What is the diameter of the hub (exact factory data)

According to the regulatory documentation provided by the manufacturer, the hub diameter on the VAZ-2114 is 58.5 mm.

Thus, the bolt-to-bolt size is 4x98 , which allows you to install wheel rims with sizes R13, R14 and R15 . To secure the wheels to the hub, use bolts measuring M12x40 mm .

Standard stamping for factory hub

In order to choose non-standard stampings, but, for example, non-standard alloy wheels, it is necessary to change the size of the hub and the inter-bolt space. Of course, the manufacturer and car enthusiasts do not advise doing this unless absolutely necessary, so you should think several times before taking this action.

The most common size on European cars is 4*100 . Therefore, many people want to install just such disks. This is the hub size for Hyundai Accent and Renault Logan.

Catalog of VAZ-2114 hubs

Hub made by AvtoVAZ

2108-3103012 – original catalog number of the front wheel hub manufactured by AvtoVAZ. Using this article, you can determine a list of analogues that are suitable for installation on the Lada 2108-21099 and 2113-2115 family of cars.

Standard stamping on the rear wheel, hub diameter 4*98

So, using the catalog number, it is determined which hub becomes available for installation.

Standard wheel sizes VAZ 2110 1.5i 2110x

The VAZ 2110 1.5i 2110x model was produced from 1998 to 2004. Table of standard and suitable wheel sizes for VAZ 2110 1.5i 2110x.

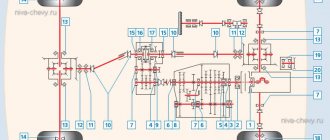

Disc drilling parameters are usually called bolt pattern:

- LZ (number of holes)

- PCD (hole center circle diameter)

- ET (disc offset)

- DIA (hole diameter)

Useful articles and reviews Announcements of certificate drawings among subscribers. Subscribe to VK group

| Make model modification Auto | Year of issue | Options | Disc width | Disc diameter | Bolt pattern LZ*PCD | Departure ET | Diameter DIA | type of instalation |

| VAZ 2110 1.5i 2110x | 2004 | 5Jx13 4/98 ET35 d58.6 | 5 | 13 | 4X98 | 35 | 58.6 | Factory |

| VAZ 2110 1.5i 2110x | 5Jx14 4/98 ET35 d58.6 | 5 | 14 | 4X98 | 35 | 58.6 | Factory | |

| VAZ 2110 1.5i 2110x | 5.5Jx14 4/98 ET35 d58.6 | 5.5 | 14 | 4X98 | 35 | 58.6 | Acceptable | |

| VAZ 2110 1.5i 2110x | 2003 | 5Jx13 4/98 ET35 d58.6 | 5 | 13 | 4X98 | 35 | 58.6 | Factory |

| VAZ 2110 1.5i 2110x | 5Jx14 4/98 ET35 d58.6 | 5 | 14 | 4X98 | 35 | 58.6 | Factory | |

| VAZ 2110 1.5i 2110x | 5.5Jx14 4/98 ET35 d58.6 | 5.5 | 14 | 4X98 | 35 | 58.6 | Acceptable | |

| VAZ 2110 1.5i 2110x | 2002 | 5Jx13 4/98 ET35 d58.6 | 5 | 13 | 4X98 | 35 | 58.6 | Factory |

| VAZ 2110 1.5i 2110x | 5Jx14 4/98 ET35 d58.6 | 5 | 14 | 4X98 | 35 | 58.6 | Factory | |

| VAZ 2110 1.5i 2110x | 5.5Jx14 4/98 ET35 d58.6 | 5.5 | 14 | 4X98 | 35 | 58.6 | Acceptable | |

| VAZ 2110 1.5i 2110x | 2001 | 5Jx13 4/98 ET35 d58.6 | 5 | 13 | 4X98 | 35 | 58.6 | Factory |

| VAZ 2110 1.5i 2110x | 5Jx14 4/98 ET35 d58.6 | 5 | 14 | 4X98 | 35 | 58.6 | Factory | |

| VAZ 2110 1.5i 2110x | 5.5Jx14 4/98 ET35 d58.6 | 5.5 | 14 | 4X98 | 35 | 58.6 | Acceptable | |

