One fine day I got into the car, drove back and turned off the rear, but it didn’t turn off electronically. After checking the connections, it turned out that the shutdown frog grunted. For some time I simply turned it off and drove like that, because there was simply no time to replace it. A couple of days later I went and bought a frog just like this for the VAZ 21194 model

The replacement process itself is very simple. We take a key for 22, WD40 (well, some may not need it, but I personally couldn’t do without it) and unscrew the sensor counterclockwise. True, before all this manipulation it is necessary to remove the left front wheel, unscrew the metal protective casing with a 8mm head and bend it down towards you.

Oh yes, and have your thumb or plug ready, because when you unscrew the sensor from the box, oil will flow. And if you don’t want to drain and fill it back, but you will need to keep the hole from it plugged the whole time you change the sensor. Even if you lose 20 grams of oil, this is not critical. All the best. I hope it helps someone.

Reasons for reverse gear not engaging

- Before disassembling, you need to check the gear shift lever, since the cause of problems with reverse gear may be hidden in it. In addition, the cause is often in the rocker and cardan.

- The splines are worn out or the clamp is loose (an inspection hole is needed to correct it).

- Broken release bearing. However, in this case, when the gears were engaged, a characteristic crunch would be heard, and this would require effort.

- There are problems with the reverse gear locking mechanism. To confirm or refute this assumption, you need to remove the gear shift knob, as well as the dashboard between the seats, then carefully inspect everything.

In the example discussed in this article, the cause of the malfunction was precisely the faulty wiring of the gear lock solenoids (broken or torn).

How does the system work in Kalina?

The gear selection lever of the Lada Kalina transmission is equipped with a special ring. If you do not lift it, it is impossible to activate reverse gear. The lifting of the element is accompanied by the application of a certain electrical impulse to the coil. As a result, the core is drawn into the coil, which allows the transmission to be engaged. The same pulse generates a signal to activate the reverse movement indicator.

In the reverse process, the core is installed in its original place. Here, a pulse is also generated inside the coil, which enters the control system for the stern lighting devices. As a result, the lamps responsible for reverse gear turn off. Structurally, the reverse switch we are considering is located on the bottom of the transmission housing. Wires go to it. It is these components that become the reason for damage, since this arrangement creates a risk of touching uneven road surfaces. Breaks of patch cables are quite common here, as evidenced by many reviews.

Also check out

- Using a paper clip, we close the contacts of the connector from which the wires are lowered under the floor of the car. Try to engage reverse gear. If this works, the switch is broken.

- Disconnect the connector from the solenoid and install 2 pins into it. Use a tester to change the voltage. The device readings should be 12 Volts. It is worth charging it with a light bulb (5 Watt or 12 Watt). If it does not light up, then there is an open circuit, and the voltage arises due to resistance formed due to copper oxide. Very often, breaks and fractures occur on the harness in the place where the clamp is located on the pallet.

- Remove the clamp by pressing its fastenings at the bottom.

- Disconnect the connector from the stop switch and remove the harness. Remove the electrical tape from the corrugation, after which you can remove the wires. In the event of a break or breakage, characteristic signs will be noticeable.

- Use wire cutters to disconnect the wires and connect them of similar cross-section and diameter. The twist should be soldered and insulated (you can use heat shrink). If necessary, put on a new corrugation. This is done so that moisture does not penetrate inside, otherwise it is possible that all the troubles will happen again. The harness should be secured with a plastic clamp.

- Connect the connectors and check the operation of the solenoid. Failure of this element is quite rare. To check it you need to connect a tester. The resistance should be 2.2 Ohm. If the cause of the malfunction lies there, you will need to drain the oil from the box. One option is to quickly block the hole with something and install a new solenoid. In this case, it is important to apply sealant to the threads so that oil does not ooze down the threads during operation.

How to restore functionality?

Reverse faults can occur throughout the power and control circuit. If such a situation occurs, then you should not rush to replace the sensor. It would be more advisable to check all links of the designated chain.

