Description of IAC

The idle speed control was installed only on Nivas with fuel injection and a mechanical throttle. When installing an electronic throttle, IAC is not used, since the entire IAC process is controlled electronically.

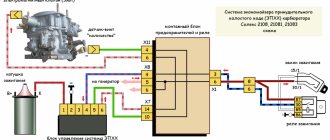

The regulator is designed to regulate engine speed at idle by adjusting the air supplied to the cylinder head. The IAC is a DC motor with a worm gear on the shaft, which has a cone installed that regulates the air supply through the IAC channel in the throttle assembly.

This sensor is quite unreliable, often subject to breakdown and replacement. Due to its unreliability, it was subsequently abandoned in favor of an electronic throttle.

Symptoms of a problem

The sensor is completely mechanical and if it breaks, the check engine warning light does not light up. A breakdown can be diagnosed only by the signs of an IAC malfunction, which are described below.

Signs:

- Spontaneous engine stop at idle;

- Stopping the engine when switching to neutral;

- There are no warm-up speeds on a cold engine;

- The revolutions are floating;

- Spontaneous increase and decrease in speed at idle;

All these signs indicate IAC only when they are detected at idle, since the regulator operates in idle mode and does not participate in the operation of the internal combustion engine at high speeds.

Checking the IAC Niva

Checking this sensor to accurately identify its failure must be carried out in two ways: visual inspection and multitherm testing. Let's look at each of the checks in more detail.

Visual inspection

This check is carried out only after removing the IAC from the remote control.

It is necessary to check the condition of the regulator body; there should be no chips, cracks or gaps between the metal and plastic parts.

The presence of all rivets securing the plastic part of the sensor is checked, since the absence of a rivet may be accompanied by the passage of air.

Check the condition of the rubber sealing ring. There should be no burrs or cracks on it.

The mobility of the worm shaft is checked. He should move around without biting.

Check that there is no carbon deposits on the regulator cone.

Checking with a multimeter

Since the sensor is mechanical and, in principle, its design is based on a conventional DC motor, the test is carried out by measuring the resistance of the IAC winding.

To check on a multimeter, set the switch to measure a resistance of 200 ohms.

We connect the multimeter probes to the central terminals of the IAC and measure the resistance on them. The reading on the device screen should be close to 50 ohms. If the device shows 1 or infinity, then most likely a winding break has occurred.

If the winding breaks, the idle speed regulator VAZ 2121-2123 must be replaced with a new one.

Method for checking the sensor using a multimeter

The most reliable and common way to check the functionality of the sensor is to use a multimeter. But to do this, the regulator must first be removed. Typically, it is secured with several screws near the throttle sensor, but on some cars it can be secured with a special solution or varnish.

It is impossible to dismantle the IAC using force, since there is a high risk of damaging the intake system. In such a case, you will have to remove the entire throttle assembly.

To check the electric motor, it is necessary to measure the resistance of the windings. The multimeter contacts must be connected in turn to each of the windings A and B, C and D. If everything works properly, the data obtained will fall in the range of 40–80 Ohms.

As an additional check with a multimeter, the contacts can be swapped. The sensor, in this case, should indicate an open circuit.

How does the idle speed sensor work on a Niva 21214 injector?

The regulator, idle speed sensor Niva-21214 injector is responsible for the cold start of the engine and its operation at low speeds when the gear is off. Previously, on carburetors, these functions were performed by 2 units: an air damper with a cold start membrane and an electric valve with an idle jet.

To some extent, diagnosing malfunctions was easier than after the advent of the electronic fuel control system. Nevertheless, if you wish, you can also understand it in order to detect problems with the regulator and fix them yourself.

What to do when a breakdown is discovered?

Most often, the main source of all breakdowns of the idle air regulator is the accumulation of dust and dirt. In this case, you can try to clean the sensor yourself.

