In order not to be a complete layman, even as a novice car enthusiast, we will look at this topic in more detail using the example of VAZ cars - the latest models of this amazing vehicle manufacturer. As they say, let's look under the hood, listen, smell, look and decide what can be done with such a domestic miracle of technology as Priora or Kalina.

Idle speed regulator Lada Kalina: operating principle and troubleshooting methods

Idle speed is an engine operating mode in which the gearbox is isolated from it. In this case, the throttle valve is in the closed position. This mode is designed to warm up the engine to the operating temperature of all ICE (internal combustion engine) systems. When the gas pedal is released, engine speed is maintained by the idle air control (IAC). It is this device on the Lada Kalina that ensures the supply of a minimum amount of air-fuel mixture to the cylinders.

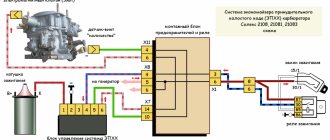

Reasons for a carbureted engine

Nowadays, fewer and fewer carburetor cars are produced, but they are still quite common in our country. Most of their problems, for example - maintaining high speeds and not reducing them, are similar to the problems of injection engines, so I start with carburetor ones. Video about this problem If such a problem occurs, the owner should immediately check the following details:

- Adjustment of the system that serves to maintain idle speed. Perhaps something was out of adjustment due to vibration, or they forgot to make adjustments after repairing the carburetor, or other procedures associated with it. If it was recently adjusted, it means that the ratio of the fuel-air mixture was not set correctly.

- Check the operation of the throttle valve; it may not open/close well, which is caused by carbon deposits on it. If necessary, the valve should be cleaned; if it is cracked or chipped, then replace it or the entire carburetor. Also check the free play of the damper control cable so that it does not jam or get snagged.

- When the needle valve is stuck, fuel flows unevenly, depending on the position in which it stops, the speed can either increase or decrease.

- The cylinder head gasket has burned out. This is just a replacement. The easiest way to check is by starting the engine, opening the hood and removing the radiator cap. White smoke coming from under it is definitely a gasket burnout.

- The choke does not close. To make sure of this, we check whether the damper located in the primary chamber is working. If it jams, then the issue is resolved by lubricating the damper and its cable.

This is the reason for the high idle speed of carburetor engines.

Don't forget about another probable reason for any type of engine, this is when the gas pedal in the car gets stuck and it does not return to its normal position.

Where is the IAC located and how does it work?

The Kalina idle speed sensor performs four main functions:

- Maintaining a certain number of engine revolutions.

- Providing conditions for starting the engine in winter at sub-zero temperatures. This means that the IAC can increase the speed so that the engine warms up faster. As operating temperature is reached, the speed gradually decreases.

- Maintaining minimum engine speed when the gas pedal is released. Many motorists underestimate this function until problems with starting and unstable engine operation begin.

- Creation of a fuel-air mixture with the required percentage of fuel and air. This ensures optimal fuel consumption and stable operation of the power plant.

Since the IAC is responsible for supplying air to the cylinders, it is located on the throttle assembly. The regulator on almost all naturally aspirated gasoline engines is located next to the throttle position sensor, and Kalina is no exception.

Reason 6. Pressure and air flow sensor

The car does not consume gasoline in its pure form, but converts it into a fuel-air mixture. Its quality determines how well the car will respond to pressing the gas pedal. If the sensors are broken, the calculations to create the optimal mixture will be incorrect, which means the car will lose traction.

Do not assume that a faulty sensor is indicated on the dashboard. If everything were easy, diagnosticians would not be useful as specialists. The car control system is programmed for a short circuit and for wire separation. If the reason is different, then you need to look for the breakdown yourself.

Operating principle of IAC

When the engine is running without increasing speed, that is, at idle, a minimum volume of air enters the combustion chambers of the cylinders. This occurs regardless of the throttle valve being in the closed position. The volume of intake air consumed is monitored and measured by the MAF (mass air flow sensor), which sends data to the ECU.

Based on the information received, the control unit supplies the required amount of fuel to the cylinders through the injectors. At the same time, the controller monitors the crankshaft speed using its position sensor (DPKV). According to the data obtained, the IAC needle opens or closes, controlling the air supply past the throttle valve, which at this stage is not involved in the operation of the engine.

If the engine has not yet reached the set temperature, the controller uses the IAC to increase the air supply, increasing the crankshaft speed to warm up the power unit faster. Thanks to this mode, the car can start moving almost immediately, without the need to reach operating temperatures.

