One of the malfunctions that occurs most often and interferes with the proper use of the car is considered to be violations in the operation of the idle speed sensor of the VAZ 2112 and its varieties. This mechanism is known among car owners by the name sensor, but its more correct name is regulator (IAC), this is determined by the fact that every sensor in a car is considered a device that determines various indicators. And the mechanism in question is used to control and stabilize idle rotation, applying the rule of oxygen supply to the VAZ 2112 engine, with the throttle valve tightly closed

Idle speed sensor VAZ 2110 (IAC): repair and replacement

General concepts

One of the most common troubles that prevents you from fully driving a car is the idle speed sensor of the VAZ 2110 and modifications. Although this device is called a sensor among drivers, it will still be correctly called the idle speed controller, abbreviated as IAC, because all automobile sensors are measuring equipment, and this product serves to automatically stabilize and maintain idle speed by supplying air to the engine VAZ 2110 with the throttle valve fully closed.

IAC is an important component of the engine and plays a significant role in the stable and uninterrupted operation of any VAZ vehicle.

Idle speed control

The VAZ 2110 idle speed sensor (abbreviated DXX) is an actuator, simply a valve consisting of an electric motor, a spring, and a rod on which a shut-off needle is installed (you can see it in the photo). It is through which the volume of air is dosed. That is, when the throttle of a VAZ 2110, 2112 is completely closed, and the controller determines that the idle speed needs to be increased, the IAC generates a command to change the position of the needle. It moves, partially or completely opening the intake port, through which air bypasses the throttle and then mixes with fuel. As a result, the engine does not stall.

Reasons why revolutions fluctuate

As mentioned above, there are quite a few reasons for floating engine speeds, and it will take a lot of time for a person who does not understand cars to find the reason. Below are all the possible reasons why a car engine begins to work unstably, and its speed begins to jump chaotically, so that the tachometer needle can drop to almost zero.

Air leak in the system

As you know, for an engine to operate, it requires not only fuel, but also air. These two substances mix with each other and form a fuel-air mixture. This mixture must be formulated within strict parameters for proper and stable operation of the engine; if any of the parameters are violated, the engine begins to run unstable.

Air enters the car engine through rubber and plastic tubes, which are joined with special fittings, clamps and pressed with bolts through special O-rings. All air supplied to the internal combustion engine is taken into account by special sensors that send a signal to the engine control unit; as soon as unaccounted air appears in the system, the fuel mixture is formed incorrectly, which leads to unstable engine operation.

Most often, air leaks occur in the following places:

- At the junctions of the inlet pipes;

- At the junction of the receiver and the cylinder head;

- In the sealing rings of fuel injectors;

- On the throttle assembly.

If the speed of your car begins to fluctuate, you need to check the engine for air leaks, and this can be done at a service station using a special smoke generator or by holding the inlet pipe with your hand, then the engine should stall and the pipes will shrink. If the engine does not stop, it means there is a strong air leak in the system.

Idle speed control

This part is responsible for supplying air in idle mode when the throttle valve is closed, that is, the gas pedal is not pressed. This sensor opens a special channel in the throttle valve through which air enters the system.

The sensor has many design flaws, namely, the principle of operation is based on a worm gear, which often becomes dirty and disables the sensor, thereby causing the engine to operate unstably.

The idle speed regulator is installed on the throttle valve of the car engine, through a special sealing ring, which also quite often dries out and begins to let air through, which leads to air leaks.

It should be noted that IAC affects engine operation only at idle speed.

Throttle position sensor

The TPS is installed on the throttle assembly and serves to determine the angle of rotation of the valve inside the throttle. Thanks to this part, the engine control unit understands how much the throttle has opened and how much air will flow into the engine. Such a sensor is made on the principle of a resistor, which changes its resistance as the bar moves. When the throttle opens, a slider moves along special tracks on the sensor.

The main reason for the failure of this part may be the rubbing of these tracks, which will lead to unstable operation of the internal combustion engine.

When the TPS fails, the engine speed begins to jump from 500 to 2500 rpm.

Throttle valve

The throttle is a part inside which has many mechanisms and channels through which air flows. Contamination of these channels can seriously affect the operation of the entire internal combustion engine. Quite often, engines with high mileage experience contamination of the throttle assembly, which leads to improper air supply to the engine. Because of this contamination, engine operation becomes unstable, and the speed begins to fluctuate.

