tubes, rinse and clean them, clean the wells, blow everything out with compressed air and put it back. The image shows what should be cleaned on the carburetor 2105, 2107 Ozone.

On the Solex carburetor, unscrew the air jets and take them out along with the emulsion tubes. At the bottom of the opened wells there are fuel jets. We turn them out with a thin long slotted screwdriver. Clean, rinse with acetone and blow with compressed air.

Fuel and air jets and idle system channels are clogged

Unscrew the jets, rinse and clean them, and blow them with compressed air.

air and fuel jets for CXX carburetors 2108 Solex and 2105, 2107 Ozone

The fuel level in the carburetor float chamber is broken

The fuel mixture is either very lean or very rich due to incorrect adjustment.

Articles on the site about adjusting the fuel level:

The carburetor air damper drive is not adjusted (“choke”)

A not fully open air damper causes the fuel mixture to become richer in some cases to such an extent that it is difficult to start the engine, especially when it is hot. The spark plugs may become flooded with fuel. Adjust the drive:

With the choke handle fully extended, the air damper should completely cover the cross-section of the first chamber of the carburetor.

With the handle fully recessed, the air damper should be strictly vertical.

Notes and additions

— Before searching for the reasons that a carburetor engine starts and stalls, it is recommended to check the serviceability of the ignition system, since the symptoms of its malfunction are similar to the symptoms of a malfunction of the ignition system and the presence of fuel supply through the power system.

Five more articles on the site on carburetor malfunctions

Location

Knowing the principle of operation of the VAZ-2109 idle speed sensor (injector), it is not difficult to guess where it should be installed. On this vehicle it is located near the throttle valve and throttle position sensor. The device is fixed with screws on the damper body. In case of failure, the car owner can easily replace it himself.

What causes it to stall?

If you have a carburetor nine and it does not want to start, the following vehicle malfunctions may be the cause:

- the battery has either already served its purpose or has lost its charge - in this case, the starter can turn, but due to the lack of energy, the ignition is blocked. In case of this breakdown, it will be enough to charge the battery or replace it;

- if the synchronizer sensor is connected incorrectly (the poles of the wires are reversed), you just need to change them from one place to another, checking them before doing so;

- if the valve on the gearbox is depressurized, in this case the car will be in trouble, because gasoline (or its vapors) will enter the receiver and enrich the combustible mixture. To eliminate the malfunction, you need to restore the tightness of the gearbox valve.

A very common problem that drivers of nines encounter is when the car stalls immediately after starting. Sometimes the machine starts working on the third or fourth try, but then starts to misbehave again. You should not ignore such moments. It’s better to take a look and fix the problem right away. In this case, it is better for inexperienced mechanics to go to a service station. Cleaning the throttle valve, adjusting the idle speed or replacing the IAC may help if:

- the car stalls immediately after starting (whether the engine is cold or hot);

- idle speed returns to normal after heavy gas release;

- You can start the car only by using the accelerator;

- When braking hard, the motor turns off.

In order to find the problem, you need to diagnose your car. This procedure will help you determine for sure where and what needs to be repaired.

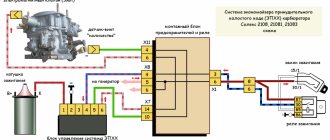

DXX connection diagram

The idle air control is connected with a single four-wire cable. The wire of the VAZ-2109 idle speed sensor is connected to the ECU. Such wiring creates certain problems when trying to diagnose the sensor yourself. You won’t be able to simply apply voltage to the terminal for testing: the ECU supplies voltage to the windings of the stepper motor in pulse mode. Therefore, checking with a multimeter in case of a malfunction is not very effective.

VAZ 21099 injector stalls when starting off

Often, a breakdown of this kind may be the result of insufficient warming up of the engine, a malfunction of the brake system or chassis. But with adequate operation of the above-mentioned components, the root of all evil is in the operation of the power unit. If a problem occurs when starting off, the VAZ 21099 car may have several reasons:

- incorrect ignition operation;

- malfunction in the fuel supply system;

- malfunction of electronics;

The injector on the VAZ 21099 car is quite capricious and unreliable. When troubles arise, the first thing you need to do is conduct a computer diagnostic of the system and, based on the result, move on.