Technically, the IAC is not a sensor, it is an actuator, so the controller cannot diagnose its malfunction. This means that the “Check Engine” icon will not light up on the instrument panel if the regulator breaks down. In their symptoms, IAC malfunctions are similar to TPS (throttle position sensor) malfunctions. But in the case of the latter, the icon will definitely light up, indicating engine problems.

RPM fluctuates when cold

When cold, the speed floats, with increased fuel supply to the cylinders for quick warm-up, when there is a leak of unaccounted air in the intake manifold, in case of problems with sensors (oxygen, throttle position, mass air flow, engine temperature sensor), low fuel pressure, faulty regulator idle speed and a number of others, depending on the type of engine. If the sensors are faulty, the ECU issues incorrect commands, which can cause the engine speed to fluctuate when cold.

Most of the problems, regardless of whether it is an injector, a carburetor or a diesel engine, are the same, but there are also some peculiarities that may be the reason why there are drops in speed when cold, and often when hot too. In short, all the reasons why the engine does not maintain speed when cold are displayed in the table, but if you need more specific recommendations for eliminating jumps in the speed of a cold engine, read the article and the comments to it, where car owners often share their experience.

| Cause of malfunction | Faulty node | Necessary actions |

| Injector | ||

| Atmospheric air suction |

| Check all the listed parts by pinching the hoses, using a compressor (compressed air), or a smoke generator |

| Engine sensor malfunction |

| Perform diagnostics of the listed sensors. If necessary, replace them with new ones. |

| Insufficient fuel to maintain engine speed | Perform diagnostics, cleaning or replacement of injectors. Fuel up with better quality gasoline. | |

| Problems with the ignition system |

| Check the operation of the listed elements. The spark plugs can be cleaned or replaced. Wires and coils are replaced with new ones. |

| Compression reduction |

| Perform a compression check in the cylinders, repair measures depending on the diagnosis |

| Low fuel pressure |

| You need to check the fuel pump, fuel filters (fine filters and mesh), and pressure regulator (the mesh may become clogged). |

| Carburetor | ||

| Not enough fuel or air | Incorrectly adjusted carburetor or clogged jets | Adjust the carburetor, select the optimal idle speed, and clean the jets. |

| Excess air intake | Dirty throttle valve | Clean the damper, check its drive |

| Aperture malfunction | Check and, if necessary, replace the unit | |

| Carburetor gasket | Replacing the node with a new one | |

| Solenoid valve | Diagnostics and, if necessary, valve replacement | |

| Diesel engines | ||

| Insufficient fuel pressure |

|

|

| Incorrect commands from the electronic control unit |

|

|

| Excessive exhaust gases in the intake manifold | EGR system | Check the EGR valve and the operation of the entire system. Correct it or properly suppress it. |

| Air in the fuel line |

| Check the listed elements, if there is a diesel leak, restore the seal, replace the fuel filter. |

Signs of IAC malfunction

Among the signs that directly or indirectly indicate incorrect operation of the idle speed sensor are the following:

- the engine does not start well - it becomes impossible to start the engine without pressing the gas pedal;

- when switching to neutral gear, “dips” in speed and their instability are observed;

- when changing gears, the speed drops or the engine stalls completely;

- the engine does not warm up well at low temperatures, since increased speeds (1500 rpm) are not reached;

- after turning on energy consumers (high beams, heater, air conditioner), the speed begins to “sag” or “float”;

- The engine spontaneously increases and decreases speed.

The IAC cannot be repaired; the device must be replaced. Before changing the idle air regulator, it is advisable to flush the throttle assembly.

How to check the regulator

There are a lot of ways to diagnose ICC. The most effective and simple methods for checking the Kalina idle speed control:

- Routine IAC testing for performance. To do this, the device must be removed from the throttle assembly and the terminal block connected if it was disconnected for dismantling. After this you need to start the engine. At the moment of startup, the needle of a working device should extend. If this is not observed, the regulator is broken.

- Checking the supply of the required voltage to the sensor. You need to disconnect the terminal block from the IAC and connect a voltmeter to the terminals. After this, one person turns on the ignition, and the second measures the resistance at all terminals of the block. If there are no faults, the voltmeter reading should be approximately 50 ohms. The voltage should be at 12 V. If it is significantly less, this indicates a battery malfunction or an electrical circuit break in one of the sections.