This problem can be solved quite simply by washing the throttle with carburetor cleaner.

Mass air flow sensor

The air flow sensor (AFS) is used to count the air supplied to the engine. He does this through a special sensitive element that reads the amount of air. It happens that this particular element becomes dirty or becomes covered with plaque over a long period of time, which prevents it from determining the exact amount of air in the engine. Sometimes a problem with the mass air flow sensor can be solved by cleaning it, but this does not always help.

You can read more about how to check the mass air flow sensor here.

Signs of IAC malfunction

Unfortunately, the 2110 VAZ DXX is not equipped with a self-diagnosis system, so the “CHECK ENGINE” light signal will not indicate a malfunction. Loss of performance on the VAZ 2110, 2112 is determined by the following main features:

- the engine “stalls”, for no apparent reason, at idle;

- idle speed “floats”;

- when a “cold” VAZ 2110, 2112 engine is started, there is no increased speed at all;

- The engine stalls, namely, after turning off the gear while driving.

The symptoms completely coincide with the failure of the VAZ 2110 TPS, but in the case of this sensor the “CHECK ENGINE” indicator will light up.

Types and designs of IAC

The appearance of the sensor resembles an electric motor with a conical needle. The device is responsible for supplying the required amount of air bypassing the throttle valve at idle.

There are several types of such sensors:

- Solenoid based. This is the simplest version of the device. When voltage is applied to the windings of the device, the core is triggered and placed in a special socket to reduce the diameter of the passage channel. As a result, the air supply volume becomes smaller. This regulator is inexpensive due to its simplicity of design. This device only works in the closed or open position.

- Stepper. It includes windings and a ring magnet. The rotation of the main rotor occurs due to the stepwise supply of voltage to all structural elements under the influence of electromagnetic force. The opening of the air duct is controlled by an actuator depending on where the rotor is located.

- Rotary. The air supply is regulated by alternating frequency pulses. The sensor design is similar to the PXX solenoid. The main role in the design is played by the rotor.

Read with this

How to remove IAC

If signs of malfunction characteristic of the IAC are detected, then it will need to be removed (first for inspection). On the VAZ 2110, this sensor, which is small in size (easily fits in the palm of your hand), is located in a seat on the throttle body (can be seen in the photo).

Removing the idle air control

If necessary, its dismantling is quite easy - it is secured with only two screws. In extremely rare cases, it is necessary to remove the entire VAZ 2110 throttle assembly.

Dismantling is carried out in the following sequence:

- The VAZ 2110 is placed on the handbrake;

- The negative terminal of the battery is disconnected;

- The wiring harness connected to the IAC is disconnected;

- Be sure to clean the connection between the sensor and the throttle body to prevent dirt and rust from getting into the hole;

- Unscrew the fastening screws holding the idle speed sensor of the VAZ 2110.

How to check the sensor?

If you have a tester, checking is easy:

- Set the VAZ 2110 to the handbrake;

- Disconnect the IAC connector to check;

- Check the voltage of the VAZ 2110, 2112 sensor circuit, while connecting the “minus” to the engine, the “plus” to the removed block, namely to terminals A: D (marked on the block, you can see the diagrams);

- The ignition is turned on and the readings given by the idle speed regulator are checked, which should be about 12 V. The value will be less - most likely the battery is discharged. When there is no voltage, it is necessary to check the entire circuit, and then the electronic control unit. There are no malfunctions, which means the circuit is working - the IAC installed on VAZ 2112 engines and other modifications are checked;

- The tester terminals are connected to the block, the circuit is as follows - first to terminals A: B, then to C: D. The resistance should be within 53 Ohms;

- Next, pairs A: C, B: D are checked - in this case, the resistance on a working product will be infinitely large.

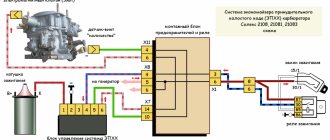

IAC diagram

When, as a result of these checks, the sensor reveals a discrepancy in the readings, it should be replaced. Also, the inoperative state of these VAZ 2110, 2112 engine sensors, in the unscrewed position, can be checked by attaching a block to them, then you need to turn on the ignition.

When the power is connected to the working product, the rod with the needle will change position. No changes will occur on a broken sensor. If a breakdown of the idle air regulator is detected, of course, it must be repaired. But there is no need to rush to a car service center - you can do the repairs yourself, saving money and time. But first, in general, it is worth cleaning the IACs; often after this they return to “life”.