It is recommended to start checking with the ring present on the lever. Some craftsmen turn off the sensor and blocking and “ride” further. However, this is not a correct measure, since it jeopardizes security. It’s no secret that the movements of the lever when engaging both reverse and first gear are carried out almost identically, that is, “toward and forward.” The only difference is that the first speed is activated without a ring, and the rear speed is activated with it. That is, this element acts as a “safety guarantor” against accidental engagement of reverse gear.

Lifting the cover on the lever, you can find several wires that are fed from the ring to the connectors. This special solution is implemented to prevent wires from breaking while manipulating the transmission lever. It is also recommended that these cables be thoroughly checked.

The most common situation associated with a reverse gear malfunction is a break in the wires that go directly to the sensor. In addition to the risk of hitting road irregularities, there is also the influence of the external atmosphere. This implies the negative impact of not only moisture, but also various particles of debris, as a result of which the wiring and reverse sensor become unusable over time.

Finding these wires will not be difficult. They are the only cables that are connected to the transmission unit, or more precisely to the sensor located on the LADA Kalina crankcase. In addition to visual inspection, inspection is reduced to testing using a device. If, after calling the wiring, we find its integrity, then the likely cause of the system failure and failure is the designated sensor.

How to remove air from the stove on Kalina

Lada Kalina Cross station wagon

Radiator Lada Kalina

Characteristics of the XX controller

Let's take a closer look at the XX sensor.

Purpose and principle of operation

The idle speed sensor is an electric motor with a conical needle of a certain thickness. This device is located on the throttle body next to the throttle position device, and is secured with two screws or using technical varnish.

The device has a single purpose: to stabilize the engine idle speed, and everything happens this way:

- When the engine is idling, a certain volume of air enters, which allows it to operate normally.

- The device does not read or control anything, it does what the ECU tells it to do. The unit controls, reads and, according to the tachometer readings, gives a command to the XX regulator.

- If you warm up the car engine to the optimal temperature, the controller will maintain speed. If it is not warmed up, then due to the operation of the IAC controller, the speed will increase. This manipulation will ensure the optimal engine temperature at higher speeds by analyzing the operation (author - RussianTuning).

Typical faults

Like any systematically operating device, the DXH may experience various problems, for example:

- The car suddenly stalls while idling.

- The DXX turnover is not systematic and “floats”.

- When starting the engine without preheating, the controller does not start working and the sensor does not rotate as it should.

- It suddenly stalls when changing gear on the gearbox.

- The DHW speed hangs after releasing the pedal or when activating various automotive equipment.

When all these strange things happen to a car, it is obvious that the problem lies with the regulator. Unfortunately, this device does not have self-diagnosis, so to figure out what exactly is the cause of the malfunction, you need to check it yourself. And if it can’t be fixed, then replace it. Replacing the idle speed sensor on Kalina will be covered below.

Part location

Checking the electrical wiring

If the current does not reach the lamp socket, you should check the rest of the electrical circuit in reverse order.

- Check your repair manual for the color and route of the reversing wires.

- Probe each wire along its entire length.

- In most cases the wire will disappear into the cable where you can't reach it.

- In this case, you should be extremely careful, because you risk damaging the working wire.

- Once you have identified the faulty section of the wire, remove it and install a piece of new wire in its place.

Important! Be sure to provide high-quality insulation at the wire connection points. The quality of the insulation primarily determines the reliability of the contact and the safety of the driver. You can also eliminate the possibility of a short circuit.

Video - Reverse gear does not light up on VAZ 2108, 2109, 21099. We are looking for the reason

A modern car is literally packed with electronics, and the Lada Kalina is no exception in this sense. On the one hand, electronics make life much easier for the driver. On the other hand, it can also become a cause and source of headaches for the driver, since the abundance of electronics can seriously complicate troubleshooting. The most common electronics-related problem on Kalina is the inability to engage reverse gear. We will tell you why the transmission does not turn on and how to fix it in this article.

Fuses

In many cases, the fuse protects the reversing lamps and also covers other accessories. If this does not give a positive result, replace the fuse and test again. If after replacement the new fuse melts again, then this indicates a short circuit that has occurred somewhere in the circuit. In this case, you should contact an electrician who can quickly determine the location of the short circuit in the electrical circuit.

If the other fused components are still working, then you need to check the rest of the circuit using a test light.

