Print this article Font size 16

If there are problems with the operation of the idle speed sensor, difficulties may arise with controlling your VAZ 2109. To determine the breakdown and learn how to correctly change the sensor, we will introduce you to the basic principles.

Appearance of the device

Principle of operation

It is not entirely correct to call the idle speed sensor a sensor. After all, they are measuring instruments that process and convert information, displaying it on mechanical or electronic indicators on the dashboard.

Alas, the self-diagnosis systems on the VAZ 2109 are not perfect, therefore, if the idle air regulator fails, the car does not notify you about it even by turning on the Check Engine warning light. Therefore, you have to navigate by signs of breakdown.

The IAC works as follows. When the ignition switch is turned on, the rod on the sensor extends all the way and rests against a special hole in the throttle pipe. The IAC begins to read the steps and the valve returns to its original position. When the engine is running, increasing or decreasing the number of steps causes a change in the volume of air entering through the hole. Consequently, the required amount of air flows into the engine, ensuring stable operation of the engine at idle.

Idle speed VAZ 2109 carburetor

Recently I encountered the following problem: Lada cars with a carburetor power system stopped idling. The car starts on choke and runs. Everything is fine, you can drive, but as soon as you remove the choke and take your foot off the gas pedal, the engine stalls. Of course, the car is running, but it is very difficult, especially at traffic lights when driving around the city, when you constantly need to either accelerate or slow down and drive without idling. When the car warms up to operating temperature, it may not stall at idle, but shake terribly at idle, the engine speed being about 500-600 rpm. We urgently need to restore the car's normal idle operation, let's look at how. There are many articles on the Internet explaining the reason why the idle speed does not work on nine. 90% of such articles only consider manipulation of the idle air solenoid valve. Indeed, problems with the valve are very often the cause of idle loss, but there are other reasons. I’m sharing my experience because I myself spent many hours searching for normal material, but I only came across hundreds of articles that dealt with EPHH in one go. So, let's go in order: your VAZ 2109 has lost idle speed, with the gas pedal pressed the car works, as soon as you release it it stalls. The reason for this phenomenon is as follows. The carburetor has a special idle system: an idle fuel passage with a jet, an idle air passage and a solenoid valve. When the car is idling, the combustible mixture enters the engine through the idle passage. The throttle valve is closed, and therefore the vacuum in the engine is huge and it sucks the combustible mixture into the engine through the idle channel. The fuel and air nozzles have special holes of a certain diameter, which are selected for stable engine operation at idle. Why does the idle speed disappear? It's simple: either fuel does not flow through the idle fuel channel, or there is an air leak somewhere in the system and the fuel/air ratio in the combustible mixture is maintained incorrectly. The idle speed solenoid valve (hereinafter referred to as ESV) is responsible for the fuel supply. If the valve is not working, fuel will not flow into the space behind the carburetor throttle plate at idle.

Functions

The IAC regulates the amount of air entering the engine when the throttle valve is closed. This suggests that the IAC performs the functions of automatically adjusting the specified engine speed when idling.

The regulator also takes part in the process of warming up the engine to optimal operating temperatures in winter. The operating temperature range of the IAC is quite wide - from -40 to +130 degrees Celsius.

The IAC, despite such important functions, is small in size and consists of three main elements:

- Stepper electric motor;

- Spring;

- A rod with a cone-shaped needle at the end.

The idle speed control is mounted on the throttle body with a pair of screws.

IAC location

Symptoms of a problem

Under no circumstances should you ignore signs of failure of the idle speed sensor on your injection or carburetor VAZ 2109. This will make driving uncomfortable at first, but can soon cause a serious accident.

There are several main symptoms that may indicate problems with ICC:

- The revolutions spontaneously begin to increase and decrease;

- When turning on a cold power unit, the speed does not increase;

- When using additional electrically dependent devices, such as headlights or a heater, the speed immediately begins to drop at idle;

- When shifting gears or idling, the engine may stall.

This is not a complete list of possible symptoms, but they are all indirect. Therefore, to make sure that the problem lies precisely in the IAC, and not in other engine components, it is necessary to check the current state of the sensor.

Checking status

To check the current state of your IAC on a VAZ 2109 car, follow several sequential steps.

Verification step

Your actions

Apply the handbrake on the car and install chocks under the wheels. Safety should always come first when doing DIY car repairs.