How to replace the regulator?

When replacing the idle speed sensor on a VAZ-2112, you must follow the following sequence of actions:

- First, turn off the engine, let it cool a little and disconnect the negative terminal from the battery.

- Disconnect the plug from the regulator.

- Unscrew the bolts securing the device body and remove the regulator.

- Install the new device in reverse order.

The setup procedure looks like this:

- Connect the power wires to the regulator.

- Be sure to tighten all fasteners as tightly as possible.

- Perform calibration after connecting the battery. To do this, just turn on the ignition, but do not start the engine.

Calibration consists of the fact that when the ignition is turned on, power is supplied to the IAC winding, the rod moves from one extreme position to another, and the electronic control unit remembers the number of rotor revolutions. Nothing complicated, simple electronics. Once you have completed the calibration, you can begin operation. If during the repair you see that the hole is very dirty, clean it with special sprays. And only after that can you install a new regulator.

IAC cleaning

It is recommended to wash and clean any non-working idle speed sensor on the VAZ 2110 to make sure it is faulty. The process is very simple and will not take much time. To do the job you need: carburetor cleaner, WD-40. The following actions are performed:

- The block is removed from the sensor;

- Apply any of the listed cleaning liquids to a regular cotton swab and carefully treat the contacts;

- Unscrew the screws securing the idle speed sensor;

- Remove the IAC from the seat;

- Inspect the idle speed sensor. If black dirt, oil, or IAC are detected, it is necessary to clean the entire throttle assembly. If not, spray WD-40 or cleaner onto the needle with a spring, thereby cleaning it. Dry the idle speed sensor VAZ 2110, 2112;

- Before reinstalling, measure the distance between the idle speed sensor housing and its needle, which on a working regulator is 23 mm.

When the IAC VAZ of the tenth family did not work normally, the guide needles wore out and the wire inside the housing broke. In these cases, the idle air regulator must be replaced.

On a VAZ 2110, the idle speed sensor is mounted in the reverse order of dismantling.

Didn't find the information you are looking for? on our forum.

If you find an error, please select a piece of text and press Ctrl+Enter.

We recommend reading:

How to drain gasoline from grants, several waysVAZ 2114 stalls on the move when the clutch is depressedExhaust on a VAZ 2110 8 valvesOn a VAZ 2106 why the low beam does not workReplacing the outboard bearing on a VAZ 2107Replacing a radiator heater on a VAZ 2114Where is the speed sensor on a VAZ 2110Ephh VAZ 2109 carburetor wiring diagram

Similar articles

What kind of oil to pour into the VAZ 2115 engine? Choosing oil for the VAZ 2110 VAZ color chart, codes, names, descriptions VAZ error codes - table with a list of all errors

Car : VAZ-2112. Asks : Ivanov Sergey. The essence of the question : How to replace the idle speed control?

Good afternoon Tell me how to solve my problem! On the VAZ-2112, the speed began to fluctuate, when the car is idling, it stalls. I was told that the problem could be with the idle air control. Tell me how to replace it?

How to change a part?

Replacing the throttle position sensor in a VAZ of the “tenth” family and Lada Priora is quick and easy. But there is one question - what type of sensor should I choose? The fact is that new contactless elements of increased reliability and equally high cost have appeared on the market.

They do not contain a resistive film, and use the principle of magnetic induction to operate. So, if possible, it’s better to put one in your “top ten” and forget about the troubles with TPS for a long time.

The replacement operation is performed as follows:

- Disconnect the battery and disconnect the sensor from the connector.

- Unscrew the mounting bolts and remove the part. Don't lose your foam pad unless you have a new one.

- Install the new element with gasket and connect all wires.

If diagnostics and replacement are carried out correctly, then engine operation should stabilize in all modes.

Hi all! I hope the information from this post will be useful and will be useful to someone! Good luck on the roads and a full tank!

The “symptoms” of a faulty throttle position sensor include the following:

1. Increased idle speed. 2. The engine stalls in neutral gear. 3. Idle speed floats. 4. Jerks during acceleration. 5. Deterioration in dynamics. 6. In some cases, the Check Engine light may come on.