After the sensor is disconnected, all contacts must be wiped with alcohol or a special liquid. If the needle or rod is heavily covered with dirt, you can use WD-40. As an additional insurance, it is better to check the condition of the throttle valve and, if necessary, clean it. If cleaning does not help, it would be better to completely replace the inoperative device and not compromise the safety of road users.

You can learn more about the technology for checking the idle speed sensor in the video:

Additional function of the regulator

An additional function of the device in question is to block the air flow in forced idle mode. This mode is activated when 3 conditions are met:

- the car is coasting;

- any gear is engaged;

- engine speed above 1800 rpm.

Under such conditions, it is impractical to supply the air-fuel mixture to the cylinders, since the car moves by inertia. So fuel will be wasted. Therefore, based on the damper and speed sensors, the controller stops the supply of fuel and air, giving the corresponding commands to the injectors and the idle speed controller. When the speed drops below 1800 rpm or the driver presses the gas pedal, the supply of the combustible mixture is resumed. If the driver switches the gearbox to the neutral position, the regulator opens the channel, and only idle speed is activated.

Replacing an element

Signs of failure of the idle speed element are very similar to the failure of the throttle position sensor, only in this case the “Check engine” display does not flash on the instrument panel. The car does not start well when cold, is unstable at idle and may stall when coasting. The regulator cannot be repaired; it only needs to be replaced.

The element is replaced in the following order:

- Disconnect all pipes from the throttle body, unscrew and remove this unit. Without this, dismantling the regulator is impossible.

- The element in the form of a barrel with a flange is screwed to the body with 2 screws. Unscrew them and pull out the regulator without losing the gasket.

- Measure the length of the rod on the new element, starting from the flange of the part; it should not exceed 23 mm. If the rod is longer, then you need to retract it, briefly applying a voltage of 12 V to the contacts marked “D” and “C”.

- Wipe the seat with a rag to remove dirt, lubricate the gasket with motor lubricant and install the new regulator in place.

After replacement, you need to install the throttle valve assembly back, connect the pipes and start the engine to check.

Source

Where is the Chevrolet Niva located?

As follows from the description of the principle of operation, the regulator is located on the body of the throttle unit of the power system, at the bottom left in the direction of travel . It is located rather inconveniently, which can create problems when replacing it without a certain skill.

The IAC is placed in the housing socket and secured with two screws . Between the regulator and the body there is a sealing rubber ring that prevents air from leaking around the valve.

A clearly visible sector placed on the throttle axis will help you visually locate the regulator . A cable from the accelerator pedal connects to it, which is clearly visible when looking at the engine from above. There are two sensors located on the side of the throttle assembly opposite the cable. The upper one is on the same axis with the cable sector - this is the throttle position sensor (TPS). And the required IAC stands immediately below it, on the same side.

Replacing the idle speed regulator VAZ 21214

The regulator, idle speed sensor Niva-21214 injector is responsible for the cold start of the engine and its operation at low speeds when the gear is off. Previously, on carburetors, these functions were performed by 2 units: an air damper with a cold start membrane and an electric valve with an idle jet.

To some extent, diagnosing malfunctions was easier than after the advent of the electronic fuel control system. Nevertheless, if you wish, you can also understand it in order to detect problems with the regulator and fix them yourself.

We carry out the adjustment ourselves

Niva 21213 can be subject to adjustment of the starting system by the gap at the edges of the valves, if the carburetor is removed, or by the crankshaft speed directly on the car. In the first case, the gap at the location of the lower edge (in the direction of air movement) from the throttle valve is set to a width of 1.1 mm. It is adjusted with a screw that has a 0.7 cm hexagon on the head and a slot from the shank. This operation is carried out with the cam lever turned counterclockwise from the starting system control (all the way). In the same position, the gap at the lower edge of the air damper is set to 3 mm using a screw in the cover from the diaphragm mechanism in the starting system (you need to loosen the lock nut). At the same time, the rod from the diaphragm must be forcibly recessed completely into the adjusting screw. After adjustment, the screw is fixed with a locknut.