Due to the low reliability of electronic ignition systems, the car develops a number of typical “diseases”. If the electronics are faulty, there may be loss of power at high speeds or the car may stall when trying to start moving. In this case, the ECU is diagnosed.

Symptoms of a problem

This element is responsible for the operation of the engine at idle, which means that any malfunction will affect the stability of the idle speed. Among the main symptoms of HPP failure are:

- unstable idle;

- drop in crankshaft speed when additional electrical consumers are turned on;

- absence of increased warm-up speeds during cold starts of the power unit;

- stopping the internal combustion engine when turning off or changing gear.

These symptoms will not always be the cause of a malfunction of the VAZ-2109 idle speed sensor (injector), since the same symptoms will occur if the TPS fails. But if there is a problem with the throttle position sensor, the check engine light will come on. Since the IAC, or idle speed sensor, does not have its own diagnostic system, the lamp will not light up with the same symptoms.

The speed drops after releasing the gas on a VAZ 2114: what's the matter?

Compared to the previous carburetor generation, the new injection VAZ 2114 turned out to be much more efficient and reliable, but from time to time they are plagued by various problems. A situation such as a drop in speed after releasing the gas on a VAZ 2114 is almost always caused by problems with the injection system, but other causes must be excluded during the diagnostic process.

How to find the cause of the problem

If the speed of the VAZ 2114 drops, you need to comprehensively diagnose the functioning of the injection system on your car, which can be done in your garage if you have a little experience and appropriate instructions. In this case, those “fourteeners” that were equipped from the factory with a dashboard from the German manufacturer VDO have an important advantage, since it, in comparison with the analogue from Schetmash, is equipped with a self-diagnosis mode.

To carry out this procedure, you will need to perform a few simple steps:

After reading the manual, you can find out what errors shown on the screen may be associated with the fact that the speed constantly drops when the gas is released on the VAZ 2114.

So, it could be one of the following situations:

- code 1 – controller error;

- code 14/15 – coolant sensor error;

- code 22/23 – throttle position sensor error;

- code 33/34 – mass air flow sensor error;

- code 42 – faulty ignition;

- code 44 – fuel mixture is lean or too rich.

The owner of a VAZ 2114 should remember a specific feature of the self-diagnosis mode on his car: if there are several errors, the computer sums their codes arithmetically, which can be misleading. This can be indicated by a logical discrepancy between the displayed code and the actual problems.

To be completely sure, you will either need to take the car to a service center and pay for its inspection, or buy a diagnostic scanner yourself, which is not that expensive. Another option is if you have the same VAZ model (fully operational), one by one, remove it from it and install potentially vulnerable sensors on your car, using the method of elimination to find the problem.

The simplest diagnosis of DXX

The easiest way to check the idle speed sensor of the VAZ-2109 is the following method. Need a friend's help. The sensor is disconnected from the connector, then the mounting screws are unscrewed and the device is dismantled. Next, the regulator will be plugged into the connector again, but held in your hands.

At this time, the assistant starts the power unit, and the IAC rod should at this moment retract completely and then extend to a certain distance. If the device behaves this way, then it is operational - the rod is not bent, it is not jammed inside the valve. But there is no guarantee that the device matches the ECU firmware. The rod extends, but the number of steps is unknown. There is a marking on the connector - you can use it to ensure that the ECU sensor matches.

This is the initial stage of diagnosis. Next, check the electrical part, the condition of the valve, and the degree of needle wear.

Reason No. 1 – no spark is supplied to the cylinder:

- Irregularities in the spark plug. It may make its way onto the body or its gap may be set incorrectly. To control the correct operation of the spark plug, you need to unscrew it and lean it against any metal part. After that, by turning the starter, we determine by eye whether sparks appear on the spark plug. It is taken with pliers; Rubber gloves should be worn on hands. Anyone who has been hit by a 20 kV shock will fully agree that safety is absolutely necessary. Remember that although there is a spark jumping on an unscrewed spark plug, this is not a 100% indicator of its correct operation. After all, the cylinder has a completely different environment.