Diagnosis of the throttle position sensor is carried out as follows:

1. Turn on the ignition, then check the voltage between the slider contact and the minus with a voltmeter. The voltmeter should show no more than 0.7 V. 2. Next, turn the plastic sector, thereby fully opening the damper, then measure the voltage again. The device should show at least 4 V. 3. Now turn off the ignition completely and pull out the connector. Check the resistance between the slider contact and any terminal. 4. Slowly, turning the sector, monitor the voltmeter readings. Make sure that the needle moves smoothly and slowly; if you notice jumps, the throttle position sensor is faulty and must be replaced.

Replacing the throttle position sensor:

1. Disconnect the wire from the “–” terminal of the battery. 2. Disconnect the block with wires from the throttle position sensor by pressing the plastic latch. 3. Unscrew the two mounting screws and remove the throttle position sensor from the throttle pipe. 4. Install the new sensor in the reverse order, but do not forget about the foam ring. The throttle position sensor does not require any adjustment, since the controller perceives idle speed (i.e. completely closing the throttle valve) as zero. A faulty idle speed sensor can be attributed to the following:

1. Spontaneous unregulated change in engine speed (sudden decrease or increase). 2. When turning on a “cold” engine, there is no increase in speed. 3. When using additional vehicle devices (heater, headlights), the idle speed is simultaneously reduced. 4. The engine stalls at idle and when shifting gears. It is necessary to remember that the readings of the VAZ 2110 injector idle speed sensor are not “readable” by the automatic on-board power system, and it is not integrated into the “Check Engine” alarm system.

Diagnostics of the idle speed controller is carried out as follows:

There are several ways to analyze the idle speed sensor, but the main ones - the simplest and most effective - are the methods described below:

1. First you need to “get” to the device, disconnect it from the connecting block of wires 2. Using the most common voltmeter, check for the presence of voltage - the “minus” goes to the engine, and the “plus” to the terminals of the same block of wires A and D. 3. Turns on ignition, and the received data is analyzed - the voltage should be within twelve volts, if less, then most likely there are problems with the battery charge; if there is no voltage, then you will have to check both the electronic control unit and the entire circuit. 4. Then we continue the inspection with the ignition on, and analyze terminals A:B, C:D one by one - the optimal resistance will be about fifty-three ohms; During normal operation of the IAC, the resistance will be infinitely high.

Sensor design

The following two tabs change content below.

By design, the idle speed sensor is a special valve, at the end of which a shut-off cone needle is mounted. The main task of the IAC is to dose the required amount of air that enters the combustion chamber while the engine is idling. This prevents the system from stalling, since the crankshaft rotation speed is adjusted.

How to choose a sensor for a VAZ-2112?

The VAZ-2112 is supplied with two different types of idle speed controllers under the article numbers: 2112-1148300-02 - produced by KZTA (Kaluga) and 2112-1148300-01 - produced (Kostroma).

Sensor

However, besides them, you can also find analogues from other manufacturers on the shelves, for example: 2112-1148300-04 and 2112-1148300-03 , as well as Omega (Moscow) - 2112-1148300.

The most popular among owners of VAZ-2112 (Moscow) and KZTA (Kaluga).

Sensor from

Please note that when purchasing such sensors you should beware of counterfeits. Look carefully at the quality of the fonts on the packaging and the presence of special hologram stickers on the product. As for its mechanical part, all elements must be reliably connected to each other, there must be no play in parts and all kinds of gaps.

Characteristic differences between a fake and an original

- The body of counterfeit products is 1 mm smaller than that of the original.

- The counterfeit spring is white and has more frequent coiling, while the original spring is black and is equipped with more rare coiling.

As an example, the top is fake, the bottom is original. - The rubber ring on the counterfeit is black and thinner in size; on the original, the rubber ring is thick and has a reddish tint.

- The needle tip on low-quality products has the darkest color.

- The packaging has visible differences that are not immediately noticeable, so it is necessary to inspect it more carefully.

Without paying attention, you can take a fake.

Where is the regulator located?

Idle speed sensor close up on an editorial VAZ-2112 (124 engine)

The idle speed sensor is located on the throttle body (TVB), below the throttle position sensor. It is secured with two crosswise screws.

IAC on the throttle assembly

Checking the idle speed sensor

In order to check the functionality of the IAC, we suggest you read this article, where it is written about this in great detail.

Sensor replacement process

It is necessary to replace the idle air regulator in the following order:

- First of all, disconnect the negative terminal from the battery.

- We press on the plastic latch that holds the sensor power supply and remove it.