| VAZ 2110 1.5i 2110x | 2000 | 5Jx13 4/98 ET35 d58.6 | 5 | 13 | 4X98 | 35 | 58.6 | Factory |

| VAZ 2110 1.5i 2110x | 5Jx14 4/98 ET35 d58.6 | 5 | 14 | 4X98 | 35 | 58.6 | Factory | |

| VAZ 2110 1.5i 2110x | 5.5Jx14 4/98 ET35 d58.6 | 5.5 | 14 | 4X98 | 35 | 58.6 | Acceptable | |

| VAZ 2110 1.5i 2110x | 1999 | 5Jx13 4/98 ET35 d58.6 | 5 | 13 | 4X98 | 35 | 58.6 | Factory |

| VAZ 2110 1.5i 2110x | 5Jx14 4/98 ET35 d58.6 | 5 | 14 | 4X98 | 35 | 58.6 | Factory | |

| VAZ 2110 1.5i 2110x | 5.5Jx14 4/98 ET35 d58.6 | 5.5 | 14 | 4X98 | 35 | 58.6 | Acceptable | |

| VAZ 2110 1.5i 2110x | 1998 | 5Jx13 4/98 ET35 d58.6 | 5 | 13 | 4X98 | 35 | 58.6 | Factory |

| VAZ 2110 1.5i 2110x | 5Jx14 4/98 ET35 d58.6 | 5 | 14 | 4X98 | 35 | 58.6 | Factory | |

| VAZ 2110 1.5i 2110x | 5.5Jx14 4/98 ET35 d58.6 | 5.5 | 14 | 4X98 | 35 | 58.6 | Acceptable |

Despite the fact that this information is taken from the websites of auto manufacturers, our catalog is for informational purposes only and does not guarantee full compliance of the proposed sizes with your car.

conclusions

In this article, the diameter of the VAZ-2114 wheel hub was determined, as well as the bolt-to-bolt distance and fasteners with which the wheels can be attached to this unit. Many motorists practice replacing the hub in order to change the size of the disks, but not everyone takes into account that it is also necessary to change the steering knuckles.

The wheel bearing ensures uniform rotation of the wheel around its own axis. Of all the elements of the car's chassis, it is the first to meet and distribute shock loads, so the main requirements for this part are strength and durability.

In this article we will talk about what a rear wheel bearing is on a VAZ-2108. We will look at the design of this device, its dimensions, and also understand the process of replacing it.

Wheels of the country of the Soviets: factory wheels of VAZ cars

Unlike many other parts, FIAT-124 wheels “took root” on the VAZ-2101 practically unchanged. The disk, 4.5 inches wide and with an offset of 37 mm, had eight ventilation holes of a characteristic oval shape. Since in the first months the plant experienced difficulties with components, on the “kopecks” of the period 1970-1974. one could also find other disks - with sixteen round holes, around which peculiar stampings were made.

To protect the mounting bolts and wheel bearing, the central part of the rim was covered with a beautiful chrome cap - exactly the same as on a Fiat, only without the inscription with the name of the car in the center. In order for it to stay on the disk, special “ears” were provided, and such a cap could be removed thanks to its spring properties.

In the early years, the wheels were painted silver, but later on all cars of the 2101 family only wheels with oval holes, painted in a gray-white shade, were installed.

Already in 1991, wheels of type 2101 became half an inch wider and received humps - special protrusions on the shelves for a tight fit of tubeless tires. At the same time, the “penny” wheels got rid of the “lugs” for the hubcaps.

Those who are currently engaged in restoration should take into account that, according to the offset parameters, it is permissible to mount only 2101 or 2108 wheels.

2103/2106

“Treshka” received new wheels. In appearance, they were very similar to the “Fiat” ones already found on the early VAZ-2101: the same sixteen round holes, but the rim width increased to five inches, and the offset, on the contrary, decreased to 29 mm. Such a disc was installed on “three-ruble” and “six” cars, and on cars of the third model a cap of type 2101 was used, and on the “six” there was an original one. You can distinguish it by the black round overlay in the center.

True, other wheels were planned for the “six,” the angular design of which echoed the appearance of the then newfangled light-alloy (aluminum, as they were called) wheels. However, for technological reasons, such a disc did not go into production.