You need to get to the sensor you are looking for, disconnect it from the power supply with wires, and then use a voltmeter to check for voltage. The minus is placed on the engine, and the plus is installed on the terminals of the wire block A and D

Turn on the ignition, check the voltage readings. Normally they are about 12 Volts. If the voltmeter shows lower values, there may be a problem with the battery charge level. If there is no voltage at all, you will have to check the entire computer and electrical circuit. Breaks are possible.

Carry out another test with the ignition on. Check terminals AB and CD one by one. In normal condition, the resistance across them should be approximately 53 ohms. If the IAC is working normally, the meter will show infinite resistance

With the idle speed control removed and the ignition on, connect the power supply to it. If at the same time the conical needle moves out, everything is fine with the device. If the cone-shaped needle does not extend, then the IAC is out of order and requires replacement

Having determined that the old idle speed sensor has already served its purpose on the VAZ 2109, it needs to be replaced. The procedure is completely doable without outside help.

How to repair idle speed on a VAZ 2109 carburetor engine

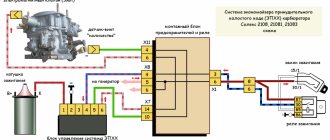

On cars of the VAZ 2109 family, Solex-type carburetors are used, which have an electromagnetic valve (EMV) with an idle jet in the idle speed system.

The valve is controlled by the electronic forced idle unit. There are three most common causes of idle speed disappearance:

- clogging of the EMC idle jet;

- EMC burnout;

- lack of power supply to the EMC.

For work you need: wrenches “8”, “10”, “12”, “13”, “14”, a 12 V probe or test lamp with wires, a piece of wire with stripped ends, a compressor or air pump.

Remove the air filter housing cover by unscrewing the nut with a “10” wrench and unfastening the spring clips. Remove the air filter.

We unscrew the four nuts with a key “8”, use a screwdriver to loosen the clamp of the crankcase ventilation hose at the point of connection to the valve cover and remove the air filter housing.

Turn on the ignition. Remove the power wire from the solenoid valve.

We try to touch the power wire terminal to the EMC terminal several times. At the moment of contact, distinct clicks should be heard. If this is not the case, then unscrew the EMC from the carburetor cover. Using an additional piece of wire, we apply the “+” from the battery to the terminal of the EMC, and with its body we touch the “–” terminal of the battery several times. At the moment of contact, distinct clicks should be heard.

If there are no clicks, the valve is burnt out. We replace it with a serviceable one, after checking it first.

To get to the nearest auto shop, you can convert a faulty EMC into a forced open one. To do this, remove the idle fuel jet with two fingers, break off the plastic tip of the valve, and put the jet and EMC in place.

We put the wires in place and start the engine. When using such a valve, problems may arise with turning off the engine: it will try to work after the ignition is turned off. In such a situation, you don’t need to turn it off right away, but let it run for 1-2 minutes, and after turning off the ignition, smoothly press the gas pedal all the way.

If the EMC is working normally, you need to check the idle jet. To do this, unscrew the valve from the carburetor cover. Using two fingers, remove the idle fuel jet. Pay attention to the central hole: remove debris from it using a compressor or air pump.

We install the jet and EMC in place and tighten it until it stops.

If the solenoid valve is working properly, the jet is not clogged, and there is still no idle speed, then the electronic forced idle speed control unit may have failed.

How to check it? Turn on the ignition and check with a tester or test lamp for the presence of “+” at the terminal of the EMC power wire.

If there is no power, the electronic forced idle control unit has failed. It cannot be repaired. Replacing it is not difficult. To get to the nearest auto shop, you can temporarily use an additional wire to supply power to the EMC at least from the “+B” terminal of the ignition coil. As an option, you can first bend the rubber cover from the connector of the wire bundle of the forced idle block and connect the wires at terminals “4” and “6” with a jumper. The numbering order of the terminals is indicated on the cover of the electronic unit to the right and left of the connector - numbers “1” and “7”.

A frequent malfunction of the engine associated with the forced idle block is a significant decrease in rotation speed (up to a complete stop) when the clutch is depressed, for example, when changing gears or stopping at a traffic light. In this case, in order to safely get to a car shop or service center, it is enough to disconnect the connector of the control circuit of the forced idle unit, located near the mixture amount adjusting screw.