How to replace spark plugs on a car?

You can find an article about this here. You may also be interested in our new article on the topic “How to adjust the clutch.”

Replacing the sensor

Replacing the sensor is easy, but requires some skill and knowledge.

You can see the sensor by looking under the car from the front, after turning the steering wheel to the left. But the replacement is done on an overpass or from a pit:

- First of all, you need to disconnect the wires.

- Then unscrew the reverse switch from the box and immediately screw in a new one. If you hesitate, a lot of oil will leak out of the box. Therefore, everything must be done quickly. When unscrewing, do not stand directly under the box, the oil will simply flow out. It is recommended to let the machine cool down a bit before replacing the sensor. Then the oil pressure will not be so strong (and its fluidity will decrease slightly). But most importantly, keep the new sensor on hand.

- They pulled out the old one and immediately installed a new one. Then oil loss will be minimal.

If you do not have enough experience, simply place a clean container under the crankcase to catch the spilled oil. Then it can be refilled.

Related Issues

In some cases, the reverse still turns on, but there is no lamp. It is important to look at the overall plan here. If we are talking about one of the lamps, then most likely the problem is there. Although this is rare. If both lamps do not turn on, then you need to “ring” the circuit from the sensor to the lamps.

If only one of them does not light, then most likely the reverse lamp needs to be replaced.

This is done from the trunk. Remove the casing and unscrew the lamp socket (counterclockwise). Then you need to remove the lamp itself from the socket. Press and turn counterclockwise. Done, install the new lamp in reverse order.

tweet

back Characteristics of the on-board computer on the Lada Kalina and its replacement

Next How to fix the idle speed sensor on Kalina?

Tag sensor, reverse sensor, replacement

Burnt out lamps

One of the most common problems is a burnt out lamp. To check this, remove the light bulb from the holder and connect it to the battery terminals with a short wire. If the light comes on, then the fault must be looked for at another point in the electrical circuit.

First, check that the light bulb socket and electrical terminals are clean and bright. If there are any signs of corrosion, clean the socket with wet and dry paper, then reinstall the bulb and retest.

A burnt out light bulb is the most common cause

If the reverse light still does not come on, the fuse may have blown. Also, everything indicates a blown fuse if two reversing lights are constantly on. In this case, a replacement will be needed. Fortunately, getting to the fuse box where they are located will not be too difficult for you.

Place of the switch in the light switching circuit

On cars with manual transmission, voltage to the lamps when reversing is supplied through a limit switch (the so-called frog), which is screwed directly into the gearbox housing. When reverse gear is engaged, the switch button is pressed inside the gearbox. The contacts inside the “frog” bridge, and current begins to flow to the lamps.

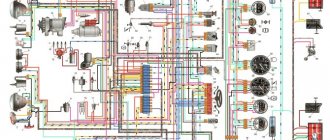

On the circuit diagram for turning on the reversing lights, we can see that on the VAZ 1118 Kalina, the current from the battery through the ignition switch (No. 2) is supplied to fuse F1. Passing through the fuse that protects the switching circuit, “+” goes to the limit switch (No. 10). The contacts are in a normally open state and close only when reverse gear is engaged. Thus, current begins to flow to the light bulbs. The second contact of the lamps is connected to the “–” battery through the common ground contact of the lamps.

On cars with automatic transmission, the role of the limit switch lies with the selector position sensor. Information about changing the location of the gearshift knob is transmitted to the engine ECU, the light control unit.

How to check the "frog"

- Remove the headlight switch chip.

- Turn on the ignition.

- Using a small piece of wire, connect the contacts of the reverse gear sensor connector to each other.

If the reverse lights are on, then the problem is in the “frog”. Some drivers disassemble the switches, clean the contacts, after which the device continues to work properly. It is up to you to judge the appropriateness of such measures. But keep in mind that on many cars (including VAZ models) the limit switch is located below the oil level in the gearbox. We recommend simply replacing the power sensor. To minimize oil loss, jack up the car on the side where the end switch is installed.