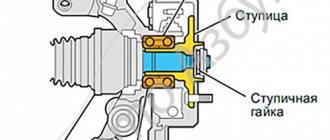

Design Features

The rear hubs of the V8 are equipped with sealed angular contact ball bearings. Each of them has two rows of balls. This makes the structure as resistant to loads as possible, and also allows them to be distributed with the greatest efficiency.

The rear wheel bearing of the VAZ-2108 is made of heavy-duty steel. Its service life, declared by the manufacturer, is 90-120 thousand kilometers. By the way, these are not empty statements. Oddly enough, VAZ wheel bearings actually last a very long time and, if used correctly, can last twice as long as the stated mileage.

Main characteristics and varieties

The rear wheel bearing on the VAZ-2108 is produced under catalog number 256706. It has the following technical characteristics:

- weight, g – 400;

- number of balls, pcs. – 28;

- ball diameter, mm – 9.525;

- static load capacity, KN – 25.9;

- dynamic load capacity, KN – 30.1;

- rated rotation speed, rpm – 6500.

The VAZ-2108 rear wheel bearing number may be different. If a store offers you a product marked 537906, don’t be surprised. This is a high-load bearing. Some of its characteristics differ from the characteristics of the standard spare part:

- weight, g – 511;

- static load capacity, KN – 90.1;

- dynamic load capacity, KN – 64.8;

- rated rotation speed, rpm – 5000.

As you can see, the reinforced rear hub bearing on the VAZ-2108 has increased resistance to loads. But at the same time, its rotation frequency should not exceed 5 thousand rpm. Such products, when properly used, can “walk” freely up to two hundred thousand kilometers.

Rear wheel bearing VAZ-2108: dimensions

As for the size of the wheel bearing, they are the same for both modifications:

- outer diameter, mm – 60;

- internal diameter, mm – 30;

- width, mm – 37.

If you are offered a rear wheel bearing for a VAZ-2108, the dimensions of which do not correspond to those specified, it is better to refuse this purchase. All the above parameters are provided for by GOST 520-2002. Foreign analogues of spare parts are manufactured in accordance with the requirements of ISO 15:1998 and have the same dimensions.

How to understand that it is time to change the wheel bearing

A failed VAZ-2108 rear wheel bearing may indicate a malfunction:

- the appearance of a characteristic hum from the wheel;

- uneven rotation of the wheel;

- backlash formation.

If you notice that there is a hum coming from one or both rear wheels, rush to diagnose the wheel bearings. You can do this right in your garage. Simply jack up the rear wheel and turn it by hand. It should rotate easily and evenly without making any sounds. Next, grab it with both hands and try to shake it from side to side in a horizontal direction. If the wheel rotates unevenly and you feel play when it becomes loose, get ready for repairs.

Features of choice

When buying a rear wheel bearing for a VAZ-2108, pay attention to the manufacturer. Currently, more or less high-quality domestic parts are produced by the following enterprises:

- SPZ (Saratov Bearing Plant);

- SPZ-4 (Samara);

- VBF (GPZ-23, Vologda);

- GPZ-20 (Kursk).

It is believed that the best domestic manufacturer of bearings is the Saratov plant. His products are very reliable, but not very expensive. Thus, a rear wheel bearing for a VAZ-2108 manufactured by SPZ costs between 400-450 rubles.

VBF products are also highly reliable and are slightly cheaper. Bearings SPZ-4 and GPZ-20 are designed for those who are used to saving on spare parts. Their cost is even less, but the quality leaves much to be desired.

There are also imported analogues on sale. They are, of course, expensive, but their quality is beyond doubt. For example, a SKF VAZ 2108 rear wheel bearing, produced in Sweden, costs about 900 rubles. The Japanese equivalent, NSK, will cost about the same.

List of suppliers

- SKF is the second-ranked supplier of bearing products, known in the markets for 100 years;

- NSK is also the second largest manufacturer of wheel bearings in the world from Japan;

- FAG is a manufacturer from Germany, absorbed by the INA concern, with high quality products;

- NTN is Japan's largest manufacturer;

- Kouo is the third largest manufacturer in Japan and is part of the Toyota concern;

- Timken is a manufacturer from the USA, the largest in the production of tapered bearings, the quality of which is exceptional.