Replacement or cleaning

Practice shows that in a fairly large number of cases, simply cleaning the idle air regulator allows you to restore its functionality. Therefore, we advise you to try this method first. And if it does not give results, then it will not be difficult to replace the device.

- Buy a container of carburetor cleaner. In this case, your engine may well be fuel-injected. It’s just that this composition is excellent for cleaning IACs and more.

- Disconnect the connector with wires from the sensor, unscrew the two fasteners and remove the affected regulator itself.

- Clean the regulator from accumulated debris and contaminants, and be sure to clean the needle and spring itself. This should be done with carburetor cleaner. Use available tools to tidy up a fairly compact device.

- Be sure to clean the idle air control housing on the throttle assembly. This is where the cone-shaped needle of the XX sensor enters.

- After completing the cleaning of the device, return it to its place and check its operation.

- If cleaning does not bring the desired result, the engine continues to behave inadequately, you will have to purchase a new regulator and install it in place of the old sensor.

- Before replacing, be sure to turn off the power to the car by disconnecting the negative terminal from the battery, then disconnect the block with the power wires, unscrew the mounting screws and remove the device.

- Reassemble in reverse order.

Disassembling the unit for cleaning or replacement

The main thing here is to act carefully and not to overdo it with the carburetor cleaner if you first decide to try cleaning the device. Otherwise, replacing the IAC does not cause problems even for beginners.

Injection cars use a power system that is different from the carburetor with its channel for idling the engine. To support engine operation in idle mode, the VAZ-2109 injector idle speed sensor is used. Experts call it differently: XX sensor or XX regulator. This device practically does not cause problems for the car owner, but sometimes it still fails.

Dismantling the IAC

Dismantle the regulator as follows:

- Block the car with a handbrake or wheel chocks.

- Remove the terminals from the battery.

- Disconnect the connecting connector from the IAC.

- Clean the area around the IAC from contamination.

- Unscrew the 2 mounting screws.

Having completed all these operations, the regulator is removed from the mounting socket.

Device

At the initial stage of development of injection engines, rotor and solenoid devices were used as idle speed regulators. They could have two operating positions - here we can draw an analogy with a shut-off valve. The sensor operated in the fully open or fully closed position. This did not allow the idle speed to be effectively stabilized.

Subsequently, AvtoVAZ engineers created an idle speed sensor for the VAZ-2109 injector in the form of a stepper valve. It is distinguished by the presence of stepwise adjustment of the air supply through a bypass channel in the throttle valve.

The IAC is designed as follows: it is based on a small stepper motor, and the device also contains a rod, a spring and a needle.

Operation and repair

The VAZ 2109 carburetor, like all other parts, tends to break. Typically, a breakdown involves the failure of any spare part. In such cases, repair usually helps.

The first thing that can break is the accelerator pump. Its purpose is to enrich the fuel mixture, regardless of the air supply, when the throttle valves are opened. If, when you sharply press the gas pedal, the car jerks, it means that there is either not enough fuel, and significant gaps occur in the supply, or, on the contrary, there is too much of it, and it overflows the spark plugs. So, to avoid this problem, an accelerator pump is used. It regulates the exact amount of fuel required for normal engine operation, even when the gas is pressed hard.

The accelerator pump more often becomes clogged with sediment than breaks down, and then repairs are not needed, but simply cleaning is enough. But, if this is not the case, but there is still a breakdown, then the pump needs to be repaired urgently, otherwise operation of the engine of the VAZ 2109 car will be impossible, and you are guaranteed to have pedal failures.

The first symptoms that the pump is faulty is that when you press the pedal, the speed does not increase steadily, but floats. This is due to a shortage, or vice versa, an excess of fuel. The spark plugs do not have time to burn out all the gasoline, and they are simply flooded, so the car jerks while driving. Also, the pedal may fail when pressed.

Repair for such a breakdown is as follows:

We take out the sprayer; Shake it. If there is a characteristic knocking sound of the ball inside, then the sprayer is working, if not, then this will be the reason why the pedal failed; The pump has a rather heavy structure with parts. A large number of holes and channels increases the chance that the pump will clog, and pedal failure will be inevitable. If the holes are clogged, then repairs are not needed. You just need to buy carburetor cleaning fluid and use it to blow out the channels.