When the block is removed, all that remains is to unscrew the bolts. - Next, using a small screwdriver, unscrew the two screws, the order does not matter.

- When the regulator is dismantled, we check it for functionality, or simply replace it with a new one.

The sensor has been removed from the seat - We tighten all the bolts into place, and then connect the power supply.

Idle speed sensor VAZ 2112

The idle speed sensor (idx), or more correctly called the “idle speed controller” (irx), is designed to stabilize and automatically adjust the idle speed. The idle speed sensor is an electric motor with a tapered needle.

Table of contents

Where is it located How to check Replacement Signs of malfunction

Where is

The idle speed sensor is located on the throttle body. The idle speed sensor is located next to the throttle position sensor. The DXX is secured with two screws. It also happens that the sensor is mounted on the varnish.

What to do, the phase sensor is faulty.

How to check the engine temperature sensor using the link.

How to check

There are several ways to test the sensor. The first is checking with a multimeter. You need to turn off the ignition. Disconnect the block being tested from the regulator. To do this, you need to disconnect the connector of the block. And then the integrity of the IAC windings is tested using a multimeter. The instructions for using the multimeter describe all the necessary steps.

Second way. Checking with a homemade tester. Not all cars can be tested with a multimeter. For example, in cars with an injection system it is difficult to check and the readings will most likely be inaccurate. The main failure of the regulator is coking. If the screw pair is coked, the unit begins to periodically jam, which means that the engine will run unevenly in idle mode.

There are special testers for checking IAC, but purchasing them is not cheap. And why buy it? It is quite possible to make such a tester yourself. Take a regular transformer operating with a voltage of 6 volts. This voltage is supplied by a regular mobile phone charger. For reference, the current is alternating. Using such a simple tester, you can test the forward and reverse stroke of the IAC.

An indicator of the health of the unit will be the light of the light bulb. If the rod is jammed inside the regulator, the light from the bulb will be bright. It is necessary to either clean the unit or replace it. If the light is dim, then everything is in order - the IAC is working.

Replacement

With the ignition off, disconnect the regulator connector.

Using a Phillips screwdriver, unscrew the two screws securing the regulator to the throttle assembly.

For clarity, we perform this operation on a dismantled throttle assembly.

We remove the idle speed regulator VAZ 2112.

Before installing the regulator, clean the valve seat, air channel and the surface for the regulator's o-ring in the pipe.

When installing a new regulator, the distance between the end of the valve needle and the mounting flange should be no more than 23 mm.

Before installation, lubricate the regulator O-ring with engine oil. The tightening torque of the regulator fastening screws is 3–4 N•m.

Checking the sensor yourself

To dismantle the IAC, you need to disconnect the block and unscrew two screws.

Before dismantling, you need to thoroughly clean the place of its attachment from dust and dirt and remove the negative terminal from the battery. But first, a check.

Sensor connection diagram.

We look at the connection diagram and check the sensor using a conventional multimeter in the following sequence:

- Check for power supply to the sensor. To do this, measure the voltage at the two outer contacts of the block, A and D. Turn on the ignition, place the black probe of the multimeter on the engine ground, and the positive probe on the contacts one by one. The voltage should be within 12 Volts. If it is less or absent altogether, we look for an open circuit or blame the electronic control unit for everything. But first, we check the voltage at the terminals from ECU 4 and 54. Here, naturally, there should also be 12 V.

The voltage is normal.

It cannot be said that this testing method 100% guarantees the functionality of the sensor; we only checked its electrical part. The mobility of the cone valve and the magnitude of its stroke are of great importance. And this can only be checked either at a special stand or with a special tester.

Checking the operation of the mechanical part of the sensor

To check, remove the sensor from the throttle assembly.

However, if the electrical part is in order, you can check the mechanical part of the regulator by eye:

- Unscrew the sensor and remove it from the throttle body.

- We connect the contact block to the sensor.

- Turn on the ignition. When turned on, the valve should move forward. If this does not happen, the rod is coked or the stepper motor is not working properly.

- We measure the distance between the sensor body and the conical valve - nominal 24 mm.

We measure the distance with a caliper.

If we removed the sensor from the car and the electrical test passed, but we still did not achieve mobility of the cone valve, we try to clean the regulator using a soft swab, a cotton swab and WD-40 penetrating lubricant or an aerosol carburetor cleaner. Good luck to everyone and stable idle speed in any weather!

Source