These companies own many factories around the world, producing products of similar quality that meet the most stringent requirements.

If you need bearings for agricultural machinery, then it is better to pay attention to FKL, a Russian company located in Voronezh. Parts from this company have been supplied to all European countries for 50 years, are known for their high quality, and have no analogues in the world.

What tools will you need?

Before you begin repair work, make sure you have the necessary tools and supplies:

- wheel chocks;

- jack;

- wheel bolt wrench;

- chisel (core);

- some object to fix the position of the car body when jacking up (a stump, several bricks, etc.);

- hammer;

- spacer made of wood (block);

- head at “30” with an extended handle;

- key to "7";

- vice;

- a piece of pipe for the outer diameter of the bearing;

- long nose pliers;

- special puller for the hub;

- special pliers for retaining rings;

- anti-rust liquid.

If you decide to change the rear wheel bearing on a VAZ-2108, also replace the hub nut. At least that's what the car manufacturer recommends. The fact is that the nut has a special edge that bends during installation and gets knocked down during disassembly.

Corrosion protection

For reliable operation of the chassis, everything is important: the bolt pattern, the dimensions of all components, the alignment/camber settings, and even the protection of the arches from corrosion. It is the arches that are more susceptible to adverse factors than other parts of the body - from ordinary moisture during rain to reagents on winter roads.

To ensure reliable protection of the arches, it is best to install lockers (fender liners) on the VAZ 2110. Such protection will cost much less than subsequent repairs of rusted arches. It is important to choose the correct size of the lockers and ensure their tight fit in the area of the arches.

We hope that by completing all the repair work yourself, you will provide your VAZ 2110 with many years of trouble-free service on the road.

Changing the rear wheel bearing with your own hands

Replacement of the VAZ-2108 rear wheel bearing is carried out in the following order:

- We install the car on a flat surface, fix the front wheels by placing wheel chocks under them.

- Remove the cap covering the hub nut.

- Using a chisel (core), we bend the bent edge of the hub nut so that it does not interfere with its unscrewing.

- Using a 30mm socket with an extended handle, unscrew the nut. If it does not give in, treat the threaded connection with anti-rust liquid.

- After unscrewing the nuts, unscrew (not completely) the wheel mounting bolts.

- We lift the body with a jack, fix its position with stumps (bricks), and unscrew the wheel bolts. We dismantle the wheel.

- Using a key set to “7”, unscrew the guide bolts on the drum (2 pcs.).

- We remove the drum. If it is not removable, we treat the place where it fits onto the hub protrusion with a rust-fighting liquid, and then knock it down using a hammer and a wooden spacer.

- Now completely unscrew the hub nut.

- Using a special puller, we dismantle the hub, grasping it with “paws” and rotating the nut. If you do not have such a device, take the removed wheel and screw it to the hub with the back side. Use the wheel as a lever.

- Remove the hub from the axle.

- Using long-nose pliers or special pliers, remove the bearing retaining ring.

- We place the hub in a vice and, using a hammer and a piece of pipe, carefully knock out the bearing.

- When the bearing is knocked out, lubricate the inner surface of the hub with grease.

- We install the new bearing without removing the hub from the vice.

- We place a wooden spacer on top of the bearing and, hitting it with a hammer, hammer the part into the hub until it stops.

- We put the locking ring in place.

- We put the hub with the new bearing on the axle. If she sits down tightly, we help her sit down using a hammer and a spacer.

- Screw on the new hub nut. We tighten it until it stops. The hub should still move inward.

- Install the brake drum and secure it with guide bolts.

- We mount the wheel.

- Remove the jack and tighten the hub nut completely. If you have a torque wrench, observe the tightening torque (186.3-225.6 Nm).

- We bend the edge of the nut, fixing its position.

- We put a cap on the nut.

- We jack up the body, check how the wheel rotates and whether there is any play. It is also recommended to check the operation of the parking brake.

Welcome to the website Bearings in Russia

To quickly find the information you need, use the site search in the upper right corner.