If the VAZ 2109 jerks when idling, and there are dips when you sharply press the gas pedal, then the EPHH control unit has a malfunction. Its repair primarily depends on which control unit is installed. They can be 4 or 6 pin. Repair of EPHH must be carried out by a specialist. If you do not have the appropriate knowledge, simply replace the part with a new one.

The reason that the VAZ 2109 jerks when driving, or even stalls, and when you press the gas pedal, failures occur, may be not only the carburetor or the EPHH control unit, but also the spark plugs. When used for a long time, carbon deposits appear at the contact site. Because of it, the spark plugs do not completely burn out the fuel in the cylinder.

Sometimes the spark plugs flood even at idle. This is due to the fact that the EPHH control unit is selected incorrectly. The valve opening does not occur synchronously, and the engine speed fluctuates. At the same time, gas pedal failures and late ignition are observed. In order to understand which EPHH is better to install, you need to decide on the choice of carburetor jets. The type of device depends on their diameter.

In general, before repairing the carburetor, make sure that the speed is fluctuating precisely because of it. Also, gas pedal failures occur for this reason. After all, maybe the candles are to blame for everything. If they are flooded, the car will jerk and stall. But in this case, the cause must be sought in the fuel lines, pump and similar components. But this is better than repairing the carburetor, since this work is quite painstaking.

If you find an error, please select a piece of text and press Ctrl+Enter.

Source

Operating principle

When the car is moving and the throttle valve is open, the IAC is not involved in the process, its valve is closed and the rod is motionless. When the damper closes and the engine goes into idle mode, voltage is applied to the electric motor and the rod moves towards the opening - the valve comes into operation. It opens slightly, and air enters the engine bypassing through a special hole.

When the driver turns on the ignition, the IAC rod fully extends to its extreme position and closes the calibration hole in the throttle pipe. The sensor then counts the steps and the valve returns to its home position. As for this basic position, it can be different and depends on the firmware installed in the ECU. For January 5.1 firmware the position is 120 steps, for Bosch firmware it is 50 steps.

How does he work

The car performs a number of specific functions that are very important. If this part does not work well or fails, then it may be impossible not to turn off the car when you need to stop, for example, at a traffic light. Driving a car with a faulty idle speed sensor is not only uncomfortable, but also very dangerous. As soon as it is noticed that there is a problem with a given part, it may need to be repaired or replaced. The idle speed sensor is also called a regulator. On models such as the VAZ 2114 or other modifications of the Samara, this idle speed regulator is designed to stabilize idle speed. On the VAZ 2109 it performs a more complex function. The sensor is a small electric motor equipped with a conical needle.

This part is located in cars of the VAZ family on the throttle body, next to the damper. The idle speed sensor itself, which we will call IAC, is attached here with two screws. But it also happens that dismantling this element sometimes causes difficulties. And all this is due to the fact that in addition to fixing with screws, the DXX is mounted on varnish. Let's look at what happens when the ignition is turned on:

- At this moment, the rod located on the idle speed control moves completely forward, resting against a special calibration hole located in the throttle pipe.

- After this, the sensor begins to work. He counts the steps and returns the valve back. And the position of this very valve depends on the time of year and engine warm-up. For example, this could be equal to 50 steps with the motor running.

- As the steps increase or decrease, the air passing through the calibration hole is under constant change. When the rod is extended, the steps increase. The reverse process occurs when the rod returns to its original position. The stroke of the rod itself on the vase is approximately 250 steps.

- The idle speed is controlled by a sensor that is assisted by air. In other words, air entering the engine regulates idle speed.

- The mass flow sensor analyzes the incoming air based on its quantity. As for the controller, it supplies the required amount of gasoline or other fuel directly to the engine through the fuel injectors. Thus, the process of supplying the required volume of air occurs.

- As for a cold engine, the controller in this case increases the speed only due to the presence of the DXX. And this mode allows you to move away even without necessarily warming up the engine.

Location

Knowing the principle of operation of the VAZ-2109 idle speed sensor (injector), it is not difficult to guess where it should be installed. On this vehicle it is located near the throttle valve and throttle position sensor. The device is fixed with screws on the damper body. In case of failure, the car owner can easily replace it himself.

Photo report on replacing IACs with your own hands

The idle speed sensor is an important part of a modern engine, and it is important for stable engine operation and fuel economy. So let's get started.