- Measuring the resistance of the internal and external windings of the regulator. To do this you need to use a multimeter. The measurement results should not be lower than 40 Ohms and higher than 80 Ohms. If you deviate from the specified range, the idle air control must be changed.

Troubleshooting options

It is clear that if any emergency situations arise with the motor, it is advisable to contact a specialized service. However, this procedure is not always possible. Therefore, it is worth knowing how to independently diagnose the main systems and key parts.

Throttle valve and assembly

When the speed drops at idle and the car stalls, you need to pay close attention to the details of the throttle assembly. Long-term operation of the car on low-quality fuel and untimely maintenance of the air filter can lead to malfunctions of the throttle valve. It periodically jams if debris gets into the equipment.

Throttle valve VAZ 2112

The problem can be solved by cleaning the system. The throttle is cleaned using carburetor cleaners. Using a compressor, you need to blow out the damper under the pressure of compressed air. It is not recommended to touch the screws located inside and on the side. If cleaning does not correct the situation, the device must be replaced. This operation is not particularly difficult.

Crankcase malfunction

There is an oil trap in the crankcase ventilation system of the engine. Its contamination can also lead to interruptions in engine operation. Crankcase gases do not allow the engine to function normally, the speed fluctuates, the internal combustion engine stalls.

Sensors

If a gasoline car stalls at idle, then one of the sensors is likely to break. In injection cars with an electronic engine control system, the engine usually starts normally, but then it stops working. It's worth checking here:

- Electronic car indicators;

- DRХХ – device that regulates idle speed;

- Air flow meter (air intake in the carburetor);

- Sensor indicating the position of the throttle curtain.

Electronic control unit in VAZ 2114

Interruptions in the operation of any sensors immediately affect the behavior of the electronics - errors appear in the car control unit. The “brains” of the machine receive unreliable information. It is not transmitted correctly to the engine. It starts working with parameters that do not correspond to reality. Self-testing of this device is not possible. You need to contact a professional for service.

Diagnostics of mass air flow sensor

The idle air control device is usually to blame for engine malfunction when the car idles poorly. But you pressed the gas pedal and the engine started. In the latest VAZ modifications, error information appears on the instrument panel.

When diagnosing, you must use a multimeter. If a part is faulty, it is recommended to replace it with a new one. All sensors are reasonably priced. It is better to start checking with parts that have a simpler design. Then gradually move on to complex devices. We must not forget that the problem may lie not only in the sensors themselves. It is also necessary to check the wiring to them and the presence of stable contact.

Carburetor

If the VAZ carburetor stalls at idle speed, then the jets may become clogged. Low-quality gasoline, deposits from the gas tank, contain small particles of debris. They can easily disrupt the operation of the fuel injection system. It is worth replacing the filter in front of the carburetor and cleaning the device itself. The dispensing part is cleaned using a cleaning solvent, which is sold in aerosol cans. Another reason is often a prolonged lack of carburetor adjustment.

In a mechanical fuel pump of carburetor cars, the filter mesh may be clogged with dirt. This reduces the performance of the device. Wear of the membrane and its destruction often leads to clogged carburetor channels.

Injector

A situation that often arises is that various Lada models, as well as the VAZ 2110 injector stalls at idle. It is necessary to check the fuel pump strainer for clogging. This is a common problem with injection machines. It is better to immediately replace the part with a working one.

Filter problem

If the VAZ 2112 stalls at idle, then the fuel filter may be dirty. This also applies to other models of the concern. Generally, it is not practical to clean it. The part must be replaced. The same should be done with a dirty air filter. Low throughput leads to the fact that the air-fuel mixture simply floods the spark plugs.

IAC cleaning

Do-it-yourself troubleshooting of the idle air regulator consists of simply washing it to remove carbon deposits. To do this you need to follow the instructions:

- disconnect the wire plug from the sensor;

- Unscrew the two fastening screws with a small shaped screwdriver and remove the sensor from the mounting socket;

- Clean the needle cone using WD-40 or carburetor cleaner.

The same means can be used to wipe the regulator contacts and the entire throttle assembly.

After cleaning, the IAC is installed back. In this case, you need to measure the distance from the end of the needle to the body - it should be approximately 2.3 cm.

Replacing the air flow sensor

The replacement procedure is as follows:

- First you need to loosen the clamp that secures the air duct, for this you use a Phillips-head screwdriver. The pipe itself can be dismantled.