Element location and operating principle

In fact, the term "sensor" is not very suitable for the name of this element, since it does not measure any parameters. It is more correct to call the device the idle speed controller VAZ-21214. This is a small unit with a stepper motor built inside, to which a retractable rod is attached. At the end of the rod there is a spring-loaded valve in the form of a cone, whose task is to block the cross-section of the channel where the air moves.

As in carburetors, the operation of an engine with an injector at idle is ensured by a separate system, where the main role is played by a regulator controlled by a controller. The air supply control unit has a special channel that bypasses the throttle valve. That is, the Niva’s power unit idles with the throttle completely closed, while air enters the injector through the bypass. This is where the VAZ-21214 idle speed sensor is located; its task is to increase or decrease the air flow passing through the bypass at the command of the controller. To start a cold engine, it is always necessary to supply an enriched mixture to the cylinders, and as it warms up, gradually deplete it to normal. Previously, the issue was solved by closing the primary chamber using a damper, which caused a vacuum to arise in the manifold and the engine drew in more fuel.

"Solex" and "Ozone"

The VAZ 2121 Niva model can be equipped with an “Ozone” carburetor with the serial designation 2107-110-7010-10 or 2107-110-7010-20. They differ from each other in that the first option has an old-style breaker and does not have a vacuum corrector. The second carburetor does not have a microswitch from the economizer, which affects the environmental friendliness of emissions and has some impact on fuel consumption.

This is the car part

The Niva 21213 is equipped with Solex type carburetors (model 21073-110-7010). They are considered quite “capricious”, which is primarily due to the negligence of the owners themselves. The incorrect operation of the device is primarily affected by low-quality fuel with a large amount of impurities, since in this model the fuel is taken through holes in the bottom of the float chambers (in other models these elements are raised above the bottom).

In addition, problems arise for those “nivovods” who do not promptly change the fuel or air filter, and also do not pay attention to proper cleaning of the carburetor from oil soot emissions through the ventilation system.

Adjustment of the VAZ carburetor is usually carried out in the float mechanism or in the starting and idle systems. These are very important operations that are best left to the experts.

The float mechanism on the Niva 2121 is adjusted in terms of the position of the floats relative to each other and relative to the walls of the float chamber. In addition, the mechanisms in the open and closed positions of the needle valve may need to be adjusted. In order not to disturb good adjustment, the car owner needs to carefully handle the carburetor cover when removing it, monitor the level of wear of the shut-off cone from the needle (its seat and tongue), as well as the axis of the mounting bracket.

We are looking for the reason why the idle speed on the VAZ 21214 floats

- The first thing I recommend paying attention to is the mass air flow sensor (MAF or flow meter). Read this article on how to check the mass air flow sensor.

- The second “suspect” usually becomes the idle air regulator (IAC), if after checking the flow meter you do not find anything, check the IAC.

- After this, inspect the wiring of the speed sensor (DS). Read how to check and replace the DS here.

- The next sensor that can cause floating idle speed is the crankshaft position sensor (CPS). The sensor itself is unlikely to have failed; most likely the reason is in the wiring or chip. If you don’t find anything strange in the wiring, check the DPKV.

- The throttle assembly can also often affect the idle speed, so it would be a good idea to check the TPS (throttle position sensor), as well as the throttle valve itself, it may need cleaning. How to clean the throttle valve I wrote here.

- Plugs, high-voltage wires and the ignition module can cause problems with idle, so first check the high-voltage wires, and then the spark plugs.

- Engine idle speed fluctuates often due to a faulty idle speed solenoid valve. To test this valve, remove power from it, then turn on the ignition and connect the power wire to the contact on the valve. In this case, you should hear a distinct click; if this does not happen, connect the wire to the contact that is connected to the “positive” terminal of the battery. Even if you do not hear a click, you can conclude that the valve is faulty. If there is a click, but the engine speed fluctuates as before, check its jet.