- Wire breakdown. If it breaks through, the spark will become extremely insignificant or disappear completely. I mentioned safety due to the fact that in my case, the factor that caused the carburetor in the VAZ 2109 to malfunction and the engine to not pull was precisely the breakdown. I began to move the wire with the engine running and took it with my unprotected hands. When receiving an electric shock, a person is unable to release the wire on his own. It was lucky that an acquaintance was nearby. Be carefull!

- There is a problem with the car's ignition distributor. For example, a contact burned out or mechanical wear occurred. This can lead to the fact that a spark from the distributor stops going to a specific cylinder.

- Hall Sensor. If it is not fully operational, it is capable of transmitting pulses from the drum on the car distributor shaft and not sending them to the switching device. That is, sparks will be missed.

How to check a sensor with a multimeter

Using a multimeter, you can diagnose the VAZ-2109 idle speed sensor (injector) in two ways: first, measure in ohmmeter mode, then in voltmeter mode.

If you close the contacts on the CD and AB plugs, the multimeter should show a resistance in the range of 40-80 Ohms. If you close the DC and AD contacts with probes, then the multimeter on a working IAC will show infinity.

In voltmeter mode, the voltage on the sensor when the ignition is on should be 12-20 V.

The cause of a stalled engine is a power supply failure

In this type of problem, 3 reasons may be involved:

- Poor contact with the terminals of the new battery;

- Detection of poor contact or breakdown along the entire length of high-voltage wires;

- The appearance of malfunctions in the generator or ignition coil system of the car.

If the problem lies in damp high-voltage wires, then it is best to replace them completely along with the battery contacts. If the terminals make poor contact, you need to carefully clean them with sandpaper and try to reconnect them. If the generator is found to be inoperable, the problem usually boils down to problems in the following parts:

- Broken timing belt;

- There is a malfunction inside the housing of the unit itself.

Diagnostics on the stand

The simplest stands for checking IAC will cost the average car enthusiast 1,500-2,000 rubles. Replacing the idle speed sensor on a VAZ-2109 will cost 300 rubles. Therefore, purchasing a stand is not economically feasible. You can assemble a simple stand with your own hands. The circuit consists of a charger from any mobile equipment with a voltage of 6 V, a plug block and a test lamp. If the lamp lights up during the test, then the IAC is faulty. If the lamp burns at half intensity, then the device is working properly.

Problems common to both engine types

These malfunctions can be attributed to both injection and carburetor engines, since they occur on both power plants.

- Dirty air filter . If the air purification filter is sufficiently dirty, then air begins to flow in rather small quantities, which leads to oxygen starvation. In this case, it is necessary to replace the filter element and continue to operate the vehicle.

- Ignition system malfunction . First of all, check for the presence of a spark on the high-voltage wires and spark plugs. This requires two people. The first turns the engine using the starter, and the second checks for the presence of a spark. The spark plug is unscrewed and reinserted into the wire. A partner leans the end of the spark plug against the cylinder block at a distance of approximately 5-10 millimeters. If a spark does not appear while the engine is rotating, you need to check the serviceability of the spark plug or armor wire. The absence of a spark on all spark plugs and armor wires indicates a malfunction of the ignition module or coil. The element is replaced, and the spark plugs are cleaned of any deposits that have appeared.

If there was no spark, then the armored wire is not leaned against the cylinder head, but against the spark plug itself, screwed to the block. If a spark appears, then we can say with confidence that the spark plug is faulty.

Attention! When checking the spark, you should not hold onto the body of the car, as you may receive an electric shock of 40 thousand volts. This voltage is not lethal at low current strength, but there is nothing pleasant about it. Also, do not use prolonged sparking as there is a chance of damaging the ignition module or the coil winding insulation.

It is worth noting that the absence of a spark on all spark plugs is accompanied by the absence of signs of engine life, that is, it does not start at all. Therefore, most often, one spark plug or wire fails, which is immediately replaced. Although it is true that even if all spark plugs are in good working order, they still work unstably on your engine. You can try to fix the problem by replacing parts.