The very first thing to do is to disconnect the battery, i.e. turn off the power to the car.

This is much easier to do if you purchase quick-release battery terminals for your car. They will come in handy more than once, especially in winter. Having disconnected the battery, we find the XX regulator itself, which we will change. It is located on the engine, on the interior side, under the throttle valve.

When you have disconnected the chip from the sensor (photo 3), unscrew the two bolts that are located on the sides of the sensor.

It is more convenient to “crawl” up to the bolts with a thin screwdriver, preferably a magnetic one, since the bolt may fall under the engine or to the ground.

It is better to place the container down. Then you won’t have to be distracted by searching for the “lost thing.” And also, after tightening and pulling out the first bolt, do not rush with the second. It’s better to alternate actions: unscrew a little, pull out the sensor a little, and so on until the end. Then the likelihood of the bolt falling out is reduced to nothing. Having unscrewed the regulator, we pull it out to the white light.

Compared to the new idle speed sensor, the old one has deposits, play, etc. If it is not possible to purchase a new idle speed sensor, restore the old one. But it is better to purchase a new idle speed sensor from a trusted manufacturer. This guarantees the car owner that it is efficient and of high quality.

The new sensor, compared to the old one, “makes an impression.” There is no play in it, it is clean, shiny, and much better than the refurbished old one. Installing a new idle speed sensor occurs in the reverse order of how the old one was removed. One piece of advice! To install the new sensor with the correct side, before installing and screwing it, put a “chip” on it. Then, if you try to install the idle speed sensor with the wrong side, the “chip” wire will not allow you to do this.

We tighten the top bolt first, since it is more difficult to hit the bottom one. To make it easier for the bottom bolt to fit onto the thread, it is recommended that before installing the sensor, insert a bolt into the bottom hole of the mount, and with it, insert the device into place. If the lower bolt is not inserted into the hole first and the upper bolt is tightened, then even a magnetized screwdriver will not help; it will be impossible to get the lower bolt onto the thread.

Symptoms of a problem

This element is responsible for the operation of the engine at idle, which means that any malfunction will affect the stability of the idle speed. Among the main symptoms of HPP failure are:

- unstable idle;

- drop in crankshaft speed when additional electrical consumers are turned on;

- absence of increased warm-up speeds during cold starts of the power unit;

- stopping the internal combustion engine when turning off or changing gear.

These symptoms will not always be the cause of a malfunction of the VAZ-2109 idle speed sensor (injector), since the same symptoms will occur if the TPS fails. But if there is a problem with the throttle position sensor, the check engine light will come on. Since the IAC, or idle speed sensor, does not have its own diagnostic system, the lamp will not light up with the same symptoms.

Lada 2109 › Logbook › Unreliable XX system on the VAZ 2109 carb!

The long torment is over and it looks like I have solved the problem! I used to have difficulty idling my car. then the wire flew off, then the solenoid valve did not work, and then the EPHH unit itself flew off. I decided not to bother and, as they say in the language of garage “bugs,” drown it out. Work order: 1) Remove the pan (carburetor cover). You need to remove both covers 2) Next, we unscrew the electromagnetic valve with a peck at 13 (you can see it; there’s just a wire going to it) 3) We take out the yellow jet and see a plastic needle on the valve, carefully cut it off with pliers to the very root. put the jet in place. tighten the valve by hand 4) start the car by sound, tighten it a bit with the key (it’s important not to overtighten it, otherwise I broke the thread and bought a new carb cap) 5) assemble the pan and don’t forget to put in the air filter Consequences: The car will consume more gasoline But not by a lot, since gasoline will always be present in the idle jet. But I think it’s better to turn it off and forget about the problem than to constantly stall without suction) Thank you for watching! I'm waiting for comments!

Like 4 Subscribe

The simplest diagnosis of DXX

The easiest way to check the idle speed sensor of the VAZ-2109 is the following method. Need a friend's help. The sensor is disconnected from the connector, then the mounting screws are unscrewed and the device is dismantled. Next, the regulator will be plugged into the connector again, but held in your hands.