Among other things, check the condition of the air filter; it may need to be replaced. Make sure that the ignition system is working properly and that there are no air leaks.

If the tips and recommendations described above do not produce results or you are not sure that you can cope with such work, seek help from professionals; specialists will quickly and accurately determine the source of the malfunction and stabilize the floating idle speed of the engine.

Thank you for your attention, I will be glad if it helps someone. If you know other reasons or methods of verification, you can safely add to this article using the comment form. Until we meet again, take care of yourself and your car.

Didn't find the information you are looking for? on our forum.

We recommend reading:

- How to remove the catalyst on a VAZ 2114, as well as on a “classic”, “Kalina”, “Prior”, “Niva”

- How to check struts on a VAZ 2110

- VAZ 2114 valves knock when cold

- Gasoline consumption VAZ 2115 injector, city, highway, combined cycle

- How to check the oil pressure in a VAZ 2112 16 valve engine

- The dimensions on the VAZ 2110 are missing, the reason for how to repair it

- Replacing the throttle cable on a VAZ 2115

- How to install Euro handles on a VAZ 2107

NIVA.RU

Problem with idling. Diagnostics does not show errors, the check is not lit. Consumption has increased slightly. It didn't affect the dynamics in any way, but the engine was shaking at idle.

I went to see the injector: his verdict was that the injectors were clogged (mileage 38,500), everything else was fine. The injectors were washed - the problem did not go away.

The second injector also did not find any errors, he only said that the consumption at idle was too high, 1.17-1.20 instead of the required 0.9. He advised me to change the air flow sensor (I haven’t found such a sensor in stores yet :pardon: )

Over the weekend I cleaned the intake manifold and throttle body with a spray gun - it didn’t help. This weekend I'll try to clean it by removing the unit completely.

I also checked the clutch and brake position sensors, cleaned them, adjusted them - everything is the same.

Tell me, maybe someone has encountered this.

Re: Rough idle

- Quote

Post by Sunny » 12 Dec 2012, 09:13

Re: Rough idle

- Quote

Message by Slava N » 12 Dec 2012, 09:16

Re: Rough idle

- Quote

Post by airat13 » 12 Dec 2012, 09:24

Re: Rough idle

- Quote

Post by Ficus » Dec 13, 2012, 11:22 pm

Re: Rough idle

- Quote

Post by airat13 » Dec 17, 2012, 09:20

The new MAF sensor did not correct the situation.

Compression in all cylinders is normal, there is almost no variation among the cylinders, the fuel pressure is also normal.

If anyone needs it, on the fields with E-Gaz there is a Priorovsky mass air flow sensor, the end of the code is 225

Re: Rough idle

- Quote

Post by Sash » 17 Dec 2012, 09:29

Re: Rough idle

- Quote

Message by Slava N » 17 Dec 2012, 11:25

Re: Rough idle

- Quote

Post by ParaLanik » Dec 17, 2012, 5:37 pm

on my own Engels candles - and that’s what happened to me.

On DensoTT it became 1.0 (1.1).

On BKUR6ET-10 at idle it is 0.7 (0.9).

Two numbers because the difference is due to long driving in the city or on the highway.

Re: Rough idle

- Quote

Post by vm75 » May 28, 2013, 08:24

airat13 wrote: Auto Niva 212140M, E-Gas, Bosch controller (like 7.9.7)

Problem with idling. Diagnostics does not show errors, the check is not lit. Consumption has increased slightly. It didn't affect the dynamics in any way, but the engine was shaking at idle.

I went to see the injector: his verdict was that the injectors were clogged (mileage 38,500), everything else was fine. The injectors were washed - the problem did not go away.