- Disconnect the power connector from the regulator; to do this, simply press the latch at the bottom and pull the plug itself to the side.

- Next, using 10mm wrenches, you need to unscrew the two bolts. It may be difficult at this stage, so you can use a ratchet to unscrew the bolts quickly.

- The regulator can then be moved to the side and removed.

- The installation procedure is carried out in reverse order.

Operating principle of the throttle valve

This device reduces or, conversely, increases the air supply to the engine cylinders, enriching or leaning the mixture with fuel.

When the driver presses the gas pedal, the throttle valve opens, allowing more air into the combustion chambers. Oxygen is mixed with fuel, after which the prepared mixture burns. The more the driver presses the gas pedal, the wider the throttle opens and the more air flows in. But often carbon deposits accumulate on the walls of the damper, and its loose closure causes disturbances in the operation of the power plant.

The throttle assembly is located behind the engine air filter. This arrangement is typical not only for the Lada Kalina, but also for many other cars. Depending on the engine type, the damper operation can be controlled by an electronic gas pedal or a cable drive.

Removing the throttle

Before cleaning this device, it must be removed. You can wash it without removing it, but this method is less reliable and effective. The dismantling process is as follows:

- Disconnect the air pipe that goes from the air filter directly to the throttle body.

- Remove the throttle cable drive.

- Disconnect the throttle body heating hoses that supply coolant - it is best to carry out the work on a cool engine. To avoid draining antifreeze, these hoses can be plugged.

- Disconnect the terminal blocks from the throttle position sensor and IAC.

- Unscrew the 4 fastening nuts and remove the throttle assembly assembly.

This completes the dismantling. The work is not difficult, even a beginner can do it.

Cleaning the damper

Using cleaning products, you can wash the damper at home. Additionally, you will need several pieces of clean rags. Algorithm for the cleansing process:

- After dismantling the throttle assembly, you need to remove the idle speed control and TPS, as well as all accessible rubber seals, since the cleaning agent is quite aggressive and can corrode them.

- Typically, cleaning fluid comes in an aerosol can. The jet must be directed to the damper, all air channels and internal walls. External cleaning is not necessary.

- After treatment, you need to wait 10-15 minutes for the product to eat away carbon deposits and dirt.

- Next, wipe the surfaces with a rag; if the surface is heavily soiled, the treatment can be repeated.

Never use metal brushes or other abrasive materials to clean the throttle body. The internal surface of the unit is coated with molybdenum, damage to which can lead to metal oxidation and corrosion.

conclusions

Floating idle speed of the Lada Kalina engine can cause other, more serious problems to appear. So, if such an effect occurs, it is necessary to find the cause and eliminate it. If you can’t do it yourself, you need to contact a car service, where they will quickly find and fix the problem. Repeatedly, due to the constant effect of floating speed, car owners have had to change the electronic control unit.

Many car enthusiasts have come across the concept of floating engine idle speed. For the Lada Kalina, as practice shows, this is a common malfunction that can be fixed with your own hands, but sometimes you will need to use a car service.

RPM fluctuates at idle

After talking with car owners, as well as with car service technicians, we can conclude that floating engine speed on a car is a fairly common effect. As a result . Most car enthusiasts assure that this malfunction appears during warranty service.

This may be due to many factors.

Let's consider the main reasons for the occurrence of floating engine speeds:

- Fuel system malfunction

.Malfunction of fuel system elements

- Ignition problems

.Problems with the ignition switch or wiring

- ECU errors

.Troubleshooting ECU errors

- Poor quality fuel

.Low-quality gasoline directly affects the operation of the power unit

All these reasons contribute to the appearance of such an effect. The most common reason is problems with injection.

Treatment methods

Before moving on to correcting the problem, it is worth noting that floating speed is just the beginning, since untimely elimination of the malfunction can lead to a “start-stall” effect.

So, let's consider the sequence of actions to eliminate the causes of floating engine speed.

Fuel system

As practice and experience show, floating speeds appear in the event of an uneven supply of fuel to the combustion chambers, or a constant change in the amount of the fuel mixture.

Cleaning a removed injector

First of all, this is due to the injectors, which may be dirty. At the same time, this may not be felt when driving, but at idle the tachometer will immediately show it. Therefore, it is necessary to dismantle and check the injectors on a special stand.