- Fuel filter is dirty . It occurs during long-term use of the car, when there are fewer and fewer holes in the filter and the engine performs worse each time. The fuel filter is being replaced.

These are, perhaps, all the reasons why idle speed may fluctuate. As you can see, their diagnosis and elimination methods will not cause any particular difficulties, so this procedure can be performed with your own hands, without the help of car service employees.

How to replace the idle speed sensor

If cleaning does not help and the IAC does not work, then the VAZ-2109 idle speed sensor (injector) needs to be replaced. This is done very simply.

The sensor is installed on the throttle body. It is secured with two screws, just like the fuel pump. To remove, unscrew the mounting bolts and disconnect the plug from the device. Before installing a new DXH, it is recommended to sand the seat.

The new IAC is installed in the same way, in reverse order. The element is installed in place, fixed with bolts, and wires are connected. But sometimes it happens that replacement does not solve the problem, and the idle speed fluctuates even with a new sensor. The reason here is the quality of spare parts in stores - before installation, it is better to make sure that the new sensor is working.

Let's list them.

- The most basic is a malfunction or failure of the mass air flow sensor.

- No less common is the breakdown of the idle air control valve.

- A crankshaft position sensor providing incorrect information to the control unit can also be the root cause of a high or floating idle.

- The throttle position sensor may also be to blame.

- It happens that for some reason the gas pedal does not return all the way back. Moreover, this happens both because of a banal malfunction of the cable, and because of something completely ridiculous - for example, after washing the car, they covered the driver’s mat in such a way that the tip of the mat began to touch the pedal.

- The air filter is very clogged. Because of this, the combustion mixture is too rich in gasoline, again resulting in high idle speeds.

- The cable came off the throttle valve.

- Engine temperature sensor faulty. It gives the car’s “brains” incorrect values, which increase the crankshaft speed, thinking that the engine is cold.

As you can see, we have before us a whole forest of very different reasons why high revs appear! Next, we will take a closer look at the most typical, plus the most common problems associated with the problem described. At the same time, we’ll figure out how to eliminate them with our own hands.

Ways to eliminate the “sore”

If such a problem occurs, you need to look for which node is to blame analytically, checking all the specified sensors

First, let's consider the following option for correcting the problem situation. Let's assume that a VAZ 2110 has high revs. An examination of the suspected components for faulty components showed that the throttle position sensor has traces of rust. It is located directly above the throttle valve. Measurements with a voltmeter showed that when the engine is idling, the voltage on it remains high - which means it does not close the damper.

How to fix the problem? For this we only need a screwdriver. Let's begin the procedure.

- By disconnecting the terminal block and also unscrewing two screws, we dismantle the assembly. We notice that traces of rust inside interfere with the movement of the wheel that regulates the position of the damper.

- We fill the insides of the defective device with a penetrating anti-rust aerosol.

- Use a development screwdriver to turn the wheel.

- We reassemble in reverse order.

Check to see if the engine idle speed is now high. The problem should go away.

Now let's look at another case. Let's say we have high idle speed in a VAZ 2114. This is what we do when faced with this situation.

When clarifying the circumstances of the problem under investigation, we always initially check the operation of the idle speed sensor. This device consists of a needle built inside an electromagnetic coil. The needle either moves inside the coil, moving away from the hole in the throttle pipe, or moves out, closing this hole, thereby stopping the supply of air for combustion of the mixture.

This element is located at the throttle valve, opposite the gas pedal cable. To diagnose it, we pull out the terminal block from it, start the car, after which we see that we still have high engine speeds that have not changed at idle. Then we remove this defective unit, then clean it or replace it. For work we take:

- screwdriver;

- toothbrush;

- petrol.

Nuances of choice

The stores offer a huge number of different sensors from different manufacturers. The original part must be marked XX-XXXXXXX-XX. By the last two digits you can figure out compatibility. So, numbers 01 and 03 are interchangeable, and 02 and 04 can also be swapped. Instead of 02, you cannot put 01 or 03. If the sensor is original and new, it is better to additionally lubricate the spring and rod with thick lubricant.