The second injector also did not find any errors, he only said that the consumption at idle was too high, 1.17-1.20 instead of the required 0.9. He advised me to change the air flow sensor (I haven’t found such a sensor in stores yet :pardon: )

Over the weekend I cleaned the intake manifold and throttle body with a spray gun - it didn’t help. This weekend I'll try to clean it by removing the unit completely.

I also checked the clutch and brake position sensors, cleaned them, adjusted them - everything is the same.

Additional function of the regulator

An additional function of the device in question is to block the air flow in forced idle mode. This mode is activated when 3 conditions are met:

Under such conditions, it is impractical to supply the air-fuel mixture to the cylinders, since the car moves by inertia. So fuel will be wasted. Therefore, based on the damper and speed sensors, the controller stops the supply of fuel and air, giving the corresponding commands to the injectors and the idle speed controller. When the speed drops below 1800 rpm or the driver presses the gas pedal, the supply of the combustible mixture is resumed. If the driver switches the gearbox to the neutral position, the regulator opens the channel, and only idle speed is activated.

Operating principle of the idle speed sensor.

The idle speed sensor, otherwise known as the regulator (IAC), allows you to select the optimal crankshaft speed depending on the specified conditions. If this part breaks down, the rhythm of the engine’s operation is disrupted, since a sufficient amount of air does not enter the combustion chamber, or a too lean mixture is formed, as a result of which the engine speed begins to float, this is especially noticeable at idle speed.

The principle of operation is as follows: the air mixture flow sensor (MAF) determines how much air has entered the combustion chamber, after which the electronics calculates how much fuel needs to be supplied to the injectors. The engine speed is read by the crankshaft sensor (CPS), and if this indicator is low, the IAC increases the air supply, simulating pressing the gas pedal.

On the Niva 2123, the idle speed control is made in the form of a small electric drive with a spring and a rod ending in the form of a needle, which are enclosed in one housing. The IAC is attached to the throttle body. The sensor starts working when the key is turned in the ignition switch. At this moment, the rod rests against a special hole to count the necessary steps, after which the valve returns to its original position.

The speed sensor for Niva 21214 is based on the action described by physicist Hall. It reads electromagnetic pulses, which are then processed by the on-board computer. One kilometer of travel is equal to 6000 pulses sent by the DS, and if the speed increases, the frequency of the pulses increases. As a result, calculations occur in a special controller, which provide information to the instrument panel in a more convenient form.

And also interesting: Niva Chevrolet instrument panel designations. Improving the Chevrolet Niva dashboard

Engine operation at idle

Operating the engine at the lowest speeds is a very difficult mode for it. It’s worth starting with the fact that fuel and air are supplied very slowly into the combustion chamber, therefore, the formation of the mixture is ineffective. It is also worth considering that there is very little pressure in the engine intake manifold, so it is possible for exhaust gases to flow back into the combustion chamber. From this we can conclude that there is a decrease in efficiency, an increase in exhaust toxicity, and excessive wear of the elements of the cylinder-piston group. It is worth noting that the device does not have a very high price. The idle speed regulator costs about 400-500 rubles.

Replacing an element

Signs of failure of the idle speed element are very similar to the failure of the throttle position sensor, only in this case the “Check engine” display does not flash on the instrument panel. The car does not start well when cold, is unstable at idle and may stall when coasting. The regulator cannot be repaired; it only needs to be replaced.

The element is replaced in the following order:

- Disconnect all pipes from the throttle body, unscrew and remove this unit. Without this, dismantling the regulator is impossible.

- The element in the form of a barrel with a flange is screwed to the body with 2 screws. Unscrew them and pull out the regulator without losing the gasket.

- Measure the length of the rod on the new element, starting from the flange of the part; it should not exceed 23 mm. If the rod is longer, then you need to retract it, briefly applying a voltage of 12 V to the contacts marked “D” and “C”.

- Wipe the seat with a rag to remove dirt, lubricate the gasket with motor lubricant and install the new regulator in place.

After replacement, you need to install the throttle valve assembly back, connect the pipes and start the engine to check.