Clean fuel pump mesh

Also, the malfunction may be caused by a breakdown of the gasoline pump, which does not supply fuel evenly or a clogged fuel filter. If necessary, you need to replace the filter element and check the fuel pump.

Cleaning the throttle body

A change in the amount of fuel mixture may be due to a clogged throttle or worn air filter. Therefore, the filter element changes, and...

Removed throttle before and after cleaning

Ignition problems

Problems with idle speed may occur due to incorrect operation of the ignition system. Namely, it may be related to the lock or wiring. So, it is worth checking and, if necessary, replacing damaged elements. It is best to change the ignition switch assembly and test the wires that go from it to ensure they are working properly.

ECU errors

Often, a car malfunction is associated with, as well as a malfunction of the controllers on the board. Of course, another reason could be the firmware that is out of order. Many car enthusiasts change the operating system, but this does not always help.

ECU removed from the vehicle

As practice shows, an ECU malfunction can pose a problem for the performance of many systems. Therefore, if the fault cannot be eliminated using the previous methods, it is necessary to replace the control unit. Of course, installing the operating system from the Lada Kalina Sport K-Line can help, but the problem does not always disappear completely.

Poor quality fuel

In many cases, poor quality of the fill can cause clogging of the fuel pipeline and injection system, which in turn gives the effect of uneven fuel supply. To eliminate the malfunction, you should drain the old fuel, clean the fuel system and fill in with new high-quality gasoline.

It is worth understanding that not only the operation of the engine, but also its durability depends on the quality of the fuel.

Replacing the idle air control

To do the job you only need a shaped screwdriver. If dismantling involves removing the entire throttle assembly, you need to prepare a set of standard socket wrenches or sockets.

- First, wait until the engine has cooled down, after which you can disconnect the terminals from the battery.

- The clamps must be removed from all hoses.

- From the idle speed control and throttle position sensor, disconnect the wire chips and remove the throttle cable.

- The throttle heating hoses must be removed and plugged.

- Use a 13mm wrench to unscrew the fastening nuts, then the throttle assembly can be removed.

- Next, all that remains is to unscrew the two screws holding the idle speed control and remove it. A new IAC is installed in its place and secured with two screws.

Tips and tricks

Let's look at how you can eliminate some of the malfunctions that lead to floating and speed jumps, and do it yourself.

- As mentioned above, the leakage of excess air can cause surges. To exclude or confirm the possibility of supplying such air, you need to check the tightness of the air supply system to the intake. You can remove the air hose and feed it air from a compressor or pump by placing the hose in a container of water. This method helps to identify cracks.

- As for the idle air control, you need to measure the resistance with a multimeter. If the resistance is between 40 and 80 ohms, this means that the device is not working.

- Also, as part of diagnostic procedures, in some cases it is necessary to clean the crankcase ventilation valve. The valve must be removed and washed with carburetor cleaning fluid or kerosene. This approach will remove deposits from the valve.

- As for the ECM sensors, in this case it is not advisable to try to repair such elements. For example, if the mass air flow sensor is faulty, it is better to immediately replace it with a new one.

- It is better to trust specialists to flush the throttle valve without proper experience, especially if such flushing is necessary with the removal of the valve. If we talk about the method of flushing the throttle without removing it, you can do the procedure yourself. The hoses are disconnected from the valve, then a cleaning aerosol is injected into the throttle.

The main thing is to disconnect the electrical contacts from the throttle valve. Let us add that on many cars where the damper was heavily dirty, you then need to additionally set the correct opening gap of the damper or “teach” the throttle using the appropriate equipment.

- On a car with a carburetor, you need to adjust the idle speed by setting it with the quality and quantity screws on the carburetor. The idle jet may also need to be cleaned. To do this, it is often enough to inject a carburetor cleaning aerosol and then blow it with compressed air.

According to drivers, this helps protect the pump from corrosion and is a preventative measure. At the same time, we note that this method is suitable for construction equipment and it is highly not recommended to practice such solutions on modern diesel internal combustion engines.

Idle speed sensor Lada Kalina 16 valves

The idle speed control is designed to maintain engine operation when the gas pedal is released, namely supplying a minimum air and fuel mixture to the engine. The incorrect operation of the IAC can be judged by the following criteria:

- Difficulty starting the engine without the gas pedal or not starting at all.

- When the car is parked at neutral speed, the speed fluctuates.

- When changing gears, the car stalls or the speed drops to a minimum level (almost stalls).