When buying a sensor, even in a trusted store, you should look at the following nuances:

- there are no marks on the packaging by which the manufacturer can be distinguished;

- the sticker on the device body is yellow and has no frames;

- the needle has a dark tip;

- the o-ring is thin and black;

- rivet heads less than 3 mm in diameter;

- white spring;

- The length of the body is 1 mm less than the length of the standard AvtoVAZ sensor.

All these nuances indicate that a counterfeit VAZ-2109 idle speed sensor is being offered. You can see photos of real and fake devices above.

Symptoms of a faulty engine control unit (ECU)

The engine control unit (ECU), also called the engine control module or transmission control module, is one of the most important components found on almost all modern vehicles. Essentially, it functions as the main computer for many of the car's engine and driving functions. The controller receives information from various engine sensors and uses this information to calculate and adjust the engine's spark and fuel for maximum power and efficiency.

The ECU plays a critical role in newer vehicles, where many (if not all) of the vehicle's major functions are controlled by the ECU. When the ECU has any problems, it can cause all sorts of problems with the vehicle, and in some cases even render it unusable. Typically, a bad or faulty control unit will cause several key symptoms that can alert the driver to a potential problem.

Check if the Check Engine Light comes on

An illuminated check engine light is one possible sign of an ECU problem. The check engine light usually comes on when the computer detects a problem with any of its sensors or circuits. However, there are cases when the control unit turns on the check engine light by mistake, or when there is no problem. Scanning your computer for trouble codes can help reveal whether the problem is with the control unit or elsewhere in the vehicle.

The engine stalls or does not start

Another sign of a bad or faulty control unit is erratic engine behavior. A faulty computer can cause your car to experience intermittent problems such as freezing or misfires. Symptoms may come and go and may not have any pattern to their frequency or severity.

Engine problems

Problems with engine operation are another sign of a possible problem with the control unit. If the control unit has any problems, it can reset the engine's valve timing, which can negatively impact performance. A faulty ECU can cause decreased fuel efficiency, power, and acceleration.

The car won't start

Another sign of a bad or faulty control unit is a car that won't start or is difficult to start. If the control unit fails completely, it will leave the vehicle without engine control control and, as a result, will not start or start. The engine may still start, but it will not be able to start without important data from the computer. This symptom can also be caused by a number of other problems, so it is best to get a full diagnosis from a professional to pinpoint the cause.

Since the control unit plays such an important role in the operation of the engine, any problems with it can cause serious problems with the overall functionality of the vehicle. Because the computer systems used in modern cars are quite complex and also difficult to diagnose. For this reason, if you suspect that there is a problem with your vehicle's control module, have the vehicle inspected by a professional technician to determine if your vehicle will need an engine control module replacement.

Source

Replacement or cleaning

Practice shows that in a fairly large number of cases, simply cleaning the idle air regulator allows you to restore its functionality. Therefore, we advise you to try this method first. And if it does not give results, then it will not be difficult to replace the device.

- Buy a container of carburetor cleaner. In this case, your engine may well be fuel-injected. It’s just that this composition is excellent for cleaning IACs and more.

- Disconnect the connector with wires from the sensor, unscrew the two fasteners and remove the affected regulator itself.

- Clean the regulator from accumulated debris and contaminants, and be sure to clean the needle and spring itself. This should be done with carburetor cleaner. Use available tools to tidy up a fairly compact device.

- Be sure to clean the idle air control housing on the throttle assembly. This is where the cone-shaped needle of the XX sensor enters.

- After completing the cleaning of the device, return it to its place and check its operation.

- If cleaning does not bring the desired result, the engine continues to behave inadequately, you will have to purchase a new regulator and install it in place of the old sensor.

- Before replacing, be sure to turn off the power to the car by disconnecting the negative terminal from the battery, then disconnect the block with the power wires, unscrew the mounting screws and remove the device.

- Reassemble in reverse order.