Removal and installation of gearbox Lada Kalina 1117 2004 - 2013

Tools:

- Open-end wrench 8 mm

- Open-end wrench 10 mm

- Open-end wrench 17 mm

- Open-end wrench 19 mm

- Straight box spanner 13 mm

- Straight box spanner 19 mm

- Driver for socket attachment

- Knob attachment 10 mm

- Knob attachment 13 mm

- Knob attachment 15 mm

- Knob attachment 17 mm

- Knob attachment 19 mm

- Knob attachment E-14

- Extension for socket bits

- Adjustable stops 2 pcs.

- Medium Phillips screwdriver

- Medium flat screwdriver

Parts and consumables:

- Wooden blocks 2 pcs.

- CV joint grease-4

- Studs M12x1.25 mm 2 pcs.

- Transmission oil

- Rags

- 3.5 liter capacity

- Funnel with hose attached

Note:

We carry out the work with an assistant on an inspection ditch or overpass.

1. Drain the oil from the gearbox as described here. Disconnect the wire terminal from the negative terminal of the battery. Remove the air filter as described here. Remove the starter as described here. We remove the clutch cable lead from the groove of the clutch release fork lever, following the instructions described here. Remove the left mudguard of the power unit, as described here. Disconnect the wire block from the reverse gear lock solenoid.

2. Disconnect the wiring block from the reverse light switch.

3. Disconnect the wire block from the speed sensor.

4. Using a 10mm wrench, unscrew the three bolts securing the lower clutch housing cover.

5. Remove the clutch housing cover.

6. Remove the right and left front wheel drives, as described here. Using a 13mm spanner, loosen the tightening of the nut of the coupling bolt of the clamp securing the control rod to the shank of the gear selector rod hinge. Then disconnect the transmission control rod.

7. Using a 19mm wrench, unscrew the nuts of the two bolts securing the clutch housing to the gearbox housing (which also secure the torque rod bracket), holding the bolts from turning with a head of the same size.

8. We remove the reaction rod with the bracket from the gearbox.

9. Disconnect the plastic throttle cable holder from the gearbox bracket.

10. Using a 13mm socket, unscrew the bolt securing the ignition coil bracket to the clutch housing.

11. Using a 19mm socket, unscrew the two upper bolts securing the gearbox to the cylinder block, which simultaneously secure the bracket with the holders of the throttle cable and wiring harness. The front bolt (in the direction of vehicle travel) is shorter than the rear bolt. We remove the bracket with the cable and wiring harness from the gearbox.

12. Remove the left front suspension brace as described here. We install adjustable stops through wooden blocks under the engine oil pan and gearbox housing.

13. Using a 19mm spanner, unscrew the nut of the lower rear mounting of the gearbox to the cylinder block.

14. Using a 19mm socket, unscrew the bolt of the lower front fastening of the gearbox to the cylinder block.

15. Using the “E-14” head, unscrew the two screws securing the front left support bracket of the power unit to the support.

16. Using a 15mm socket, unscrew the three nuts securing the bracket for the front left support of the power unit to the gearbox.

17. Remove the bracket.

18. Using a 19mm socket, unscrew the two outer bolts 1 securing the rear support bracket of the power unit to the gearbox, and using a 17mm socket, unscrew the middle bolt 2.

19. We move the gearbox away from the engine, removing the input shaft from the hub of the driven clutch disc.

20. When removing and installing the gearbox, do not rest the gearbox input shaft on the clutch diaphragm spring petals so as not to damage them. Before installing the gearbox, apply a thin layer of CV joint-4 lubricant to the splined end of the input shaft. To facilitate the operation of installing the gearbox, we screw two guide pins M12x1.25 mm (with sawn slots for a screwdriver) into the front lower threaded hole of the cylinder block and into the rear upper hole.

21. We insert the input shaft of the gearbox into the splines of the driven clutch disk and, orienting the gearbox so that the two guide pins fit into the corresponding holes in the clutch housing, and the standard pin of the clutch housing into the hole in the cylinder block, push the gearbox all the way into the engine cylinder block . Use a screwdriver to unscrew the guide pins from the holes in the cylinder block. We carry out further assembly operations in reverse order.

22. Fill the gearbox with oil as described here.

The article is missing:

- Photo of the instrument

- Photos of parts and consumables

- High-quality photos of repairs