- When warming up in cold weather, the engine speed does not rise to 1500.

- When you turn on electrical appliances (stove, light, heated glass), the engine speed drops too much.

- Spontaneous increase and decrease in engine speed, as well as freezing of engine speed that differs from the normal value.

Personally, I had a problem in the heat with the air conditioner running; when I released the gas, the engine would stall or the speed would drop so much that engine detonation appeared and the engine oil pressure light came on. If the regulator is not working correctly, the check engine light does not light up.

If your car has already traveled a lot of kilometers, more than 50 thousand, then it is advisable to first flush the entire throttle assembly and, based on the results, proceed to replacing the regulator itself.

The idle air control valve cannot be repaired; it is easier and faster to change it.

How it happens in reality

You leave the house, get into the car, start the engine and then bam! – the idle speed begins to jump like mad, then rising to 3 (or even 4 thousand), then dropping to a thousand revolutions per minute or less, until the car finally stalls.

However, the situation can develop completely differently: sometimes these surges can just as suddenly disappear after a short warm-up of the engine, but it also happens the other way around - you’ve been driving for a long time, you stop at a traffic light, for example, and then pandemonium begins.

Replacing the idle air control (IAC)

To replace the idle speed control, you need to turn off the engine and it is advisable to disconnect the power from the battery.

The regulator itself is located on the throttle assembly, below the throttle position sensor.

To replace it, you need to disconnect the plug and unscrew 2 bolts, then pull it out of the seat.

Here is the catalog number of the sensor, analogues are possible.

Installation in reverse order.

On a new regulator, do not move the rod itself under any circumstances, this will lead to its breakage.

When you first start it, the revolutions will most likely jump above 1500, don’t worry, you just need to turn off the car and start it again. The machine program adjusts its parameters to the new controller.

Mileage 54100 km. Many people clean much earlier. There are no problems with idle speed (except that the BC shows from 800 to 880 rpm periodically - it pumps up the engine a little).

I decided to look at the structure of this device not in pictures, but live (it’s also much more informative). Well, and carry out preventive cleaning of the throttle assembly.

What we need: 1. Carburetor cleaner - 130 rubles (used about 5%) 2. compressor (can be done without it) 3. A little time. 4. Direct hands are welcome!

1. The throttle assembly itself.

2. We begin removing the assembly. We unscrew the clamps that secure the hoses (4 small ones and one healthy one for the air intake). We disconnect the pads from 2 sensors: IAC and TPS. Remove the throttle cable. We fix the antifreeze supply hoses upward so that there is no antifreeze leakage. And unscrew the two nuts with a 13mm wrench.

FakeHeader

Comments 21

When the rpm drops to 600 - is it once every about 30 seconds or constantly?

Once every 1-2 seconds

Then it's definitely not an adsorber. If the AIR fitting of the canister is clogged, then when the canister valve is opened, air will be driven out of the tank (the speed will drop exactly once every 30 seconds), but the canister works for no more than 3-4 seconds, after which it turns on again only after about 20-30 seconds. You can safely cross it off the list.

I’m having this problem myself now, but I have it once every 20-30 seconds, and that’s exactly when the adsorber valve opens for purge. I disconnected the hose from the adsorber going to the valve, the speed stopped falling. It seems to me that this is exactly the situation when the AIR on the adsorber is clogged with dirt or coal. The valve opens and, instead of fresh air, draws gasoline vapor directly from the tank, then the rpm drops to 500 and a sharp rise to 1200. The valve closes and everything is fine until the next opening. =(

And what should I do with it so that the revs don’t fluctuate?

When the rpm drops to 600 - is it once every about 30 seconds or constantly?

And so on constantly in neutral until you turn it off. The voltage in the onboard after a drop in rpm also drops to 13.6 and rises with the rpm

The revs are fluctuating - first of all, look for air leaks. Whistling occurs more often. Possible places: a rubber plug on the intake manifold, a stuck absorber valve, a vacuum booster, stiffened injector rings and intake manifold seals at the joints. Everything is checked by clamping the pipes or temporarily replacing them with plugs. That is, for example, you pull out the vacuum pipe from the manifold and stupidly plug it with your finger, etc.

I have the same problem, but only in winter you stop at a traffic light and the revs start to float, also e-gas, the check does not light up, I changed the spark plugs, it helped, the factory spark plugs lasted 3000 km, new ones for another 4000 km, then I installed NGK, so far it’s ok