Any spare part of a modern car must be perfectly matched to fit and technological dimensions. Unfortunately, the manufacturer does not always take into account the specifics of using materials in spare parts, which affects their service life, reliability, and, ultimately, traffic safety. The chassis of a car is subject to enormous loads, so it is simply impossible not to pay attention to the correspondence of the factory dimensions with the ones being replaced.

Content:

VAZ 2108 front wheel bearing size

If we take this issue more specifically, the chassis of cars of popular models and brands most often suffers from low-quality spare parts. First, let's look at this problem using the example of a VAZ 2108 front wheel bearing.

It would seem that there is nothing complicated - the hub has its own standard dimensions, which the roller bearing must correspond to:

internal diameter - 34 mm; outer diameter - 64 mm; Bearing width - 37 mm.

Only by these parameters can you select a bearing, of which domestic factories produce thousands. Manufacturers from China actively help in this, providing products that are not of the best quality and do not stand up to any criticism. Neither the steel grade, nor the number of balls, nor the dynamic performance of such bearings meet the standards. There are bearings without any markings at all, and there are particularly zealous owners who buy them. Such bearings burn out within 1000 km and simply fall apart while driving.

Features of choosing a wheel bearing for a VAZ 2108

Naturally, we will not be able to check the dynamic load on the bearing races and on each of its balls. But you need to remember, like the Our Father, that:

- The VAZ 2108 wheel bearing is marked 25 69 07;

- according to the international marking system it is designated 53 20 66 DA;

- the bearing has a mass of 0.445 kg;

- ball diameter - 9.525 mm;

- number of balls - 28.

The difficulty in choosing bearings is that they are not consumable parts, and they are not changed as often as piston rings or silent blocks. That's why some manufacturers don't even bother making human packaging. In addition, the bearing used in the front wheel hub of the VAZ 2108 is maintenance-free, which means:

- the bearing does not require lubrication;

- does not require preload;

- does not require adjustments during installation and operation;

- must have a very high resource.

Design of wheel bearings for VAZ 2108

All VAZ cars are equipped with only three types of wheel bearings - wheel bearings for front-wheel drive VAZ cars, wheel hub bearings for rear wheels, and wheel bearings for Kalina and Grant cars, which are smaller in size.

All VAZ bearings are of the HUB-1 type, and this type is characterized by the design and installation features. The bearing has a double-row design, is a type of angular contact ball bearings with closed working surfaces and does not have flanges for attachment to the hub.

Manufacturers and prices of VAZ wheel bearings

These bearings belong to the middle price segment, so the demand for them is very high. Because of this, you can often find the fakes we mentioned. However, the transition of the VAZ plant to bearings of this type, instead of roller ones of the old type, made it possible to choose bearings not only of domestic production, but also of many other foreign factories.

The main percentage share of bearings used on VAZ cars lies with domestic manufacturers, among which several factories can be distinguished:

- Saratov Bearing Plant (SPZ) - 28%.

- "Volzhsky Standard" - 2%.

- Samara plant SPZ9 - 8%.

- "Lada Image" - 7%.

- Vologda Bearing Plant VBF - 4%.

Let us only note that Lada Image supplies products directly to the plant’s conveyor belt, and SPZ has the largest share in the spare parts market. It is impossible to say anything specific about the quality of workmanship, because there may be failures at every plant, but even if the bearing turns out to be of poor quality, the enterprise must replace it. Prices for VAZ 2108 front wheel bearings rarely exceed 250 rubles apiece, and imported models may cost a little more, but their quality is appropriate.

So, bearings from Kraft, SCT, Trialli, LGR can cost about 300-350 rubles, but these are world-famous manufacturers, and you can definitely count on the quality of the bearing. Choose the right bearings and let your figure eight roll forward with confidence!

Also, using this method, you can replace the wheel bearing on the road with a simple tool. I have a wheel bearing puller, but I will deliberately change the wheel bearing using improvised means, close to travel and close situations. Explaining and appearing in photos the details of the replacement.

Loosen the wheel mounting bolts. We hang up the front part of the car (namely both front wheels, because otherwise the anti-roll bar interferes with dismantling, pressing the suspension elements upward). We remove the wheel, the brake pad guide together with the caliper and the brake disc (see Removing parts of the front wheel brake mechanism). We tie the guide of the brake pads with the caliper so that they do not hang on the brake hose.