At this time, the assistant starts the power unit, and the IAC rod should at this moment retract completely and then extend to a certain distance. If the device behaves this way, then it is operational - the rod is not bent, it is not jammed inside the valve. But there is no guarantee that the device matches the ECU firmware. The rod extends, but the number of steps is unknown. There is a marking on the connector - you can use it to ensure that the ECU sensor matches.

This is the initial stage of diagnosis. Next, check the electrical part, the condition of the valve, and the degree of needle wear.

Nuances of choice

The stores offer a huge number of different sensors from different manufacturers. The original part must be marked XX-XXXXXXX-XX. By the last two digits you can figure out compatibility. So, numbers 01 and 03 are interchangeable, and 02 and 04 can also be swapped. Instead of 02, you cannot put 01 or 03. If the sensor is original and new, it is better to additionally lubricate the spring and rod with thick lubricant.

When buying a sensor, even in a trusted store, you should look at the following nuances:

- there are no marks on the packaging by which the manufacturer can be distinguished;

- the sticker on the device body is yellow and has no frames;

- the needle has a dark tip;

- the o-ring is thin and black;

- rivet heads less than 3 mm in diameter;

- white spring;

- The length of the body is 1 mm less than the length of the standard AvtoVAZ sensor.

All these nuances indicate that a counterfeit VAZ-2109 idle speed sensor is being offered. You can see photos of real and fake devices above.

How to check a sensor with a multimeter

Using a multimeter, you can diagnose the VAZ-2109 idle speed sensor (injector) in two ways: first, measure in ohmmeter mode, then in voltmeter mode.

If you close the contacts on the CD and AB plugs, the multimeter should show a resistance in the range of 40-80 Ohms. If you close the DC and AD contacts with probes, then the multimeter on a working IAC will show infinity.

In voltmeter mode, the voltage on the sensor when the ignition is on should be 12-20 V.

Hall sensor VAZ 2109 (carburetor)

Its malfunction can cause problems in the carburetor. And it is very difficult to determine that this tiny detail is to blame. Perhaps, by the method of elimination. Sometimes they suggest checking its operation using a special device.

A simple way to check the performance of the Hall sensor of a VAZ 2109 (carburetor)

Take a sample with a light bulb. Its plus and minus (these are the extreme contacts) on the plug are connected to the distributor. There should be a gap between the center wire and ground. After this, you need to close the “minus” and the center. terminal. A spark will appear on the wire or spark plug. If it appears, the Hall sensor needs to be changed. If not, check further.

However, it also happens that the sensor works, but incorrectly. Here you can find out only by replacing.

If you do not know where the Hall sensor is located on a VAZ 2109 (carburetor), the photo below will help you.

"Hall sensor" number 8 in this photo

The price for a VAZ 2109 Hall sensor (carburetor) is usually low - about 120 rubles.

This photo shows a VAZ 2108 breaker plate with a Hall sensor:

Fan switch on VAZ 2109 (carburetor)

If you are interested in replacing the VAZ 2109 carburetor fan switch sensor, many are interested in whether it is possible to change it without draining all the coolant?

The answer is yes. But you will lose some coolant during the replacement process. This sensor is essentially an ordinary thermostat. There are special toggle switches on sale that can be used to turn it on forcibly.

Fan switch on VAZ 2109 (carburetor)

Sometimes you just need to take everything apart and clean it. Dirt and scale may get on the sensor. In any of these cases, even if you need to change the sensor, there is nothing wrong with that. The part itself is very cheap; it can be replaced either by the driver himself or by car workshop workers.

You can also read on this topic:

Diagnostics on the stand

The simplest stands for checking IAC will cost the average car enthusiast 1,500-2,000 rubles. Replacing the idle speed sensor on a VAZ-2109 will cost 300 rubles. Therefore, purchasing a stand is not economically feasible. You can assemble a simple stand with your own hands. The circuit consists of a charger from any mobile equipment with a voltage of 6 V, a plug block and a test lamp. If the lamp lights up during the test, then the IAC is faulty. If the lamp burns at half intensity, then the device is working properly.

DXX connection diagram

The idle air control is connected with a single four-wire cable. The wire of the VAZ-2109 idle speed sensor is connected to the ECU. Such wiring creates certain problems when trying to diagnose the sensor yourself. You won’t be able to simply apply voltage to the terminal for testing: the ECU supplies voltage to the windings of the stepper motor in pulse mode. Therefore, checking with a multimeter in case of a malfunction is not very effective.